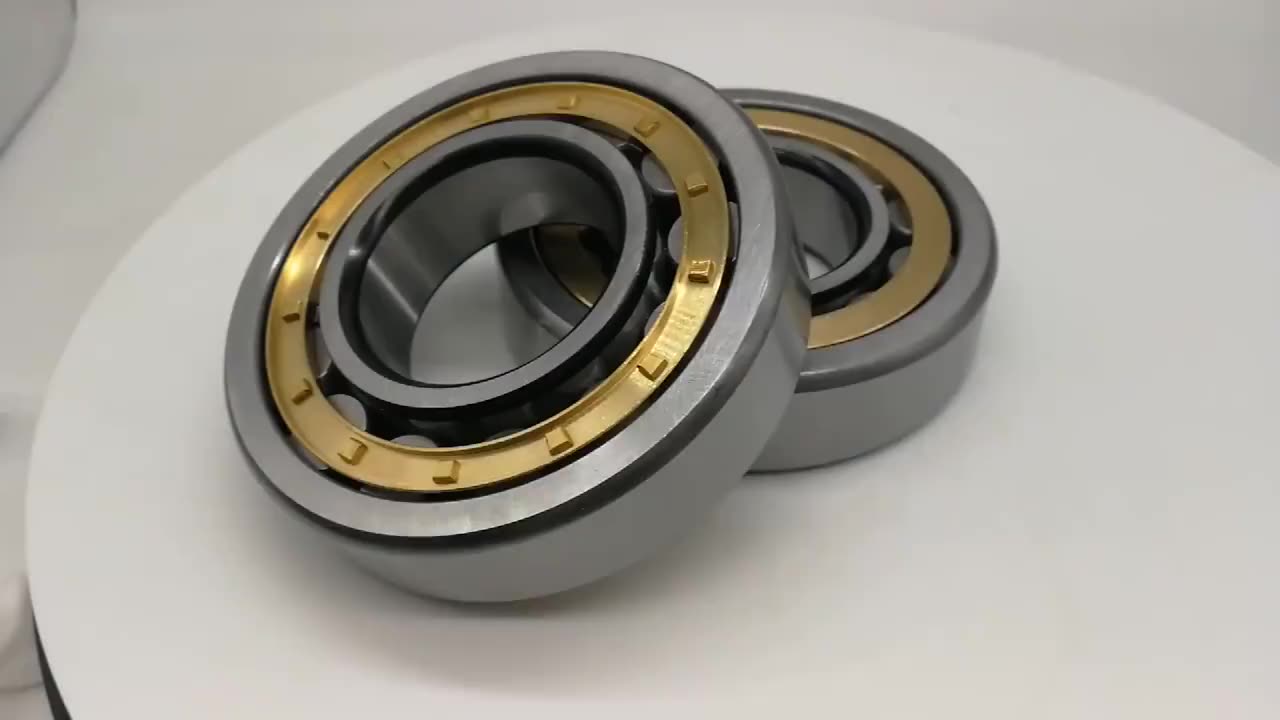

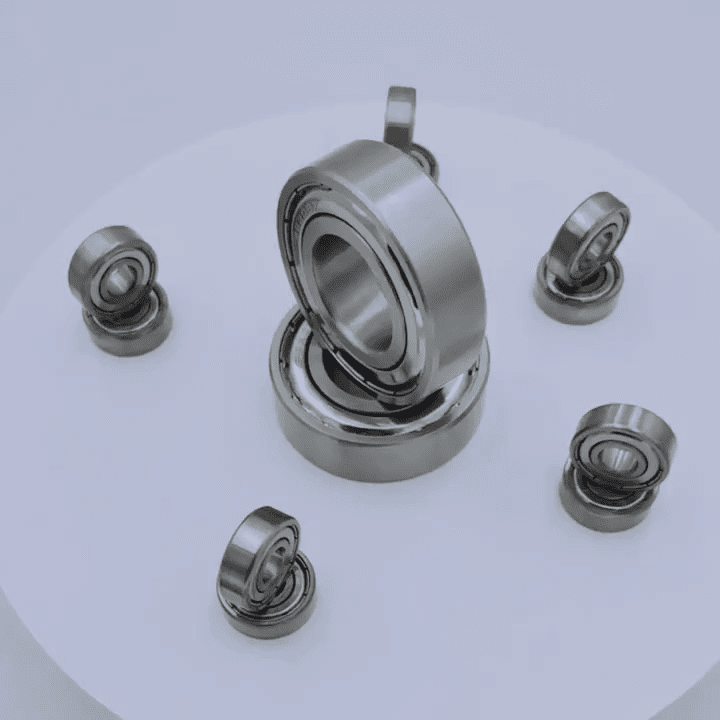

High Temperature Deep Groove Bearing 6202TN9/C3 6202-ZTN9 with nylon bearing

- Shipping:

- Support Sea freight

Alibaba.com Freight | Compare Rates | Learn more

Alibaba.com Freight | Compare Rates | Learn more

High Termperature Deep Groove Bearing 6202TN9/C3 6202-ZTN9 with nylon bearing

TFL high-temperature bearings maintain exceptional performance at temperatures to 200°C and beyond. These bearings which are deal for extreme high temperature applications are designed to provide high reliability, longer life and reduce machine operating costs.

1.For 150°C ~ 200°C working conditions, WM high-temperature bearing is made of high quality bearing steel GCr15 by S2 grade 250°C high temperature tempering which make the hardness reaching between 58 HRC and 62HRC. It uses Silicon fluoride grease as lubrication, ACM rubber seal for sealed type bearing (-2RS), and SPCC shield for shielded type bearing (-ZZ).

2.For 200°C ~ 250°C working conditions, WM high-temperature bearings is made of high quality bearing steel GCr15 by S3 grade 300°C high temperature tempering which make the hardness reaching 62HRC. It uses Polyether grease as lubrication, FKM rubber seal for sealed type bearing (-2RS) , SPCC shield for shielded type bearing (-ZZ).

3.TFL high-temperature bearing is produced according to ABEC-3 (P6) tolerance precision, and the radial clearance is looser than normal bearings to accommodate larger coefficients of expansion. It has advantages of low noise and non-sticking during normal operating, and afford the friction and impact from external environment.

Applications:

TFL high-temperature bearing are used include:

Packaging industry: Corrugating Roller, Pressure Roller

Food and beverage industry: Continuous baking ovens, wafer baking ovens, etc.

Motor industry: Air-blower, ventilator, hot melt fan, furnace blower, etc.

Machinery Industry: Drying oven, Painting equipment, coating & conveying equipment, ceramic curing furnace, etc.

| BEARING NO. | Dimension(mm) | Rated load(KN) | Max. Speed(rpm) | Weight | |||||

| d | D | B | Rsmin | Cr | Cor | Grease | Oil | (kg) | |

| 6300 | 10 | 35 | 11 | 0.6 | 5.88 | 3.47 | 20000 | 26000 | 0.054 |

| 6301 | 12 | 37 | 12 | 1.0 | 7.48 | 4.65 | 17000 | 22000 | 0.058 |

| 6302 | 15 | 42 | 13 | 1.0 | 8.80 | 5.43 | 16000 | 20000 | 0.082 |

| 6303 | 17 | 47 | 14 | 1.0 | 10.45 | 6.56 | 15000 | 19000 | 0.110 |

| 6304 | 20 | 52 | 15 | 1.1 | 12.26 | 7.81 | 13000 | 17000 | 0.140 |

| 6305 | 25 | 62 | 17 | 1.1 | 17.22 | 11.39 | 10000 | 14000 | 0.220 |

| 6306 | 30 | 72 | 19 | 1.1 | 20.77 | 14.17 | 9000 | 12000 | 0.330 |

| 6307 | 35 | 80 | 21 | 1.5 | 25.66 | 17.92 | 8000 | 10000 | 0.410 |

| 6308 | 40 | 90 | 23 | 1.5 | 31.35 | 22.38 | 7000 | 9000 | 0.600 |

| 6309 | 45 | 100 | 25 | 1.5 | 40.66 | 30.00 | 6300 | 7500 | 0.770 |

| 6310 | 50 | 110 | 27 | 2.0 | 47.58 | 35.71 | 6000 | 7000 | 1.030 |

| 6311 | 55 | 120 | 29 | 2.0 | 55.05 | 41.91 | 5600 | 6700 | 1.367 |

| 6312 | 60 | 130 | 31 | 2.1 | 62.88 | 48.60 | 5000 | 6000 | 1.710 |

| 6313 | 65 | 140 | 33 | 2.1 | 72.21 | 56.68 | 4500 | 5300 | 2.100 |

| 6314 | 70 | 150 | 35 | 2.1 | 80.10 | 63.48 | 4300 | 5000 | 2.550 |

| 6315 | 75 | 160 | 37 | 2.1 | 87.25 | 71.67 | 4000 | 4800 | 3.050 |

| 6316 | 80 | 170 | 39 | 2.1 | 94.57 | 80.35 | 3800 | 4500 | 3.610 |

| 6317 | 85 | 180 | 41 | 3.0 | 102.05 | 89.52 | 3600 | 4300 | 4.284 |

| 6318 | 90 | 190 | 43 | 3.0 | 110.81 | 100.76 | 3400 | 4000 | 4.97 |