Ceramic bearings

TFL Bearings specialize in the supply of Ceramic Bearings. Ceramic bearings have excellent electrical and magnetism resistance, wear, and corrosion resistance, maintenance-free lubrication, high and low-temperature resistance, etc. So they are suitable to be used in harsh environments and special conditions.

Ceramic bearings

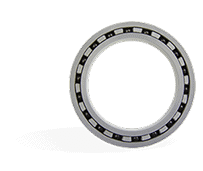

What are ceramic bearings? Ceramic bearings consist of ceramic rolling elements (balls) enclosed in ferrous metal (usually steel) inner and outer rings. Since these bearings are made of multiple materials, they typically operate with mixed capabilities. We also make ceramic bearings (that is, bearings with ceramic races). Still, they are not common because they are not very durable.

Therefore, we provide various ceramic materials to construct the rolling elements in ceramic bearings, including.

- Silicon Nitride (Si3N4)

- Alumina (Al2O3)

- Zirconia (ZrO2)

- Silicon Carbide (SiC)

Application range: Equipment involving high speed and high load often require the use of ceramic bearings. CompaThese bearings have several advantages compared to standard steel bearings, including increased acceleration, stiffness, and reduced friction. Hybrid ceramic bearings also have the advantage of not allowing current to pass through the bearing, extending the use time.

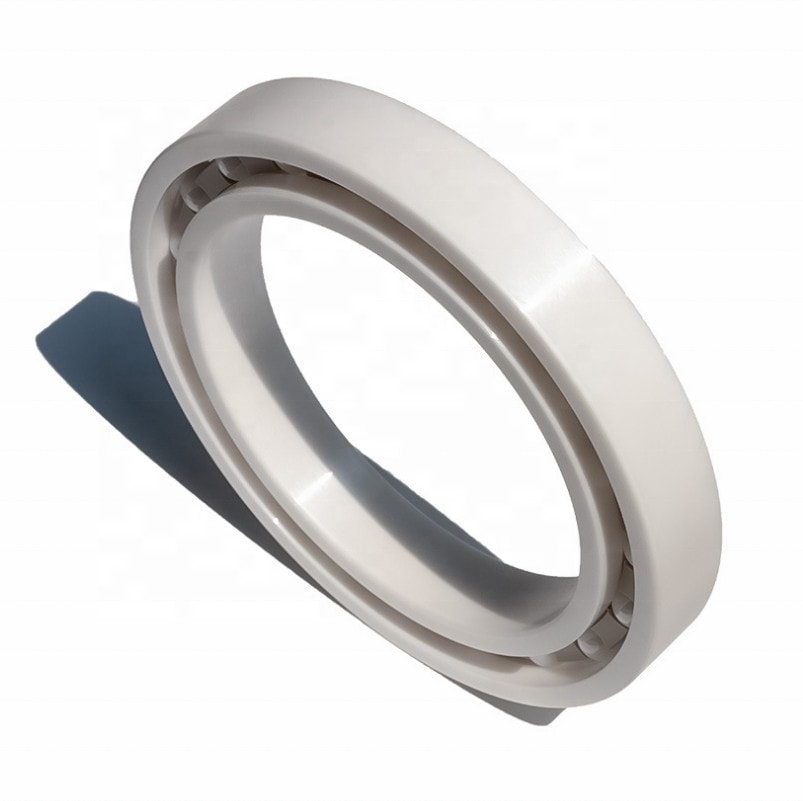

Ceramic Bearing Types

TFLBEARING manufactures ceramic bearings, which have significant advantages compared with ordinary steel bearings. The characteristics of ceramic bearings include excellent strength, better high-temperature resistance, excellent corrosion resistance and wear resistance, and excellent magnetic and electrical insulation. In addition, the weight of ceramic bearings is also lighter.

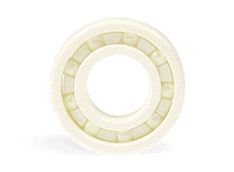

We can provide all standard ceramic bearings in three different material categories: zirconia bearings, silicon nitride bearings, and hybrid bearings (ceramic, steel, or chromium).Fine ceramics (advanced ceramics, advanced technical ceramics) — Silicon nitride materials for rolling bearing balls and rollers.

- Ceramic Ball Bearings

- Thrust Full Ceramic Bearings

- Self Aligning Full Ceramic Bearings

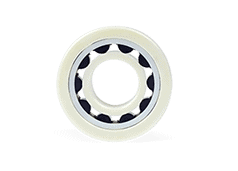

- Radial PEEK Bearings

- Radial Full Ceramic Bearings

- Mounted Unit Thermoplastic Bearings

- Insert Full Ceramic Bearings

- Double Row Full Ceramic Bearings

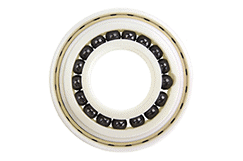

- Ceramic Insulated Bearings

- Angular Contact Full Ceramic Bearings

Application of Ceramic Bearing

Medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, food processing machinery.

In the fields of aerospace, navigation, nuclear industry, petroleum, chemical industry, textile industry, machinery, metallurgy, electric power, food, locomotives, subways, high-speed machine tools, scientific research, and defense military technology, it is necessary to use high temperature, high speed, cryogenic, flammable, Working under special working conditions such as explosive, strong corrosion, vacuum, electrical insulation, non-magnetic, dry friction, etc., the indispensable substitute role of ceramic bearings is gradually being recognized.

With the continuous progress of processing technology and the increasing level of craftsmanship, the cost of ceramic bearings has been declining. It has only been applied in a small range of high, precise, and cutting-edge fields from the past. It has been gradually extended to various industrial areas of the national economy. The product market price is also approaching practicality progressively, reaching a level acceptable to users. The wave of large-scale application of ceramic bearings has surged!

Benefits of Ceramic Bearings

High-speed bearing: It has the advantages of cold resistance, small force elasticity, high-pressure resistance, poor thermal conductivity, lightweight, and small friction coefficient. It can be used in high-speed spindles and other high-precision equipment at 12,000 rpm-75,000 rpm ;

High-temperature resistant bearing: The material itself is resistant to a high temperature of 1200℃, and it is self-lubricating. The use temperature is between 100℃ and 800℃ without expansion caused by temperature difference. It can be used in furnaces, plastics, steel, and other high-temperature equipment;

Corrosion-resistant bearings: The material itself has corrosion-resistant properties and can be used in fields such as strong acids, strong alkalis, inorganic, organic salts, and seawater, such as electroplating equipment, electronic equipment, chemical machinery, shipbuilding, medical equipment, etc.

Antimagnetic bearing: Because it is non-magnetic, it does not absorb dust, reducing the peeling of the bearing surface, thereby reducing the operating noise. It can be used in demagnetization equipment: precision instruments, and other fields.

Electrically insulated bearings: Because of their high resistivity, they can avoid arc damage to the bearings and be used in various electrical equipment requiring insulation.

Vacuum bearings: Due to ceramic materials’ unique oil-free and self-lubricating properties, it can overcome the problem that standard bearings cannot achieve lubrication in an ultra-high vacuum environment.

Note: For the above five types of bearings, the same set of bearings can be applied to high temperature, high speed, acid-base, magnetic field, and non-insulation. However, due to the different material properties (please refer to the performance table of Ceramic Bearing vs. Steel Bearing Material Comparison Chart), when customers choose products, choose the ceramic bearing with the most suitable material according to your application.

Latest content

Category

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.