Deep Groove Ball Bearing Applications: Comprehensive Guide

Deep Groove Ball Bearing Applications Guide: Key to Industrial Efficiency

Introduction

Deep groove ball bearings are characterized by high load-carrying capacity, low friction, high-speed performance, good wear resistance and life span. They are widely used in mechanical and industrial fields. The purpose of this paper is to comprehensively introduce the application of deep groove ball bearings in various fields, to provide reference and guidance for people in related fields.

Basic Concepts of Deep Groove Ball Bearings

Deep groove ball bearings, formerly known as single-row radial ball bearings, are the most common and widely used type of rolling bearings and are one of the key components indispensable to modern industrial production.

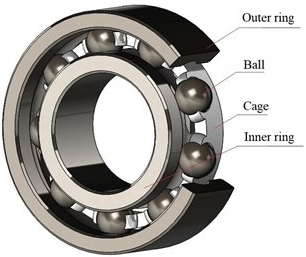

Structure of Deep Groove Ball Bearings

The basic structure of deep groove ball bearings is mainly composed of inner and outer rings, rolling bodies (steel balls), and cages.

Main Features and Advantages

The main features of deep groove ball bearings include simple centring, strong structural capability, high load-carrying capacity, low frictional resistance, high precision, and wide adaptability. At the same time, it has the advantages of cost reduction, improved operational efficiency, extended service life, ease of installation and dismantling, strong stability and so on.

Applications of Deep Groove Ball Bearings in Industrial Sectors

Deep groove ball bearings are characterized by simple structure, high speed, and small coefficient of friction, and can withstand radial load or radial and axial at the same time. The role of the joint load in the industrial field is mainly used in the automotive industry and power industry.

Heavy Machinery

Deep groove ball bearings in the automobile industry are commonly used in automobile and motorcycle wheel bearings, transmission bearings and other parts, used to bear the weight of the vehicle and the force of various road conditions, to ensure the smooth running of the car. In the automobile engine, transmission and other key components, at the same time, can provide the normal operation of the engine and transmission so as to improve the overall performance of the car. Deep groove ball bearings in motors and generators are not only able to support rotating parts, reduce friction loss, and withstand load capacity but also have high precision, heat and high-speed resistance, as well as easy installation and maintenance, etc. These advantages make them one of the indispensable key components in motors and generators. As a key component in heavy machinery, deep groove ball bearings can support rotating parts, reduce friction and wear, withstand heavy loads and high rotational speeds, improve the precision and reliability of machinery, and adapt to harsh working environments.

Applications of Deep Groove Ball Bearings in Home Appliances

Deep groove ball bearings are used in appliances such as washing machines and dryers, air conditioners and fans, small household appliances, etc. Their superior performance makes them an indispensable part of household appliances.

Small Household Appliances

Deep groove ball bearings in washing machines and dryers are mainly reflected in the support and stable operation of rotating parts. In washing machines, they can support the rotating parts of the motor, reduce noise and vibration, and improve the washing effect. In dryers, they can support the fan and transmission parts, improve the drying efficiency, and reduce noise and energy consumption. Deep groove ball bearings are critical in air conditioning and fan applications, not only to support rotating parts and withstand a variety of loads but also to reduce noise, improve energy efficiency and adapt to a variety of operating conditions. Deep groove ball bearings are used in small household appliances, such as refrigerators, air conditioning fans, air purifiers, etc., to improve the operating efficiency and service life of these devices while reducing noise and vibration.

Performance of Deep Groove Ball Bearings in High-Speed Applications

The unique design and excellent performance of deep groove ball bearings make them perform well in high-speed applications. They have the advantages of high-speed running ability, load-carrying capacity, stability and durability, etc., and their application prospects in high-speed rotating equipment will be broader.

High-Speed Electric Motors, Turbines, Precision Machine Tools

Deep groove ball bearings play an important role in high-speed motors, turbines, precision machine tools and other fields. Their high load-carrying capacity, low coefficient of friction, high precision, low noise and anti-fatigue properties make them indispensable key components in this high-precision, high-speed running equipment.

Key Factors in Choosing the Right Deep Groove Ball Bearing

Key factors in selecting the right deep groove ball bearing include load and speed requirements, space and location of machinery, size and nature of load, speed requirements, accuracy and rigidity, lubrication and sealing, as well as environmental conditions, life and maintenance considerations.

Load and Speed Requirements, Environmental Conditions, Lifespan and Maintenance

Considerations such as load and speed requirements, environmental conditions, longevity, and maintenance considerations are critical when selecting the right deep groove ball bearing by analyzing and comparing different types and sizes of bearings, the one that best suits the needs of the equipment is preferred.

Conclusion

Deep groove ball bearings are key components in mechanical transmission systems, carrying radial and (partially) axial loads on equipment, ensuring stability and precision at high speeds, and should be widely used in various fields of household appliances and industrial equipment.TFL Bearing is a professional bearing manufacturer dedicated to providing high-quality, high-performance deep groove ball bearings, so I encourage readers to give full consideration to TFL Bearing products in the Therefore, I encourage readers to provide a full consideration to TFL Bearing’s products when choosing deep groove ball bearings.

Enhance your machine performance with TFL Bearing’s premium deep groove ball bearings. Contact our expert team now for professional advice and customized solutions. Click here to browse our product catalogue and start your journey to improved efficiency!

Frequently Asked Questions:

What’s the difference between deep groove ball bearings and regular bearings?

Compared with ordinary bearings, deep groove ball bearings have a simple structure and strong load-carrying capacity, are applicable to high-speed working conditions, etc., and are suitable for a variety of mechanical equipment requiring high precision and high speed.

How long do deep groove ball bearings last?

The basic life of deep groove ball bearings is 20,000 to 50,000 hours.

How to choose the right deep groove ball bearing for a specific application?

Selecting the right deep groove ball bearing for a particular application requires consideration of a number of factors, including allowable space, nature of the load, magnitude of the load, operating speed, rotational accuracy, and more.

How often should deep groove ball bearings be replaced?

Replacement intervals for deep groove ball bearings are usually 3 to 4 years.

What are the advantages of deep groove ball bearings in high-speed applications?

The advantages of deep groove ball bearings in high-speed applications are mainly due to their design construction to withstand radial and axial loads, low friction, and low resistance to motion. Deep groove ball bearings also offer durability and low maintenance requirements for high-speed operation.