Ball Bearings

At TFL-BEARING, we can provide the following types of ball bearings, a variety of sizes can also be customized according to customer demand for bearings; TFL company can provide global customers with a series of radial ball bearings, thrust ball bearings, angular contact ball bearings, deep groove ball bearings, hub ball bearings, self-aligning ball bearings, inserts Bearings, bearing sizes support metric and inch. If necessary, please send me an e-mail.

Ball Bearings

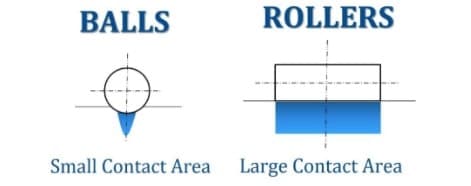

A ball bearing is a kind of rolling bearing. The ball is installed between the inner ring and the outer ring and can bear a large load. While promoting movement, it has three main functions: load-bearing, friction reduction, and positioning of moving machine parts.

Ball bearings are mainly composed of four essential elements: ball, inner ring, outer ring, and retainer, also called cage or retainer. General industrial ball bearings meet AISI 52100 standards. Balls and coils are usually high chromium steel, with Rockwell C-scale hardness between 61-65. The hardness of the retainer is lower than that of balls and rings, and its materials are metal (such as medium carbon steel, aluminum alloy) or non-metal (such as Teflon, PTFE, polymer materials). Ball bearings have lower rotational frictional resistance than journal bearings, so the temperature generated by friction will be lower at the same speed.

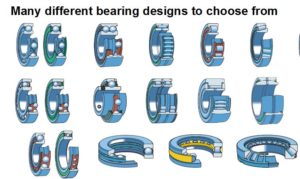

Types of Ball Bearings

Deep Groove Ball Bearing: Deep groove ball bearings are the most common type of rolling bearings. Deep groove ball bearings are composed of an outer ring, an inner ring, a set of steel balls, and cages. There are two types of deep groove ball bearings, single row, and double row. The deep groove ball structure is also divided into two types: sealed and open. The open type refers to the bearing without a sealed structure.

Thrust Ball Bearing: Thrust ball bearings are designed to withstand thrust loads during high-speed operation and are composed of washer-shaped ferrules with the ball rolling raceway grooves. Because the ring is in the shape of a cushion, thrust ball bearings are divided into flat base cushion type and self-aligning spherical cushion type. In addition, this kind of bearing can bear axial load but cannot bear radial load.

Angular Contact Bearing: Angular contact ball bearings have inner and outer ring raceways that are displaced relative to each other in the direction of the bearing axis. This means that these bearings are designed to accommodate combined loads, i.e., simultaneously acting radial and axial loads.

Miniature Ball Bearings: Miniature ball bearings are deep groove ball bearings in small. Their dimensions make them suitable for special applications. In addition, they allow very high speeds with low noise.

Self Aligning Ball Bearing: Self-aligning ball bearings have two structures: cylindrical bore and tapered bore, and the cage is made of steel plate, synthetic resin, etc. Its characteristic is that the outer ring raceway is spherical, with self-alignment, which can compensate for the errors caused by misalignment and shaft deflection. Still, the relative inclination of the inner and outer rings should not exceed 3 degrees.

linear Ball Bearing: Linear bearing is a kind of linear motion system used for linear stroke and cylindrical shaft. Because the bearing ball is in point contact with the bearing jacket, the steel ball rolls with the least frictional resistance. Therefore, the linear bearing has low friction, is relatively stable, does not change with the bearing speed, and can obtain smooth linear motion with high sensitivity and accuracy.

The consumption of linear bearings also has its limitations. The most important thing is that the impact load capacity of the bearing is poor, and the carrying capacity is also poor. Secondly, the linear bearing has greater vibration and noise during high-speed motion. An automatic selection of linear bearings is included. Linear bearings are widely used in sliding parts of precision, textile, food packaging, printing, and other industrial machinery.

Application of Ball Bearing

Most of these deep groove ball bearings have a shielded design, which means they do not require continuous lubrication or maintenance. However, some are open; adding some appropriate lubricants can prolong the service life and effectiveness of the bearing. Fortunately, ball bearings are also cheap and easy to replace if necessary.

Ball bearings are an essential part of heavy machinery. They are instrumental in the following areas: gearboxes, motors, pumps, construction equipment, construction machinery, wind turbines, agricultural machinery, mining, machinery and tools, office supplies, medical equipment, food processing machinery, aerospace.

These ball bearings are not limited to industrial use; they are also a standard part of the items in your home. Any appliance with a motor has at least one deep groove ball bearing, including washing machines, clothes dryers, vacuum cleaners, and dishwashers.

They are also found in computer fans, pool pumps, and even skateboards. Even the toy spinning top contains multiple ball bearings, allowing the toy to rotate in various directions.

FAQ

Latest content

Proper Bearing Storage Guide: Preventing Failure Before Installation

The Ultimate Guide to Bearing Installation and Startup in Cold Weather

Why Road Roller Bearings Fail: A Case Study of EAE4 vs. MB Cages

Spherical Roller Bearing Suffixes Decoder, Guide & Cross-Reference (2026 Updated)

Further Information

Category

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.