Types of Deep Groove Ball Bearings: A Comprehensive Guide

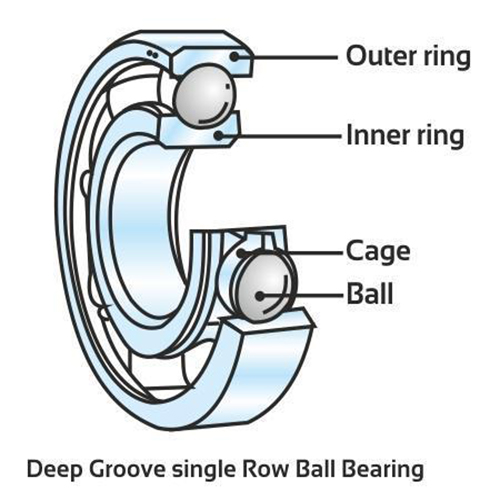

Deep groove ball bearings, also known as single-row radial ball bearings, are a widely used and most common type. The basic structure includes inner and outer rings, steel balls and a cage. Characterized by high load-carrying capacity, low friction and energy loss, high-speed performance, good wear resistance and life, etc., they are key components in various mechanical equipment.

Understanding the necessity of different types of deep groove ball bearings is conducive to adapting to diversified application requirements, optimizing equipment performance and life, reducing the failure rate and maintenance costs as well and promoting technological innovation and industrial upgrading, which helps to improve the productivity and competitiveness of enterprises.

Classification by Row Count

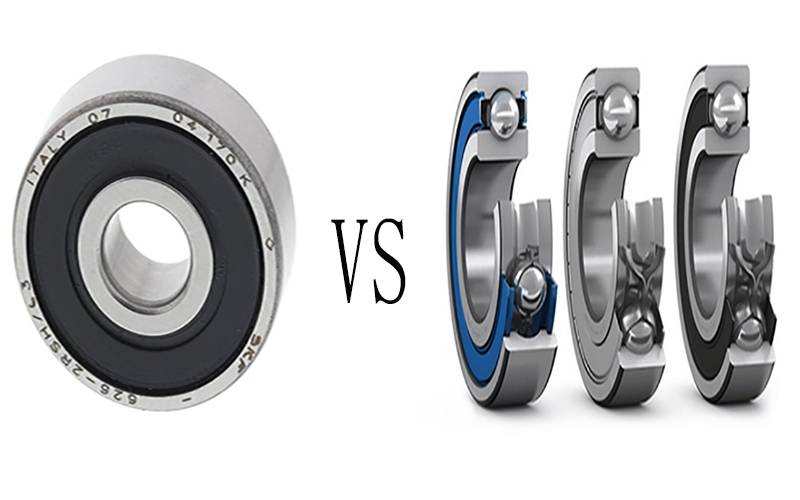

Deep groove ball bearings are mainly categorized into single-row and double-row types according to the number of rows.

Single-row Deep Groove Ball Bearings

Single-row deep groove ball bearing consists of inner and outer rings, a group of steel balls (known as rolling elements) and a cage; the structure is relatively simple, the manufacturing cost is low, and it is easy to achieve high manufacturing accuracy. The outer ring and inner ring through the steel ball rolling contact in order to realize the rotary movement, and the inner and outer ring on the raceway cross-section for the arc shape, usually with dust cover, seal or both.

Application scenarios

Single-row deep groove ball bearings are often used in electric motors and household appliances, transportation, all kinds of machinery, instrumentation and internal combustion engines and other fields.

Double-row Deep Groove Ball Bearings

The design of double-row deep groove ball bearings is essentially the same as that of single-row deep groove ball bearings, which contain basic components such as an outer ring, inner ring, steel ball cage, etc. However, double-row deep groove ball bearings are more complex in structure, with two juxtaposed raceway systems. However, double-row deep groove ball bearings are more complex in structure, with two parallel raceway systems, and can withstand radial and axial loads from two directions at the same time.

Suitable situations

Double-row deep groove ball bearings are suitable for the need to withstand large radial and axial loads; precision and speed have certain requirements and the working environment is relatively harsh occasions, widely used in a variety of mechanical and metallurgical equipment.

Classification by Sealing Method

Deep groove ball bearings are mainly categorized into two types: co: contact seal and non-contact seal, according to the rows.

Open Deep Groove Ball Bearings

Open-type deep groove ball bearings are characterized by seal-less structure, high rotational speed performance, high load carrying capacity, diversified sizes and forms, low noise and low vibration, etc. Advantages include high durability, a wide range of applications, and high adaptability.

Usage environment

Open deep groove ball bearings are used in a variety of environments, including high speeds, radial and axial loads, a wide range of industrial areas, and relatively harsh but maintainable operating environments.

Sealed Deep Groove Ball Bearings

Sealed deep groove ball bearing sealing type, according to the sealing method, has contact sealing and non-contact sealing, according to the sealing material classification, has rubber sealing ring and dust cover (standard iron cover), according to the sealing ring and the bearing inner and outer ring with the way, sealed deep groove ball bearing can also be divided into the inner ring without groove type, inner ring with groove type and other different forms of cooperation.

Dust and water resistance effects

The dustproof and waterproof effect of sealed deep groove ball bearings is mainly affected by many factors such as sealing method, sealing material and design structure. When choosing sealed deep groove ball bearings, you need to select according to the specific use environment and requirements.

Classification by Size

Deep groove ball bearings can be mainly classified into miniature bearings, small bearings, medium and small bearings, medium and large bearings, large bearings and extra large bearings according to the size classification.

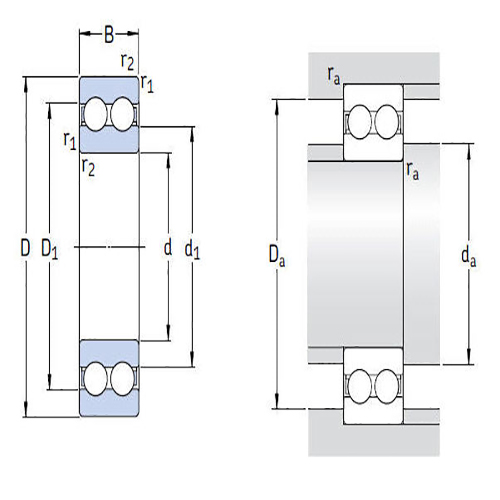

Standard Size Deep Groove Ball Bearings

Standard-size deep groove ball bearings are commonly available in a wide range of sizes, including inside diameters from 10mm to 1320mm, outside diameters from 30mm to 1600mm, and width sizes between 9mm and 300mm.

Application areas

Standard-size deep groove ball bearings are one of the most representative rolling bearings with a wide variety of applications; the main application areas are the automotive industry, electrical industry, machinery manufacturing, instrumentation and so on.

Miniature Deep Groove Ball Bearings

Miniature deep groove ball bearing size range is the inner diameter and can be as small as 0.6mm. Generally, the inner diameter of 1mm more, and the outer diameter according to the metric series and inch series is different, metric series outer diameter being less than 9mm and the inch series outer diameter being less than 9.525mm. Learn More.

Applications in precision instruments

The main fields of application of miniature deep groove ball bearings in precision instruments are precision measuring instruments, medical equipment, aerospace equipment and laboratory equipment.

Classification by Material

Steel Deep Groove Ball Bearings

The common types of steel used for steel deep groove ball bearings mainly include high carbon chromium bearing steel (e.g. GCr15/GCr15SiMn) and carburized bearing steel (e.g. G20Cr2Ni4A); in addition, some other steels may be used for the manufacture of deep groove ball bearings, such as carbon steel (e.g. 08F high-quality cold rolled steel strip), and so on.

Advantages and suitable environments

The advantages of steel deep groove ball bearings include strong load-carrying capacity, high precision, high speed, low noise, strong adaptability, easy maintenance, etc. They are widely used in the fields of machinery and equipment, heavy-duty working conditions, high-speed rotation and harsh environments.

Stainless Steel Deep Groove Ball Bearings – Corrosion resistance characteristics

Stainless steel deep groove ball bearings’ corrosion resistance is mainly due to the superiority of its material; stainless steel is primarily composed of iron, chromium, nickel and other elements, of which chromium is the key; it can form a dense layer of oxidized film on the surface of the stainless steel (passivation film), this layer of film can prevent the oxygen, water and other corrosive substances and the stainless steel inside the iron element in direct contact, so as to play the role of rust and corrosion prevention.

Application scenarios

The main application areas of stainless steel deep groove ball bearings are mechanical equipment, industrial production equipment, household appliances, precision instruments and other fields.

Ceramic Deep Groove Ball Bearings

Ceramic deep groove ball bearings are characterized by high precision, low coefficient of friction, corrosion resistance, high-temperature stability, high-speed performance, long life, insulation and self-lubrication.

High-temperature and high-speed applications

Ceramic deep groove ball bearings are well suited for applications in high-temperature and high-speed environments due to their unique physical and chemical properties—for. For example, aerospace, new energy vehicles, high-speed machine tools and other fields.

Special Purpose Deep Groove Ball Bearings

In fact, in addition to the above classification method, people also like to distinguish different kinds of deep groove ball bearings according to different use scenarios, for example, the high-temperature deep groove ball bearings suitable for use in high-temperature environments, high speed and low noise deep groove ball bearings and so on.

High-temperature Deep Groove Ball Bearings

The temperature range of high-temperature deep groove ball bearings is generally around 300°C. Still, the exact value will be affected by a variety of factors such as material, design and lubrication.

Material selection

High temperature deep groove ball bearing material selection should be considered factors are working temperature, load conditions, corrosive environment and cost factors. In the selection process, we should give priority to the material of high-temperature resistance, wear resistance, fatigue resistance, corrosion resistance and other factors.

Low-noise Deep Groove Ball Bearings

The noise reduction design of low noise deep groove ball bearings needs to be considered comprehensively from a number of aspects such as material selection, geometric structure design, machining process, lubrication method and assembly accuracy, and reasonable design and optimization.

Application areas

The main application areas of low-noise deep groove ball bearings are the automotive industry, household appliances, industrial production equipment, precision instrumentation and automation equipment.

How to Choose the Right Deep Groove Ball Bearing

Choosing the right deep groove ball bearing requires comprehensive consideration of load, speed, environment and many other factors. Load factors include load size and type, load direction, speed factors include limit speed and rotational accuracy; environmental factors include operating temperature, lubrication conditions, corrosion and pollution, etc., as well as the space occupied by the bearing, precision and rigidity, noise and vibration and other factors.

Conclusion

Deep groove ball bearing types, according to the number of rows, can be divided into single-row and double-row deep groove ball bearings. According to the sealing method, it can be divided into open deep groove ball bearings and miniature deep groove ball bearings. According to the classification, materials can be divided into steel deep-groove ball bearings, ceramic deep-groove ball bearings and stainless steel deep-groove ball bearings. According to the classification of special purposes, it can be divided into high-temperature deep groove ball bearings and low-noise deep groove ball bearings.

Selection of the appropriate type of deep groove ball bearings is directly related to the performance, reliability, life overall operational efficiency and economic benefits of the equipment.

People Ask Questions

What’s the difference between single-row and double-row deep groove ball bearings?

The difference between single-row deep groove ball bearings and double-row deep groove ball bearings is mainly reflected in the structure, bearing capacity applicable scenes and other aspects of the differences:

- The structure difference: single row deep groove ball bearing structure is relatively simple, mainly by the inner and outer ring, steel ball and cage composition, inner and outer ring diameter is the same, the ball diameter is moderate, and bearing area is limited. Double row deep groove ball bearing design is similar to a single-row. Still, with two raceways, it can accommodate more steel balls, so the inner and outer ring diameters are different, and the ball diameter is also larger than a single-row bearing.

- The bearing capacity is different; single row deep groove ball bearings bearing capacity is relatively limited, suitable for low-speed rotation and small load environment. Double-row deep groove ball bearings have higher rigidity and load-carrying capacity for high-speed rotation and large load conditions.

- Adapted to different scenes, single-row deep groove ball bearings are widely used in low-speed rotation and small-load environments, such as household appliances, automobiles, motorcycles and so on.

Double row deep groove ball bearings are more suitable for high speed rotation and large load working conditions, such as machine tools, heavy machinery, ships and so on.

How to choose the correct size of deep groove ball bearing?

The main steps in selecting the correct size deep groove ball bearings are determining the application requirements and working environment, measuring and calculating the size of the required bearings, considering the accuracy class and clearance of the bearings, selecting the right type and construction of the bearings, referring to standards and specifications and consulting professionals or suppliers.

What factors affect the lifespan of deep groove ball bearings?

Deep groove ball bearing life by material factors, manufacturing process factors, use conditions factors, maintenance factors and other factors.