Stainless Steel Deep Groove Ball Bearings: The Ultimate Guide for Corrosion Resistance and Durability

Introduction: The Power of Stainless Steel in Ball Bearings

Stainless steel deep groove ball bearings are a common rolling bearing that is widely used in various mechanical equipment. Its internal structure consists of an outer ring, an inner ring, a row of steel balls and a cage capable of withstanding large radial and axial loads. The stainless steel material gives this bearing a low coefficient of friction and high limiting speed, which is suitable for high-speed application scenarios. Stainless steel deep groove ball bearings occupy an important position in the industrial field due to their excellent performance and wide range of application scenarios.

Understanding Stainless Steel Deep Groove Ball Bearings

Stainless steel deep groove ball bearings are, as the name suggests, made of stainless steel. Compared with ordinary materials, stainless steel bearings are relatively more advantageous. In the working process, stainless steel bearings are stable, low noise, corrosion resistant, and widely used. The material also has obvious advantages in the process, such as precision control, but the ordinary is strict.

Composition and Properties

Bearing rings and rolling body raw materials used in AISI SUS440C stainless steel material quenched and tempered by the vacuum environment processing, cage and sealing ring skeleton selection of AISI304 stainless steel materials. Stainless steel shaft and general bearing steel, compared with a stronger anti-rust, corrosion prevention, selection of appropriate lubricant, dust cover, etc., can be selected in -60 ℃ ~ +300 ℃ environment. Stainless steel material deep groove ball bearings can resist corrosion caused by moisture and many other media. This kind of single-row deep groove ball bearings and carbon chrome rolling bearing steel production manufacturing standard deep groove ball bearings has a very deep bearing raceway groove, bearing raceway and ball each other with a high degree of cooperation.

Design Features

Single-row stainless steel deep groove ball bearings are widely used. They belong to the non-separating type, are suitable for high speed, and have a sealing design that has been added to the grease without maintenance. They can withstand radial and axial loads and are commonly used in motors, gearboxes, power tools, air conditioners, etc.

With a loading notch, stainless steel deep groove ball bearings are characterized by the inner and outer rings. Each has a loading notch, can be larger than the standard product loading more large balls, and has a higher radial load carrying capacity, but its axial load carrying capacity is small, with the type of bearing speed than the standard deep groove ball bearings, mainly used in automotive gearboxes, as well as the application of heavy loads of low-speed rotation.

The row design and single-row product structure are very similar, with just one more column; in addition to withstanding radial load, it also withstands bi-directional axial load; the use of single-row deep groove ball bearings is not enough to carry the load of the bearing configuration. In addition, high-temperature occasions are used in stainless steel deep groove ball bearings. Generally, its clearance is larger. For the C5 clearance of 4 times, it can be used for the -40-+250-degree temperature range.

Manufacturing Process

The manufacturing process of stainless steel deep groove ball bearings mainly includes the following steps: billet machining, spheroidizing annealing, billet hot rolling, billet shaping and cutting, recrystallization annealing, soft grinding kits, kits of fine holes, cold rolling and enlarging kits, turning kits, fine grinding kits, and mounting bearings. From the direction of the machining process, it is much more precise than general bearing support. Stainless steel bearings have precision engineering technology and strict quality control measures, are extremely stable in the operation process, and noise is also very small and widely used.

Advantages of Stainless Steel Deep Groove Ball Bearings

Stainless steel deep groove ball bearings are a widely used type of bearing with various features and advantages. Their main features are long service life, resistance to rust and corrosion and high temperature.

Superior Corrosion Resistance

Stainless steel bearings do not rust easily and have strong corrosion resistance. The main material of stainless steel bearings is AISI SUS440C stainless steel; this material is vacuum quenching and tempering treatment, with extremely strong rust and corrosion resistance. In addition, stainless steel bearings are also washable and can be operated in liquid, with slower depletion, hygiene and high heat resistance. Stainless steel deep groove ball bearings can resist corrosion caused by moisture and other chemical media and are suitable for application environments where corrosion, moisture and high rotational speeds exist.

High-temperature resistance

Stainless steel bearings fitted with high-temperature polymer cages or without cages in a complete complementary structure can operate at higher temperatures ranging from 180 °F to 1000 °F. (High-temperature grease is required.) Stainless steel bearings are classified into 440 stainless steel bearings, series 316 stainless steel bearings, and 304 stainless steel bearings. They are mainly used in medical machinery.

Slow consumption rate

AISI 316 stainless steel does not require oil or grease to prevent corrosion and, therefore, does not require lubrication if speeds and loads are low. Fifthly, it is hygienic. Stainless steel is naturally clean and non-corrosive and, therefore, more hygienic. Sixth, high heat resistance. Stainless steel bearings are equipped with high-temperature polymer cages and can operate from 80°C to 550°C and beyond (high-temperature grease is required).

Applications of Stainless Steel Deep Groove Ball Bearings

Stainless steel deep groove ball bearings are widely used in the transmission parts of various machines such as food and beverages, chemicals and pharmaceuticals, medical and healthcare equipment, the aerospace industry, and the textile and paper industry.

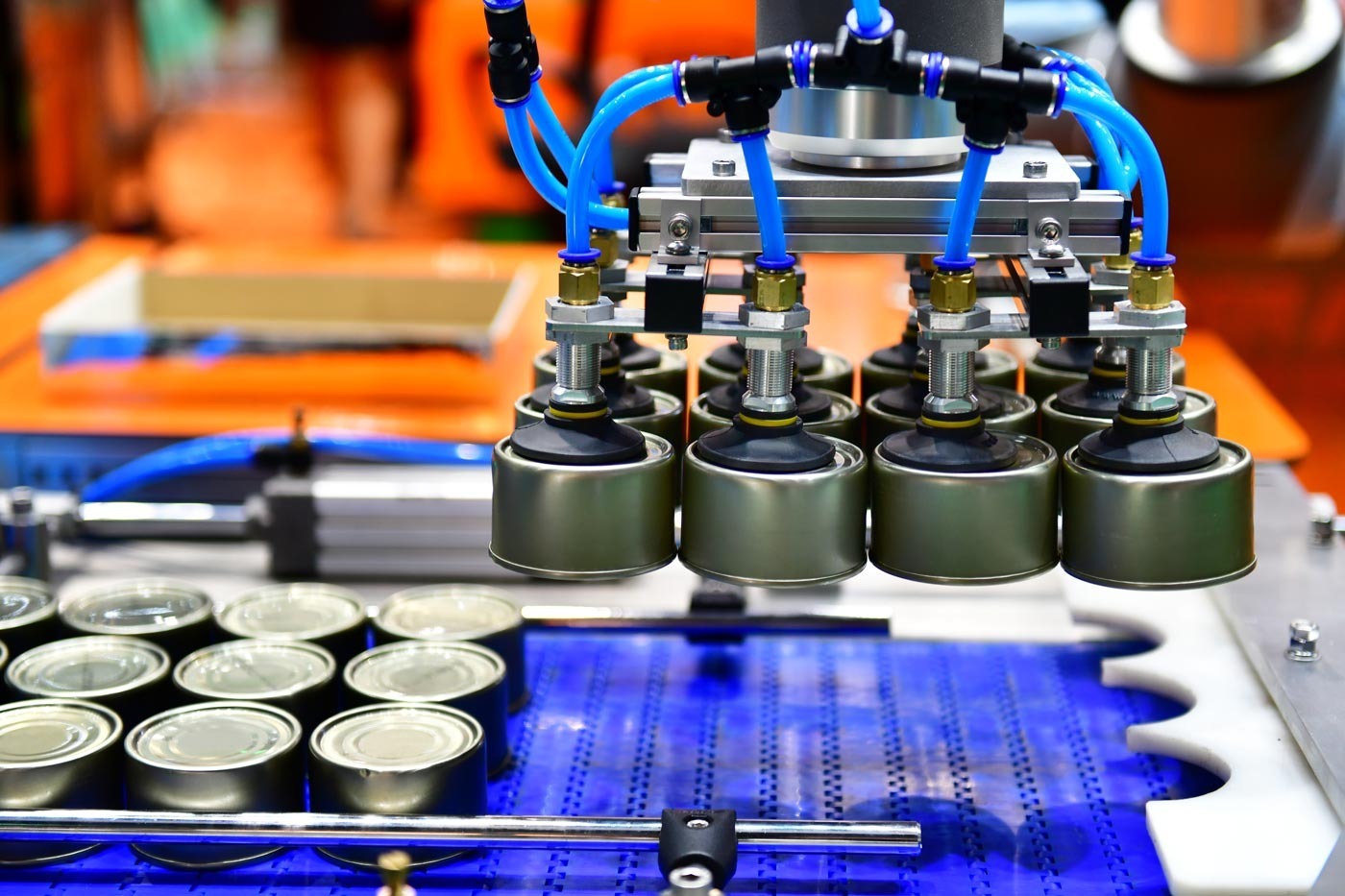

Food and Beverage Industry

Food and beverage machinery often need frequent flushing to keep clean, so most food processing machinery is often in the environment’s humid or strong chemical aggressiveness. Repeated flushing will affect the bearing grease; the common solution is to replenish the grease often; although it can ensure normal use, frequent grease replenishment greatly increases labour costs. Stainless steel deep groove ball bearings have excellent corrosion resistance, especially suitable for applications where the bearings need to be exposed to moisture and water vapour. This type of bearing has a wide range of uses, and the sealed type can be equipped with various greases, such as food-grade, non-toxic USDA H1 grease, which has a high resistance to washing.

Stainless steel deep groove ball bearings improve food safety and comply with strict regulations. They also reduce maintenance and unplanned downtime, which can help avoid sudden shutdowns and costly replacements. Third, they improve overall productivity, and stainless steel deep groove ball bearings can maintain better operational efficiency even in chemically washed and wet environments.

Chemical and Pharmaceutical Sectors

Precision instruments: In spectrometers, chromatographs, and other precision instruments, stainless steel deep groove ball bearings support rotating parts and ensure the accuracy and stability of the instrument’s measurements.

Centrifuge: A centrifuge is a commonly used separation equipment in the laboratory. Stainless steel deep groove ball bearings can withstand the centrifugal process of high-speed rotation and shock load to ensure the centrifuge’s normal operation.

Stirrers and Mixers: Stirrers and mixers are commonly used in chemical, biological and other laboratories. Stainless steel deep groove ball bearings support the stirring shaft to ensure a smooth and efficient stirring process.

Pump equipment: The laboratory uses a variety of pump equipment, such as peristaltic pumps, vacuum pumps, etc., and also needs to use stainless steel deep groove ball bearings to support the rotating parts to improve the operational efficiency and reliability of the equipment.

Environmental simulation equipment: In laboratory equipment that simulates extreme environments (such as high temperature, low temperature, high humidity, etc.), the stainless steel deep groove ball bearings can maintain stable performance and ensure the accuracy of the experimental results.

Medical and Healthcare Equipment

Operating room equipment:

Stainless steel deep groove ball bearings are mainly used in operating room equipment for surgical beds and instruments. The use of stainless steel deep groove ball bearings in surgical beds ensures smooth lifting and lowering, providing the surgeon with a stable operating platform, which is vital to the success of the surgery. Using stainless steel deep groove ball bearings in surgical instruments ensures their flexibility and precision, thus improving surgical efficiency.

Diagnostic imaging equipment:

In diagnostic imaging equipment such as CT machines and MRIs, stainless steel deep groove ball bearings are used to ensure the precise rotation and positioning of the equipment, providing doctors with an accurate diagnostic basis. This accuracy is important for the diagnosis and treatment of diseases.

Therapeutic equipment:

In therapeutic equipment such as hemodialysis machines and artificial respirators, stainless steel deep groove ball bearings are used to ensure the stable rotation of key components such as blood pumps and gas pumps, providing reliable patient treatment. Stable rotation ensures the continuity and safety of the treatment process.

Aerospace and Aviation

SKF’s stainless steel deep groove ball bearing type 32317/VA0213 has a wide range of applications in the aerospace industry. With an inner diameter of 17mm, an outer diameter of 37mm, and a thickness of 15mm, this type of bearing is suitable for low-temperature environments and has an accuracy class of P0. Its high rotational speed makes it suitable for use in mechanical equipment. In aircraft, stainless steel deep groove ball bearings can manufacture turbine blades, hydraulic press valves, compressor rotor blades and other components. These parts need to withstand high temperatures and pressures. The high strength and corrosion resistance of stainless steel deep groove ball bearings make them ideal.

Support rotary shaft and transmission device: stainless steel deep groove ball bearings are mainly used to support the rotary shaft and transmission device, reduce friction and wear, and make the machine run more smoothly and reliably.

Solar panels: Stainless steel deep groove ball bearings can withstand the requirements of high-speed rotation and heavy loads, supporting and transmitting torque to ensure the stable operation of solar panels. Their special rolling mechanism and sealing design ensure the bearing’s stability in harsh environments and long-term operation. In addition, the corrosion and contamination resistance of stainless steel deep groove ball bearings enable them to operate for long periods of time in harsh outdoor climates, reducing the risk of equipment contamination.

Clean Energy and Environmental Technology

Application scenarios for stainless steel deep groove ball bearings in water treatment equipment include:

Water softening equipment: Use 6206ZZ and 6207-2RS model bearings, these bearings are capable of withstanding high rotational speeds and are suitable for the operational needs of water softening equipment.

Variable speed machine: 6206ZZ and 6207-2RS type bearings are also used. These bearings perform well in variable speed machines and can ensure stable operation of the equipment.

Plastic Pelletizer: Use Model 6207-2RS bearings, which exhibit excellent corrosion and water resistance in plastic pelletizers.

Textile and Paper Industries

In textile printing and dyeing machinery, stainless steel deep groove ball bearings are often used in the transmission system, winding mechanism and other key parts to ensure high-speed rotation and precise control of the equipment. For example, some types of stainless steel deep groove ball bearings (such as S6018ZZ 2RS) are specially designed for textile machinery, with specific dimensions and performance parameters to meet the special needs of textile machinery.

Selecting the Right Stainless Steel Deep Groove Ball Bearing

To choose the right deep groove ball bearings, we must consider the following aspects: suitable stainless steel environments, bearing load, speed, size and specification, etc.

Environmental Considerations

304 stainless steel: good corrosion resistance and mechanical properties, suitable for food, medical, chemical and other industries.

316 stainless steel: molybdenum is added based on 304, which is more corrosion-resistant and suitable for marine and acidic environments.

440 stainless steel: high hardness, excellent wear resistance, suitable for high load, high friction environment, such as high-speed rotating equipment and high-precision machine tools.

420 stainless steel: higher hardness, slightly poorer corrosion resistance, applicable to general mechanical equipment, electrical equipment, etc.

Load and Speed Requirements

The rated load is the maximum load the bearing can withstand under the specified test conditions. Select the appropriate bearing according to the load size in the actual application, and select the stainless steel bearing with higher strength when bearing higher loads. Bearing speed affects its service life and performance. The rotational speed size of stainless steel bearings should be determined according to the actual use. Suitable lubrication can reduce friction and wear and improve the service life of bearings. Choose the right lubricant or lubricant and ensure the lubrication method is correct.

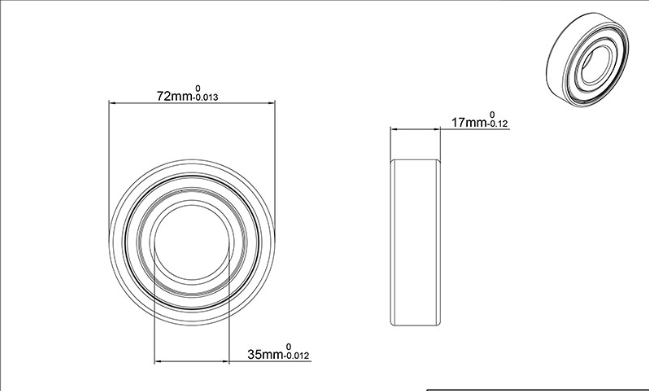

Size and Fit Specifications

The basic dimensional parameters of deep groove ball bearings mainly include inner diameter, outer diameter and width. The inner diameter is the diameter of the inner ring of the bearing, the outer diameter is the diameter of the outer ring of the bearing, and the width is the width of the bearing. When selecting deep groove ball bearings, the specific values of these dimensional parameters must be determined according to the needs of the equipment. Bearing accuracy refers to the tolerance values of the inner and outer rings of a bearing. The higher the accuracy, the better the bearing’s load-carrying capacity and stability. The accuracy level is selected according to the application requirements and load range to ensure service life and efficiency.

Maintenance and Care for Stainless Steel Deep Groove Ball Bearings

Maintenance and care of stainless steel bearings require attention to daily lubrication, using different lubrication methods. The use of bearings should also follow precautions, observe whether there is a failure phenomenon and find the reason for repair.

Lubrication Practices

Lubrication is important, not just for bearings but for all bearings. Please note, however, that stainless steel bearings should not be over-greased. The lubrication of stainless steel deep groove ball bearings mainly includes the following types:

- Oil cup drip lubrication: suitable for low speed and light load working temperature on low occasions, through the oil cup in the oil saving mouth to deep groove ball bearing drip lubrication. This method is simple and easy to implement, but the lubrication effect is affected by the capacity of the oil cup and drip oil speed.

- Oil bath lubrication: Deep groove ball bearings are partially immersed in lubricating oil, suitable for low—or medium-speed occasions. This method has a better lubrication effect, but we must pay attention to prevent lubricant pollution.

- Splash lubrication: The oil is brought into the deep groove ball bearings after splashing through other running parts, which is suitable for bearings with higher speed. This method is suitable when the oil tank volume is large and the oil quantity is sufficient.

- Circulating oil lubrication: The oil pump will lubricate oil from the oil tank suction after the delivery to the bearing needed to lubricate the part. It suits high speed, high temperature, and heavy load occasions. This method has the best lubrication effect but must be equipped with the corresponding oil pump and tank.

- Oil Mist Lubrication: The lubricant will be in the oil mist generator. This method uses compressed air and a small amount of lubricant mixed with the formation of an oil mist, and it is suitable for high-speed occasions. This lubrication method has a better effect, but it needs to be equipped with an oil mist generator.

Precautions for use

When using stainless steel deep groove ball bearings, you need to pay attention to the following points to ensure its performance and life:

- Keep clean: Keep the bearings and their surroundings clean to prevent dust and other impurities from entering the bearings.

- Correct mounting: Use proper mounting tools and methods, and avoid strong punching and direct striking of the bearings.

- Rust prevention treatment: When used in humid or corrosion-prone environments, rust prevention treatment should be done.

- Regular maintenance: although stainless steel deep groove ball bearings do not require frequent maintenance, it is still necessary to regularly check the running condition and lubrication of the bearings.

Faults and causes

Stainless steel bearings can be based on common failures to identify the sound; according to the sound, one must have sufficient experience to carry out the identification. Must be adequately trained to be able to identify the bearing sound and non-bearing sound. Therefore, this task should be carried out by professionals whenever possible. Bearing rattles can be clearly heard by applying a megaphone or a listening stick to the casing.

Stainless steel bearing fracture causes failure:

Stainless steel bearing fracture failure’s key root cause is flaws and load two root causes. When the applied load exceeds the material strength limit and causes parts fracture, it is called load fracture. The root cause of load is sudden mechanical failure or installation and unreasonable use. Bearing parts of micro-cracks, shrinkage, bubbles, block foreign impurities, super-temperature organization localized burns and other defects in the impact load or violent vibration will also be in the defects caused by fracture, called defective fracture. It should be put forward, bearing in the manufacturing process, the raw materials of the factory re-inspection, forging and heat treatment quality control, production process control can be accurately analyzed through the instrumentation whether the above defects exist in the future still need to strengthen the control. However, in normal circumstances, most stainless steel bearing fracture failures are load failures.

Conclusion: Embracing the Benefits of Stainless Steel Deep Groove Ball Bearings

With the progress of science and technology, the stainless steel deep groove ball-bearing industry is ushering in the climax of technological innovation. The application of new materials, the improvement of the manufacturing process and the integration of intelligent technology are injecting new vitality into the performance improvement and quality assurance of bearings. These innovations enhance the bearing capacity, wear resistance, and service life, making it more adaptable to the complex and changing working environment. Contact us at TFL Bearings for higher quality deep groove ball bearings to upgrade your machinery to a higher level of reliability!

Frequently Asked Questions

- Are stainless steel bearings suitable for food processing equipment?

Stainless steel deep groove ball bearings are suitable for food processing equipment. Food processing equipment usually needs to work in humid or chemically aggressive environments, so the bearings have high corrosion resistance and hygiene requirements. Stainless steel deep groove ball bearings have excellent corrosion resistance and hygienic properties, are especially suitable for use in humid and chemically aggressive environments, and can minimize the accumulation of bacteria and the risk of contamination.

- How often should I lubricate stainless steel deep groove ball bearings?

In a normal-use environment, stainless steel deep groove ball bearings usually need lubricant added once a week for about six months after installation. In harsh environments, such as high temperature, high speed, high load, strong corrosion, etc., the lubricating oil cycle must be decided according to the specific circumstances. For example, in a high-temperature environment, the oxidation speed of grease will be accelerated, and it may be necessary to add grease more frequently.

- Are stainless steel bearings more expensive than standard steel bearings?

Stainless steel bearings are usually more expensive than standard steel bearings. This is mainly due to the higher cost of stainless steel material. At the same time, stainless steel is more difficult to process and requires more craftsmanship, increasing the cost.

- Can stainless steel bearings be used in marine environments?

Stainless steel bearings can be used in marine environments. Stainless steel bearings can excel in marine environments due to their excellent corrosion resistance. The main materials used in stainless steel bearings include AISI440C, AISI304, and AISI316. Among them, AISI440C material excels in corrosion and wear resistance and is suitable for high load and high-speed environments; AISI304 material is suitable for light load and low-speed applications; AISI316 material is suitable for high temperature, high pressure and strong corrosive working environments.

- What is the average lifespan of a stainless steel deep groove ball bearing?

Stainless steel deep groove ball bearings typically have an average life of 20,000 to 50,000 hours. This figure is based on the commonly used life calculation formula L10, considering the operating conditions, accuracy class, material and maintenance of the bearing.