Electrically Insulated Bearings

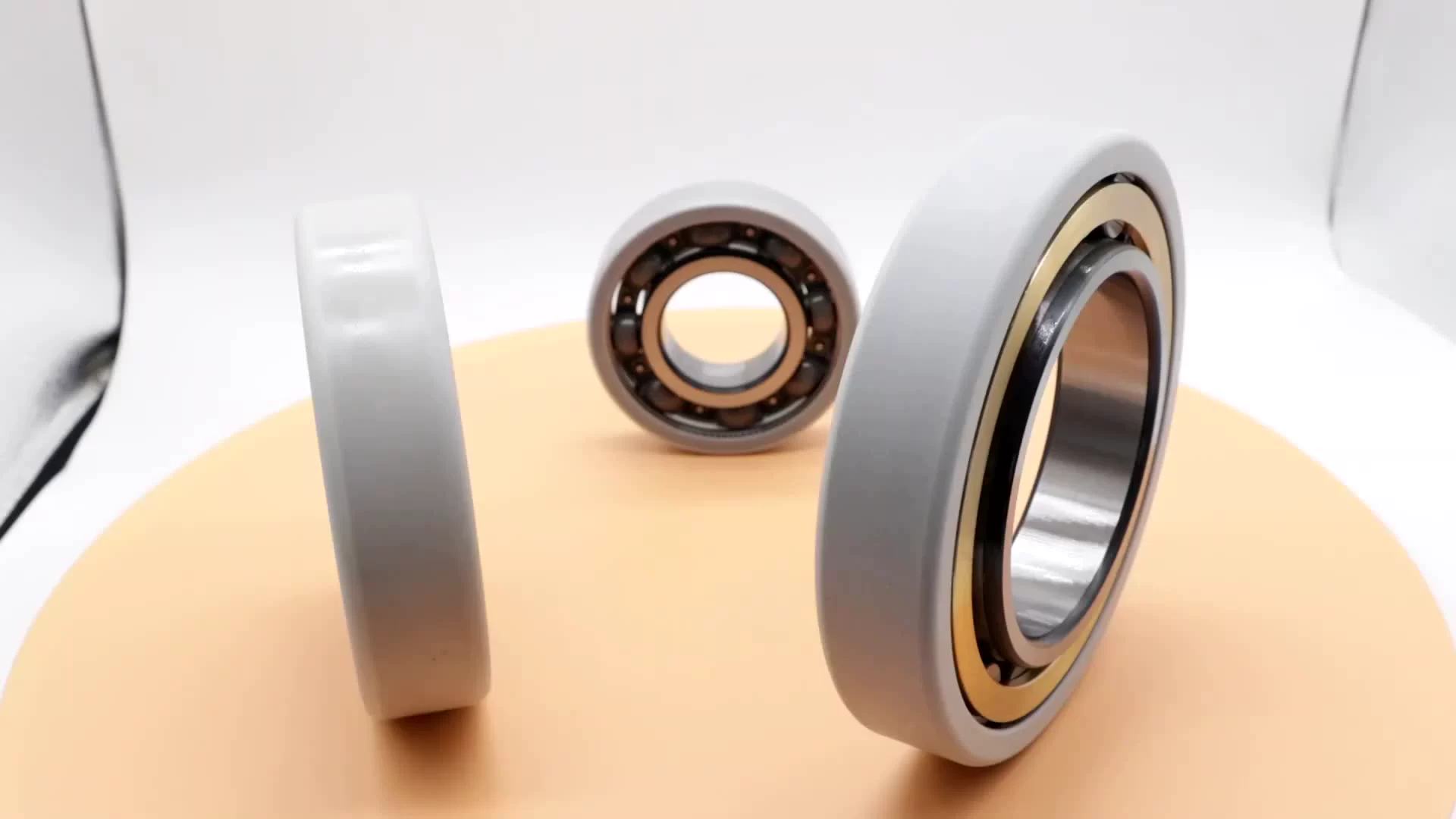

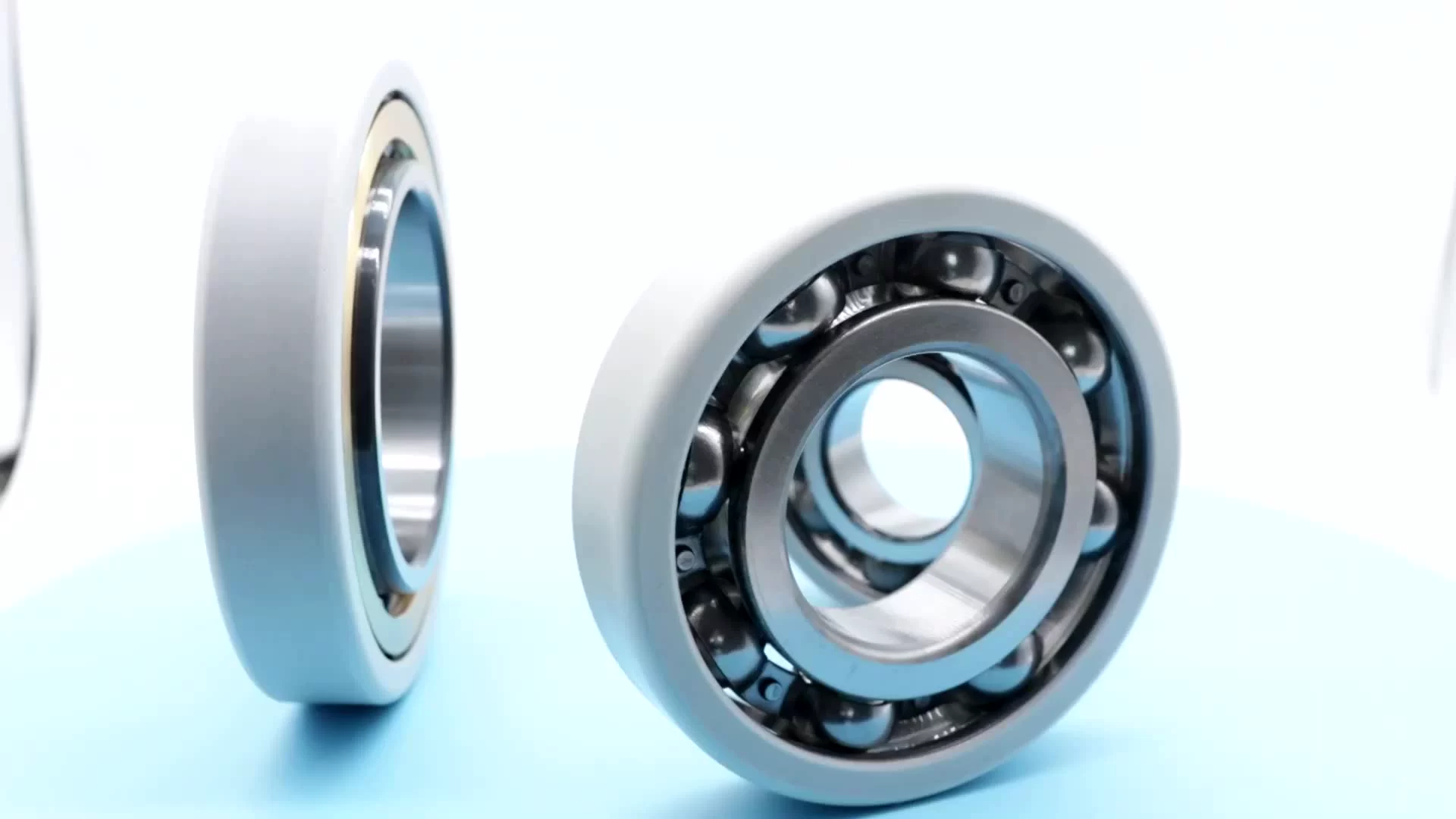

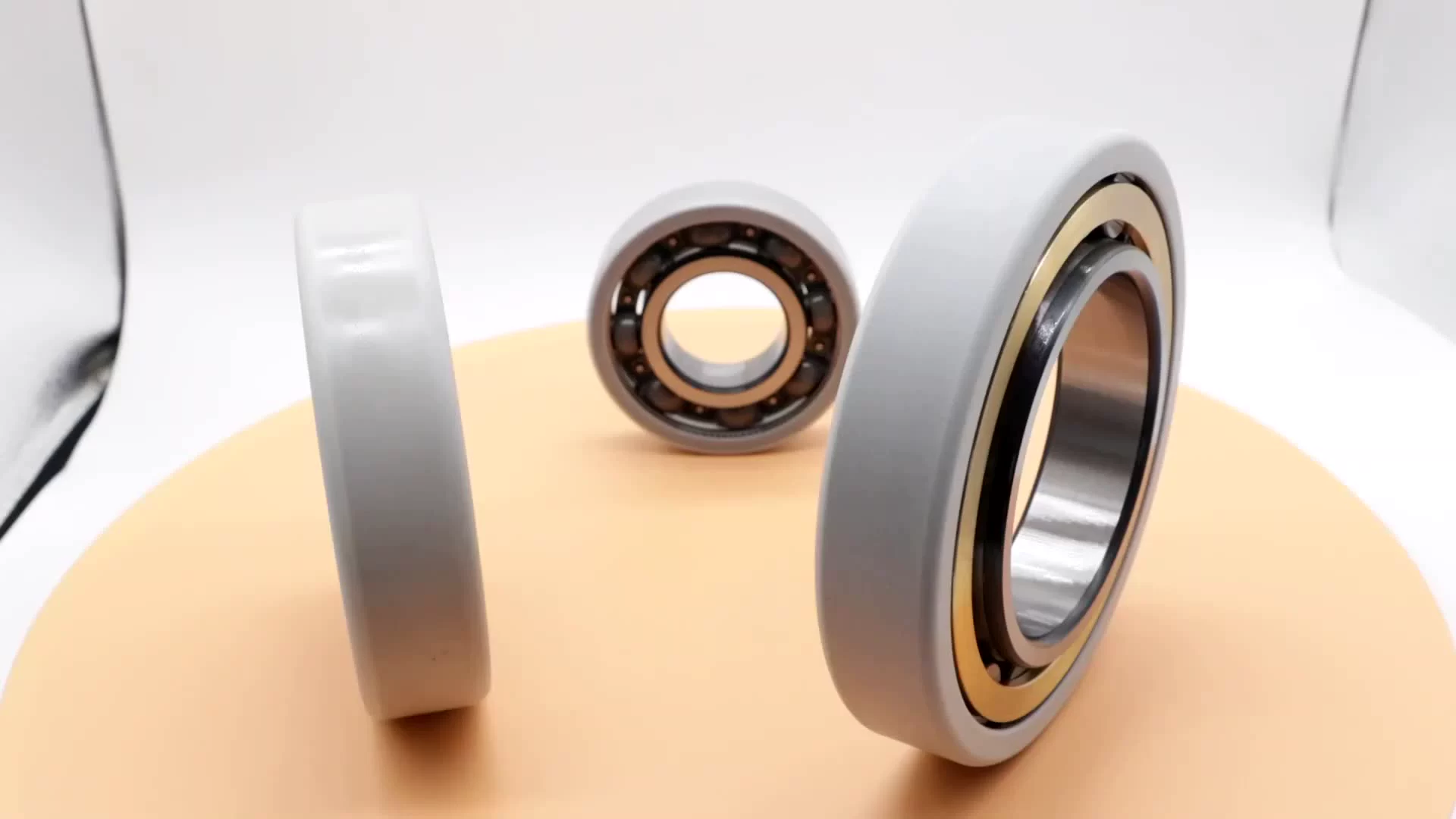

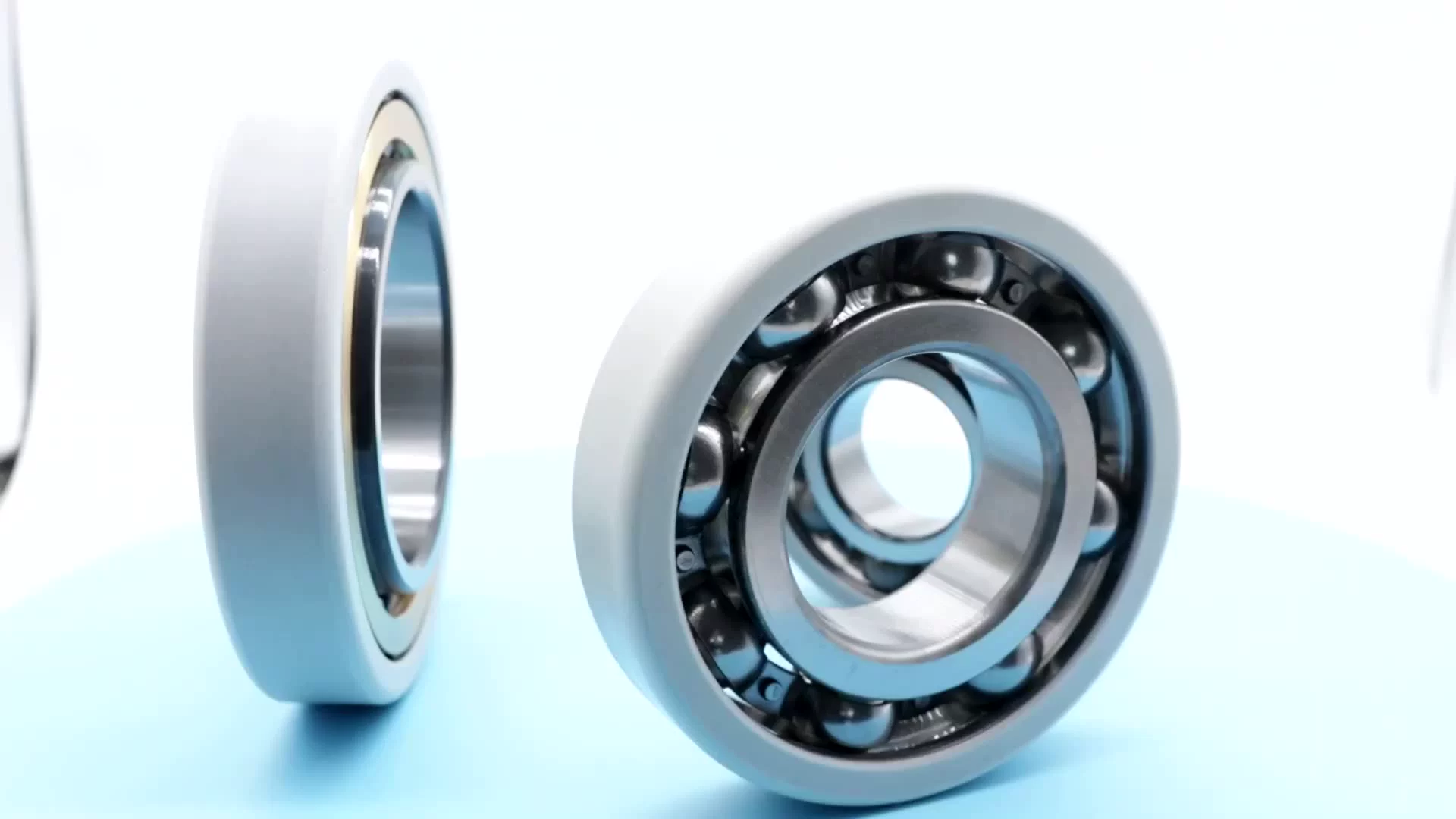

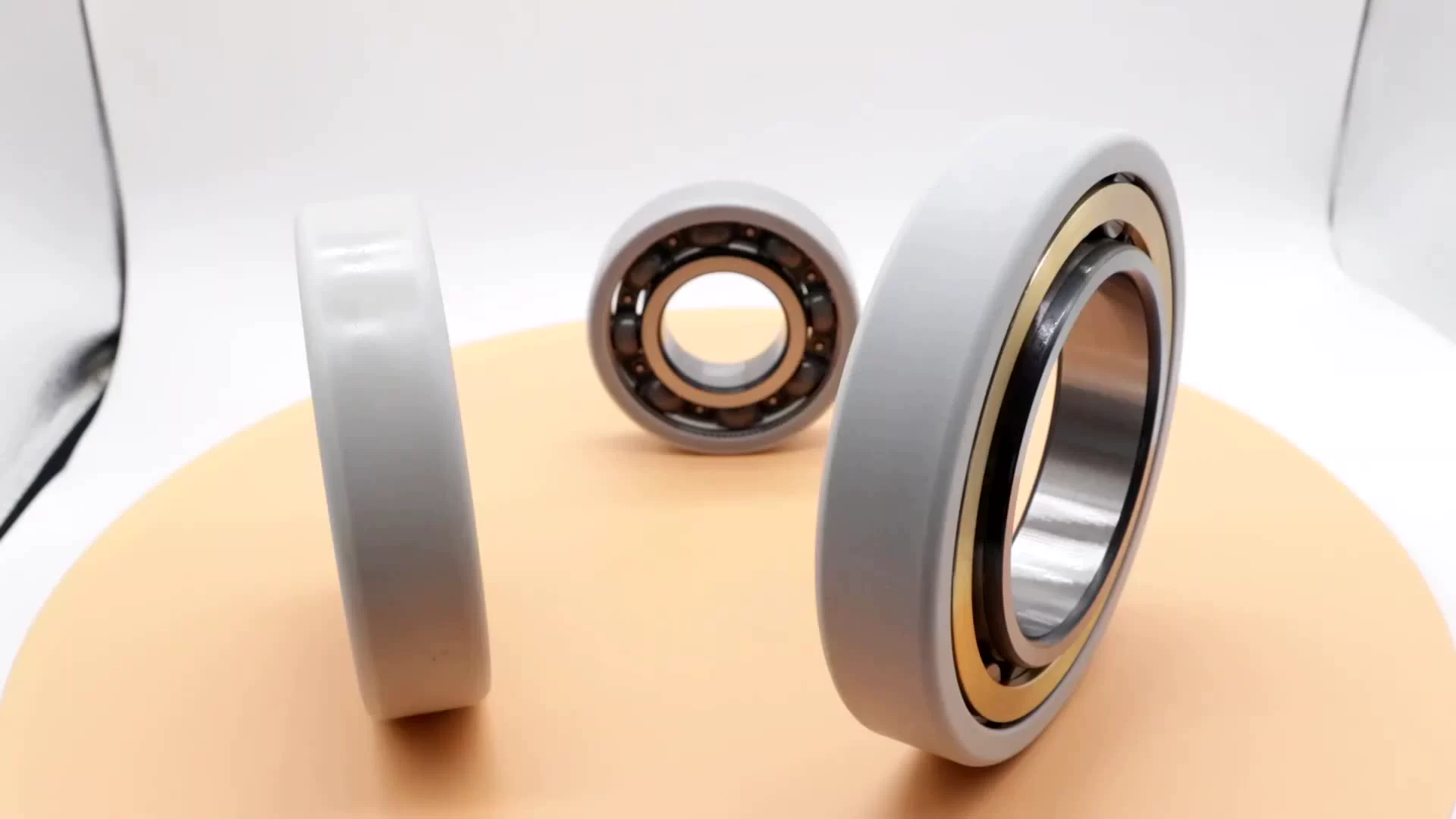

Insulated bearing (ceramic-coated bearings)refers to the ability to block the current through the bearing itself has insulating properties of the bearing of the general term. Its insulation performance is usually a special process in the bearing inner ring or outer ring coated with a protective layer of insulating material or its rolling body made of ceramic to achieve the purpose of insulation.

Insulated bearings are based on the type of bearings they belong to, and the bearings are insulated. Therefore, in addition to the original functions of all kinds of bearings, insulated bearings also have insulating properties. The most effective solution to the problem of current corrosion in bearings is the use of insulated bearings. Commonly, there are three types of insulated bearings: ceramic-coated, resin-coated, and ceramic rolling elements. Ceramic-coated bearings are the most widely used. This guide details what you need to know about insulated bearings!

FAQ

Latest content

Category

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.

All Prices in US Dollars