How to Match EMQ Bearings Z and V Ratings to Your Application

When sourcing EMQ bearings (Electric Motor Quality bearings), you will inevitably encounter the ratings Z1, Z2, Z3 and V1, V2, V3. But looking at a catalog specification sheet rarely tells the whole story.

Is a Z3 bearing always necessary? Does a V1 rating mean the bearing is “bad”?

Here is the quick summary of how to match Z/V ratings to your specific motor application:

| Grade | Description | Primary Benefit | Ideal Applications | Cost Impact |

|---|---|---|---|---|

| Z1 / V1 | Standard Industrial | Rugged Performance | Power Tools, Agricultural Machinery, Outdoor Equipment | $ Low (Base) |

| Z2 / V2 | Intermediate | Balanced Quality | Office Equipment, Standard Pumps, Automotive Auxiliary | $ Moderate |

| Z3 / V3 | Premium Silent | Silence & Longevity | Home Appliances, HVAC, Ceiling Fans, Fitness Equipment | $ Premium (Best Value) |

| Z4 / V4 | Ultra-Precision | Zero Vibration | HDDs, Gyroscopes, Dental Drills (Custom Only) | $ High (Niche) |

Note for Engineers: The table above provides a general selection strategy. If you require the exact vibration limits (dB & μm/s) and tolerance data for specific bore sizes (from 3mm to 60mm), please jump to the Detailed Technical Data Sheet at the bottom of this article.

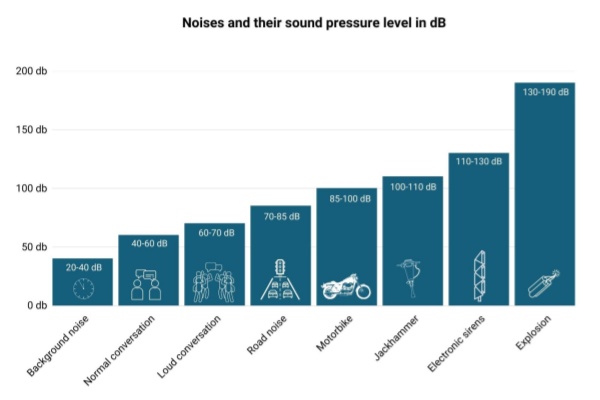

What Exactly Are Z-Ratings (Z1, Z2, Z3) and How Do They Measure Sound?

The Z-Group ratings specifically measure Sound Pressure Level (SPL), quantified in decibels (dB). This test is performed using a decibel meter (like the BVT-1) while the bearing rotates at a set speed.

Think of Z-ratings as what the human ear perceives:

-

Z1: Standard noise level.

-

Z2: Low noise level (< Z1 by approx. 3-5 dB).

-

Z3: Silent/Premium noise level (< Z2 by approx. 3-5 dB).

While Z-ratings are useful for consumer appliances where “quietness” is a key selling point, they mainly focus on high-frequency acoustics. For industrial engineers concerned with longevity, Z-ratings are only half the picture.

Why Should Engineers Care More About V-Ratings (V1, V2, V3)?

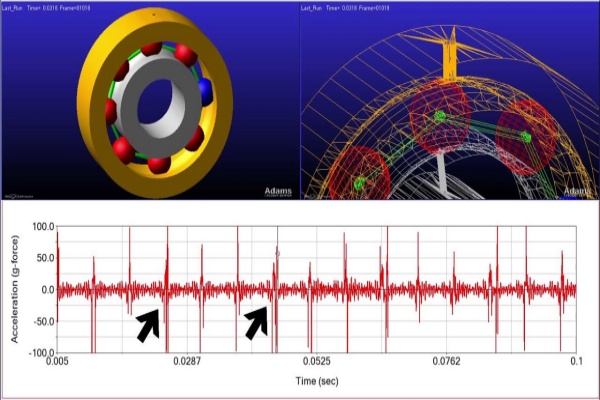

V-ratings measure Vibration Velocity (typically in μm/s or mm/s) across low, medium, and high-frequency bands. This detects structure-borne noise—the physical vibration that transfers from the bearing to the motor shaft and housing.

-

V1: Standard vibration.

-

V2: Low vibration.

-

V3: Extremely low vibration (Required for high-precision motors).

High vibration velocity implies raceway waviness or ball defects. Even if a bearing sounds quiet (Z3) initially, if it has a poor vibration rating (V1), the internal friction will eventually cause metal fatigue, grease degradation, and shortened MTBF (Mean Time Between Failures).

Key Takeaway: For high-speed or industrial motors, always prioritize the V-value.

Does Your Motor Really Need Premium Z3/V3 Bearings?

It is a common misconception in sourcing: “Higher specs are always better.” While Z3/V3 bearings represent the pinnacle of silence and smoothness, specifying them for every project is often a case of over-engineering.

For a procurement manager, the goal is not just to buy the “best” bearing, but the “right” bearing. Paying a 15-20% premium for Z3/V3 grades when the application doesn’t demand it simply inflates your costs without adding value.

Here is a quick guide to matching bearing grades with applications to optimize your ROI:

Category A: Z1 / V1 (Standard Industrial Grade)

-

Best For: High-noise environments or heavy-duty outdoor equipment.

-

Typical Applications: Power tools (Angle grinders, drills), agricultural machinery, industrial gearboxes, and conveyors.

-

The Logic: In these applications, the operating noise of the machine itself (gear mesh, wind noise, cutting sounds) far exceeds the noise of the bearing. Using a Z3 bearing here is like whispering at a rock concert—nobody will notice the difference.

Category B: Z2 / V2 (Standard Precision Grade)

-

Best For: Commercial environments requiring a balance of reliability and moderate acoustics.

-

Typical Applications: Office equipment (Printers, copiers), automotive auxiliary motors (wipers, seat adjusters), and standard water pumps.

-

The Logic: This is the “Goldilocks” zone. It offers smoother running than Z1 to ensure reliability but avoids the premium price tag of Z3.

Category C: Z3 / V3 (Premium Silent Grade)

-

Best For: “Silent” selling points, indoor comfort, and precision stability.

-

Typical Applications: Ceiling fans, HVAC systems, medical devices, and high-end home appliances (Robotic vacuums, washing machines).

-

The Logic: In these products, silence is a feature. A noisy bearing here leads to direct customer complaints and negative reviews. Furthermore, the low vibration (V3) is critical for protecting sensitive electronics in medical or precision equipment.

Pro Tip: Before finalizing your spec sheet, consider your housing tolerances. If your motor housing is not machined perfectly, it will compress the bearing outer ring, causing a Z3 bearing to perform like a Z1 bearing.

What About Z4 and V4?

You may occasionally see specifications or inquiries regarding Z4 or V4 ratings. This is a common point of confusion for buyers looking for the “absolute best.”

Here is our honest engineering advice regarding these ultra-precision grades:

The Law of Diminishing Returns (Don’t Spend Unnecessarily)

For 95% of electric motor applications—including premium home appliances and industrial pumps—Z3/V3 is the functional limit.

Moving from Z3 to Z4 often results in a significant increase in manufacturing cost, yet the difference in noise reduction is usually undetectable to the human ear. In many cases, the wind noise of your cooling fan or the electromagnetic noise of the stator will be louder than a Z3 bearing. Specifying Z4 for a standard motor is typically a waste of your BOM budget.

When is Z4/V4 Actually Required?

However, “unnecessary” does not mean “impossible.” These grades are critical for ultra-precision applications where absolute zero-vibration is non-negotiable, such as:

-

HDD (Hard Disk Drive) Spindle Motors

-

High-Speed Dental Handpieces

-

Gyroscope Rotors

-

Optical/Laser Scanning Equipment

Our Capability:

Unlike many suppliers who simply relabel standard bearings, we possess the manufacturing capability to produce custom Z4/V4 grade bearings for these specialized sectors. This involves specialized grinding processes, ceramic balls, and specific damping greases.

The Verdict: If you are building a standard motor, stick to Z3/V3 to maximize ROI. If you are building a precision instrument and truly need Z4/V4, contact our engineering team—we are one of the few who can deliver it.

Does a Higher ABEC Rating (Precision) Guarantee a Quieter Bearing?

No.

This is the most common myth we encounter from global buyers:

“I want an ABEC-7 bearing because I need it to be quiet.”

The Truth: ABEC ratings (P0, P6, P5, etc.) measure dimensional tolerance—how perfectly sized the ring is. They do not measure surface finish, waviness, or noise.

-

You can have an ABEC-7 bearing with poor surface finish that is noisy.

-

You can have an ABEC-1 bearing with Superfinished raceways that is Z3/V3 Silent.

For EMQ applications, do not rely on ABEC alone. You must specify the Z and V ratings explicitly.

How Can You Verify if Your Supplier is Delivering True EMQ Quality?

Achieving a stable Z3/V3 rating requires advanced manufacturing capabilities. It is not just about sorting; it is about process control.

When auditing your bearing supplier, ask about these three factors:

-

Superfinishing (Honing): This process removes microscopic peaks on the steel surface, reducing waviness.

-

Grease Selection: A Z3 bearing must use filtered, low-noise grease (brands like Kyodo Yushi or Kluber). Standard grease can generate noise.

-

100% Noise Testing: Does the supplier use automatic testing lines (like BVT or S0910 standards) to check every single bearing, or do they only spot-check? Also, ask for the CpK Values (Process Capability Index) to ensure batch consistency.

Conclusion

Choosing between Z1, Z2, Z3 and V1, V2, V3 is a balance between customer experience (Noise) and product longevity (Vibration).

-

Choose Z3/V3 if your customer values silence (HVAC, Home Appliances).

-

Choose Z1/V1 if you need rugged performance and cost savings (Power Tools).

Still unsure which grade fits your new motor design?

We don’t just sell bearings; we provide solutions. Contact our engineering team today for a Custom Noise Test Report or request our EMQ Sample Kit to hear the difference yourself.

Technical Snapshot

Below is a sample of our testing standards for common bore sizes. Note the significant drop in vibration levels from Z1 to V4.

| Bore Size (mm) | Series | Z1 (dB) | Z2 (dB) | Z3 (dB) | Z4 (Custom) | V1 (Low Freq) | V3 (Low Freq) |

|---|---|---|---|---|---|---|---|

| 8mm (e.g., 608) | 60 Series | 38 | 35 | 31 | - | 92 | 44 |

| 10mm (e.g., 6200) | 62 Series | 42 | 39 | 35 | 30 | 120 | 55 |

| 17mm (e.g., 6203) | 62 Series | 47 | 43 | 38 | 33 | 150 | 65 |

| 25mm (e.g., 6205) | 62 Series | 51 | 47 | 42 | 37 | 260 | 80 |

(Note: Data represents maximum allowable values. Lower is better.)

Need the complete data for specific shaft sizes?

We adhere to strict JB/T and international standards.

Download our Full TFL Z1-Z4 & V1-V4 Technical Specification Sheet (PDF)