Deep groove ball bearings — Versatile for radial and axial loads

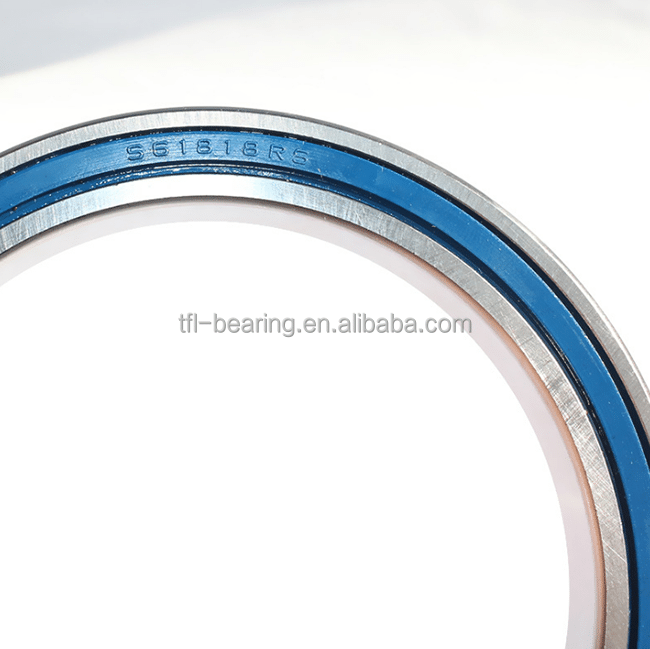

Deep groove ball bearings are the most common type of rolling bearings. Deep groove ball bearings are composed of an outer ring, an inner ring, a set of steel balls, and cages. There are two types of deep groove ball bearings, single row and double row. The deep groove ball structure is also divided into two types: sealed and open. The open type refers to the bearing without a sealed structure.

TFL as a leading bearing manufacturer and supplier in China, We can provide various types of deep groove ball bearings, imperial thrust ball bearings, and bearing sizes support metric and inch.

Various sizes can also be customized according to customers’ needs for bearings. If necessary, please email me.

Deep groove ball bearings Applications

TFL® bearings can provide customers with a variety of products bearing the fields of industrial applications. No matter what industry you are in service, we offer comprehensive solutions, from product training to sales support and then engineering resources that can help you maximize the use of TFLBearing products. TFL Bearing has extensive experience in providing cost-effective solutions:

FAQ

Latest content

Category

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.

All Prices in US Dollars