The Complete ABEC Rating Guide: Scale, Chart, and What They Actually Mean

Quick Guide: Which ABEC Rating Do You Need?

| ABEC Rating | Precision Level | Price | Best Application (Use Case) |

| ABEC 1 | Standard | Low | General industry, Conveyors, Basic machinery |

| ABEC 3 | Good | Avg | Automotive parts, Electric motors, Household appliances |

| ABEC 5 | High | Avg | Skateboards, Precision motors, High-speed fans |

| ABEC 7 | Very High | High | High-end Skating, CNC Routers, Robotics |

| ABEC 9 | Ultra Precision | Prem | Medical equipment, Aerospace, High-RPM spindles |

What is the ABEC Rating? Meaning & Origin

The ABEC rating is an industry-accepted standard used to measure the dimensional tolerances and precision of ball bearings. The higher the ABEC number, the tighter the tolerance and the more precise the bearing. This system helps manufacturers and consumers determine how close a bearing is to being mathematically perfect in its dimensions.

The acronym ABEC stands for the Annular Bearing Engineering Committee of the American Bearing Manufacturers Association (ABMA). The ABEC scale was developed to provide a universal language for bearing manufacturers worldwide. It ensures that a bearing produced in one country matches the precise dimensional specifications required for machinery designed in another.

While ABEC is the standard mainly used in the United States, you will often see it compared to other international standards. The ABEC grades correspond directly to ISO 492 (International) and JIS B 1514 (Japan) standards. While ABEC specifically governs ball bearings, similar concepts apply to roller bearings under different classifications.

It is important to note that the ABEC rating focuses strictly on dimensional precision (size and geometry). It does not account for other critical factors such as:

- Materials quality (steel grade)

- Load handling capabilities

- Noise and vibration levels

- Lubricant quality

Therefore, a higher ABEC rating does not automatically guarantee a faster or longer-lasting bearing if the materials are poor. It is just one tool to help you select the right bearing type for your specific application.

ABEC Rating Classes Explained: 1, 3, 5, 7, and 9

The ABEC scale consists of five accepted grades: 1, 3, 5, 7, and 9. The scale works on odd numbers only. The rule is simple: the higher the ABEC number, the tighter the tolerance and the more precise the bearing dimensions.

“Watch this video for a visual explanation of how ABEC tolerances affect bearing spin and performance.”

- ABEC 1 Bearings (Normal Class): This is the standard grade for most general-purpose ball bearings. They are affordable and durable. While they have the “loosest” tolerance in the scale, they are perfectly sufficient for low-speed applications like conveyors or basic machinery.

- ABEC 3 Bearings (Class 6): A step up from standard. ABEC 3 bearings generally offer smoother operation and can handle slightly higher speeds than ABEC 1. They are a common choice for budget-friendly automotive parts and electric motors.

- ABEC 5 Bearings (Class 5): This is the “mid-range” sweet spot. ABEC 5 offers a significantly tighter tolerance than ABEC 1 or 3. They are widely used in high-performance applications where precision matters, such as skateboard wheels, high-end electric motors, and precision robotics.

- ABEC 7 Bearings (Class 4): These are high-precision bearings. ABEC 7 is designed for very high speeds and extremely tight tolerances. You will often see these marketed to skaters and machinists who demand minimal friction and maximum efficiency.

- ABEC 9 Bearings (Class 2): The highest ABEC rating available in the standard scale. These are ultra-precision components used in medical equipment, aerospace applications, and high-RPM machinery. They are expensive and require perfectly machined housings to utilize their full potential.

Note on ABEC 11 and higher: You may see some brands advertising “ABEC 11” or “ABEC 13” bearings. Please note that these are not official ABEC ratings. The ABMA standard tops out at ABEC 9. Ratings higher than 9 are usually marketing terms used by manufacturers and do not reflect an official industry standard.

Does higher ABEC mean faster?

Not necessarily. A higher ABEC grade guarantees better dimensional accuracy (tolerances), which can allow for higher speeds and efficiency. However, speed is also heavily influenced by the lubricant, material quality, and load. An ABEC 9 bearing with poor grease will run slower than an ABEC 1 bearing with high-quality oil.

Bearing standards and other grades

While ABEC ratings are the standard in the United States (governed by the ABMA), the rest of the world often uses different systems. If you are sourcing bearings internationally, you need to know how to convert these ratings.

The most common equivalents come from ISO 492(International), DIN 620 (Germany), and JIS B1514 (Japan). The table below shows how the ABEC grades strictly correspond to these international precision classes:

ABEC Rating Conversion Table

| ABEC | ISO 492 | DIN 620 | JIS |

| ABEC 1 | Class Normal | P0 | Class 0 |

| ABEC 3 | Class 6 | P6 | Class 6 |

| ABEC 5 | Class 5 | P5 | Class 5 |

| ABEC 7 | Class 4 | P4 | Class 4 |

| ABEC 9 | Class 2 | P2 | Class 2 |

What does the rating actually change?

Let’s look at a practical example of bearing tolerance.

Consider a standard bearing with an outer diameter of roughly 2 inches.

- ABEC 1: The outer ring width is allowed to deviate by up to -0.0050 inches.

- ABEC 7: For the same bearing, the deviation must not exceed -0.0010 inches.

In simple terms, the ABEC 7 bearing is 5 times more precise in its manufacturing consistency than the ABEC 1 bearing.

To determine these ratings, the committee does not just look at one factor. The ABEC grade is calculated based on the testing of several key physical properties related to dimensional accuracy and running accuracy.

Key tolerances measured include:

- Bore Diameter: The precision of the inner hole (where the shaft fits).

- Outer Diameter: The precision of the outer casing (where it fits into the housing).

- Ring Width: The exact thickness of the inner and outer rings.

- Radial Runout: How much the bearing deviates from a perfect circle when rotating.

- Taper/Cone Error: Any deviation in the shape of the inner bore.

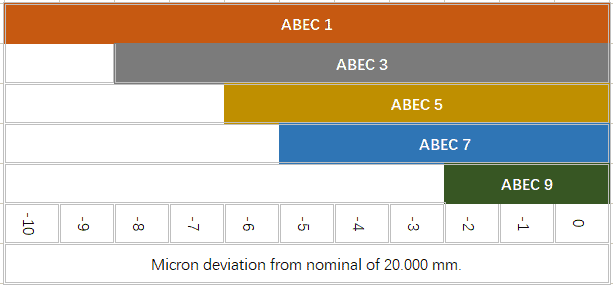

Visualizing ABEC Tolerances: The Micron Chart

The ABEC rating system primarily limits the eccentricity (also known as radial runout) of the bearing’s inner ring.

In simple terms, this measures how “perfectly round” the bearing is. A lower runout means the bearing spins smoothly with minimal vibration or “jitter.” The values below indicate the maximum permissible eccentricity—meaning the bearing cannot be less round than these numbers.

Here is the maximum eccentricity allowed for a standard 20mm inner diameter bearing:

- ABEC 1: 0.0075 mm (0.000295 inches)

- ABEC 3: 0.0050 mm (0.000197 inches)

- ABEC 5: 0.0035 mm (0.000138 inches)

- ABEC 7: 0.0025 mm (0.000098 inches)

- ABEC 9: 0.0012 mm (0.000047 inches) Reference sources: American Bearing Manufacturers Association (ABMA) Standards.

How precise is this?

To put these numbers in perspective, an average human hair is about 0.050 mm thick.

- An ABEC 1 bearing allows a tolerance that is roughly 1/7th the width of a human hair.

- An ABEC 9 bearing allows a tolerance of just 0.0012 mm—that is 40 times smaller than the width of a human hair.

As shown in the chart above, the “tolerance window” (the colored bars) gets smaller as you go up the scale.

- ABEC 1 (Orange) has a wider margin for error (10 µm range).

- ABEC 7 (Blue) has a tiny margin (5 µm range).

This explains why ABEC 7 and 9 bearings are more expensive: manufacturing them requires much stricter quality control and precision machinery.

Need the Full Data?

For a complete list of specific precision bearing tolerances (including outer diameter and width variations), we offer a detailed technical document.

Contact TFL Bearing to Get the Full ABEC PDF Guide

Frequently Asked Questions about ABEC Ratings

Q: Is a higher ABEC rating always better?

A: Not always. A higher ABEC rating only means tighter dimensional tolerances. It does not guarantee better materials or load capacity. For low-speed applications, an ABEC 3 bearing is often more cost-effective and durable than an ABEC 9 bearing.

Q: What is the difference between ABEC 1 and ABEC 3?

A: The main difference is precision. ABEC 3 bearings have tighter tolerances than ABEC 1, allowing for slightly smoother operation at higher speeds. However, for general industrial use, the difference is often negligible.

Q: Does ABEC rating affect bearing speed?

A: Indirectly, yes. Higher precision reduces vibration, which can allow for higher RPMs. However, the lubricant (grease vs. oil) and the cage material have a much bigger impact on maximum speed than the ABEC rating alone.

Why Source Precision Bearings from TFL?

When precision matters, you need a partner, not just a supplier. Here is why clients in over 150 countries trust TFL Bearing:

- Rapid Response & Delivery: We know downtime costs money. 99% of inquiries are answered within 24 hours, and 75% of stock orders are shipped the same day.

- Expert Engineering Support: Don’t know if you need ABEC 5 or ABEC 7? Our technical experts don’t just sell parts; we solve problems. We help you calculate the exact precision level needed for your specific application to save costs without sacrificing performance.

- Global Quality Assurance: Our quality control program is rigorously enforced. Whether it’s a standard ABEC 1 bearing or a high-precision ABEC 9 component, every product undergoes strict inspection before leaving our facility.

Still unsure which bearing rating fits your project?

Don’t guess. Let our engineers verify the tolerances for you.

[Contact TFL Bearing Team Today]