Oil-Air Lubrication Systems for Bearings: Working Principle & Advantages

Introduction

What is Oil-Air Lubrication?

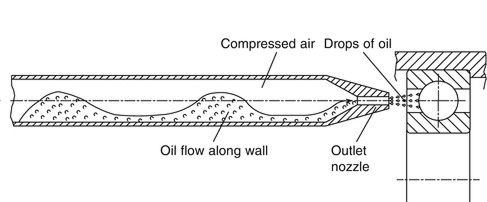

Oil-air lubrication (also known as Minimal Quantity Lubrication or MQL) is a precision technology designed to replace traditional grease or oil mist methods. Instead of flooding the bearing, it utilizes a continuous stream of compressed air to transport tiny, metered droplets of oil along the inner wall of a tube directly to the bearing point.

How an Oil-Air Lubrication System Works

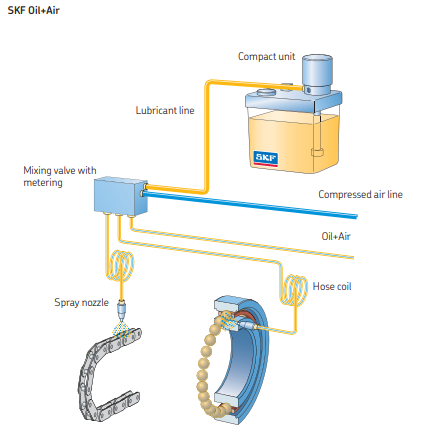

As illustrated in the diagram, the system operates in four key stages:

-

Metering: A pump delivers a precise, minute volume of lubricant to the mixing valve.

-

Mixing: Inside the valve, the oil is introduced into the compressed air stream. Crucially, the oil is not atomized (like a mist) but is stretched into a continuous film or streak.

-

Transport: The compressed air pushes this oil film along the tube wall toward the application point.

-

Injection: A spray nozzle projects the mixture into the bearing. The air expands to cool the bearing components, while the oil coats the rolling elements with a fresh lubricating film.

This mechanism ensures that the bearing receives fresh oil continuously without the risk of “stray mist” contaminating the work environment.

Why Choose Oil-Air Lubrication Systems for High-Performance Bearings?

Superior Thermal Management & Higher RPMs

-

The Mechanism: Unlike grease which traps heat, the continuous flow of compressed air in an oil-air system acts as a powerful coolant, actively dissipating heat generated by the rolling elements.

-

Why it matters: This allows bearings to operate at much higher speeds (higher Dn factors) while maintaining stable temperatures.

-

The Result: Case studies show bearing temperatures dropping by 10-40°C compared to traditional methods, preventing thermal expansion and seizure.

Precision Efficiency via Minimal Quantity Lubrication (MQL)

-

The Mechanism: Oil-air lubrication is a form of MQL, delivering minute, metered amounts of oil—sometimes as little as one drop every few minutes.

-

Comparison: Compared to oil mist systems or oil baths, which often over-lubricate and cause churning drag (friction), this system eliminates fluid resistance.

-

The Result: Oil consumption is drastically reduced (often to 1/10th of mist systems), and energy efficiency is improved due to reduced friction torque.

Positive Pressure Sealing Against Contamination

-

The Mechanism: The compressed air doesn’t just transport oil; it creates a positive pressure barrier (typically 0.1-0.3 bar) inside the bearing housing.

-

Why it matters: This internal pressure effectively prevents the ingress of external contaminants like dust, metal shavings, cooling water, and acidic chemicals.

-

The Result: Significantly extended bearing life in harsh environments, such as steel rolling mills.

Environmental Safety: No “Stray Mist”

-

The Problem: Traditional oil mist lubrication creates a suspended fog of oil that can be inhaled by workers and coat the workshop floor.

-

The Oil-Air Solution: Because the oil is transported as a continuous film along the tube wall and not atomized into a fog, the exhaust air is clean.

-

The Result: A safer, cleaner workspace compliant with environmental regulations, with no need for expensive mist extraction systems.

Simplified Architecture and Maintenance

-

Design: The system utilizes a straightforward architecture comprising a pump, mixing valve, and distributor. There are no complex oil return pipes required (unlike oil circulation systems).

-

Integration: With advanced monitoring (PLC controls), operators can track oil levels and air pressure in real-time.

-

ROI: Fewer moving parts mean lower failure rates. Combined with reduced oil consumption, the Return on Investment (ROI) is typically achieved within 6 to 12 months.

Oil-Air Lubrication vs. Grease and Oil Mist

While grease lubrication is simple and cost-effective for low-to-medium speeds, it fails at high RPMs due to overheating. Oil mist, while effective for cooling, poses environmental and health hazards due to stray mist.

Oil-air systems bridge this gap by offering the cooling performance of oil without the environmental mess, making them the standard for modern CNC spindles, steel industry rolling mills, and high-speed mechanical drives.

Elevating Bearing Performance with Oil-Air Systems

At TFL Bearing, we understand the demands of high-precision environments. Whether you need specific angular contact ball bearings compatible with oil-air systems or technical advice on retrofitting, our engineering team is here to help.

[Contact Us Today for a Quote] or [Browse Our High-Speed Bearing Catalog]