Sealed deep groove ball bearings content strategy and outline

Introduction: The Unsung Heroes of Smooth Operation

The development of sealed deep-groove ball bearings can be traced back to the beginning of the 20th century; with the development of industry and technological progress, sealed deep-groove ball bearings have gradually become important mechanical components. With the development of material science and manufacturing technology, the sealing material and structure of sealed deep groove ball bearings are constantly improved. At present, sealed deep groove ball bearings play an important role in industrial automation and intelligent manufacturing. With the advancement of Industry 4.0, the performance requirements for bearings are getting higher and higher, and manufacturers continue to make innovations in materials, lubrication technology, sealing technology, etc., to meet the needs of new technology and new applications.

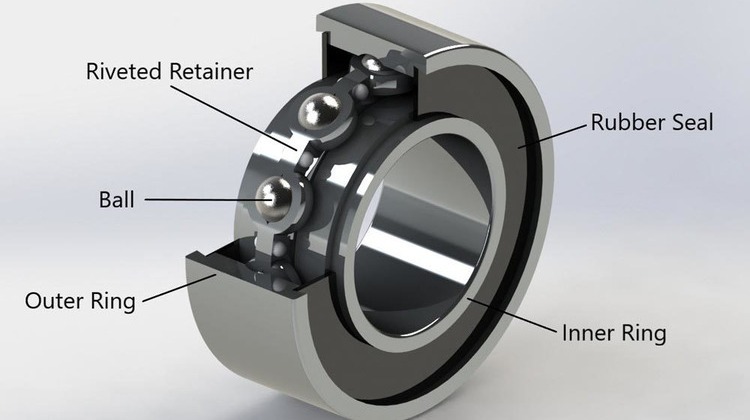

What is a sealed deep groove ball?

Sealed deep groove ball bearings mean that both sides of the bearing have covers, and the covers are set with seals or coated with sealing materials to prevent dust, moisture, grease loss, etc., from entering the inside of the bearing and to ensure that the inside of the bearing is clean and lubricated. This bearing is suitable for high speed, high precision, high temperature, high noise, high vibration, heavy load and easy-to-contaminate occasions, such as automobiles, machine tools, agricultural machinery and so on.

Understanding Sealed Deep Groove Ball Bearings

A sealed deep groove ball bearing is a kind of rolling bearing with high sealing performance, which usually consists of bearing outer ring, inner ring, steel ball and cage, and a U-shaped sealing groove is set at both ends of the inner and outer diameters of the bearing inner ring. The sealing ring is mounted to prevent the internal grease from overflowing and the external impurities from infiltrating. Common sealed deep groove ball bearing models include 6200-2RS with a size of 10309, which is suitable for mechanical equipment manufacturing in high-speed, high-temperature and high-load environments.

The Sealing Advantage

I: Non-contact sealing:

Ordinary cover type seal: By installing a cover on the bearing housing, a certain distance is left between the bearing and the cover to minimize the risk of dust, moisture, etc. entering the bearing.Suitable for low speed, light load use, but can not effectively prevent fine particles into the bearing internal.

Rubber Lip Seal: A rubber lip ring is installed on the cover to isolate the inside of the bearing from the outside. It is low-cost and easy to maintain, but it is easy to wear out under high-speed movement and load, resulting in seal failure.

Oil Seal Type Seal: Sealing is achieved by installing a gasket or oil seal on the outside of the bearing. It can effectively prevent dust, moisture and other small particles from entering the bearing interior, but the installation should pay attention to the height of the oil seal. Too high or too low will affect the sealing effect.

II: Contact seals:

Metal Cover Seal: This seal fits snugly on the end cap to isolate the inside of the bearing from the outside. It is low-cost and suitable for occasions requiring low sealing performance.

Rubber cap seal: high sealing performance but relatively short service life.

Labyrinth seal: creates resistance to flow by zigzagging small gaps, is suitable for dirty and wet environments, and is quite reliable for both lubricants and greases.

Key Advantages of Sealed Deep Groove Ball Bearings

The main advantages of sealed deep groove ball bearings include the following: excellent sealing performance, suitability for high-speed operation, versatility of application, easy mounting and so on.

Excellent sealing performance

Deep groove ball bearings with two-sided sealing rings are excellent in sealing performance. They adopt a double-layer sealing structure, which can not only effectively prevent external dust, moisture and other impurities from entering the bearing interior but also prevent the loss of lubricating grease. This feature makes both sides with sealing rings deep groove ball bearings in humid, dusty, pollution-prone working environments can maintain good working conditions, prolong the service life, and reduce maintenance costs.

Suitable for high-speed operation

The seals of deep groove ball bearings with seals on both sides are made of low-friction rubber, which effectively reduces the seals’ frictional resistance and helps minimize the energy loss when the bearings are running. The sealing ring’s design considers the internal lubrication of the bearings during operation, which makes the deep groove ball bearings with sealing rings on both sides suitable for high-speed operation and can maintain good lubrication and sealing effects.

Versatility in Applications

The structural characteristics of deep groove ball bearings enable them to withstand radial and axial loads and maintain stable performance at high speeds. When increasing the radial clearance of the bearing, deep groove ball bearings also have certain angular contact ball bearing performance and can withstand the combined radial and axial load. Sealed deep groove ball bearings are widely used in several fields, including the automotive industry, machinery and equipment, household appliances, wind power generation, aerospace and agricultural machinery. They can maintain stable performance in complex working environments and ensure the normal operation of equipment.

Easy to install

Deep groove ball bearings with seals on both sides are well-designed, easy to install, and can be quickly replaced during equipment maintenance, reducing maintenance time and improving work efficiency. The sealing ring adopts an axial tension structure, which can be better fixed on the outer ring of the bearing to ensure the sealing effect and the safety of equipment operation.

How Sealed Bearings Differ from Open and Shielded Types

Sealed deep-groove ball bearings differ significantly from open and shielded ones in structure, performance, applicable scenarios, and maintenance. The following is a detailed comparison of these three:

Structural differences

- Open-type deep groove ball bearings usually consist of an outer ring, an inner ring, a group of steel balls and a group of cages. There is no cover plate on both sides of the bearing, or the cover plate is made of non-sealing material such as iron or plastic. The inside of the bearing is not filled with sealing material, so the air between the inner and outer rings of the bearing can freely flow.

- Shielded deep groove ball bearings: based on open-type increased some shielding structures, such as metal shielding parts, but these shielding structures are not completely closed inside the bearing, and their sealing performance is between open and sealed. However, it should be noted that the commonly mentioned “shielded” may refer to the bearings with dust cover or simple non-contact seals rather than the strict sense of the complete shielding structure.

- Sealed deep groove ball bearings: Both sides of the bearings have cover plates, which are set with seals or coated with sealing materials to completely close the inside of the bearings, preventing dust, moisture, grease loss, etc., from entering the inside of the bearings and ensuring the cleanliness and lubrication of the inside of the bearings. Sealed deep groove ball bearings are divided into two types: dustproof seal and oilproof seal, dustproof seal cover material is mostly made of stamped steel plate, while oilproof type adopts contact oil seal, which can effectively prevent the grease inside the bearing from overflowing.

Applicable Scenarios

Open-type deep groove ball bearings are suitable for low speed, low precision, low temperature, low noise, low vibration, light load and easy maintenance, such as home appliances, power tools, bicycles and so on.

Shielded deep groove ball bearings: may be suitable for occasions with a certain requirement for sealing performance, but complete sealing is not required. However, due to the vague definition of “shielded,” the specific application scenarios must be based on specific products.

Sealed deep groove ball bearings: suitable for high speed, high precision, high temperature, high noise, high vibration, heavy load and easy-to-contaminate occasions, such as automobiles, machine tools, agricultural machinery and so on. On these occasions, good sealing performance is crucial to ensure normal operation and prolong the service life of the bearings.

Maintenance

Open-type deep groove ball bearing: Due to its open structure, it is easily invaded by external dust, moisture and other substances, so it needs to be cleaned and lubricated frequently to maintain good working conditions.

Shielded deep groove ball bearings: maintenance requirements are between open and sealed, depending on the complexity of the shielding structure and sealing performance.

Sealed deep groove ball bearings: Due to their good sealing performance, they effectively block outside material from entering the bearing inside, so maintenance is relatively simple. Usually, the only need to check the integrity of the seals regularly is without frequent cleaning and lubrication. However, once the seals are damaged, resulting in internal contamination of the bearing, it may be necessary to replace the entire bearing.

Maintenance and Care for Sealed Bearings

Maintenance and care of sealed bearings include the following aspects: cleaning and lubrication, periodic inspection and replacement, seal protection and balanced load distribution. Through the above maintenance and repair measures, the service life of sealed bearings can be effectively extended to ensure their long-term stable operation.

Cleaning and lubrication

Regularly clean the bearings by wiping them with a soft cloth or blowing them with air pressure to remove surface dust, followed by deep cleaning with a special cleaner. When cleaning, pay attention to protecting the bearings from direct contact with the container of dirt to avoid damage to the rolling surface of the bearings. Ensure sufficient lubricant is inside the bearings, check the lubrication status regularly, and replenish the oil immediately once it is found to be insufficient. The choice of lubricant should be based on the conditions of use and purpose, common lubrication methods include oil bath lubrication, drip oil lubrication, circulating oil lubrication and spray lubrication.

Periodic Inspection and Replacement

Periodically disassemble the bearings for inspection, record the appearance and confirm the amount of lubricant remaining. Inspect bearings for damage to raceway surfaces, rolling surfaces, mating surface condition, and cage wear, as well as increases in bearing clearance and decreases in dimensional accuracy. Replace worn parts as necessary.

Seal protection and balanced load distribution

Bearings’ sealing has a direct impact on their service life. When installing, sealing rings or plugs should be added to prevent the lubricant from leaking out and effectively block the intrusion of dust and moisture. Bearings will experience different types of loads in their work. To guarantee their stable operation, efforts should be made to reduce loads’ uneven and transient impact and prevent them from overloading.

Applications and Industries

Sealed deep groove ball bearings are widely used in various mechanical equipment, especially for high speed, high precision, high temperature, high noise, high vibration and high load occasions. Its structural features include a cover plate on both sides, which is provided with a sealing ring or coated with sealing material to prevent the loss of dust, moisture and grease and to ensure the cleanliness and lubrication inside the bearing.

Automotive and Transportation

Automobile transmission system: In the automobile transmission system, sealed deep-groove ball bearings support the transmission parts, transfer force and bear load to ensure normal operation. Bearings play a key role in regulating the engine’s power output to adapt to different driving conditions, especially in the transmission and differential gears.

Automobile Wheel and Suspension System: Sealed deep groove ball bearings are used in wheel bearings and suspension systems to withstand the vehicle’s weight and the forces of various road conditions, ensuring smooth driving and comfort. They can also withstand large radial and axial loads to ensure stable wheel rotation.

Industrial Machinery

In machine tools, printing presses, packaging machines and other mechanical equipment, sealed deep groove ball bearings are used to support rotating parts and improve the operational efficiency and precision of the equipment. In tractors, harvesters, and other agricultural machinery sealed deep groove ball bearings can adapt to the complex field operating environment to ensure the efficient operation of machinery. In wind turbines, sealed deep groove ball bearings are used to connect the generator and the main shaft, bearing huge axial and radial loads, and their excellent sealing performance and vibration and noise reduction characteristics are essential to ensure the stable operation of wind turbines.

Home Appliances and Electronics

Air Conditioner: Sealed deep groove ball bearings carry the important load of fan bearings in air conditioners, supporting the motor and fan windings to ensure that the air conditioner runs quietly even at high speeds, providing customers with a comfortable indoor environment.

Washing machine: Sealed deep groove ball bearings support the rotation of the washing machine and drive the inner cylinder to rotate. They are characterized by strong bearing capacity, smooth movement and low noise and improve the stability and service life of the washing machine.

Microwave Oven: Sealed deep groove ball bearings withstand high temperatures and high speeds in microwave ovens, providing stability and keeping them running smoothly.

Comparing Sealed Deep Groove Ball Bearings with Other Bearing Types

A comparison of sealed deep groove ball bearings with open bearings, angular contact ball bearings and roller bearings in various aspects is analyzed below:

Sealed vs. Open Bearings

I: Structural differences

Open bearings: These bearings have no cover on both sides or only a plastic or iron plate cover. The inside of the bearing is not filled with sealing material, so the air between the inner and outer rings can flow freely. This structure makes open bearings easy to load, unload and maintain.

Sealed deep groove ball bearings: there are cover plates on both sides of the bearings, and the cover plates are equipped with seals or coated with sealing materials to prevent the loss of dust, moisture and grease into the internal bearings to ensure the cleanliness and lubrication of the internal bearings. This structure makes the sealed deep groove ball bearings suitable for occasions that need to run for a long time and are not easy to maintain.

II: Sealing performance

Open bearing: Because there is no sealing ring, the sealing performance is poor, and the external environment can easily affect it.

Sealed deep groove ball bearings: The sealing performance is better with the sealing ring or sealing material, which effectively prevents the entry of dust, moisture and grease and ensures the cleanliness and lubrication inside the bearings.

III: Scope of application

Open bearings: suitable for low speed, low precision, low temperature, low noise, low vibration, light load and easy maintenance, such as home appliances, power tools, bicycles and so on.

Sealed deep groove ball bearings: suitable for high speed, high precision, high temperature, high noise, high vibration, heavy load and easy to contaminate occasions, such as automobiles, machine tools, agricultural machinery and so on.

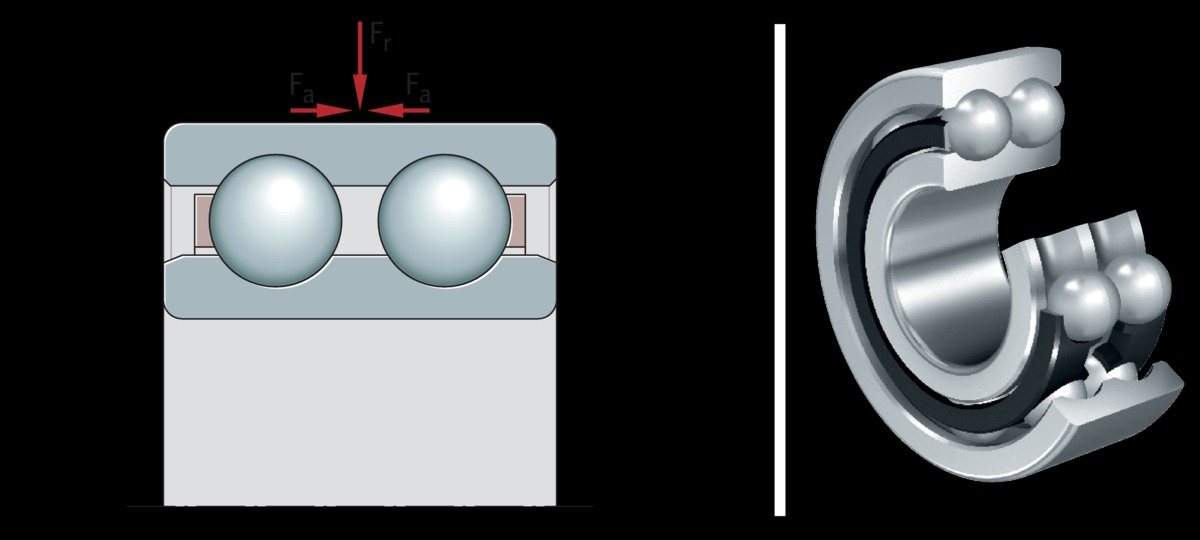

Deep Groove vs. Angular Contact Ball Bearings

I: Structural differences

Deep groove ball bearings: The outer ring groove is on both sides of the double shoulder, the outer ring groove curvature is small, and the contact angle is zero. Its structure is simple and easy to mass produce.

Angular contact ball bearings: The outer ring groove curvature is larger. For the single-shoulder design, the contact angle is usually 15 °, 25 ° or 40 °, with three kinds of standard. The larger the contact angle, the stronger the axial load capacity.

II: Differences in load capacity

Deep groove ball bearings mainly bear radial load and can also bear a certain amount of axial load. When there is a large radial clearance, they can withstand a large axial load.

Angular contact ball bearings can withstand both radial and axial loads. Single-row bearings are suitable for unidirectional axial loads, and when used in pairs, they can withstand bidirectional axial loads.

III: Differences in RPM and Accuracy

Deep groove ball bearings have a high speed and low friction coefficient, making them suitable for high-speed rotation, low noise, and low-vibration application scenarios.

Angular contact ball bearings: The reasonable design of the contact angle of inner and outer rings reduces friction and enhances speed and accuracy, making them especially suitable for high-speed and high-precision rotary applications.

Ball Bearings vs. Roller Bearings

I: Structural differences

Deep groove ball bearings: Deep groove ball bearings consist of an inner ring, an outer ring, a set of balls and a keeper. Its structure is simple. The size of the ball is larger, usually more than 12mm in diameter.

Roller bearings: Roller bearings consist of an inner ring, an outer ring and a set of rollers. The diameter of the rollers is small, usually less than 12mm, and the rollers and bearing ring raceway for line contact.

II: Differences in carrying capacity

Deep groove ball bearings: Due to their large ball diameter, deep groove ball bearings have a relatively strong load-carrying capacity and are suitable for low-speed and high-load occasions, such as heavy machinery and metallurgical equipment.

Roller bearings: Roller bearings have a larger number of balls, and although the diameter of individual balls is smaller, their load-carrying capacity is relatively high due to the quantity advantage, and they are suitable for heavy and shock load applications.

Conclusion: Investing in Quality for Long-term Performance

Sealed deep groove ball bearings are expected to be used in modern sealed deep groove ball bearings, which are widely used in various mechanical equipment. Their high rotational speed and low torque characteristics make them perform well in high-speed equipment. Sealed deep groove ball bearings will continue to develop in the direction of digitalization and intelligence. With the advancement of industrial automation and intelligent manufacturing, the performance requirements for bearings will be further improved. Sealed deep groove ball bearings are expected to continue to innovate in materials, lubrication technology, sealing technology and other aspects to meet the needs of more complex applications. At the same time, environmental protection and energy saving will become important directions for future development, promoting the transformation of the bearing manufacturing industry to green manufacturing.

Come to TFL bearing and choose high-quality sealed deep groove ball bearings to improve your mechanical performance!

Frequently Asked Questions

- What are the types of sealed deep groove ball bearings?

Sealed deep groove ball bearings are divided into two types: dustproof seal and oilproof seal. A dust-proof seal cover is usually made of a stamped steel plate, which is mainly used to prevent dust from entering the bearing raceway, while an oil-proof seal is a contact oil seal, which can effectively prevent the grease inside the bearing from spilling out.

- Can sealed bearings be re-lubricated?

Deep groove ball bearings with dust cover: These kinds of bearings have been filled with the appropriate amount of grease when assembled, do not need to be lubricated again in the process of use, and adapt to the operating temperature between -30℃ and +120℃.

Deep groove ball bearings with seals: the same assembly has been filled with the appropriate amount of grease, so the process does not need to lubricate again.

- Are sealed bearings suitable for high-temperature environments?

Sealed deep groove ball bearings are somewhat applicable in high-temperature environments, but their applicability and performance will be subject to some limitations.

The suitability and performance of sealed deep groove ball bearings in high-temperature environments depend mainly on their material and sealing method. Generally speaking, ordinary deep groove ball bearings can withstand high temperatures to a degree of about 150℃, while specially designed deep groove ball bearings can withstand higher temperatures, such as SKF’s high-temperature deep groove ball bearings can work at temperatures as high as 350℃.

- What is the maximum speed for sealed deep groove ball bearings?

Maximum speeds of different types of sealed deep groove ball bearings

W 628/7-2RS1: This type of deep groove ball bearing has a limiting speed of 28,000 r/min.

6006-2RZ: The limiting speed of this type of deep groove ball bearing is 14000r/min.

- Can sealed bearings be used in wet conditions?

Sealed deep groove ball bearings can be used in wet environments. The design of sealed deep groove ball bearings enables them to maintain good working conditions in wet environments.