Insulated Bearings Data Sheet 2026: Specification Guide for DGBB & Cylindrical Roller Series (VL0241/VL2071)

Do your motor bearings fail prematurely due to electrical erosion?

Using Variable Frequency Drives (VFDs) improves efficiency but introduces shaft voltages and stray currents. These currents arc through standard bearings, causing micro-pitting, fluting, and eventual catastrophic failure—leading to costly unplanned downtime.

TFL BEARING provides the solution. This article and our downloadable Insulated Bearings Data Sheet cover everything you need to know about replacing standard bearings with coated insulated ones. From Deep Groove Ball Bearings (DGBB) to Cylindrical Roller Bearings (CRB), we break down the critical specs: breakdown voltages (500VDC to 3000VDC), coating types (VL0241 vs. VL2071), and dimensional interchangeability.

Technical Specifications: Precision Engineering for VFD Applications

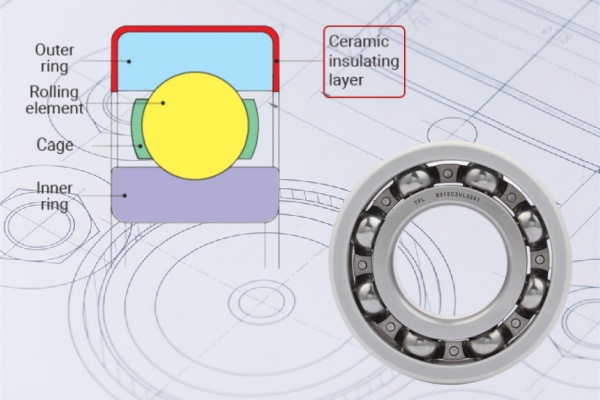

Our insulated bearings go beyond standard protection. We utilize advanced Atmospheric Plasma Spraying (APS) technology to apply a premium ceramic coating (Aluminum Oxide / Al2O3) to the bearing surfaces. Crucially, this porous coating is then treated with a specialized resin sealant to prevent moisture ingress and ensure long-term stability in humid environments.

Key Performance Metrics

-

High Breakdown Voltage (Dielectric Strength):

Guaranteed protection ranging from 1,000V DC to 3,000V DC. This creates a robust safety margin against the high-frequency shaft voltages and PWM spikes generated by modern Variable Frequency Drives (VFDs). -

Zero Dimensional Change (ISO Interchangeable):

Although the coating thickness ranges from 100µm to 300µm, we pre-grind the base steel before coating. Result: The final dimensions fully comply with ISO boundary standards. You can replace a standard bearing with a TFL insulated bearing directly—no housing modifications required. -

Superior Bond & Resistance:

Tested bond strength (>40MPa) ensures the coating will not peel under thermal shock. Every unit undergoes 100% inspection to ensure an electrical resistance of >50 MΩ @ 1000V DC, effectively blocking damaging stray currents.

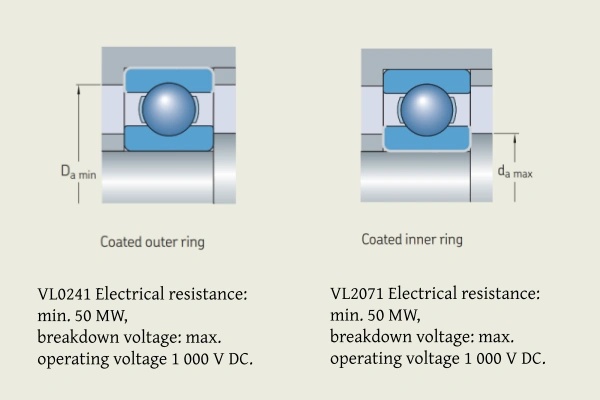

Selection Guide: VL0241 vs. VL2071

Understanding the difference between coating locations is vital for proper installation.

Which part of your bearing ROTATES?

| Comparison | 🔵 VL0241 (Outer Coated) | 🟣 VL2071 (Inner Coated) |

|---|---|---|

| Coating Location | External Surface of the Outer Ring. | Bore Surface of the Inner Ring. |

| Best Application | Standard VFD Motors Fans, Pumps, Compressors. |

Complex Applications Generators, Outer-Ring Rotation. |

| Why Use It? | Protects when current flows from housing to shaft. Easiest to install. | Critical when the Outer Ring Rotates or has a loose housing fit. |

| Market Share | ~90% (Industry Standard) | ~10% (Specialized) |

| Price Factor | $$ (Cost Effective) | $$$ (Higher Processing Cost) |

Detailed Product Portfolio: Sizes, Cages & Clearance Options

We understand that industrial applications vary from high-speed fans to heavy-duty traction motors. That is why TFL’s inventory covers a wide spectrum of types and sizes.

Insulated Deep Groove Ball Bearings (DGBB)

Built for Variable Frequency Drives (VFDs).

Our insulated DGBBs are engineered to handle the typical radial and axial loads of electric motors while providing a barrier against shaft currents.

-

Size Range (Bore):

From 40mm to 300mm (ISO Standard Dimensions). -

Series Coverage:

Comprehensive stock of 60.., 62.., and 63.. series.

(Example: 6316-C3/VL0241) -

Internal Clearance (C3 & C4):

We stock C3 clearance as standard to compensate for thermal expansion in electric motors. C4 clearance is available for high-temperature environments to prevent seizing. -

Cage Options:

-

Steel Cage (J): For standard industrial applications.

-

Machined Brass Cage (M): Recommended for larger sizes or high-inertia applications.

-

Insulated Cylindrical Roller Bearings (CRB)

Built for Heavy Radial Loads & Vibration.

Designed specifically for applications where standard ball bearings cannot handle the load, such as traction motors, wind energy generators, and large industrial pumps.

-

Size Range (Bore):

From 50mm up to 500mm. -

Series Coverage:

-

NU Series: Supports heavy radial loads; allows axial displacement (floating bearing).

-

NJ / NUP Series: Can accommodate limited axial loads.

-

-

Heavy-Duty Cages:

Unlike standard bearings, our insulated CRBs often feature Machined Brass Cages (M).-

Why Brass? It offers superior resistance to vibration and wear in harsh conditions (e.g., Railway Traction Motors).

-

(Corrected Example: NU 320 ECM/C3VL0241)

-

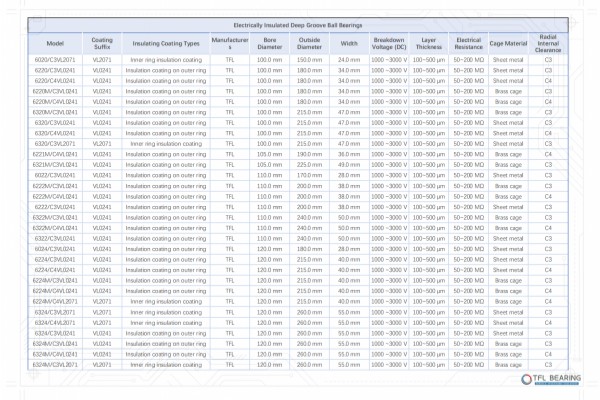

Data Sheet Preview: Dimensions & Electrical Specifications

Our downloadable data sheet is designed to provide engineers with every critical metric needed for validation and replacement. The full catalog covers the complete range of insulated bearings, adhering strictly to ISO boundary dimensions to ensure seamless interchangeability with your current equipment.

What You Will Find in the Data Sheet:

Our specification table is designed to give engineers a clear view of both the physical fit and the insulation capability. As shown in the preview, the data includes:

-

Precise Dimensions: Bore Diameter, Outside Diameter, and Width (strictly adhering to ISO standards).

-

Electrical Properties: Explicit values for Breakdown Voltage (DC), Layer Thickness, and Electrical Resistance, ensuring the insulation meets your motor’s protection requirements.

-

Construction Details: Specific columns for Coating Suffix (VL0241 vs. VL2071), Cage Material options, and Radial Internal Clearance.

Sample Specification Breakdown

To help you interpret the data shown in the table above, here is a detailed look at two distinct configurations listed:

1. Model 6020/C3VL2071 (Inner Ring Insulation)

-

Dimensions: 100.0 mm Bore × 150.0 mm OD × 24.0 mm Width.

-

Coating Type: Features the VL2071 suffix, indicating the insulation coating is applied to the Inner Ring.

-

Electrical Specs: Rated for 1000V–3000V DC breakdown voltage with a layer thickness of 100–500 µm.

-

Configuration: Equipped with a standard Sheet Metal cage and C3 radial clearance.

2. Model 6320M/C3VL0241 (Heavy-Duty Brass Cage)

-

Dimensions: 100.0 mm Bore × 215.0 mm OD × 47.0 mm Width.

-

Coating Type: Features the VL0241 suffix, indicating the insulation coating is on the Outer Ring.

-

Construction: This “M” variant utilizes a Brass Cage, offering superior durability for high-vibration applications compared to standard sheet metal.

-

Insulation Performance: Tested to ensure an electrical resistance of 50–200 MΩ, providing a robust barrier against stray currents.

Searching for a specific size?

The table above is just a sample of our 100mm bore series. Download the full PDF below to access the complete list of available models, ranging from smaller series to large-scale industrial sizes.

Why Industry Leaders Partner with TFL BEARING?

It comes down to balancing Cost-Efficiency with Uncompromising Quality. While we provide competitive pricing typical of a premier Chinese manufacturer, our true value proposition lies in our reliability, speed, and engineering support.

1. Rapid Deployment (Minimize Your Downtime):

We understand that every minute of unplanned downtime costs you money. Unlike competitors who treat insulated bearings as “special orders” with 8-12 week lead times, TFL maintains a massive inventory of common models (62xx, 63xx, NU series).

-

The Result: Most standard orders ship within 48 hours, getting your equipment back online faster.

2. Verifiable Quality Assurance:

We don’t just claim quality; we prove it. Every TFL insulated bearing undergoes rigorous testing before leaving our facility.

-

Testing Protocol: 100% inspection for Insulation Resistance (IR) and Dimensional Accuracy.

-

Traceability: We provide detailed test reports with every shipment, ensuring the coating bonds perfectly to the steel and won’t flake under load.

3. Engineering & OEM Solutions:

Do you have a unique application? Whether you need a specific breakdown voltage (e.g., upgraded to >3000V DC) or a non-standard clearance, our engineering team works directly with OEM clients.

-

Flexibility: We accept small batch customization, helping you develop tailored solutions without the burden of massive Minimum Order Quantities (MOQs).

Protect Your Motors Today & Download the Full Technical Guide

Do not wait for the next unplanned shutdown. Electrical erosion is a preventable threat that compromises your operational efficiency. By upgrading to TFL Current-Insulated Bearings, you are not just buying a component; you are making a strategic investment in the longevity of your entire drive system.

Access the Complete Data Sheet

Get instant access to detailed load ratings, speed limits, and dimensional drawings for our full range of DGBB and Cylindrical Roller Bearings. This document allows you to verify ISO dimensional compliance and select the exact voltage protection level for your project.

[Download Full Insulated Bearings Data Sheet & Catalog: DGBB & Cylindrical Roller Series (VL0241/VL2071) (PDF)]

Need a Quote or Cross-Reference Help?

If you are unsure which bearing suffix replaces your current model (e.g., SKF or FAG equivalents), our technical team is ready to assist. We offer free cross-reference services and custom quotations for bulk orders.

Contact Our Export Team:

We are committed to providing rapid support. Send us your inquiry, and our engineers will respond within 24 hours.

-

Email: [info@tflbearing.com]

-

WhatsApp / WeChat: [0086 15806631151]