2025 Comprehensive Guide to Deep Groove Ball Bearing Maintenance and Troubleshooting

Introduction

Importance of deep groove ball bearings

Deep groove ball bearings are the core components of modern mechanical equipment. They have superior performance characteristics and are widely used in a variety of mechanical equipment. They improve the performance and life of mechanical equipment and reduce the cost of maintenance, improving the economic efficiency of enterprises.

Purpose and audience of this guide

The Deep Groove Ball Bearing Guide is intended for a wide range of audiences, including salespeople, purchasers, mechanical design engineers, etc. The primary purpose of the guide includes the provision of comprehensive, accurate, and practical information to help them better understand and use deep groove ball bearings to improve the operational efficiency of mechanical equipment.

Basics of Deep Groove Ball Bearings

Deep groove ball bearings are universal rolling bearings with the advantages of simple structure, ease of use, and high load-carrying capacity.

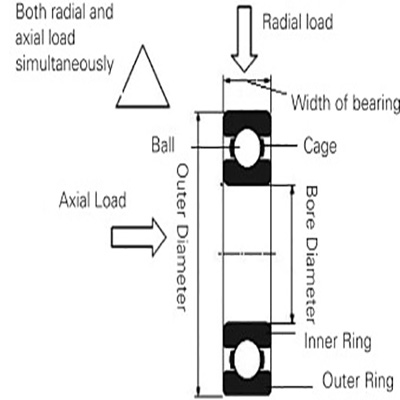

Structure and working principle

The structure of deep groove ball bearings is relatively simple. They are mainly composed of inner and outer rings, steel balls, and a cage. The working principle primarily relies on rolling friction; when the bearing is subjected to radial or axial load, the steel ball rolls in the deep groove between the inner and outer rings and transmits the force by rolling friction.

Common types and applications

The common types of deep groove ball bearings are single-row and double-row deep groove ball bearings, which are widely used in automobiles, motors, and other fields.

Daily Maintenance Tips

Routine maintenance of deep groove ball bearings includes keeping them clean, lubricating them properly, avoiding overloading, replacing them regularly and standardizing their operation.

Daily maintenance methods and Cleaning steps and precautions

Deep groove ball bearings daily maintenance techniques can effectively maintain the performance and life of deep groove ball bearings mainly through regular inspection, cleaning and maintenance, selecting the proper lubricant, adding the right amount of lubricant and paying attention to avoiding overload, shock and vibration.

Preventive Maintenance Strategies

The preventive maintenance strategy of deep groove ball bearings mainly includes regular inspection and monitoring, cleaning and lubrication, correct installation, etc., which can effectively reduce the failure rate of deep groove ball bearings and extend their service life.

Developing maintenance schedules

Deep groove ball bearings can effectively reduce the failure rate of deep groove ball bearings by formulating a maintenance plan, including determining the maintenance cycle, specifying the maintenance content (cleaning, lubrication, inspection, recording), etc.; adopting condition monitoring technology, including vibration monitoring, temperature detection, sound detection, etc.

Predictive maintenance methods

We are implementing a predictive maintenance methodology, including the collection of inspection data and the establishment of a life prediction model for bearings and other methods.

Common Issues and Troubleshooting

Common faults of deep groove ball bearings include high bearing temperature, noise in bearing operation, fatigue spalling, wear and corrosion. Through regular inspection and maintenance, timely detection and troubleshooting to ensure the regular operation of bearings.

Analysis of common failures

Common failures of deep groove ball bearings include fatigue spalling, wear, rust, and cage damage.

Solving noise and vibration issues

The noise and vibration problem can be solved by choosing bearings with high precision grade and low noise characteristics, adopting the correct lubrication method, etc.

Causes of overheating and solutions

Poor lubrication, seizing of inner and outer rings, incorrect mounting and other causes of deep groove ball bearing overheating can be solved by timely refuelling or replacing lubricants, timely cleaning or replacing bearings and reasonably designing bearing loads.

Maintenance in Special Environments

In high temperatures, high humidity, strong corrosion and other unique environments, deep groove ball bearing maintenance is crucial through the selection of appropriate lubrication and lubricants, the use of high-performance materials, strengthened sealing and protection, regular cleaning and inspection, reasonable mounting and dismounting, as well as the implementation of proper storage and transportation, etc., can ensure that deep groove ball bearings can be a long time and stable operation in unique environments.

Maintenance in high-temperature environments

Maintenance measures for deep groove ball bearings in high-temperature environments are mainly the selection of high-temperature bearings, the use of high-temperature lubricants, the installation of cooling systems for bearing installation, and so on.

Protection measures in humid and corrosive environments

In humid and corrosive environments, it can be sealed for protection, coated with an anticorrosive coating, selected with corrosion-resistant materials, regularly lubricated with bearings, keeping the environment dry and other measures to protect.

Tips for Extending Bearing Life

Tips for extending bearing life include proper mounting and dismounting, maintaining cleanliness, adequate lubrication, controlling temperature, regular inspections, preventing corrosion, and maintenance, among many others.

Proper installation and usage methods

The correct installation method for bearings mainly includes pre-installation inspection, bearing cleaning, and selection of suitable installation methods. During use, attention should be paid to the cleanliness and lubrication of the bearings, load speed control, and regular inspection and maintenance.

Optimizing load and speed conditions

The selection of suitable materials, good lubrication, correct installation and maintenance, specific working conditions to take appropriate protective measures, etc., can optimize the performance of bearings in load and speed conditions, improving the overall performance of the equipment.

Conclusion

Do an excellent job of deep groove ball bearing maintenance to ensure the regular operation of the equipment, extend bearing life, improve equipment performance, reduce maintenance costs, ensure production safety, and other aspects of great significance. Therefore, encouraging regular inspection and maintenance of deep groove ball bearings can ensure the stable operation of equipment and smooth production.

Frequently Asked Questions:

How do you properly lubricate deep groove ball bearings?

The correct method of lubricating deep groove ball bearings mainly depends on the specific use environment and equipment requirements. The lubrication of deep groove ball bearings can be divided into two categories: dry friction lubrication and lubricant lubrication. Dry friction lubrication suits low speed, low load, low temperature, and low precision equipment. Lubricant lubrication is ideal for a broader range of applications, including oil and grease lubrication.

What causes noise in deep groove ball bearings?

The causes of noisy deep groove ball bearings may be manifold, including improper installation, poor lubrication, quality problems of the bearings, and interference from the external environment.

How often should deep groove ball bearings be replaced?

Deep groove ball bearings generally require a replacement after 800-1000 hours of operation.

What are the common causes of deep groove ball-bearing overheating?

Common causes of deep groove ball bearing overheating include poor lubrication, inadequate cooling, improper mounting, bearing wear, excessive loads, internal contaminants, and incorrect selection of bearing type.

How to detect wear in deep groove ball bearings?

Detecting the degree of wear of deep groove ball bearings can be realized by observing the running state of the bearings, measuring the temperature and vibration of the bearings and other indicators.

The degree of wear of deep groove ball bearings can be detected by a variety of methods including, but not limited to, geometric measurements, mechanical property tests, material and surface inspections, identification by sound, identification by the condition of the lubricant, visual inspection, and nasal sniffing.

What to do if deep groove ball bearings rust?

When deep groove ball bearings are rusty, they can be treated in the following ways: Use vitamin C to remove the rust, replace the bearings directly with new ones, and use a combination of lime and salt: the lime peel removes the rust layer without harming the metal.

What causes increased vibration in deep groove ball bearings?

The main reasons for the increase of deep groove ball bearing vibration include the defect of the bearing itself or the internal structure of the error, incorrect installation methods, as well as the use of environmental contaminants, etc. will affect the deep groove ball vibration increase.

How to extend the lifespan of deep groove ball bearings?

The key to extending the service life of deep groove ball bearings lies in correct lubrication, proper maintenance, reasonable installation and use conditions.

What to consider when purchasing deep groove ball bearings?

When purchasing deep groove ball bearings, you need to pay attention to product quality, size specifications, clearance, sealing type and cost-effective.