Roller Bearings

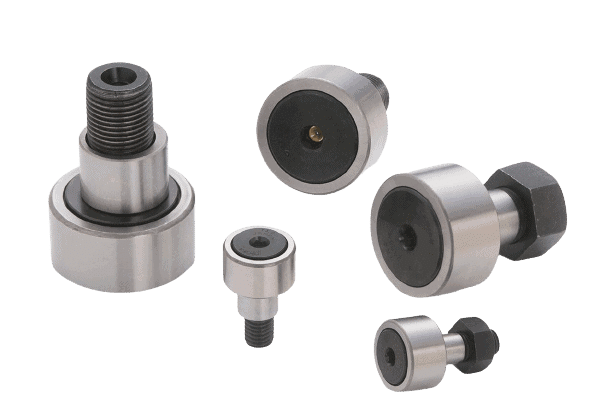

At TFL-BEARING, we can provide the following types of roller bearings: Tapered roller bearings, needle roller bearings, cylindrical roller bearings, spherical roller bearings, cross roller bearings, etc. We can also customize various sizes according to customers’ needs for bearings; If necessary, please email me.

Roller Bearing

Roller bearings allow withstanding more significant radial load because the cylindrical shape produces a linear contact surface. Dispersion radial load on the linear roller bearing of the larger contact area than ball bearings provides a much larger volume of similar size. Innovative design allows further modification of roller bearing can bear greater axial force. A conveyor belt and large equipment are needed for the most typical roller-contact bearing platforms.

Types of Roller Bearings

Cylindrical bearings: These linear roller bearings have unparalleled performance in terms of radial load capacity, making them ideal for heavy equipment and large operations. Usually formatted inline configuration, for example. Single row cylindrical roller bearing types for standard applications and up to four rows of cylindrical roller bearings for extremely high radial load requirements.

Tapered roller bearings: These are designed to provide balanced performance for large axial and radial forces. The sharp geometry is a crucial design attribute, which provides a large roller bearing contact surface and the ability to carry higher loads. Tapered roller bearings are usually used in row configurations to increase load capacity.

Spherical roller bearings: These linear roller bearings provide consistent performance for the most demanding applications. In situations where extreme speeds, non-optimal lubrication, misalignment, or other performance challenges are expected, spherical roller bearings provide the best results when subjected to heavy radial loads.

Thrust bearings: These roller bearing types are optimized to withstand high axial (thrust) loads. Usually, thrust bearings are used for high-speed applications, and the load is generally lighter. There are many different variants of thrust bearings, some of which allow greater loads at reduced speeds.

Cross Roller Bearing: The crossed roller ring is a roller bearing with high rotation accuracy, which can bear loads in all directions. Because it has orthogonally arranged cylindrical rollers, it can withstand loads in all directions.

Needle roller bearings: Small cylindrical bearings of the needle roller bearing type ensure the smallest possible friction profile.

Application of Roller Bearing

Roller bearings are used to replace sliding motion with low friction, rolling motion in rotating applications. The main types of roller bearings are cylindrical, spherical, and conical. Generally speaking, roller bearings provide a higher load capacity than ball bearings of the same size.

Roller bearings are used for heavy-duty medium-speed applications. Potential applications for spherical and cylindrical roller bearings include power generation, oil fields, mining and aggregate processing, wind turbines, gear drives, and rolling mills. Single row tapered roller bearings are used in machine tool spindles, gear reducers, automotive drive axles, transmissions, vehicle front wheels, differential and pinion configurations, conveyor rollers, machine tools spindles, and trailer wheels.

FAQ

Latest content

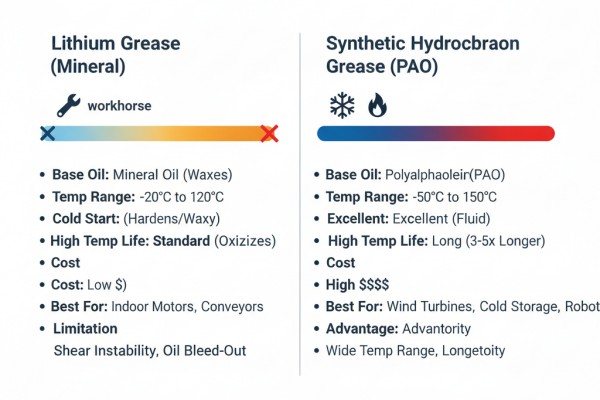

Bearing Grease: Lithium vs. Synthetic – A 2026 Technical Comparison

Proper Bearing Storage Guide: Preventing Failure Before Installation

The Ultimate Guide to Bearing Installation and Startup in Cold Weather

Why Road Roller Bearings Fail: A Case Study of EAE4 vs. MB Cages

Further Information

Category

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.