2025 Comprehensive Guide to Deep Groove Ball Bearing Installation

Deep groove ball bearings are widely used rolling bearings with high load-carrying capacity, high rotational speed, low frictional resistance, good durability and long service life, which have become indispensable components in many industries. The purpose of this guide is to ensure the proper installation of bearings and the proper operation of equipment, and its audience encompasses people in a variety of fields, including mechanical equipment maintenance, production, design, manufacturing, and education.

Basics of Deep Groove Ball Bearing Installation

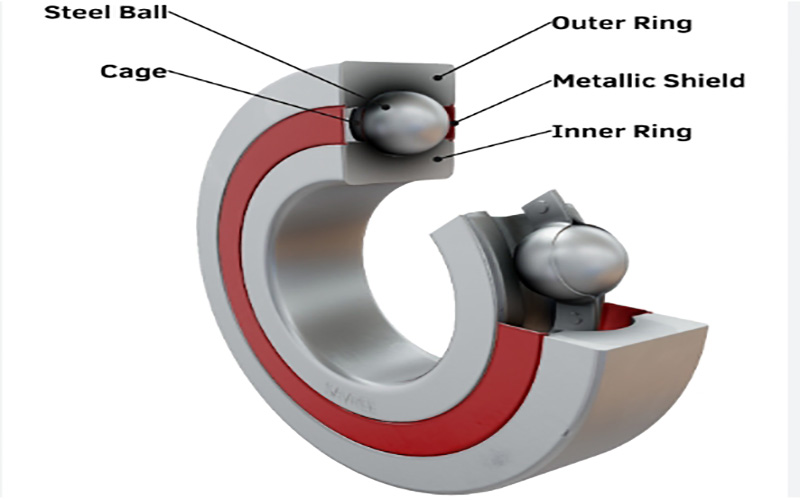

Introduction to deep groove ball bearing structure

Preparation before installation

Installation Tools and Equipment

Installation tool checklist

-

Press: Use the press to press-fit the bearings onto the shaft first, and then fit the shaft together with the bearings into the bearing housing holes. Usually, a soft metal material assembly sleeve is placed on the end face of the inner ring of the bearing to protect the bearing from damage.

-

Bearing heater: the use of the principle of thermal expansion will be changed from a tight fit to a loose fit mounting equipment. It is suitable for the mounting of bearings with large amounts of overload, and the heating temperature is generally controlled between 80-100℃ to avoid damaging the lubrication and material of the bearings.

-

Specialized puller: It can safely and effectively pull the bearings out from the shaft or the hole of the bearing housing to avoid damage to the bearings or related parts.

-

Other auxiliary tools, such as mounting hammer, thermometer, and assembly sleeve.

How to choose the right installation tools

Detailed Steps of Deep Groove Ball Bearing Installation

Cold press installation method

Heat installation method

Correct positioning and alignment techniques

Installation Considerations for Different Applications

How to install motor bearings

Tips for automotive wheel hub bearing installation

-

Before Installation: Ensure that the vehicle is securely parked on a level surface and that the car is supported with a safety bracket to prevent accidental movement. Prepare the tools and check if the new wheel bearing is intact.

-

Cleaning and Inspection: Thoroughly clean the wheel hub, bearing housing and other related parts and dry all parts before installation. At the same time, check the bearing housing hole for any damage or foreign objects and ensure that it is flat and smooth.

-

Apply an appropriate amount of fresh grease to the inner ring of the bearing and the housing bore of the hub to ensure that the bearing can rotate smoothly and minimize wear. Use special tools (e.g. press) to press the new wheel bearing evenly into the bearing housing hole. During the pressing process, uneven force or skewing of the inner ring of the bearing should be avoided to cause damage to the bearing. Install other related parts, such as dust cover, locking tabs, fixing nuts, etc., after the bearing is in place.

Precautions for mounting bearings in high-speed equipment

-

Ensure the cleanliness of the bearings and their seating rings before mounting, and the mounting site should be kept clean.

-

Professional mounting tools and methods should be used for mounting, and in the process of mounting, it is necessary to assemble in the correct order.

-

Choose the right type of lubricant according to the working load, rotational speed, ambient temperature and other factors.

-

Ensure that the matching dimensions of the inner ring and outer ring meet the requirements; adjust the axial clearance and radial clearance according to the usage requirements.

-

Avoid excessive cooling of the bearings during assembly to prevent the moisture generated by condensation from causing rusting of the bearings and mating surfaces.

Regular Inspection and Maintenance

-

Selection of suitable lubricant: choose a suitable lubricant or grease according to the environment and operating conditions of the bearing, and check and replace the lubricant regularly.

-

Bearing cleaning: bearings are susceptible to dust, moisture and other pollutants in the working environment, which can accelerate wear and corrosion of bearings and reduce their lifespan. Bearings should be cleaned with appropriate detergents and tools and then wiped dry with a clean cotton cloth or paper towel.

-

Avoid overloading: Check the operation of the bearings regularly to ensure that they are operating within the rated load. If any abnormal vibration, noise or temperature rise is found in the bearings, they should be stopped and inspected and dealt with in time.

-

Reasonable storage: The bearings should be cleaned and lubricated before storage and protected with rust inhibitor. The bearings should be stored in a dry, clean and non-corrosive gas environment, avoiding direct sunlight and high temperatures. Regularly check the storage conditions and status of the bearings to ensure that they are in good condition.

Safety Precautions

Safe practices during installation mainly include wearing protective gear (e.g., protective glasses, gloves, etc.), strict adherence to operating procedures, and regular maintenance (cleaning and lubrication, etc.).

To effectively prevent hand injury or contamination, choose protective gloves that are durable, cut-resistant, and slip-resistant. Wear safety glasses or masks to prevent eye injury from splashes of metal chips, oil, etc., during installation. If the installation environment contains pollutants such as dust and harmful gases, wear a dust mask or respirator, and the respirator should be equipped with appropriate filter elements depending on the pollutant type.

Conclusion

Properly installed bearings help ensure equipment performance, extend bearing life, improve safety and reduce maintenance costs. We encourage more detailed bearing mounting guidelines through the development of skilled mounting professionals and regular maintenance of bearings. Especially for questions related to deep groove ball bearing mounting, you can contact our technicians.