How to Select the Right Grease Temperature for Bearing Lubricating

Introduction

Correct temperature for bearing lubricating grease is crucial in the design, installation, and operation of equipment, especially for motors where grease is the primary lubricant.

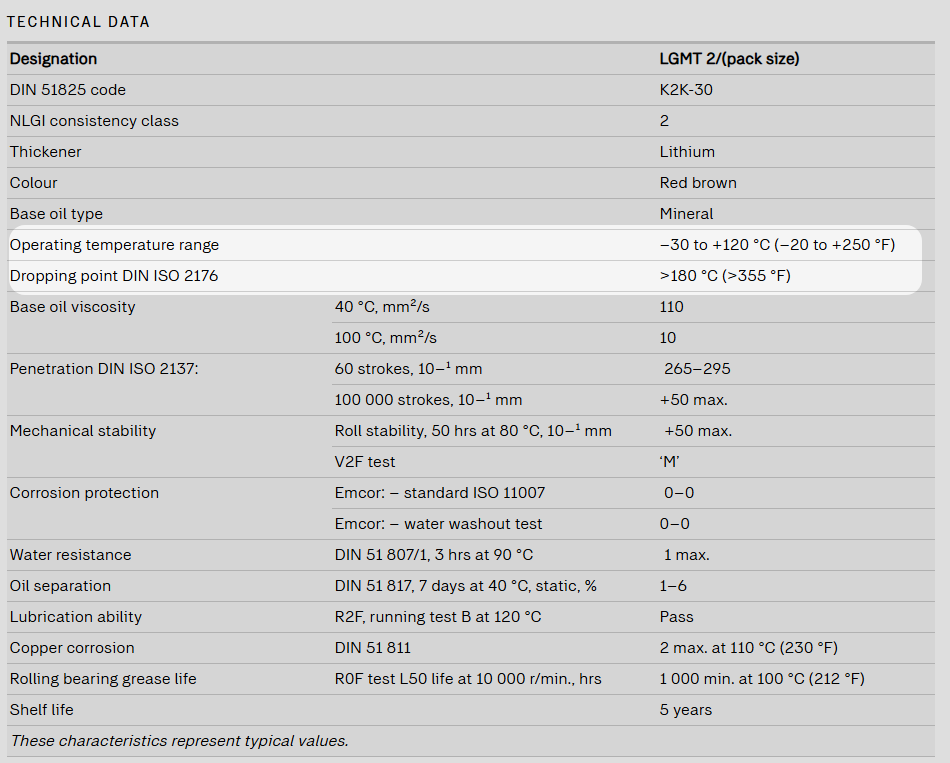

Grease suppliers provide key data like dropping point and operating temperature range, but these numbers don’t always align with real-world conditions or design needs. With various calculations and concepts floating around, it’s easy to feel lost.

This guide simplifies the process, offering a clear path to selecting grease temperature with confidence.

Understanding Grease Temperature Specs: Dropping Point and Operating Range

Grease suppliers often list two main temperature parameters: dropping point and optimal operating temperature range. Let’s break down what they mean and why they’re not the whole story.

What is Dropping Point?

-

Definition: The temperature at which heated grease shifts from semi-solid to liquid, marked by the first drop falling from a test cup.

-

Why it matters: This is the upper limit where grease loses its structure, becoming liquid and altering its lubricating ability.

-

Key takeaway: Exceeding the dropping point is a no-go, but staying below it doesn’t guarantee performance. Grease properties change with temperature, and lubrication may still falter before reaching this point.

What is the Optimal Operating Temperature Range?

-

Definition: A suggested range where grease maintains acceptable consistency and viscosity for lubrication.

-

How it works: Grease softens as temperature rises (lower consistency and viscosity) and hardens as it drops (higher consistency and viscosity). The range indicates where these properties are likely balanced.

-

The catch: This range is a general guideline—it doesn’t ensure the grease suits your specific equipment or conditions.

So, can you rely on these specs alone? Not quite. Let’s explore why a proper calculation is essential.

The Smart Way to Choose Grease Temperature: Kappa Value Calculation

Selecting grease isn’t guesswork—it’s about ensuring the grease provides adequate lubrication under your operating conditions. This is where the kappa value (κ) comes in, a simple ratio that tells you if the grease’s viscosity meets the bearing’s needs.

What is the Kappa Value?

- Formula: kappa coefficient (κ) (According to SKF data)

- Ideal range: A kappa value between 1 and 4 means the grease is suitable.

- Below 1: Too thin, risking wear.

- Above 4: Too thick, causing drag or overheating.

How Temperature Affects the Calculation

Temperature directly impacts grease viscosity, making it a critical factor. Here’s the simplified process:

-

Know your conditions: Determine the bearing’s speed, load, and expected operating temperature.

-

Find the minimum viscosity: Calculate the viscosity needed for proper lubrication (often found in bearing manuals).

-

Check grease viscosity: Use the grease’s viscosity-temperature curve to find its viscosity at your operating temperature.

-

Calculate kappa: Divide the actual viscosity by the minimum required viscosity.

-

Evaluate: If κ is between 1 and 4, you’re good. If not, adjust your grease choice or conditions.

Why This Calculation Matters

The kappa value ensures the grease works for your setup. Supplier specs like dropping point or temperature range are helpful but don’t account for your specific speed, load, or environment. This calculation bridges that gap.

Why Supplier Specs Aren’t Enough

Ever wondered why suppliers don’t just give a perfect temperature number? They can’t—grease performance varies with conditions like speed and load, which they don’t know. Dropping point and temperature range offer a starting point, but only the kappa calculation confirms if the grease fits your needs.

For example:

-

Dropping point is the absolute ceiling—don’t exceed it.

-

Temperature range suggests a broad window, but it’s not tailored to your setup.

-

Viscosity curves (used in kappa calculations) show how grease behaves at your actual temperature.

Practical Tips for Selecting Grease Temperature

-

Use supplier data as a filter: Dropping point and temperature range help you shortlist greases, but don’t stop there.

-

Run the kappa calculation: Confirm the grease meets your bearing’s viscosity needs at the expected temperature.

-

Factor in the environment: Consider ambient temperatures, cooling systems, or nearby heat sources.

-

Test and monitor: After selection, keep an eye on bearing performance to ensure the grease holds up.

-

Get help if needed: Grease or bearing manufacturers often provide tools or support for calculations.

Conclusion: Choose Wisely, Lubricate Smartly

Selecting the right bearing grease temperature isn’t about matching supplier specs—it’s about verifying performance with the kappa value. By understanding dropping point, operating range, and how they relate to viscosity, you can make informed choices that keep your bearings running smoothly. Ready to simplify your grease selection? Run the numbers and watch your equipment thrive. Got questions? Tell us—we’re here to help!