316 stainless steel bearing material

Throughout the late 1800s, stainless steel was a great boon in countless industries and applications. Today, an incredible variety of specific stainless steel grades are available, not to mention stainless steel bearings-each bearing has its advantages. The medical and food industries have gained tremendous opportunities from this material, inevitably saving lives.

As the technology and process of manufacturing stainless steel become more advanced, other industries and products also benefit from it. Even highly specific grades have been developed for use in the nuclear industry or in the vacuum of space. Although basic bearing steel has made significant progress in its development, stainless steel bearings have changed the fate of many corroded applications.

Stainless steel is a steel alloy with a chromium content of at least 11%. The other content of steel determines the grade of stainless steel. For example, increased carbon content provides increased strength. The increase in molybdenum content provides higher corrosion resistance. Even small changes in the composition will affect the characteristics of each steel grade.

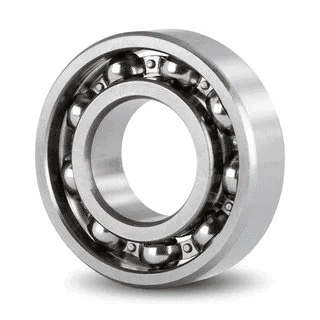

316 Stainless Steel Bearing Materials

TFL uses 316 stainless steel to manufacture radial ball bearings. Compared with traditional steel bearings and 440 stainless steel bearings, this bearing has excellent corrosion resistance. 316 stainless steel is more resistant to atmospheric and general corrosion conditions than any other standard stainless steel. 316 stainless steel is widely used in the food and medical industries. Bearings made of this kind of steel can run in liquids, and can also run dry at low speeds.

316 stainless steel is the standard stainless steel containing molybdenum. Compared with stage 304, 316 having a molybdenum better overall corrosion resistance, in particular, greater resistance to pitting and crevice corrosion in chloride environment

316 stainless steel Features

• The molybdenum content increases the resistance to the marine environment.

• High creep strength and good heat resistance at high temperatures.

• Biocompatibility.

• Manufacturing characteristics are similar to models 302 and 304.

Applications: Food and pharmaceutical processing equipment, marine environment, surgical medical equipment, and industrial equipment for processing corrosive chemicals used in the production of inks, rayon, photographic chemicals, paper, textiles, bleach, and rubber.

Corrosion resistance: better corrosion resistance than 440c, 302, and 304 stainless steel. The resistance pulp industry commonly used sodium and calcium salts of water, hypochlorite solution, phosphoric acid, sulfurous acid, and sulfite solution.

What are the common stainless steels?

There are four main series of stainless steel. For our purposes, we will discuss is limited to two – austenite and martensite – this is common throughout the two stainless steel bearings. Few of these load-bearing steel. Over the years, the load applied to the material through the development of precise, specific materials and components comprising, between strength and corrosion resistance achieved sensitive balance.

Austenitic stainless steel because of its high corrosion resistance become the most common set of steel. The purpose of the alloy, which contains varying amounts of nickel, manganese, molybdenum, and chromium. Although austenitic stainless steel is easy to form, unlike most hardened steel. This series is the most common grades 304 and 316 (or marine grade) stainless steel.

Compared with other series, the carbon content of martensitic stainless steel has increased. This carbon steel having a higher strength, but at the same time reduces the corrosion resistance thereof. Martensitic stainless steel may be appropriately hardened and machined to achieve precision tolerances. This series is the most common grade 400 series.

Which stainless steel is best for bearings?

As you can gather from the information above, none of the stainless steel suitable for use in the entire installation of ball bearings. Bearing, bearing rings, rolling elements and the slinger has different requirements. For example, the installed bearing housing needs greater ductility than seen in the rolling element.

Using the same material would at some point during operation cause some fault in the entire installation of the bearing. This is not to say that some of the stainless steel is not good enough or should not be used. During the bearing design process, engineers select the best material for a given purpose. Steel prices and availability is also an important factor.

Editor’s summary: Some stainless steels have almost the same strength as bearing steels, but they are also very expensive. Brands, manufacturers, and markets have decided which steel grade is most suitable. Unfortunately, there is no “one-size-fits-all” option for stainless steel in this application. Like any good team, all players are selected according to their own strength, so as to maximize their best performance.

TFL Bearing Company, as an excellent bearing manufacturer, has many customers all over the world. We will comprehensively consider the requirements of customers and provide them with cheap, high-quality bearings. If necessary, we always welcome and communicate.

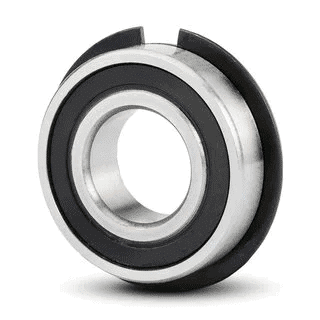

Related Deep Groove Ball Bearings Products

Additional Content