TFL Bearing Technical Parameters Guide: 2026 Ultimate Handbook

Sourcing bearings for your machinery isn’t just about matching a part number on a box; it’s about engineering reliability into your production line. Whether you are sourcing for high-speed electric motors, heavy-duty agricultural machinery, or precision conveyors, a gap in understanding bearing technical parameters can lead to catastrophic failure and costly downtime.

At TFL Bearings, we understand that a single suffix in a specification code—denoting clearance, cage material, or grease type—is often the difference between a machine that runs smoothly for years and one that fails in weeks.

In this comprehensive guide, we go beyond the basic catalog data. We will decode the most critical bearing specifications. From understanding Load Ratings (dynamic vs. static) and Precision Classes (ABEC/ISO) to selecting the right Internal Clearance (C3, C4) and Lubrication, we examine what matters most from a buyer’s perspective.

Read on to master the data sheet and ensure TFL quality drives your performance.

Basic Dimensions: Understanding Bore, OD, and Width (The “Fit”)

Before diving into load ratings or speed limits, the fundamental requirement is geometry. If the bearing doesn’t fit the shaft or housing housing perfectly, performance specifications are irrelevant.

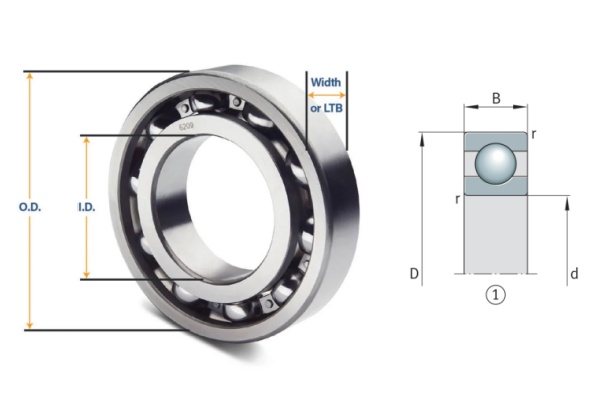

Most buyers look at the three primary dimensions, often abbreviated as d x D x B:

-

Bore Diameter (d): The inner diameter that mounts onto the shaft.

-

Outer Diameter (D): The external size that fits into the housing.

-

Width (B/T): The thickness of the bearing (or assembly width for tapered roller bearings).

-

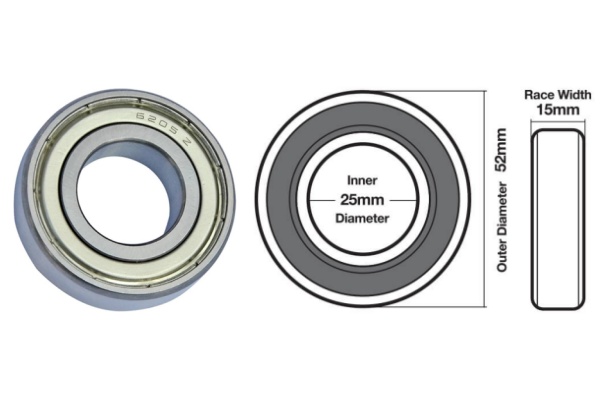

Example: The TFL 6205 bearing dimensions (25x52x15 bearing)

To visualize this, let’s look at one of the most common industry-standard parts, the 6205-2RS:

-

d (Bore): 25 mm

-

D (Outer): 52 mm

-

B (Width): 15 mm

Note: In standard metric series, the last two digits often indicate the bore size. Here, “05” x 5 = 25mm. (See Section 12 for full decoding rules).

-

The “Hidden” Dimension: Chamfer (r)

There is a critical fourth dimension that often causes installation headaches: the Chamfer Dimension (r). This is the rounded corner of the bearing ring.

-

Pro Tip: Your shaft or housing usually has a “fillet radius.” The bearing’s chamfer (r) must be larger than the shaft’s fillet radius. If not, the bearing won’t seat flush against the shoulder, leading to misalignment and early failure.

Metric vs. Inch Series

While TFL Bearings strictly adheres to ISO/DIN standards for Metric bearings (millimeter sizes), we also supply a full range of Inch-sized bearings for the North American market.

-

Note: Standard bearing part numbers (e.g., a “6205”) universally dictate specific dimensions. Decoding the part number is often the fastest way to confirm dimensions.

Need a custom dimension or non-standard size?

If your application requires modified bores or special widths that don’t fit the catalog standard, we can engineer a solution.

[Customizing Non-Standard Bearings with TFL]

Bearing Materials: Why Chrome Steel (GCr15) vs. Stainless Steel Matters

“Will it rust?” “Is it hard enough?” The material composition defines not just the bearing’s environment, but its lifespan. TFL strictly avoids low-grade Carbon Steel, focusing only on premium bearing steels.

| Material Standard | Corrosion Resistance | Load Capacity | Cost |

|---|---|---|---|

| Chrome Steel (GCr15 / 52100) | Low (Rusts easily) | ⭐⭐⭐⭐⭐ Excellent | $ Low |

| Stainless Steel (440C) | Good (Magnetic) | ⭐⭐⭐⭐ Good | $$ Medium |

| Stainless Steel (304) | ⭐⭐⭐⭐⭐ Excellent | ⭐ Very Low (Soft) | $$$ High |

Chrome Steel (GCr15 / AISI 52100 / 100Cr6):

-

-

Best For: 90% of standard industrial applications (Motors, Conveyors, Automotive).

-

The TFL Difference: We use high-grade Vacuum-Degassed Steel. This process removes impurities, ensuring the steel is pure and extremely hard (HRC 60-65). It offers the highest load capacity and fatigue resistance but requires grease protection to prevent rust.

-

Martensitic Stainless Steel (AISI 440C):

-

-

Best For: Food processing, medical devices, and humid environments.

-

Key Feature: It balances high load capacity with good corrosion resistance.

-

Buyer Note: 440C is magnetic. Do not be alarmed if a magnet sticks to it; this is necessary to achieve the hardness required for carrying loads.

-

Austenitic Stainless Steel (AISI 304/316):

-

-

Best For: Marine applications or extreme chemical exposure.

-

Key Feature: Almost completely non-magnetic and rust-proof.

-

Trade-off: It is much softer than Chrome or 440C steel. Not recommended for high-load or high-speed applications.

-

Hybrid Ceramic (Si3N4 Balls + Steel Rings):

-

-

Best For: Electric Motors (EVs) and High-Speed Spindles.

-

Why Upgrade? Ceramic balls are lighter, harder, and act as electrical insulators, preventing electrical pitting (fluting) in motor bearings.

-

Identifying Material by Part Number: The “S” Factor

How do you know if a bearing is Chrome Steel or Stainless just by looking at the box?

In the standard numbering system, the material is denoted by a Prefix (added to the front), not a suffix.

-

Chrome Steel (Standard): Has NO material prefix.

-

Example: 6205-ZZ (This implies standard GCr15 steel).

-

-

Stainless Steel: Identified by the prefix “S” (or sometimes “SS“).

-

Example: S6205-ZZ (The “S” stands for Stainless 440C).

-

-

Plastic / 304 Stainless: Often uses non-standard codes or prefixes like “PL” or “S304”.

Buyer Tip:

If you order a “608” bearing, you will get Chrome Steel. If you need it for a food machine, you must specify “S608“. One letter makes the difference between a rusting part and a long-lasting solution.

QUICK COMPARISON: Which material fits your application?

| Material Standard | Hardness (HRC) | Corrosion Resistance | Load Capacity | Magnetic? | Cost |

|---|---|---|---|---|---|

| Chrome Steel (52100) | Very High (60-64) | Low (Rusts easily) | Excellent | Yes | Low |

| Stainless (440C) | High (58-62) | Good | Good | Yes | Medium |

| Stainless (304) | Low ( | Excellent | Very Low | No | High |

Cage Types (Retainers): Steel vs. Brass vs. Nylon – Which is Best?

The cage (or retainer) doesn’t carry the load, but it is the silent guardian of the bearing. It separates the rolling elements to prevent friction and heat. Choosing the wrong cage material is the #1 cause of failure in high-speed or vibrating applications.

At TFL, we offer three primary cage materials, identified by specific suffixes in the part number:

Pressed Steel (Suffix: J / W)

-

-

The Standard Choice: Included in 80% of standard bearings.

-

Pros: High heat resistance, cost-effective, and dimensionally stable.

-

Cons: Higher friction and noise compared to Nylon; can rust if the grease fails.

-

Best For: General manufacturing, fans, and standard electric motors.

-

Polyamide / Nylon 6.6 (Suffix: TN9 / TVP / G)

-

-

The High-Speed Choice: Injection-molded glass-fiber reinforced nylon.

-

Pros: Extremely low friction (energy saving), runs quieter, and handles misalignment better than steel.

-

Cons: Temperature Limit: Strictly limited to 120°C (250°F). Also sensitive to certain extreme-pressure (EP) additives in gear oils.

-

Best For: High-efficiency electric motors, pumps, and compressors.

-

Machined Brass (Suffix: M / MA / MB)

-

-

The Heavy-Duty Choice: Precision machined from cast brass.

-

Pros: Unmatched durability. Can withstand severe shock loads, high vibration, and extreme accelerations that would shatter a nylon cage.

-

Cons: The most expensive option; heavier weight.

-

Best For: Mining screens, large industrial pumps, and wind turbines.

-

Planning to use Nylon (TN9) cages? Be careful with your lubricant.

Some synthetic oils and aggressive EP additives can chemically attack Polyamide over time, causing the cage to become brittle and snap.

If you are unsure about compatibility, stick to Steel (J) or consult TFL engineers.

Internal Clearance: Decoding C3, C4, and “Wiggle Room”

One of the most common misconceptions in bearing selection is confusing Precision with Clearance.

-

Precision is about how accurate the dimensions are (ABEC/ISO ratings).

-

Clearance is the internal “play” or room for movement between the balls and the raceways.

Think of clearance as “expansion room.” If a bearing is too tight, friction generates heat, the metal expands, and the bearing seizes (locks up). If it’s too loose, it vibrates and acts noisy.

The “Code” Breakdown

-

CN (Normal): The standard clearance for typical operating conditions.

-

Buyer Note: This is the default. If you see a part number with no suffix (e.g., “6205-2RS”), it is CN clearance.

-

Best For: General conveyors, HVAC fans, and applications with standard shaft fits.

-

-

C3 (Greater than Normal): The most common “upgrade” for industrial machinery.

-

Why use it? When bearings run at high speeds or in hot environments, the steel rings expand. C3 provides extra room for this expansion. It is also required when using heavy press fits (tight fits) on the shaft.

-

Best For: Electric motors, motorcycle engines, and alternators.

-

-

C4 (Extra Large):

-

Best For: Extreme heat (paper dryers, kilns) or violently vibrating machinery (shakers, crushers).

-

Don’t Mix Precision with Clearance!

A C3 bearing is supposed to feel slightly loose when cold. This is intentional. Do not mistake this “wiggle” for poor quality or low precision. Once it heats up to operating temperature, that looseness disappears.

Need to dig deeper?

Unsure if your electric motor needs C3 or CN? Choosing the wrong one can halve your motor’s life.

👉 See our full Application Chart: [Bearing Clearance Guide]

Precision Classes: ABEC & ISO Tolerances Explained

How precise does your bearing need to be?

In the bearing world, precision isn’t just about dimensions; it’s about Runout (how “true” the bearing spins). A higher precision class means less vibration, higher speed capability, and less noise.

However, higher precision comes with a higher price tag. The key is finding the balance. TFL uses the ISO standard (P-Series), which corresponds directly to the American ABEC system:

Normal Precision (ISO P0 / ABEC-1):

-

-

The Workhorse: This is the standard for 90% of applications.

-

Best For: Agricultural machinery, automotive transmissions, and general conveyors where extreme speed is not the priority.

-

High Precision (ISO P6 / ABEC-3):

-

-

The Upgrade: Tighter tolerances for better fit and smoother running.

-

Best For: Standard electric motors and pumps.

-

Precision & Super Precision (ISO P5 / ABEC-5 & P4 / ABEC-7):

-

-

The Specialist: Ultra-tight tolerances measured in microns.

-

Best For: High-speed robotics, CNC machine tool spindles, and medical instruments.

-

Don’t Waste Your Budget:

Moving from P0 to P4 can triple the cost. Do you really need it?

Read our cost-benefit analysis: [Bearing Precision Grades: Why P4 Costs More Than P0?]

Precision is a “System,” Not Just a Part

Here is the most common mistake we see: Buying a high-precision P5 bearing but mounting it on a shaft that was machined with loose tolerances.

If your shaft isn’t perfectly round, the bearing will deform to match it, rendering the extra expense useless. High precision requires a high-precision fit.

Installation Tip:

Ensure your shaft and housing tolerances match the bearing’s class.

Check our fitment guide: [Bearing Fits Explained: How to Choose Shaft & Housing Tolerances (H7/m6 Guide)]

Shields & Seals: ZZ vs. 2RS – Protecting Against Contamination

This is the ultimate trade-off in bearing selection: Protection vs. Speed.

You must keep the lubricant in and the contamination out. However, the more you seal a bearing, the more friction you create, which generates heat and limits your RPM.

What is your primary operating condition?

Open (No Suffix):

-

-

Design: No seals or shields.

-

Application: Used inside gearboxes or enclosed housings where the bearing is lubricated by an oil bath or external grease system.

-

Speed: 100% capacity.

-

Metal Shields (Suffix: ZZ / 2Z):

-

-

Design: A non-contact steel gap. It acts as a labyrinth to deflect large particles.

-

Pros: Zero friction. Because the metal shield does not touch the inner ring, it allows the bearing to run at maximum speed (same as Open bearings).

-

Cons: Not water-resistant. Fine dust and moisture can still penetrate.

-

Rubber Seals (Suffix: 2RS / 2RSH / DDU):

-

-

Design: A synthetic rubber lip (usually NBR) that physically rubs against the inner ring to create a tight seal.

-

Pros: The gold standard for contamination protection. Excellent against water splash and fine dust.

-

Cons: The Speed Penalty. The friction from the rubber lip generates heat. Consequently, the limiting speed of a 2RS bearing is typically 30% to 35% lower than an Open or ZZ bearing.

-

Note: Standard NBR seals are rated for -30°C to +100°C. For higher temps, request Viton/FKM seals.

-

Non-Contact Seals (Suffix: VV / RZ / LLB):

-

-

Design: A rubber seal that creates a tiny gap (does not touch).

-

Benefit: A hybrid solution. You get the low-torque speed of a metal shield (ZZ) with slightly better dust protection than metal.

-

Selection Matrix: Which one wins?

| Type | Dust Protection | Water Resistance | Max Speed | Friction / Torque |

|---|---|---|---|---|

| Open | None | None | Maximum (100%) | Very Low |

| Metal (ZZ) | Good (Large particles) | Poor | Maximum (100%) | Low |

| Rubber (2RS) | Excellent | Good (Splash proof) | Reduced (-30%) | High |

| Non-Contact (RZ) | Moderate | Poor | Maximum (100%) | Low |

Lubrication: Grease Types, Fill Rates, and Temperature Ranges

Did you know that over 50% of premature bearing failures are traced back to improper lubrication?

The grease isn’t just an accessory; it is a component. The grease you choose dictates the bearing’s speed limit, noise level, and lifespan.

At TFL, we don’t just use “generic bucket grease.” We customize the lubrication plan based on your application.

Grease Base Types (The “Engine” of the Grease)

-

Lithium Base (Standard):

-

Performance: Good mechanical stability and water resistance.

-

Application: The universal choice for general machinery, conveyors, and agricultural hubs.

-

Temp Range: -20°C to +110°C.

-

-

Polyurea (Premium / Electric Motor Grade):

-

Performance: Superior high-temperature stability, low noise, and oxidation resistance. It lasts 3-5 times longer than Lithium grease.

-

Application: Electric Motors, HVAC fans, and “Sealed-for-Life” bearings.

-

Industry Favorites: Similar to Mobil Polyrex™ EM or Kyodo Yushi Multemp.

-

-

Solid Lubrication (Food Grade / Extreme):

-

Performance: A polymer matrix saturated with oil that fills the bearing cavity. It cannot wash out.

-

Application: Food processing (H1 Food Grade) or wash-down environments where standard grease would be blasted away by water jets.

-

Fill Rates: Why “More” is Not Better

A common myth is that a bearing should be packed 100% full. This is dangerous. Overfilling causes “Churning”—the balls have to push through a wall of grease, creating massive friction and overheating.

-

Standard Fill (25% – 35%): The “Goldilocks” zone. Optimal for most motors and pumps running at normal speeds.

-

Low Fill (15% – 20%): Required for High-Speed Spindles. Less grease means less drag (low torque) and lower running temperatures.

-

High Fill (50% – 90%): Used only for Low-Speed / High-Dust applications (like conveyor rollers). Here, the excess grease acts as a physical barrier to keep dirt out.

WARNING: Do Not Mix Greases!

Never mix different grease bases (e.g., adding Lithium grease to a Polyurea bearing). They can react chemically, turning the mixture into a liquid soup or a hard rock, causing immediate failure.

Always check compatibility before re-greasing.

Custom Grease Service:

We can pre-lubricate your TFL bearings with trusted global brands like Exxon Mobil, Shell, Klüber, or Kyodo Yushi upon request.

[Contact us to customize your lubrication spec]

Load Ratings: Dynamic (Cr) vs. Static (Cor) Load Capacity

Don’t let the names fool you. These two numbers serve completely different purposes in bearing selection.

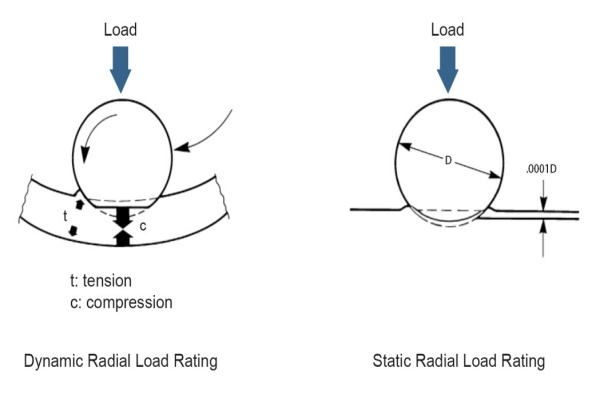

Dynamic Load Rating (Cr): The “Life” Calculator

-

-

What it is: A theoretical value used to calculate the expected service life (L10 Life).

-

The Trap: Do NOT think of this as the maximum working load. If you apply a load equal to the Cr value, the bearing will have a theoretical life of only 1 million revolutions (which might be just a few hours of operation!).

-

Rule of Thumb: For a long service life, your actual operating load should typically be 8% to 15% of the Dynamic Load Rating (Cr).

-

Static Load Rating (Cor): The “Shock” Limit

-

-

What it is: The maximum load the bearing can withstand while stationary (or moving very slowly) before permanent deformation occurs.

-

The Risk: If you exceed Cor (e.g., a heavy impact or shock load while the machine is stopped), the balls will dent the raceway. This damage (Brinelling) creates a “bumpy” ride and noise once the machine starts moving.

-

Engineer’s Tip: Safety Factor

Always calculate a Safety Factor (S0). For critical equipment (like elevators or cranes), you need a high safety factor (Load < Cor / 2). For standard conveyors, a lower factor is acceptable.

Speed Ratings: Limiting Speed vs. Reference Speed

When you look at a TFL data sheet, you will often see two different speed values. Confusing them can lead to catastrophic failure. Which one should you follow?

Reference Speed (The “Thermal” Limit)

-

Think of this as the “Comfort Zone.”

-

It represents the speed at which the bearing reaches an equilibrium temperature (usually 70°C) under standardized conditions.

-

Can you exceed it? Yes, but you must handle the extra heat (e.g., by using circulating oil cooling).

Limiting Speed (The “Mechanical” Red Line)

-

Think of this as the “Do Not Cross” line.

-

It is determined by the mechanical strength of the bearing components—specifically the cage strength and the centripetal force acting on the balls.

-

Can you exceed it? No. Exceeding this speed risks the cage disintegrating or the balls skidding.

The “Real World” Speed Adjustment

Here is the most important part that catalogs often hide. The listed speeds assume an Open Bearing with Oil Lubrication.

If you use Grease or Seals, you must apply a Reduction Factor:

-

Grease Lubrication: Reduces max speed to approx. 70% – 80% of the listed value.

-

Contact Seals (2RS): Reduces max speed significantly (often by 30% – 50%) due to seal friction.

Calculation Example:

-

Catalog Limiting Speed: 10,000 RPM

-

Your setup: Grease + 2RS Seals

-

Your REAL Limit: ~6,000 RPM.

(Don’t guess. Contact TFL engineering for precise speed calculations.)

Vibration & Noise Levels (Z & V Codes)

For electric motor manufacturers and HVAC systems, silence is quality.

A noisy bearing isn’t just annoying; noise is the audible symptom of internal friction and surface imperfections (waviness) on the raceways.

At TFL, we test specifically for two distinct standards: Sound (Z) and Vibration (V).

Z Codes (Sound Pressure Level)

-

What it measures: Decibels (dB). It measures what the human ear hears.

-

The Scale:

-

Z1: Standard noise level.

-

Z2: Low noise.

-

Z3: Silent running (Premium).

-

-

Limitation: Z codes only measure sound, not the physical vibration affecting the shaft.

V Codes (Vibration Velocity)

-

What it measures: Vibration velocity in microns per second (μm/s).

-

Why it matters: This is the critical spec for precision motors. High vibration kills motor efficiency and destroys the grease.

-

The Scale:

-

V1: Standard vibration limit.

-

V2: Precision low vibration.

-

V3: Ultra-low vibration (Required for high-end servo motors and silent fans).

-

What is “EMQ” Quality?

You will often see the term EMQ (Electric Motor Quality).

While many suppliers label standard bearings as EMQ, TFL defines EMQ strictly as Z3V3.

-

We use 100% Anderometer Testing on the production line to ensure every single bearing meets strict smoothness criteria before packaging.

Selection Guide: How quiet do you need to be?

-

Conveyors / Agriculture: Z1 / V1 is sufficient. (Don’t pay for silence you can’t hear over the machine engine).

-

Standard Pumps / Power Tools: Z2 / V2 is recommended.

-

Ceiling Fans / EV Motors / Home Appliances: Z3 / V3 is mandatory to prevent hum and resonance.

Building quiet motors?

Don’t let a vibrating bearing ruin your motor’s reputation.

Read our technical insight: [Decoding Bearing Noise: What do Z1, Z2, and V1 Mean?]

Special Features: Heat Treatment, Coatings, and Insulation

Standard bearings are designed for “happy” environments: room temperature and clean air. But real-world industry is rarely that kind.

If your application involves ovens, chemical washdowns, or stray electrical currents, a standard bearing will fail in days. You need specialized modifications.

Heat Stabilization (The “S” Codes)

Standard bearing steel (GCr15) begins to lose hardness and dimensionally expand permanently at temperatures above 120°C. For higher temps, TFL applies special tempering processes.

-

S0 (Standard): Up to 150°C.

-

S1: Stable up to 200°C.

-

S2: Stable up to 250°C (Common for kiln cars).

-

S3: Stable up to 300°C.

-

Note: High-temp bearings also require Viton seals and high-temp grease (like Krytox or Klüber).

Surface Coatings (fighting Corrosion & Friction)

Sometimes stainless steel is too soft or too expensive. Coatings offer a middle ground.

-

Black Oxide Treatment: A chemical process that turns the steel black.

Benefit: Increases resistance to rust and helps the bearing “break in” without galling. Popular in agricultural and wind power applications.

-

Zinc/Nickel Plating:

Benefit: excellent corrosion resistance for wash-down environments.

Electrical Insulation (INSOCOAT / VCL)

In modern electric motors controlled by VFDs (Variable Frequency Drives), stray currents can pass through the bearing, acting like mini welding arcs that pit the raceways (a phenomenon called Electrical Fluting).

-

Ceramic Coating (Insulated): We coat the outer or inner ring with a layer of aluminum oxide plasma.

-

Hybrid Ceramic: Using ceramic balls (Si3N4) which are naturally non-conductive.

-

Target: Essential for EV motors, Generators, and Railway Traction Motors.

Decoding the Bearing Part Number: A Step-by-Step Example

Bearing part numbers aren’t random; they are a logical code. Once you understand the syntax, you can tell the bearing’s size, type, and features instantly.

Type

Series

Bore

Seal

Clearance

Let’s dissect a fully loaded TFL specification: 6205-2RS-C3-Z2-TN9

The Anatomy of the Code:

1. The Type Code (First Digit): “6”

-

-

This identifies the Bearing Type.

-

6 = Deep Groove Ball Bearing. (Other examples: 7 = Angular Contact, 2 = Spherical Roller).

-

2. The Series Code (Second Digit): “2”

-

-

This indicates the Width/Robustness.

-

0 or 1 = Thin/Light.

-

2 = Standard/Light.

-

3 = Medium (Heavier load capacity).

-

3. The Bore Code (Last Two Digits): “05”

-

-

The x5 Rule: For codes 04 and up, multiply by 5 to get the Bore Diameter in mm.

-

Calculation: 05 × 5 = 25 mm.

-

(Exceptions: 00=10mm, 01=12mm, 02=15mm, 03=17mm)

-

4. The Suffixes (The Features): “2RS-C3-Z2-TN9”

-

-

2RS: Sealed on both sides (Rubber).

-

C3: Internal clearance > Normal (High speed/heat).

-

Z2: Low Noise Level (Electric Motor Quality).

-

TN9: Glass-fiber reinforced Nylon Cage.

-

The Interchangeability Guarantee

“Can I replace an SKF or NSK bearing with TFL?”

Yes.

TFL follows the universal ISO Designation System. A TFL 6205-2RS has the exact same boundary dimensions and load ratings as a 6205-2RS1 (SKF) or 6205-DDU (NSK).

Check our [Cross-Reference Tool] to find your match.

Conclusion: How to Choose the Right TFL Bearing for Your Application

As we have seen, buying a bearing is about more than just dimensions.

-

A C3 suffix can save your motor from seizing.

-

A V3 vibration rating can make your appliance silent.

-

Choosing Grease over Oil can change your speed limit by 30%.

At TFL Bearings, we don’t just sell parts; we engineer reliability. We ensure that every parameter—from the steel purity to the seal friction—is optimized for your specific machinery.

Ready to select the perfect bearing?

Don’t guess. Let our engineering team review your application requirements today.

[CONTACT TFL ENGINEERING TEAM] | [CHECK FULL TECHNICAL CATALOG]