F-6000 Series Deep Groove Ball Bearings (Flanged)

- High precision

- Machinery parts

- Motor bearings

- Bearing brand or OEM

A special feature of this series

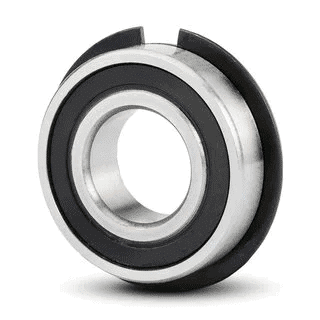

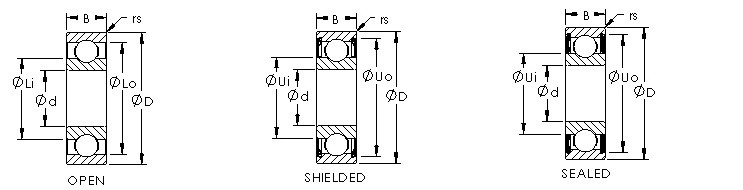

Main dimensions according to DIN 625-1. Ball bearings of the extra-light F-60 series are equipped with a flange for simplified locating bores in which the bearing is supposed to be axially fixed. Compared to deep groove ball bearings of the 63 medium series they require a smaller installation space at the same inside diameter, only weigh half of them, and allow higher speeds.

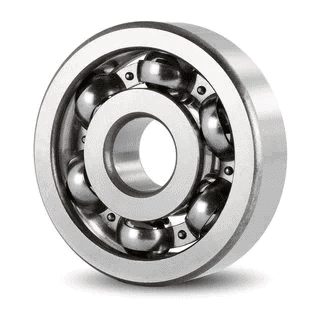

These deep groove ball bearings are suitable for low and heavy radial loads. The 6000 series can withstand medium and low thrust loads in any loading direction.

The bearings we provide can meet almost any operating accuracy requirements and application speed: our bearings have Abec tolerances of 1-9, internal clearances from C2 to C4, and several different cage designs, including J type, W Type, RJ type, TW type and so on.

Available sizes: inner diameter 10mm to 980mm outer diameter, width 8mm to 136mm.

A special feature of this series

Main dimensions according to DIN 625-1. Ball bearings of the extra-light F-60 series are equipped with a flange for simplified locating bores in which the bearing is supposed to be axially fixed. Compared to deep groove ball bearings of the 63 medium series they require a smaller installation space at the same inside diameter, only weigh half of them and allow higher speeds.

- the flange on the outer ring prevents axial displacements

- extra light series with compact dimensions and low weight

- suitable for high radial loads and light axial loads in both directions

- offers high running accuracy, quiet running, and high speeds

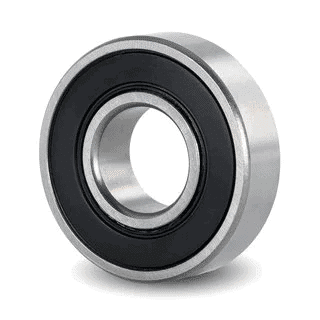

- seal: contact lip seal on both sides made of rubber (2RS) for high sealing effect

- the good fixed bearing property, but can also be used as a floating bearing, each in both directions

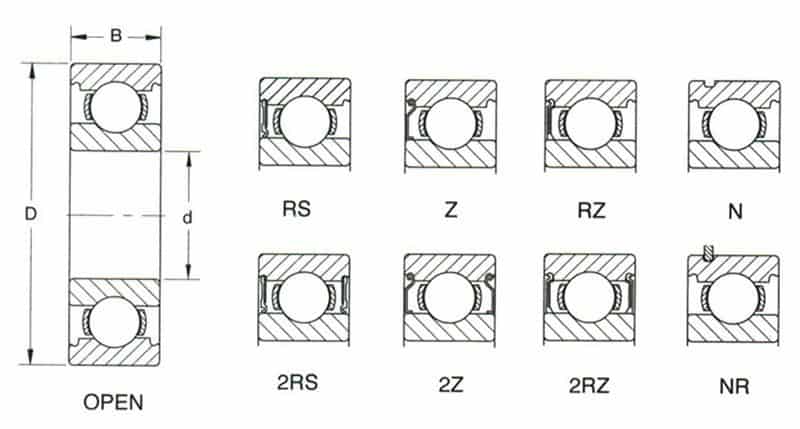

Manufacturers of bearings: such as FAG, KOYO, NSK, SKF, SNR, etc. assign different suffixes for their characteristics, for better orientation take note of the comparison table of bearings (see further information)

Can be customized to meet your specific needs.

Lightweight, stable and with good spinning characteristics. The deep groove ball bearing F-6000 is a true all-rounder and, due to its balanced properties, it is suitable for a variety of applications. With the flange, it can be fixed axially, e.g. in boreholes. Main dimensions according to DIN 625-1.

Other options: Metal shield (ZZ) or rubber seal (2RS) can be provided.

Deep Groove Ball Bearings are able to accommodate low to heavy radial loads and low to moderate thrust loads in either direction. They are available with metal shields (ZZ) or rubber seals (2RS). Several tolerance grades (Abec 1-9), internal clearance (C2 to C4) and cage designs are available to best suit the running precision and speed of the application.

Common Options:

- ZZ– Two Metal Shields

- 2RS– Two Rubber Seals

- NR– Snap Ring

- M– Brass Cage

- C0– Normal Internal Clearance

- C3– Greater than normal

| Item # | (d) Bore Diameter | (D) Outer Diameter | (B) Width | (D1) Flange Diameter | (C1) Flange Width |

|---|---|---|---|---|---|

| F-6000-OIL | 10mm | 26mm | 8mm | 28mm | 2mm |

| F-6001-OIL | 12mm | 28mm | 8mm | 30mm | 2mm |

| F-6001-2RS | 12mm | 28mm | 8mm | 30mm | 2mm |

| F-6001-Z | 12mm | 28mm | 8mm | 30mm | 2mm |

| F-6002-OIL | 15mm | 32mm | 9mm | 34.25mm | |

| F-6002-2RS | 15mm | 32mm | 9mm | 34.25mm | |

| F-6002-ZZ | 15mm | 32mm | 9mm | 34.25mm | |

| F-6003-OIL | 17mm | 35mm | 10mm | 37mm | 2mm |

| F-6004-OIL | 20mm | 42mm | 12mm | 45mm | 3mm |

| F-6004-2RS | 20mm | 42mm | 12mm | 45mm | 3mm |

| F-6005-OIL | 25mm | 47mm | 12mm | 50mm | 3mm |

| F-6005-2RS | 25mm | 47mm | 12mm | 50mm | 3mm |

| F-6005-ZZ | 25mm | 47mm | 12mm | 50mm | 3mm |

| F-6006-OIL | 30mm | 55mm | 13mm | 58.25mm | |

| F-6006-2RS | 30mm | 55mm | 13mm | 58.25mm | |

| F-6006-ZZ | 30mm | 55mm | 13mm | 58.25mm |

Related Products

Related Articles

Find more products in China.

You can contact us any convenient way. We are available 24/7 via fax or email.

You can also use the quick contact form below or visit our office personally. Please email us with any questions or inquires or use our contact data. We would be happy to answer your questions.