Accuracy and Tolerance Classes of Deep Groove Ball Bearings: Comprehensive Guide and FAQ

Introduction

In the world of precision machinery, bearing precision and tolerance are the critical indicators that define a bearing’s quality. They directly dictate the rotational accuracy, load-carrying capacity, and overall service life of your equipment.

However, these terms are often confused. To select the right deep groove ball bearing, it is essential to distinguish between them:

-

Bearing Precision (Accuracy): This refers to the magnitude of processing errors during manufacturing. It reflects the degree of accuracy in terms of geometry, size, and rotational stability (run-out).

- Bearing Tolerance: This defines the allowable range of deviation between the manufactured size and the design size. It ensures that the bearing’s size, shape, and position remain within specific limits for proper interchangeability.

According to ISO standards, bearing accuracy is categorized into specific grade systems and tolerance systems. Understanding these classes—and how they compare to the ABEC rating system—is vital for ensuring reliability in mechanical equipment.

What You Will Learn in This Guide:

-

ISO vs. ABEC: A clear comparison of accuracy classes (P0-P2 vs. ABEC 1-9).

-

Tolerance Charts: Detailed tables for identifying the right class for your application.

-

Practical Fits: How to manage positive and negative tolerances for shaft and housing fits.

Understanding Accuracy Classes & Grades

ISO Accuracy Classes (P0, P6, P5, P4, P2)

ISO accuracy classes (P0, P6, P5, P4, P2) are accuracy classification standards developed by the International Organization for Standardization (ISO) for bearings and other rotating machinery components. These grades reflect the degree of accuracy of bearings in terms of geometry, dimensions, rotational accuracy, etc., and are, in descending order, P0, P6, P5, P4, P2.

The hierarchy, in descending order (from normal to highest precision), is:

-

P0 (Normal Precision): Standard for general applications.

-

P6, P5, P4: Increasing levels of precision for tighter tolerances.

-

P2: Ultra-precision, used in the most demanding applications.

Note: In the ISO system, the smaller the number (after P), the higher the precision.

Global Standards Equivalence Table

Different countries use different codes that align with ISO standards. Here is how they compare:

| Country | Standard | Normal Precision | Precision | High Precision | Ultra Precision |

|---|---|---|---|---|---|

| China | GB/T 307.1 | P0 | P6 | P5 / P4 | P2 |

| Int’l / Swiss | ISO / SKF | P0 | P6 | P5 / P4 | P2 |

| Germany | DIN | P0 | P6 | P5 / P4 | P2 |

| Japan | JIS | Class 0 | Class 6 | Class 5 / 4 | Class 2 |

| USA | ANSI/ABMA | ABEC 1 | ABEC 3 | ABEC 5 / 7 | ABEC 9 |

ABEC rating system

The ABEC rating system is developed by the American Bearing Manufacturers Association (ABMA). It is the dominant standard in the US market and is widely recognized for deep groove ball bearings.

Unlike ISO, the ABEC system uses odd numbers (1, 3, 5, 7, 9).

-

Key Difference: In the ABEC system, the higher the number, the tighter the tolerance and the higher the accuracy.

-

Scope: While initially designed for specific annular bearings, it is now a common reference for precision instrument bearings and electric motors.

Comparison: ISO Grades vs. ABEC Ratings (Conversion Chart)

While both systems measure bearing accuracy, their numbering logic is opposite. This often causes confusion during cross-referencing.

-

ISO Logic: Lower number = Higher Precision (e.g., P2 is best).

-

ABEC Logic: Higher number = Higher Precision (e.g., ABEC 9 is best).

The following Cross-Reference Chart is essential for engineers and purchasers to find the equivalent grade across standards.

Bearing Tolerance Class Conversion Table

| Precision Level | ISO Grade (Smaller = Better) | ANSI/ABMA (Higher = Better) | DIN (Germany) | JIS (Japan) |

|---|---|---|---|---|

| Normal | Class 0 (P0) | ABEC 1 | P0 | Class 0 |

| Medium | Class 6 (P6) | ABEC 3 | P6 | Class 6 |

| High | Class 5 (P5) | ABEC 5 | P5 | Class 5 |

| Precision | Class 4 (P4) | ABEC 7 | P4 | Class 4 |

| Ultra-Precision | Class 2 (P2) | ABEC 9 | P2 | Class 2 |

Summary of Differences:

-

ISO Grade 0 (P0) is equivalent to ABEC 1. This is the standard “Normal” tolerance class for most machinery.

-

ISO Grade 2 (P2) corresponds to ABEC 9, representing the peak of manufacturing precision.

-

Application Note: For most general industrial applications (conveyors, simple motors), P0 / ABEC 1 is sufficient. High-speed spindles often require P4 / ABEC 7 or higher.

Tolerance Classes vs. Internal Clearance

When specifying a deep groove ball bearing, it is crucial to distinguish between Tolerance Classes (Precision) and Internal Clearance (Play).

Normal & Precision Tolerance Classes (P-Series)

As discussed in the previous section, the tolerance class (P0, P6, P5…) controls the dimensional deviation of the bearing. It determines how close the manufactured bearing is to its exact design dimensions.

-

Standard: P0 (Normal) is standard for most applications.

-

Precision: P6 and P5 are used where higher running accuracy is required.

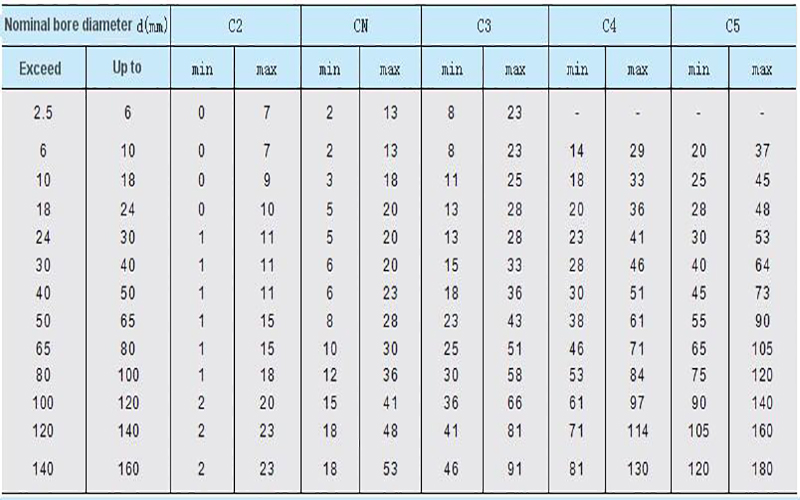

Internal Clearance Classes (C-Series: C0, C2, C3, C4, C5)

Important Correction: Terms like C2, C3, and C4 refer to Radial Internal Clearance, not tolerance precision.

Clearance is the total distance that one bearing ring can move relative to the other.

-

CN (Normal): Standard clearance for normal operating conditions.

-

C3 (Larger than Normal): The most common clearance for electric motors and high-speed applications to allow for thermal expansion.

-

C4 / C5: Extra large clearance for high-heat environments.

-

C2 (Smaller than Normal): Tight clearance for high rigidity requirements.

Shaft and Housing Fits (Tolerance Guide)

The main factors affecting the selection of tolerances are bearing load, rotational speed, accuracy requirements, mounting and dismounting methods, bearing type and size, the working environment and many other factors.

The performance of a bearing depends heavily on the fit between the bearing, the shaft, and the housing. A “Tolerance Class” on the bearing is useless if the shaft is machined incorrectly.

-

Interference Fit (Tight): Used when the load rotates relative to the ring. (e.g., Rotating Shaft + Stationary Load).

-

Clearance Fit (Loose): Used for easy installation or when the ring is stationary relative to the load.

💡 Expert Tool: For detailed fit charts (like H7/m6) and automatic calculations, please refer to our in-depth Bearing Fits Guide (H7/m6) & Free Tolerance Calculator.

Recommended Shaft Tolerances for Radial Bearings (ISO)

| Shaft Diameter (mm) | Loading Condition | Recommended Tolerance | Fit Type |

|---|---|---|---|

| All sizes | Inner ring stationary (Outer ring rotating) | g6 / h6 | Clearance / Transition |

| d ≤ 18mm | Inner ring rotating (Normal load) | j6 | Transition |

| 18mm < d ≤ 100mm | Inner ring rotating (Normal load) | k5 / k6 | Interference (Light) |

| 100mm < d ≤ 200mm | Inner ring rotating (Heavy load) | m5 / m6 | Interference (Tight) |

Measuring Parameters: From Basic Dimensions to Precision Run-out

To determine the quality or identity of a deep groove ball bearing, measurements are divided into two categories: Basic Dimensional Measurement (for identification) and Advanced Accuracy Inspection (for quality control).

How to Measure a Ball Bearing (Practical Guide)

If you need to identify a bearing or check its fit, you need to measure three key dimensions using a Vernier caliper. These dimensions usually correspond to the bearing codes found on the seal or packaging.

-

Bore Diameter (d): Insert the caliper’s internal jaws into the inner ring. Measure the inside diameter.

-

Outer Diameter (D): Use the external jaws to clamp across the widest part of the outer ring.

-

Width / Thickness (B): Measure the distance between the two side faces of the inner or outer ring.

💡 Pro Tip: Once you have these three numbers (d x D x B), you can identify the bearing series (e.g., A 25mm x 52mm x 15mm measurement usually corresponds to a 6205 bearing).

Radial Run-out (Rotation Accuracy)

For precision applications, simple dimensional measurement isn’t enough. We must measure Run-out.

Radial run-out is the maximum variation in the diameter direction relative to a fixed reference point (the axis) during a 360-degree rotation.

- Cause: It is usually caused by geometry errors (like out-of-roundness) or improper installation.

- Impact: High radial run-out causes vibration and reduces bearing life.

Axial Run-out

Axial run-out refers to the “wobble” or up-and-down vibration in the direction of the spindle axis while rotating. This is critical for thrust applications where the bearing must keep the shaft perfectly aligned longitudinally.

Dimensional Variation (Width & Diameter)

Even if a bearing looks round, its consistency matters:

- Width Variation: This refers to the change in the width dimensions of the inner and outer rings. Factors like material deformation or processing errors can cause the ring to be thicker on one side than the other.

- Bore & OD Tolerances: This indicates the allowable deviation range (Maximum vs. Minimum) for the bore and outer diameter. A loose tolerance here leads to poor fits on the shaft.

Why Precision Matters: Impact on Bearing Performance

Choosing the right accuracy class isn’t just about following a standard; it directly affects the efficiency and longevity of your machinery. Here is how tolerance grades (P0 vs. P6/P5/P4) impact real-world performance.

Running Accuracy & Rotational Stability

Running accuracy is critical for equipment requiring precise positioning, such as machine tool spindles.

-

High Precision (P4/P2): Minimizes radial and axial run-out. This ensures the shaft rotates perfectly on its axis without “wobbling,” which is essential for achieving high-quality surface finishes in manufacturing.

-

Standard Precision (P0): Sufficient for general conveying or slow-moving parts where minor run-out is acceptable.

Noise and Vibration Control

Vibration is the enemy of mechanical stability.

-

The Impact: Looser tolerances can lead to uneven clearance and internal collision between the balls and raceways. This generates audible noise and vibration.

-

Solution: For applications like electric motors or household appliances where silence is a quality indicator, upgrading from P0 to P6 or P5 serves as an effective noise reduction strategy.

Heat Generation & High-Speed Capability

Friction generates heat, and heat kills bearings.

-

Tight Tolerances: High-precision bearings (with correct internal clearance) reduce unnecessary friction and skidding.

-

Speed Factor: If your application runs at high RPMs, you need higher precision. A P4 bearing generates significantly less heat than a P0 bearing at high speeds, preventing lubricant breakdown and seizure.

Bearing Service Life (ROI)

Ultimately, precision is an investment in Return on Investment (ROI).

-

Load Distribution: High manufacturing accuracy ensures that the load is evenly distributed across all rolling elements.

-

Wear Reduction: By minimizing vibration and heat, high-precision bearings suffer less fatigue and abrasive wear, significantly extending the service life of the entire machine and reducing maintenance downtime.

How to Select the Right Accuracy Class: A Practical Guide

Selecting the correct accuracy and tolerance grade is not just a technical decision; it is an economic one. It requires balancing functional requirements with manufacturing costs.

Selection Matrix by Application

The most effective way to choose a class is to look at typical industry standards. You do not need P4 precision for a conveyor belt, nor should you use P0 for a CNC spindle.

Recommended Accuracy Grades for Common Applications

| Application Category | Typical Component | Recommended ISO Grade | Why? |

|---|---|---|---|

| General Machinery | Conveyors, Agricultural Equipment, Car Transmissions | P0 (Normal) | Cost-effective; high precision is unnecessary for low speeds. |

| Electric Motors | Small to Medium Motors, Household Appliances | P6 / P5 | Reduces vibration and noise; ensures smooth running. |

| Precision Tools | Lathes, Milling Machines, Woodworking Spindles | P5 / P4 | High rotational accuracy is required to ensure surface finish quality. |

| Ultra-Precision | Gyroscopes, Aviation Instruments, High-speed Spindles | P4 / P2 | Extreme speed and stability requirements; strictly controlled run-out. |

Analyzing Operating Conditions

Before finalizing your choice, evaluate the specific conditions under which the bearing will operate:

-

Speed (RPM): Higher speeds generally require higher precision (P5 or better) to minimize heat generation from friction.

-

Mounting & Assembly: High-precision bearings (P4/P2) require equally precise shafts and housings. If your machining capability for the shaft is low, installing a P2 bearing is a waste of money because the shaft’s errors will negate the bearing’s precision.

-

Temperature: For extreme temperatures, consider the internal clearance (C3/C4) rather than just the tolerance class.

Cost considerations

Cost is a major factor. The price of bearings does not increase linearly with precision; it increases exponentially.

-

The “Good Enough” Rule: Always select the lowest precision grade that meets the functional requirements. Over-specifying (e.g., using P4 where P0 suffices) increases raw material and machining costs without adding tangible value.

-

Total Cost of Ownership: However, for critical equipment, the extra cost of a P5/P6 bearing is justified if it prevents premature failure and expensive downtime.

Manufacturing Processes and Quality Control

Precision manufacturing techniques

Precision manufacturing technology refers to the process of manufacturing parts and products with extremely high dimensional accuracy, surface finish, and form and positional tolerances through high-precision equipment, technology, and methods.

Quality assurance methods

Quality assurance methods include: establishing a sound quality control system, standardizing quality standards, conducting process capability verification, implementing process monitoring and testing, controlling nonconforming products, continuous improvement, and strengthening employee training and supplier management.

Testing and verification procedures

Testing procedures are a series of standardized processes for testing products, raw materials, components, etc., in the production process. Usually includes the following steps: develop a test plan, prepare test samples, execute the test, and record and analyze the test results. A validation program refers to the manufacturing process and quality control activities to confirm the effectiveness of a series of activities; validation procedures usually include process validation, equipment validation and document verification.

Future Trends in Bearing Accuracy and Tolerance

Advancements in manufacturing technology

The future trend of bearing precision and tolerance will be profoundly affected by the progress of manufacturing technology, which is manifested in the continuous improvement of precision level, further narrowing of the tolerance range, constant innovation of manufacturing technology and improvement of green environmental protection requirements. These trends will jointly promote the bearing industry to high-end, precision, intelligent and green direction.

Emerging high-precision applications

The future trend of bearing precision and tolerance will be influenced by various factors such as the growth of demand for high-precision applications, the promotion of technological innovation, the integration of intelligence and digitization, environmental protection and sustainable development, as well as market expansion.

Conclusion

Key Takeaways

We have navigated through the complexities of deep groove ball bearing accuracy. By now, you should understand that:

-

Accuracy ≠ Clearance: A C3 bearing is not “loose quality”; it has internal room for heat expansion.

-

Higher isn’t always better: For a standard conveyor, a P0 (ABEC 1) bearing is cost-effective and sufficient. Installing a P4 bearing on a rough shaft is a waste of budget.

-

Measurement matters: Identifying the correct code (d x D x B) is the first step to successful replacement.

The “Cheap Bearing” Trap

Selecting the correct tolerance grade is the cheapest insurance policy for your machinery. A mismatch in tolerance—specifically regarding the shaft fit—is the #1 cause of premature vibration, noise, and eventual seizure. Don’t let a $10 bearing destroy a $10,000 motor.

Need Technical Support?

Still unsure whether your application requires ISO P6 or P5? Or do you need a custom clearance (C3/C4) for a high-temperature environment?

At TFL Bearing, we don’t just sell bearings; we provide engineering solutions.

-

[Check Our Catalog]: Browse our full range of Deep Groove Ball Bearings.

-

[Get a Quote]: Send us your technical drawing or Part Number for a fast, competitive quote.

-

[Consult an Expert]: Have a tricky fitment issue? Our engineers are ready to assist.

Frequently Asked Questions

What is the difference between Accuracy Class and Tolerance Class?

While often used interchangeably, they refer to different aspects of quality:

-

Tolerance Class (Dimensional Accuracy): Defines how much the bearing’s physical dimensions (inner diameter, outer diameter, width) are allowed to deviate from the absolute design size. It ensures the bearing fits onto the shaft correctly.

-

Accuracy Class (Running Accuracy): Defines the rotational stability (run-out). It measures how “true” the bearing spins without wobbling. A bearing can be dimensionally perfect (good tolerance) but still wobble (poor accuracy).

Does “C3” mean high precision?

No. This is a common misconception.

-

C3 refers to Internal Clearance (the gap between the balls and the raceway), specifically “larger than normal” clearance to allow for thermal expansion.

-

Precision is denoted by P-grades (ISO) or ABEC ratings.

-

Example: You can have a “P0 C3” bearing (Standard precision, loose clearance) or a “P5 C3” bearing (High precision, loose clearance).

Is ABEC 1 better than ABEC 9?

No, it is the opposite. In the ABEC system, higher numbers indicate higher precision.

-

ABEC 1: Standard precision (Equivalent to ISO P0).

-

ABEC 9: Ultra-precision (Equivalent to ISO P2).

-

Note: In the ISO system, lower numbers indicate higher precision (e.g., P2 is better than P0).

How do I choose the right accuracy class for my electric motor?

For most standard electric motors, ISO Class P6 (or ABEC 3) is the recommended “sweet spot.”

-

P0 (Standard): Acceptable for general motors but may run noisier.

-

P6 / P5: Recommended for quiet, low-vibration operation in quality motors.

-

P4: Usually unnecessary unless it is a high-speed spindle motor.

Where can I find the shaft fit tolerances for my bearing?

The tolerance of the bearing is useless if the shaft is machined incorrectly. For standard applications:

-

Use a k5 or k6 tolerance for the shaft (for interference fits).

-

Use a H7 or J7 tolerance for the housing.

-

For a complete calculation based on your specific size, please refer to our Bearing Fits Guide & Calculator.