Why Use Insulated Bearings

Introduction: The Importance of Insulated Bearings

Insulated bearings are bearings with electrically insulating properties that protect bearings and motors by preventing damage from electrical currents. Electrically insulated bearings have a wide range of applications in modern industry. Insulated bearings can keep the equipment more stable and safe to operate, which is an important component in industrial development.

What are Insulated Bearings?

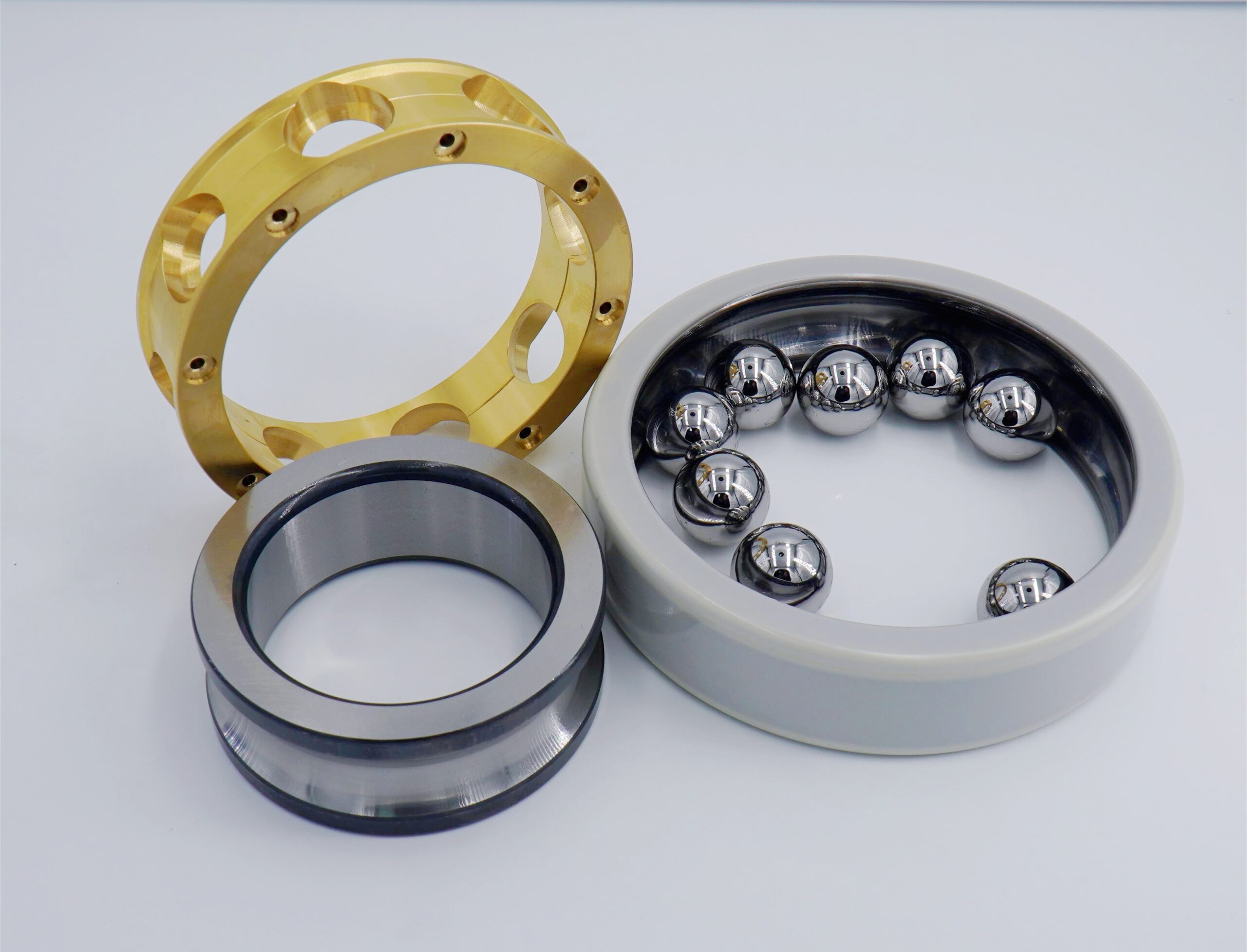

Insulated bearings are made of advanced silicon nitride and zirconium oxide insulating materials and a special coating process on the outer surface. These bearings consist of inner and outer rings made of high-quality bearing steel, retainers, and ceramic and ceramic balls, making them precision bearings with an electrically insulating effect.

The Role of Insulated Bearings in Industry

Insulated bearings, as a kind of special bearings, play an important role in many fields of modern industry. Excellent electrical insulation performance is most needed in industrial equipment, especially in electric power, railroad, machinery and metallurgical industry, petrochemical industry and so on. Electrically insulated bearings stop the damage caused by galvanic corrosion brought by electric current and escort the safe operation and prolonged life of the equipment.

Introduction to TFL Insulated Bearings

TFL Insulated Bearings, as a leading manufacturer of insulated bearings, has always paid great attention to improving the performance of insulated bearings. Let our high-performance insulated bearings become the key components of equipment in various industrial fields. TFL insulated bearings use high-quality silicon nitride and zirconium oxide materials sprayed on the inner and outer rings in electrically insulated bearings, as well as excellent ceramic materials, which give ceramics excellent insulating properties and greater protection for the smooth and safe operation of equipment.

Why Use Insulated Bearings? Key Advantages

Insulated bearings can become an essential component in various industrial fields, originating from their unique insulating properties. The main advantage of electrically insulated bearings is that they can effectively avoid the damage of galvanic corrosion on motors and bearings, so the damage rate of equipment is reduced, the life span is extended, and the efficiency of production is greatly improved.

Prevention of Electrical Current Damage

How do insulated bearings prevent current damage? This is because the outer ring or inner ring of the bearing is sprayed with an insulating material. This insulating coating is able to resist voltages up to 1000VDC, blocking the shaft current path, and so preventing electrical current damage.

Extended Equipment Lifespan

Insulated bearings reduce the frequency of maintenance because they prevent damage to equipment caused by shaft currents. An example is the use of insulated bearings in wind turbines. High shaft voltage causes shaft current to damage the inner and outer rings and balls. Insulated bearings solve the damage of galvanic corrosion in generators and extend the service life of equipment.

Improved Energy Efficiency

Principles of energy efficiency with insulated bearings: Insulated bearings reduce the damage rate of equipment by minimizing the passage of electric current. By reducing the number of equipment breakdowns and downtime, the production line can run continuously, and the efficiency of production is greatly improved. Insulated bearings are, therefore, an effective means of improving energy efficiency.

Reduced Maintenance Costs

Insulated bearings play a great role in protecting the safety of equipment. Industrial equipment caused by current damage also reduces the frequency of equipment failure and maintenance, thus reducing the cost and effort invested in equipment maintenance. For example, the maintenance of railroad traction motors is simplified but also reflects that insulation bearings can reduce maintenance costs.

Applications of Insulated Bearings Across Industries

With the development of society and the progress of industrial technology, more and more types of equipment and application scenarios put forward stricter requirements on service life, noise level and stability of bearings. Therefore, the birth of insulated bearings has become an important role in various fields, which can meet the protection of the use and life of equipment and improve the productivity of various industries.

Power Generation Industry

In the electric power industry, the application of insulated bearings is very wide and important, especially in wind power generation, hydroelectric power and other key equipment. The reason for the use of insulated bearings in electric motors is that the action of the electric current and magnetic field will produce the threat of galvanic corrosion to the motor, which will affect the stable operation of the whole power equipment. Therefore, insulated bearings are particularly important in the power industry.

Transportation Industry

Insulated bearings are of great importance in the transportation industry. Especially in electric vehicles and high-speed trains, insulated bearings are widely used in internal combustion engines and traction motors. Insulated bearings carry high speeds and heavy loads, ensure the stability and safety of trains on curved tracks, improve transportation efficiency, and also become the best solution to the phenomenon of galvanic corrosion.

Manufacturing Industry

The application of insulated bearings in the manufacturing industry, for example, in CNC machine tools, is crucial. This is because the spraying of insulating material on the outer ring or inner ring of the bearing ensures a strong bond between the overlay and the substrate, safeguarding the insulating properties and protecting the grease and the rolling elements and raceways from current damage. The application of insulated bearings in CNC machine tools not only improves the performance and life of the machine but also ensures machining accuracy and efficiency.

Renewable Energy Sector

Insulated bearings are used in renewable energy applications, mainly in solar and wind energy equipment. Insulated bearings provide electrical isolation for a variety of equipment by blocking damage caused by electrical currents with their unique insulating properties and voltage withstand capabilities, improving energy efficiency.

How Insulated Bearings Solve Common Issues

Problems such as shaft voltages and currents, galvanic and pitting corrosion, noise and vibration, and lubrication failures often occur in industrial applications. Insulated bearings provide the best solution to these problems, and the insulating properties of bearings play a key role in the industrial sector.

Shaft Voltage and Shaft Current

During the use of the motor, a certain voltage difference is generated between the shaft and the bearing, and the current generated by the voltage difference leads to galvanic corrosion damage to the bearing. For example, the role of insulated bearings in VFD applications is to protect the bearings and equipment by isolating the current through the insulating coating on the inner or outer ring.

Electrical Erosion and Pitting

Insulated bearings solve galvanic and pitting problems are also reflected in the performance of insulated bearings in high-voltage environments. Insulated bearings are coated to withstand DC voltages of up to 1,000 volts, and even insulating coatings to withstand 2,000 or even 3,000 volts are also available. The bearing becomes an insulator, and the current facing the insulating material will not produce galvanic corrosion, which fundamentally protects the equipment and the bearing.

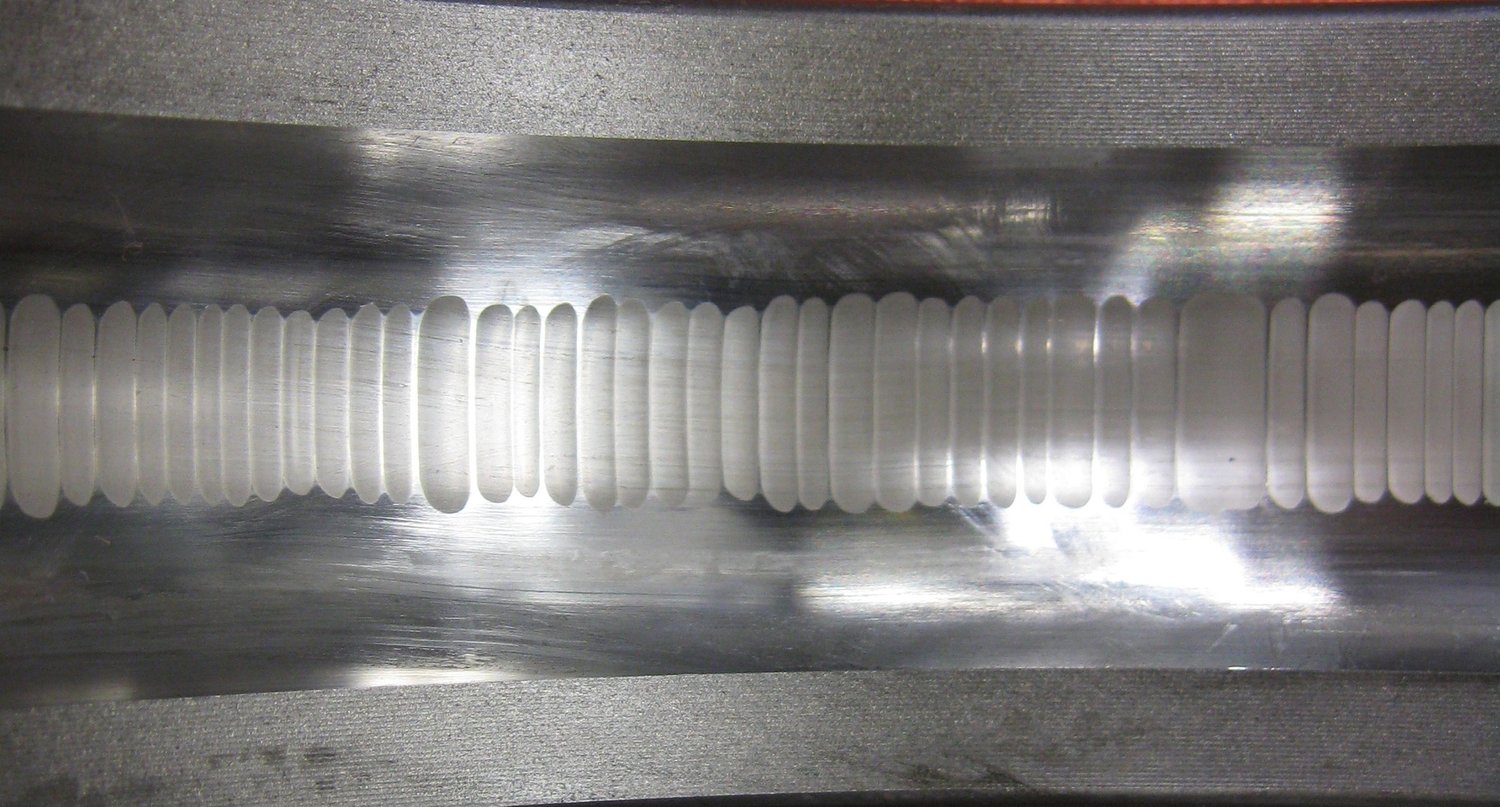

Noise and Vibration

Noise and vibration in industrial equipment are caused by current passing through the inner and outer rings and balls of the bearings and the corrosive effect resulting in dense groove striations in the form of “rubbing boards”. Electrically insulated bearings have inner and outer rings coated with insulating material to avoid the hazards of current passage and to solve noise and vibration problems.

Lubrication Failure

Electrically insulated bearings can effectively solve the problem of lubrication failure through the surface of the insulating coating to resist the damage caused by the shaft current so that it can avoid the lubrication failure caused by galvanic corrosion. In particular, the maintenance of high-speed bearings lubrication problems is critical to effectively reduce the maintenance costs of the equipment and to extend the service life.

Choosing the Right Insulated Bearing

Choosing the right insulated bearings is responsible for equipment and industrial production, which can greatly reduce maintenance costs and increase productivity at a later stage. Guidelines for choosing the correct insulated bearings generally relate to factors such as application environment, load and speed, insulation performance and cost-effectiveness.

Application Environment Analysis

Insulated bearings are used in a wide range of applications so that some equipment can operate in extremely harsh environments, such as humidity, corrosion, high temperatures and extreme cold. All of these factors affect material selection and sealing requirements for insulated bearings. According to the different environments, choose the required insulation bearings to ensure the safety and smooth operation of the equipment.

Load and Speed Requirements

Two other factors to consider when selecting an insulated bearing are load and speed requirements. On the one hand, the size of the load is taken into account; different types of insulated bearings are suitable for light, medium and large loads, respectively, and on the other hand, the speed at which the bearings are operated is taken into account to determine whether high-speed performance is required.

Insulation Performance Needs

When selecting insulated bearings, it is critical to consider insulation performance needs. Insulated bearings are coated to withstand up to 1,000 volts DC, and even coatings to withstand 2,000 volts or even 3,000 volts are also available depending on the customer’s needs. Insulated bearings with different coatings are selected for different voltage levels.

Cost-Benefit Analysis

Insulated bearings do need to be selected with cost-effectiveness in mind. Insulation increases machine uptime, reduces repair and maintenance costs, is simple to replace and is easy to install. The initial cost of selecting insulated bearings may be high, but considerations of long-term cost of use and reduced maintenance requirements make the total investment more economical.

Advantages of TFL Insulated Bearings

TFL insulated bearings have 10 years of rich experience in the industry field. We have always adhered to the original intention, focusing on the quality and performance of insulated bearings, and research and development of the most advanced bearing technology.TFL insulated bearings are made of high-quality silicon nitride and zirconium oxide materials sprayed on the inner and outer rings in electrically insulated bearings, which have excellent insulating properties. As a leading manufacturer of insulated bearings, TFL allows you to buy with peace of mind, use with TFL, as a leading manufacturer of insulated bearings, gives you peace of mind when buying and using them.

Advanced Insulation Technology

TFL Insulated Bearing Company adopts high-strength electric insulating materials and patented insulating coating technology to introduce the most excellent electric insulating products in the market.TFL electric insulated bearings can prevent the existence of equipment failure current interference, and other factors to provide a guarantee for the long-term stable operation of the machine.

Comprehensive Product Range

China Insulated Bearing suppliers and Insulated Bearing manufacturers are very numerous in the world.TFL Insulated Bearing is one of the excellent companies; our Insulated Bearing products can be supplied in different sizes with a wide range of models available to suit different industry sectors, providing you with diversified choices suitable for various applications.

Superior Performance

TFL insulated bearings have excellent electrical insulation properties and are manufactured with a special process to ensure insulation, mechanical properties and wear and corrosion resistance. Our insulating products are experimentally proven to be highly efficient, building brand strength and company reputation with excellent performance.

Reliable Quality Assurance

TFL Insulated Bearings has the most advanced bearing production equipment, bearing testing equipment, a first-class production line, and a strict quality control process, which directly guarantees the quality of bearing products. We are committed to selling brand bearings, such as SKF, NSK, KOYO, NTN, FAG and other international brands, as well as original brand bearings. Among many Chinese bearing manufacturers, we have won the trust and favor of many customers with our technical strength, flexibility, innovation and continuous research and development.

Conclusion

For your equipment performance and reliability, come to TFL Insulated Bearings for high-quality bearings! We will satisfy you with excellent products, satisfactory prices and attentive service. We have a professional technical research and development department and manufacturing plant ready to provide you with customized suggestions to improve the efficiency of your equipment! Upgrade to TFL Insulated Bearings today!

Frequently Asked Questions:

How do insulated bearings prevent electrical current damage?

Insulated bearings are made by coating the surface of the inner or outer ring with a layer of insulating material, and this coating performs the function of electrical insulation. The coating of insulated bearings is applied by a special spraying process, which cuts off the current circuit to prevent current damage.

In which industries is the use of insulated bearings most critical?

The use of insulated bearings is most important in modern industries, such as the railroad industry, metallurgical machinery industry, power industry, mining and petrochemical industries.

How do insulated bearings improve energy efficiency in equipment?

The function of insulated bearings is to reduce the passage of current through the bearing and prevent galvanic corrosion of the bearing. Therefore, frictional resistance during the operation of the equipment is reduced, and the vibration and noise of the equipment are also significantly reduced, which in turn improves the operating efficiency of the equipment.

What factors should be considered when choosing insulated bearings?

The selection of insulated bearings requires consideration of several factors: load magnitude and direction, high-speed performance, size and space, rotational accuracy, special environments and conditions, lubrication and economy.

What long-term economic benefits can businesses gain from using insulated bearings?

The long-term benefits that the use of insulated bearings brings to an organization include reduced maintenance costs, increased productivity, improved equipment reliability, a wider range of applications and longer equipment life.