Proper Bearing Storage Guide: Preventing Failure Before Installation

Did you know that 15% of premature bearing failures are caused by poor storage conditions before the bearing is even unboxed?

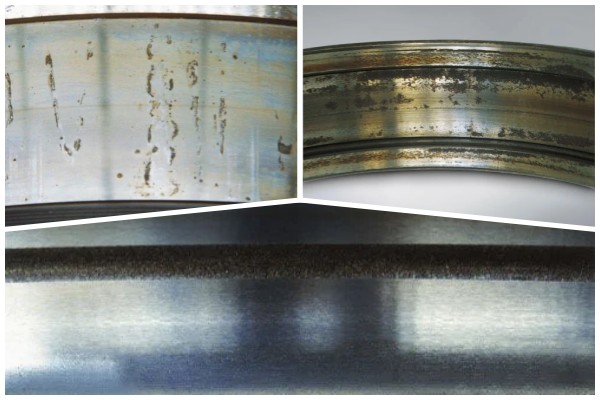

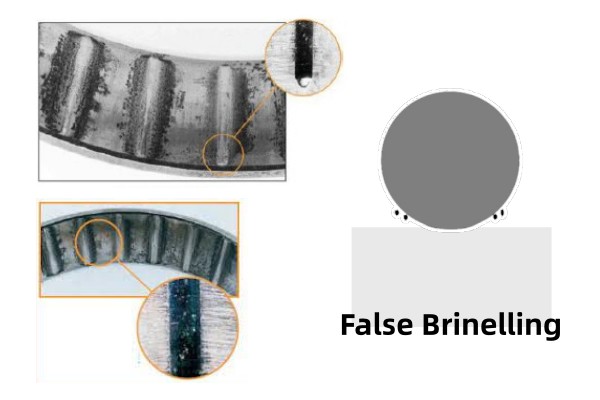

Many maintenance teams treat bearings like simple chunks of steel. In reality, a bearing is a high-precision instrument. A microscopic speck of dust or “False Brinelling” caused by vibration can destroy the raceway before the machine starts.

At TFL Bearing, we engineer reliability. This guide translates ISO 22857 standards into actionable steps to protect your inventory investment.

Executive Summary: The “Zero-Fail” Storage Checklist

Don’t have time to read the full guide? Ensure your warehouse meets these 5 critical standards:

- Humidity: Keep Relative Humidity (RH) below 60% (Ideally 50%).

- Temperature: Maintain a stable range between 20°C and 25°C.

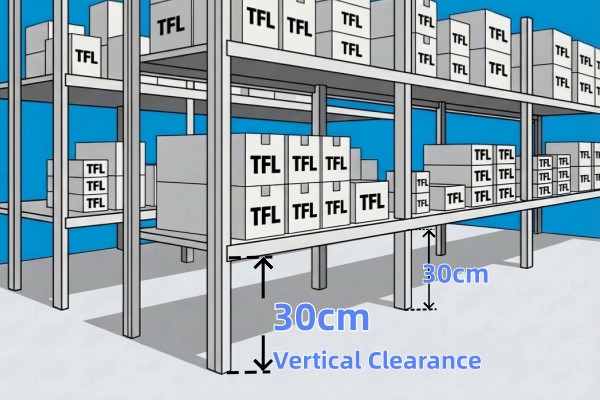

- The 30cm Rule: Never store directly on the floor; keep pallets 30cm off the ground.

- Vibration: Store away from compressors or busy forklift aisles to prevent False Brinelling.

- Rotation: Rotate sealed bearings 180° every 3-6 months to redistribute grease.

Optimal Bearing Storage Environment: Temperature & Humidity Control

The environment in your storage room is the single biggest factor in determining a bearing’s shelf life. To prevent premature failure, you must strictly control three variables: humidity, temperature, and air quality.

1. Relative Humidity (RH) Guidelines for Rust Prevention

Moisture is the primary enemy of bearing longevity. When humidity fluctuates, bearings “breathe,” drawing moisture-laden air into the packaging as air expands and contracts.

- The Standard: Keep Relative Humidity (RH) below 60%, with an ideal target of 50%.

- The Risk: If humidity exceeds 60%, the anti-rust oil on the bearing surface breaks down. This leads to micro-oxidation on the precision raceways, which is often invisible until the machine fails.

2. Recommended Storage Temperature Range

It is not just about keeping bearings cool; it is about maintaining stability.

- The Standard: Maintain a stable temperature range between 20°C and 25°C.

- The Risk: Rapid temperature swings (e.g., hot days and cold nights) cause condensation (dew) to form on the cold metal surface inside the packaging.

3. Air Quality

Store bearings away from chemical fumes, acid mists, or exhaust gases.

- Warning: Never store bearings in the same room as solvents, fuels, or chemicals. The fumes can deteriorate the rubber seals and degrade the grease thickener.

Regional Storage Protocols: Tailoring to Your Climate

Storage standards vary drastically depending on where your facility is located on the map. A warehouse in the humid tropics faces different threats than one in the arctic circle. Here is how to adapt your strategy based on your local climate:

| Climate Zone | Primary Threat | Critical Action Required |

|---|---|---|

| Tropical / Humid (e.g., SE Asia, Coastal) |

Rapid Oxidation (Rust) due to >70% RH | Must use Industrial Dehumidifiers & active VCI checks. |

| Extreme Cold (e.g., Russia, Canada) |

Condensation Shock & Brittle Cages | Use a “Transition Zone” (10°C) for 24h before installation. |

| Arid / Dusty (e.g., Middle East) |

Dust Ingress & Capillary Moisture | Strict 30cm Rule (off ground) & sealed packaging. |

| Heavy Industrial (e.g., Steel Mills) |

Chemical Corrosion (Acid Fumes) | Maintain Positive Air Pressure in storage room. |

Tropical & High Humidity Zones (e.g., Southeast Asia, Latin America, Coastal Regions)

The Threat: Rapid Oxidation. Salt mist and heavy moisture (>70% RH) can penetrate standard packaging within weeks.

- Dehumidifiers are Mandatory: Air conditioning is often not enough. Use industrial dehumidifiers to actively strip moisture from the air.

- The “30cm Rule”: Never store bearings directly on a concrete floor. Concrete wicks moisture from the earth (capillary action). Always use pallets raised at least 30cm off the ground.

- VCI Checks: Inspect the condition of VCI (Vapor Corrosion Inhibitor) paper every 6 months. If it looks discolored, re-wrap immediately.

The Threat: Condensation Shock & Brittle Plastics.

- The Buffer Zone: Moving a bearing from a -10°C unheated warehouse directly to a +20°C workshop creates instant water droplets on the metal. Protocol: Place bearings in a “transition zone” (approx 10°C) for 24 hours before bringing them fully indoors.

- Handle with Care: In sub-zero temps, Polyamide (nylon) cages and plastic packaging become extremely brittle. A simple drop that wouldn’t hurt in temperate climates can shatter the cage in freezing conditions.

Arid, Dusty & Desert Climates (e.g., Middle East, Australia, North Africa)

The Threat: Rapid Oxidation. Salt mist and heavy moisture (>70% RH) can penetrate standard packaging within weeks.

- Dehumidifiers are Mandatory: Air conditioning is often not enough. Use industrial dehumidifiers to actively strip moisture from the air.

- The “30cm Rule”: Concrete wicks moisture from the earth (capillary action). Always use pallets raised at least 30cm off the ground.

- VCI Checks: Inspect VCI (Vapor Corrosion Inhibitor) paper every 6 months. If discolored, re-wrap immediately.

Heavy Industrial Zones (Global Application)

The Threat: Corrosive Atmosphere. (Common in Steel Mills, Chemical Plants, and Paper Mills worldwide)

- Positive Pressure: If possible, keep the storage room under slight positive air pressure to push out airborne contaminants like sulfur or acid fumes, which are prevalent in heavy industrial parks regardless of the country.

Preventing Vibration Damage and False Brinelling

Even when a bearing is sitting motionless on a shelf, it can sustain serious damage from external vibrations. If your storage area is located near heavy stamping presses, compressors, or busy forklift aisles, ground vibration travels through the rack and into the bearing.

- What is False Brinelling? Since the bearing is stationary, the rolling elements vibrate against the same spot on the raceway repeatedly. This pushes the protective oil film aside and creates microscopic metal-to-metal indentations.

- The Consequence: To the naked eye, the bearing looks new; but once installed, it will be noisy and fail prematurely.

- Storage Solution: Store bearings in a dedicated, vibration-free room. If unavoidable, use vibration-damping rubber mats on metal shelves to break the resonance.

Correct Bearing Stacking Orientation: Vertical vs. Horizontal

Gravity never sleeps. How you place the bearing matters significantly to its shape retention.

Why You Should Store Bearings Flat (Horizontal)

- Protocol: Large bearings must always be stored lying flat.

- Reasoning: Even distribution of weight prevents the rings from becoming oval-shaped over time.

Risks of Vertical Storage

- Ovalization: If hung vertically or leaned against a wall, the weight of the rings causes deformation (“ovalization”).

- Lubrication Failure: In sealed bearings, storing vertically causes grease to settle to the bottom, leaving the top rollers dry and unprotected upon startup.

Bearing Shelf Life and Expiration Dates

Does a bearing expire? While the steel doesn’t, the rust preventative oil and grease definitely do.

- Open Bearings (Oil preserved): Shelf life of 1-3 years before re-oiling is required.

- Sealed Bearings (Greased): Shelf life of 2-5 years. Over time, grease hardens and loses lubrication properties.

Implementing the FIFO (First-In, First-Out) Method

To manage shelf life effectively, always place new stock at the back and pull old stock from the front.

The “Do Not Open” Policy

Never remove a bearing from its original packaging until you are ready to install it. Manufacturers like TFL Bearing use industrial-grade VCI paper to create a protective atmosphere; opening the package destroys this protection immediately.

From Shelf to Machine: The Pre-Installation Protocol

Once you take the bearing out of storage, the transition to the machine is critical—especially in extreme weather.

If you are operating in winter conditions, simply taking a cold bearing and mounting it can lead to disaster. You need to account for Thermal Expansion and Condensation.

Planning a winter installation? Don’t let your perfectly stored bearing fail during startup. Read our companion guide: [The Ultimate Guide to Bearing Installation and Startup in Cold Weather]

This guide covers how to acclimatize your bearings and use induction heating safely to prevent thermal shock.

Conclusion

Proper bearing storage is “zero-cost maintenance.” It requires no expensive tools—just discipline and knowledge. By controlling humidity, managing temperature, and respecting regional climate challenges, you ensure that every TFL Bearing performs exactly as engineered.

Need advice on setting up your spare parts warehouse? Contact TFL’s engineering team for a consultation on preserving your inventory value.

- Email Us: info@tflbearing.com

- Call Direct: +86 158 0663 1151

Frequently Asked Questions (FAQ)

Q: Do bearings have an expiration date?

A: Yes. While the steel lasts indefinitely, the preservative oils and greases degrade. Generally, use oil-preserved bearings within 3 years and greased bearings within 2-5 years.

Q: Can I store bearings directly on the floor if it is epoxy coated?

A: No. Even with epoxy coating, the floor is the coldest part of the room and most prone to vibration. Always use the “30cm Rule” to keep bearings elevated on pallets or shelves.

Q: Why do I need to rotate sealed bearings in storage?

A: In high temperatures, the oil can separate from the grease thickener and pool at the bottom. Rotating them every 3-6 months ensures the grease stays mixed and coats the rolling elements evenly.

📥 Download the “Zero-Fail” Storage Checklist

Want to hang these standards on your warehouse wall? Download the complete ISO-compliant guide in PDF format.