Steel Industry

Steel Mill Bearings

In the steel industry, bearings can be found in various plants and equipment used in upstream and downstream processes: from raw material storage sites to steelmaking, rolling, and refining processes. Different bearings are used in the plant and equipment.

TFL BEARING is an essential supplier for steel mills and the primary metal industry. We provide high-quality, cost-effective ball bearings and roller bearings to meet the performance needs of your specific application.

As a leading bearing distributor, we have close relationships with many bearing manufacturers all over the world. This allows us to provide steel mills and rolling mill suppliers with the correct bearing solutions instead of general-purpose parts. We can help you solve problems and determine solutions to design problems by identifying the best and most cost-effective bearings, whether it is parts that need to be provided regularly or custom-designed bearing designs.

Bearings for the steel industry: why choose TFL?

Our teams will assist and advise you in identifying innovative solutions to suit your needs.

Your benefits:

- optimise your costs, from installation to maintenance

- increase the service life of your equipment with the correct products for the steel industry

- reduce maintenance time: increase maintenance intervals by at least 50%

Finishing: dedicated products

We offer a wide range of products for the steel industry designed to extend the service life of your finishing line:

- Deep groove ball bearings from the TOPLINE range, HVZ for cable clamp rollers, or even F604 for cooling tables

- Plummer block housings – ductile cast iron

- Spherical roller bearings from the ULTAGE® range (open and sealed)

- Constant-velocity joints

- Complete straightening rollers

- ULTAGE® four-row tapered roller bearings

Our products for the steel industry: performance, reliability, precision

TFL BEARING can provide you with specialist solutions for every stage of the steel manufacturing process, from the preparation of raw materials through to the finishing lines. Our dedicated steel industry range combines specific developments with standard elements to provide the best solution, tailored to your needs.

Bearings in the steel mill and primary metal industry operate in extreme conditions—high temperatures, high impact, and heavy load amounts must be considered when selecting the best products for the job.

ANGULAR CONTACT BEARINGS

- Can withstand the demands of high-speed applications

- Can accept radial and thrust loads

- Different contact angles are available

COMBINATION BEARINGS

- Outer rings are produced from case hardened material

- Combi-bearings accommodate heavy radial and axial loads

- It can be offered with or without the mounting plate

CYLINDRICAL ROLLER BEARINGS

- A wide variety of options are available: Single, double, or multi-row are readily available

- Special clearances and grease allow for customized solutions

NEEDLE ROLLER BEARINGS

- Needle roller bearings offer a higher load carrying capacity and can withstand oscillation with greater rigidity

- A wide range of styles are available, including some series made from stainless steel

SPHERICAL ROLLER BEARINGS

- Can withstand the most arduous environments and operating conditions

- Can accept deviations in shaft misalignment

- Low to medium speeds are optimal when using spherical roller bearings

SPIRAL BUSH BEARINGS

- Spiral bearings are manufactured from spring strip steel, hardened, and ground to precision

- Heat resistance for Spiral Roller bearings is 350°C

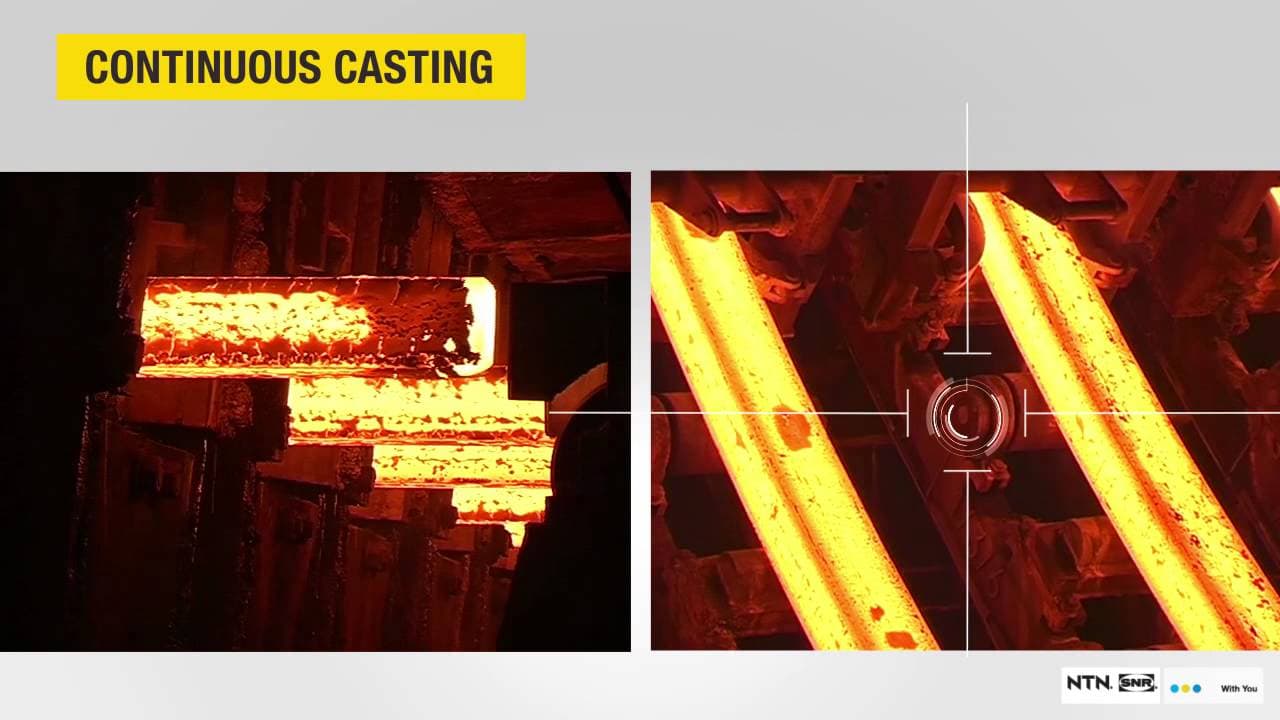

- Provides all unique bearing designs for each section of a continuous caster bow segment on consumer applications

THRUST BEARINGS

- Can be offered in single or double direction

- More significant, more robust sizes can accept heavier axial loads

- Will be able to take shaft misalignment with spherical thrust roller bearings

TOROIDAL ROLLER BEARINGS

- The product can accept angular misalignment and axial displacement

- Combines the best features of the needle roller design and the spherical roller bearing

- Utilizes a specially designed roller to accommodate the harshest environmental conditions

WATER-COOLED BEARINGS

- Specially customized water-cooled housed units for continuous caster applications

- Greater roller length allows for increased load carrying capacity

- Smaller gap design between split rings provides for trouble-free operation by the rollers

HOT AND COLD MILL APPLICATIONS (CONTINUOUS CASTER & Z MILL)

- Combination bearings

- Cylindrical roller bearings

- Multirole cylindrical roller bearings

- Needle Roller bearings

- Shoulder bearings

- Multirole tapered roller bearings

CARDAN JOINT BUSHINGS

CONVEYOR BELTS

- Coil conveyor bearings with and without flanges

COOLING BEDS

- Spherical roller bearings

LEVELERS AND STRAIGHTENERS

- Back up rollers

OVERHEAD CRANES

- Spherical roller bearings

SINTERING PLANT PRESSURE ROLLS

Available brands: INA/FAG, KOYO, NSK, SKF, NTN-SNR, IKO, NACHI, TIMKEN, different suffixes are assigned according to their characteristics. Please pay attention to the bearing comparison table (see more information). In addition, to meet the special needs of the equipment, we accept bearing customization to meet your specific needs.

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.