Bearing Precision Grades: Why P4 Costs More Than P0?

Introduction:

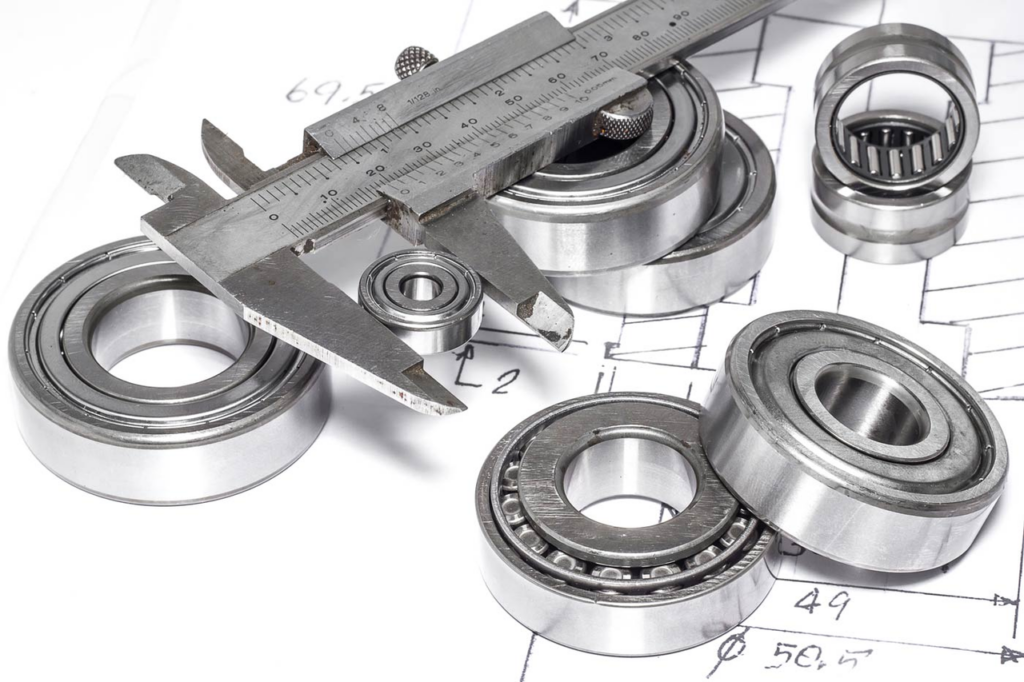

Bearings are like the joints of machines—they keep everything moving smoothly. But not all bearings are created equal. You’ve probably seen labels like P0 or P4, and noticed that P4 bearings cost significantly more.

A common question we get is: “Is P4 a material grade?” The short answer is no—it’s a precision standard. However, the two are closely linked. Achieving P4 precision often requires higher-quality materials than standard bearings.

In this guide, we’ll delve into the world of bearing precision grades. We will uncover the secrets behind the price differences and clarify the relationship between precision standards and bearing materials. By the end, you’ll know exactly what makes P4 bearings special—and when you really need them.

What Are Bearing Precision Grades?

First, let’s clear up a misconception: Precision grades (like P4) refer to dimensional tolerance and rotational accuracy, not the chemical composition of the steel. However, high-precision grades usually demand cleaner, higher-quality steel to maintain that accuracy over time.

Bearing precision grades follow international standards like ISO (or ABEC in the US). The most common grades, from lowest to highest precision, are: P0, P6 (P6x), P5, P4, and P2. Here’s a quick overview:

-

P0 (Normal): The standard, everyday bearing used in general applications (conveyors, simple motors).

-

P6 (P6x): A step up from P0, with tighter controls on size and lower noise levels.

-

P5: High precision. Often specified for machines requiring smoother running and better positioning accuracy.

-

P4 (Super Precision): The industry standard for machine tool spindles. It features extremely tight tolerances and is often manufactured with premium steel to ensure stability.

-

P2: Ultra-precision. Reserved for the most demanding applications, such as high-tech instruments and gyroscopes.

Key Differences Between P4 and P0 Bearings

While they may look identical on the outside, the difference lies in the microscopic details.

Size Tolerances (Dimensional Accuracy)

This refers to how close the bearing’s actual dimensions (inner diameter, outer diameter, width) are to the nominal values.

-

P0 Bearings: Have standard tolerance ranges. They are cost-effective and perfectly adequate for general machinery where a few microns of variance won’t affect performance.

-

P4 Bearings: Feature micron-level tolerances. Every part must fit the shaft and housing perfectly.

Rotational Accuracy (Runout)

This measures how “true” the bearing spins. In the industry, we call this Runout.

-

P0 Bearings: Allow for a standard amount of radial and axial runout. You might not see it with your naked eye, but at high speeds, this can cause vibration.

-

P4 Bearings: Offer near-zero runout. They rotate with extreme smoothness. This lack of vibration implies:

-

Less friction and heat generation.

-

Longer lifespan for both the bearing and the machine spindle.

-

Higher quality surface finish on machined parts (crucial for CNC machines).

-

Ever wonder why some high-end machines are so quiet and efficient? It’s often thanks to the extremely low runout of P4 precision bearings.

Why Are P4 Bearings More Expensive to Make?

The price gap isn’t just markup; it reflects the immense difficulty in manufacturing.

Premium Raw Materials (The “P4 Material” Factor)

While P4 is a tolerance class, you cannot achieve it with cheap steel.

-

P0 Bearings: Typically use standard GCr15 (52100) chrome steel. It’s durable but may contain microscopic impurities.

-

P4 Bearings: Demand ultra-clean steel (often Vacuum Degassed or VIM-VAR steel). Why? Because even a microscopic non-metallic inclusion can ruin the precision of a P4 bearing or cause early fatigue failure at high speeds.

-

Hybrid Options: Many P4 bearings feature Ceramic Balls (Silicon Nitride). These are lighter, harder, and more heat-resistant than steel, further increasing the cost (and performance).

Fun fact: Standard steel is like regular unleaded gas. The steel used for P4 bearings is like aerospace-grade fuel—purified to perfection.

Complex Manufacturing & Low Yield Rate

Making a P4 bearing is closer to watchmaking than standard industrial manufacturing.

-

Super-finishing: P4 bearings undergo multiple rounds of grinding and “super-finishing” to achieve a mirror-like surface. This takes significantly more time.

-

Strict Environment: Assembly often happens in clean rooms to prevent dust from contaminating the grease or raceways.

-

The “Yield Rate” Cost: This is the hidden cost driver. When manufacturing P4 bearings, a significant percentage may fail the strict final inspection. These rejected parts are scrapped. The cost of these “rejects” has to be absorbed into the price of the perfect bearings that make it to the market.

Stricter Testing for P4 Bearings

You are not just paying for the product; you are paying for the proof that it works.

Advanced Testing Tools

-

P0 Bearings: Undergo standard batch sampling for dimensions and hardness.

-

P4 Bearings: Every single bearing often undergoes 100% comprehensive inspection. Factories use advanced equipment like Roundness Testers (Taylor Hobson) and BVT (Bearing Vibration Testers) to detect even nanometer-level deviations.

Material Integrity Checks

-

Critically, P4 bearings often undergo Non-Destructive Testing (NDT) to ensure the steel material has no internal cracks or heat-treatment burns. A P4 bearing with a material flaw is useless, no matter how dimensionally accurate it is.

Higher Inspection Standards

-

P0 Bearings: Follow Acceptable Quality Limits (AQL). If a few in a batch are slightly off, the batch might still pass.

-

P4 Bearings: Zero tolerance. If a bearing fails a single micron-level test, it is rejected. This high “scrap rate” ensures that the P4 bearing you receive is guaranteed to perform.

Where Are P4 and P0 Bearings Used?

Choosing the right grade depends entirely on your application’s RPM (speed), load, and heat requirements.

P0 Applications (General Use)

-

Ideal for: Conveyor belts, agricultural machinery, standard electric motors, and automotive wheel hubs.

-

Why: These machines don’t run at extreme speeds, and a tiny bit of vibration won’t affect the outcome.

P4 Applications (Precision & High Speed)

-

Ideal for: CNC Machine Tool Spindles, high-speed turbochargers, precision printing machinery, and aerospace gyroscopes.

-

Why: In a CNC machine, if the bearing wobbles even slightly, the cutting tool will vibrate, and the finished part will have a rough surface. Here, P4 precision is mandatory.

Pro Tip: Don’t over-spec. Using a P4 bearing in a slow-moving conveyor belt is a waste of money. It won’t last longer than a P0 bearing in that environment.

Market Availability (Why Lead Times Differ)

-

P0 Bearings: Mass-produced by the millions. They are almost always in stock and prices are competitive.

-

P4 Bearings: Often manufactured in smaller batches (“Made to Order”). Because they require specific high-grade materials and longer production times, finding stock can be tricky, and lead times are longer. This scarcity drives up the market price.

Conclusion: Is P4 Worth the Investment?

To sum it up, P4 bearings are not just “expensive versions” of P0 bearings. They are engineered components defined by:

-

Premium Material Requirements: P4 demands ultra-clean steel or ceramic hybrids to maintain stability. (Yes, “P4 quality” implies “Premium Material”!)

-

Micron-Level Precision: Achieved through advanced grinding and 100% inspection processes.

-

Performance: Built for high-speed spindles and tasks where “runout” is the enemy.

The Verdict:

-

If you are building a conveyor belt or a standard motor, stick to P0. It is cost-effective and reliable.

-

If you are repairing a CNC spindle or high-precision turbine, invest in P4. The extra cost pays for itself by preventing machine vibration and ensuring surface finish quality.

Still Unsure Which Grade to Choose?

Don’t overpay for precision you don’t need, but don’t compromise on quality where it counts.

Contact TFL Bearing’s engineering team today. Whether you need a specific P4 material grade or a cost-effective P0 solution, we provide professional consultations to help you match the right bearing to your machine’s needs.

FAQ: Common Questions About P4 Bearings

Q: Is P4 a material grade?

A: No, P4 is an ISO precision tolerance class. However, P4 bearings are typically manufactured using high-grade, vacuum-degassed steel or ceramic materials to ensure they meet strict tolerance requirements.

Q: Can I replace a P4 bearing with a P0 bearing?

A: We do not recommend it. If your machine was designed for P4 (like a CNC spindle), using a P0 bearing will likely cause vibration, overheating, and poor machining accuracy.

Q: What is the difference between ABEC 7 and P4?

A: They are roughly equivalent. P4 is the ISO standard (common in Europe/Asia), while ABEC 7 is the ABMA standard (common in the US). Both represent super-precision bearings.