FAG Insulated Bearings

Introduction: The Revolutionary Impact of FAG Insulated Bearings

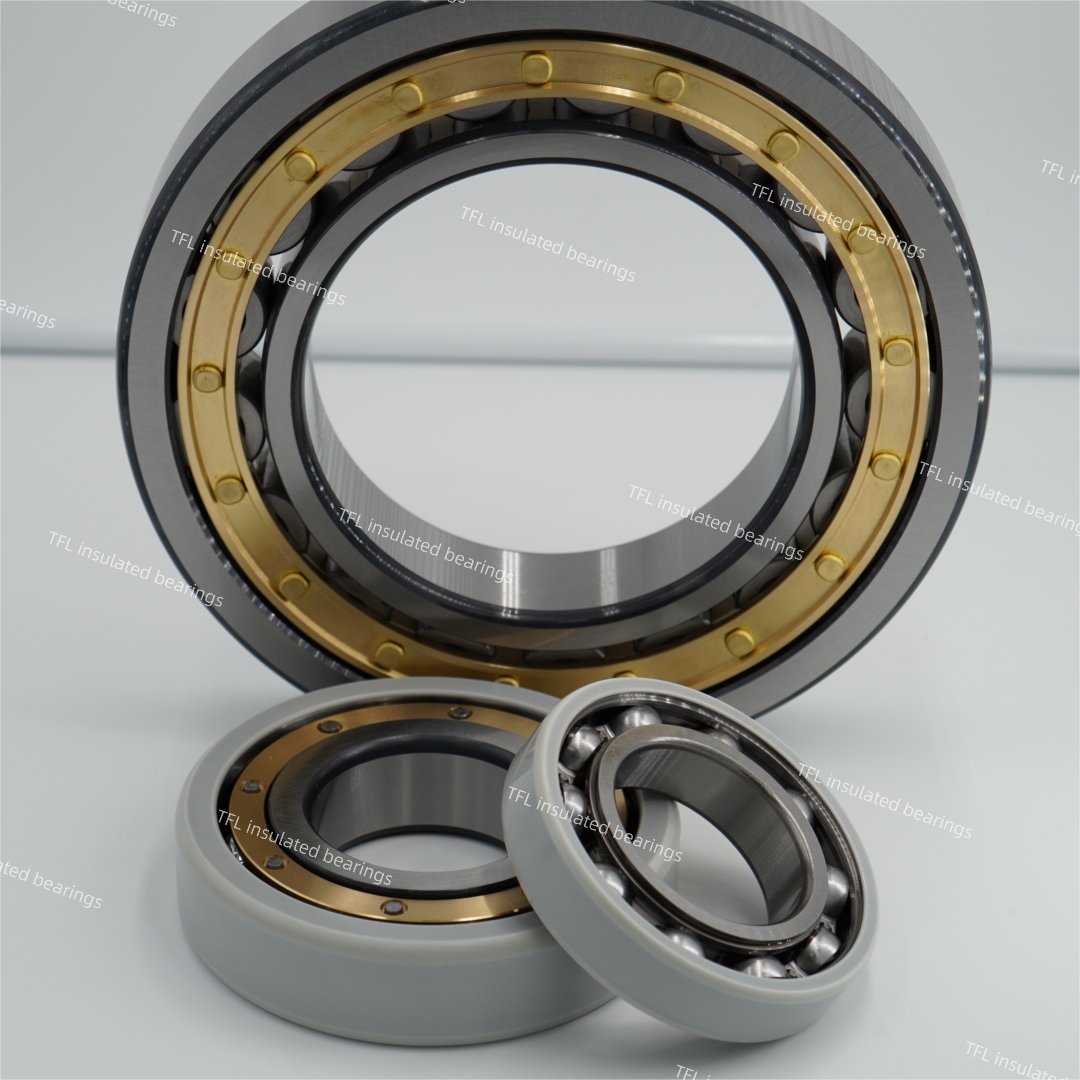

FAG bearings are fully certified in almost every possible field and have always played a very important role. FAG insulated bearings are insulated by using special materials and processes (e.g., ceramic coatings or ceramic rolling elements, as well as plasma spraying technology), which is an important technological innovation in the bearing industry. This technology improves the service life of bearings and broadens their field of application. The emergence of FAG insulated bearings has prompted the entire bearing industry to pay attention to insulation performance and has pushed up the industry standard. As technology advances, the performance and reliability of insulated bearings are also improving, further meeting the needs of a wide range of complex operating conditions.

What are FAG insulated bearings?

FAG insulated bearings are bearings that are electrically insulated and are mainly used to prevent the passage of electric current.FAG insulated bearings are mainly of the following types:

- Ceramic-coated electrically insulated bearings: These bearings have a ceramic layer on the inner ring, outer ring, or rolling element, which prevents the passage of electric current and realizes an electrically insulating effect.

- Hybrid bearings: Their rolling elements are made of ceramics, which are electrically insulated using ceramic materials to prevent the passage of electric current.

The evolution of FAG insulated bearings

The history of FAG bearings can be traced back to 1883, when Friedrich Fischer invented the ball grinder, the world’s first machine capable of grinding absolutely round steel balls. This invention is considered to be the cornerstone of the rolling bearing industry. This is why FAG bearings have long been recognized as a pioneer in rolling bearing technology. The FAG bearing brand originated from this genius invention, and in 1883 Friedrich Fischer established the world’s first bearing company, FAG Georg Schaeffler, in Schweinfurt, Germany. FAG bearings have been part of the Schaeffler Group since 2001 and play an active and important role in the Group’s aerospace, automotive, and industrial sectors.

TFL brand and FAG technology integration

FAG is known for its high-precision bearings, and the combination of FAG technology will significantly improve the performance of TFL Insulation Bearing products, especially in high-speed and heavy-duty applications. FAG’s advanced technology in rolling bearings will ensure greater durability, precision and efficiency, helping TFL insulation bearings better serve the market and customers. By exploring compatible technologies, conducting pilot applications and investigating various partnership models, TFL Insulated Bearings can capitalize on FAG’s technological strengths to drive innovation and market success.

How FAG Insulated Bearings Work and Their Technical Advantages

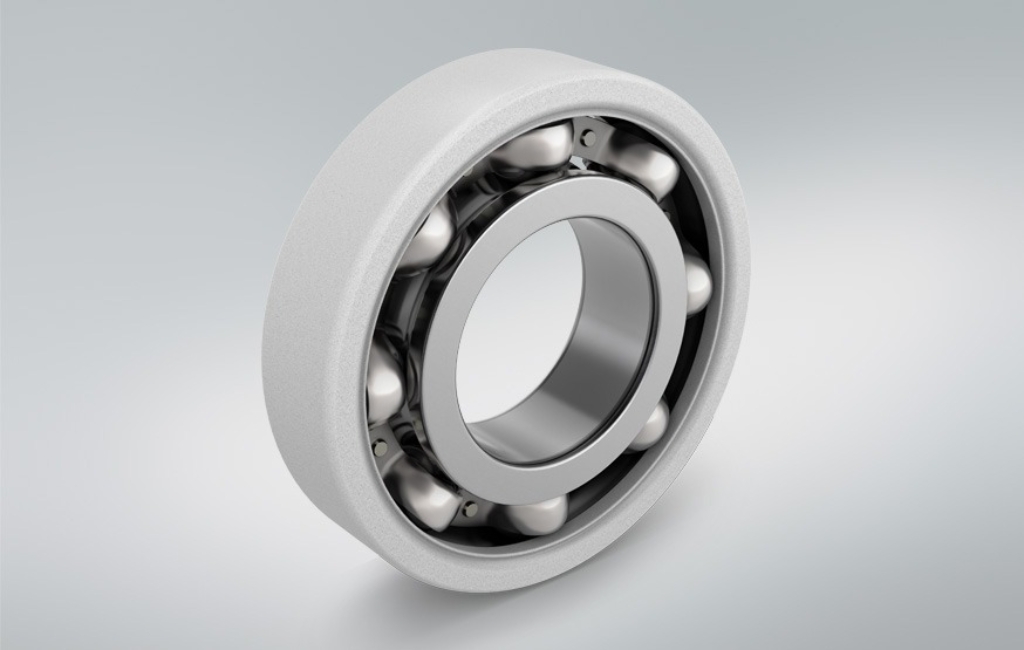

FAG insulated bearings are standard bearings with a ceramic coating Insutect on the outer or inner ring, which is applied to the bearing surface using a plasma spray coating. FAG insulated bearings have excellent electrical insulation properties, can withstand high loads and durability, as well as resistance to wear and high temperatures.

The basic structure of FAG insulated bearings

The basic structure of FAG insulated bearings mainly consists of an inner ring, an outer ring, balls or rollers, and a cage assembly.FAG insulated bearings are usually coated with a ceramic oxide coating on the outer or inner ring. This coating is applied to the bearing surface by plasma spraying, resulting in a ceramic coating and insulation.

Principles of electrical insulation

FAG insulated bearings are usually coated with a ceramic oxide coating on the outer or inner ring, which is applied to the bearing surface by plasma spraying. The ceramic coating has good insulating properties and prevents the passage of electrical currents, thus protecting the bearing from galvanic corrosion. In addition, FAG insulated bearings are available in a wide range of types, including bearings with the suffixes J20A, J20B, J20C, and J20AA, which are suitable for different voltages and size ranges.

FAG ceramic coating technology

FAG bearing coatings are applied using the plasma spraying method. In the plasma spraying method, an electric arc is generated between two electrodes, which ionizes the introduced inert gas. The resulting plasma jet is used as a carrier jet to deliver aluminum oxide powder to the equipment. The alumina powder is melted and sprayed at high velocity onto the outer or inner ring. The substrate material is roughened before the oxide layer is sprayed. The oxide layer is then sealed.

J20 Ceramic Coated Bearings

Ceramic-coated bearings are standard bearings with ceramic-coated Insutect A inner or outer rings. Bearings coated with Insutect A have a high degree of electrical insulation protection. Bearings with ceramic oxide coating are identified by the suffix J20 and the additional letter combination GA, GB, or GI. Previously, the suffixes AB, AA, or C were used.

- Dielectric breakdown strength

The coatings are subjected to 100% quality inspection and ensure a dielectric breakdown strength of at least:

- J20AB as insulation up to 1000 VDC

- J20AA, J20C as insulation up to 3 000 VDC

- J20B as insulation up to 500 VDC.

2. Types of coatings and value ranges

| Parameter | J20AB | J20AA | J20C | J20B | J20A |

|---|---|---|---|---|---|

| Puncture voltage | 1000 VDC | 3 000 VDC | 3 000 VDC | 500 VDC | 1 000 VDC |

| Operating environment | Dry, damp | Dry, damp | Dry, damp | Dry | Dry |

| Layer thickness | 100 um | 200 um | 200 um | ≤100 um | >200 um |

| Possible dimensions | 70 mm – 1400 mm outside diameter | 70 mm – 500 mm outside diameter | 70 mm – 340 mm inner ring bore | 70 mm – 1400 mm outside diameter | 70 mm – 500 mm outside diameter |

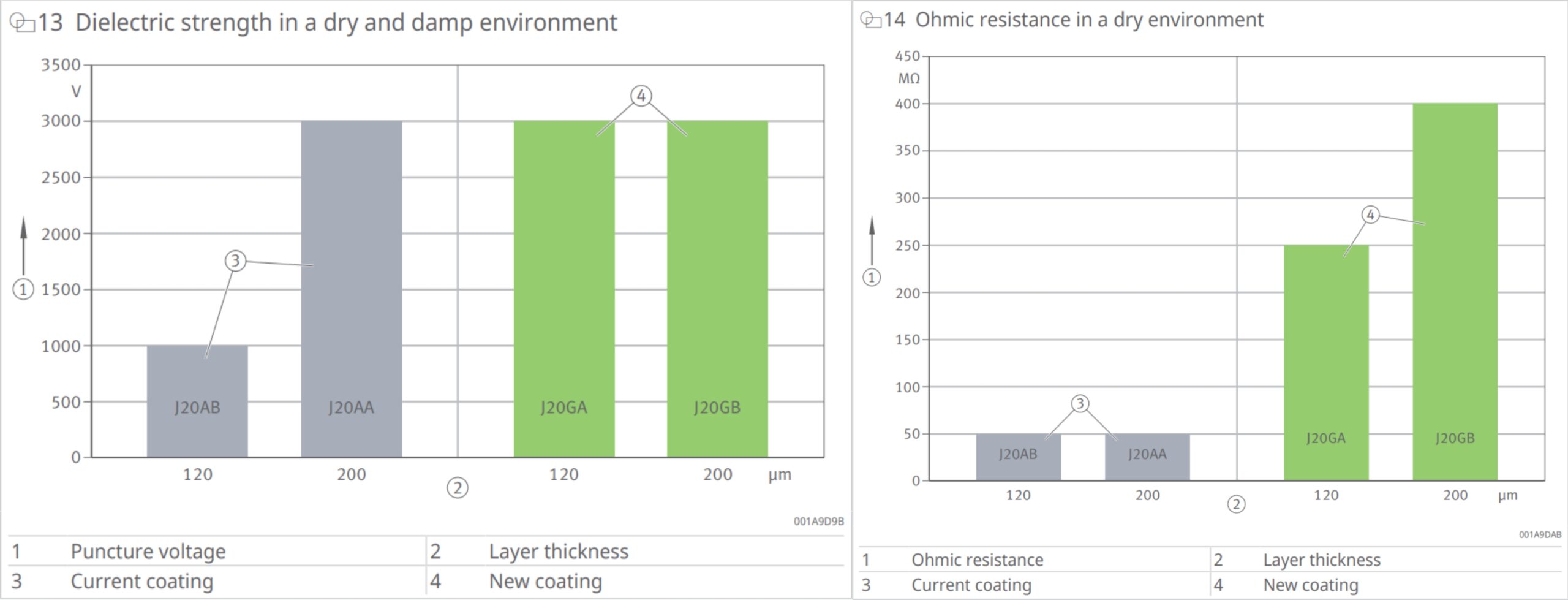

New J20G coating

The new J20G coating improves insulation properties Further system developments have improved the insulation properties of rolling bearings with the Insutect A coating. In addition to the improved electrical performance in dry environments, the performance under wet operating conditions has also been significantly improved. The graph below provides a comparison with the values of the previous coating:

- Parameters for Insutect A coating types J20G

| Parameter | Unit | J20GA | J20GB | J20GI |

|---|---|---|---|---|

| Bearing coating | _ | Outer ring | Outer ring | Inner ring |

| Layer thickness | µm | 120 | 200 | 120 |

| Operating environment | _ | Dry, damp | Dry, damp | Dry, damp |

| Electric strength | DCV | 3000 | 3000 | 3000 |

| Ohmic resistance | MΩ | 250 | 400 | 250 |

| Impedance, 6314, f = 100 kHZ | Ω | 273 | 428 | 583 |

| Possible inside diameters | mm | _ | _ | ≥ 70 |

| Possible outside diameters | mm | 70 … 800 | 70 … 800 | … 800 |

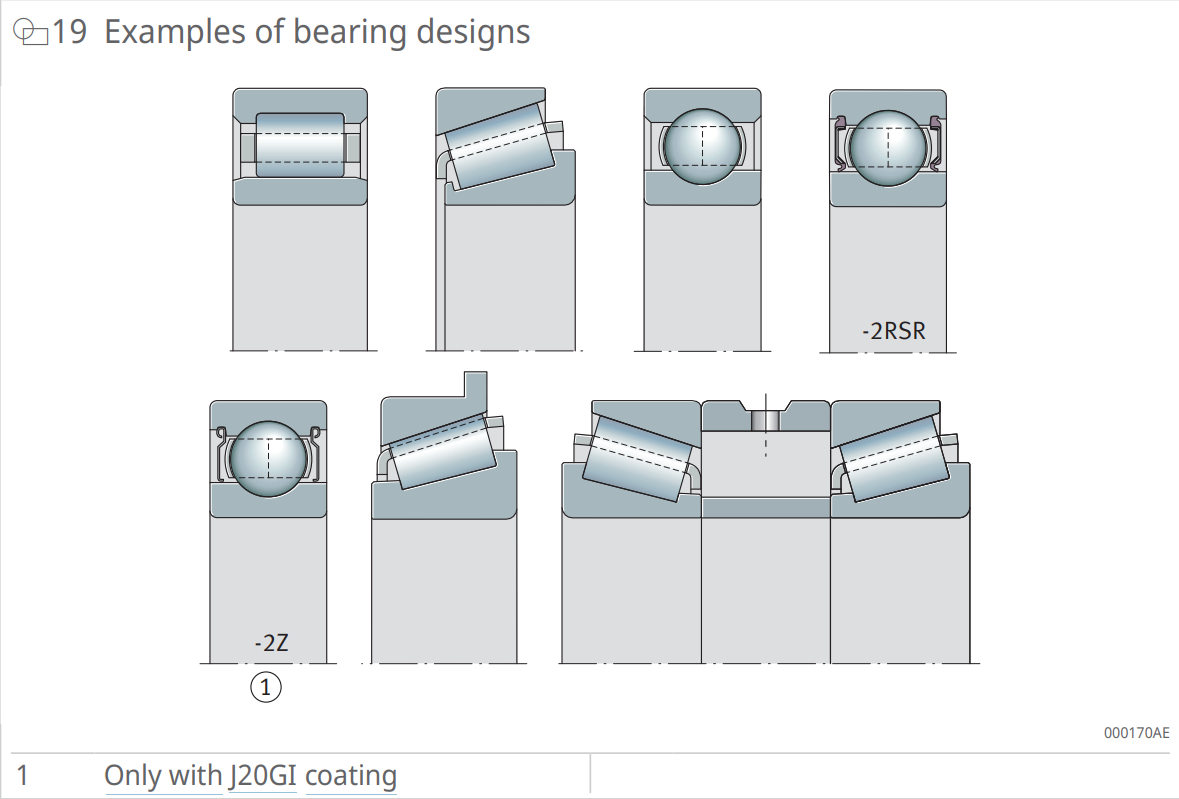

Bearing designs with ceramic coatings

- A cross-section of an existing bearing design with ceramic coating is shown below.

- Ordering example:

- Deep groove ball bearing with coated outer ring: 6214-2RSR-J20GA-C3

| 62 | Bearing series: 62 Deep groove ball bearing |

|---|---|

| 14 | Bore code:14 14 * 5 = 70 mm |

| 2RSR | Sealing: 2RSR Sealed on both sides, contact rubber seal |

| J20GA | Coating: J20GA Current insulation coating on the outer ring, layer thickness 120 µm |

| C3 | Radial internal clearance: C3 Radial internal clearance |

- Cylindrical roller bearing with coated outer ring: NU1018–XL–MP–F1–J20GB–C4

| NU10 | Bearing series: NU10 Cylindrical roller bearing |

|---|---|

| 18 | Bore code: 18 18 * 5 = 90 mm |

| XL | Premium brand: XL X-life |

| MP | Cage: MP Brass cage, single-piece |

| F1 | Variant: F1 Variant for traction motors |

| J20GB | Coating: J20GB Current insulation coating on the outer ring, layer thickness 200 µm |

| C4 | Radial internal clearance: C4 Radial internal clearance |

- Deep groove ball bearing with coated inner ring: 6330–M–J20GI–C4

| 63 | Bearing series: 63 Deep groove ball bearing |

|---|---|

| 30 | Bore code: Bore code |

| M | Cage: M Brass cage |

| J20GI | Coating: J20GI Current insulation coating on the inner ring, layer thickness 120 µm |

| C4 | Radial internal clearance: C4 Radial internal clearance |

Hybrid bearing

The replacement for Insutect A bearings is the FAG hybrid bearing. Hybrid bearings have rings made of rolling bearing steel and rolling elements made of ceramic. Hybrid bearings have the prefix HC. The rolling body has high wear resistance and is currently insulated. There are two types of hybrid bearings: ball bearings and cylindrical roller bearings.

Advantages of hybrid bearings

Hybrid bearings have an advantage over ceramic-coated bearings: Hybrid bearings have an extremely high resistance to current passage. Even at high temperatures, their DC resistance is in the GHz range. The capacitance has a typical value of 40 pF and is, therefore, 100 times lower than ceramic-coated bearings. Hybrid bearings achieve higher speeds with lower friction and, thus, lower operating temperatures. The rolling elements are lightweight and, therefore, have low friction. Reduced friction reduces CO2 emissions in the application. Hybrid bearings have better emergency running characteristics than standard bearings.

Hybrid bearings vs. standard bearings

Compared with standard bearings, hybrid bearings have the following characteristics:

- Comparable basic dynamic load rating according to ISO 20056- standard.

- Comparable basic static load ratings according to ISO 20056- Standard

- 20% increase in terminal speed

Therefore, hybrid bearings have the same dimensions and are suitable for retrofitting. In addition, hybrid bearings have twice the grease life of standard bearings. Hybrid bearings also offer advantages over standard bearings in terms of lifetime costs. The use of hybrid bearings can reduce product-specific life cycle costs by up to 20 %.

In addition, ceramic hybrid bearings have a longer grease life than standard bearings with lifetime lubrication. Hybrid ceramic designs are more economical than ceramic-coated bearings for smaller rolling bearings.

Applications of FAG Insulated Bearings

FAG insulated bearings are used in a wide range of applications, including the motor industry, wind power generation, railroad transportation and streetcars.

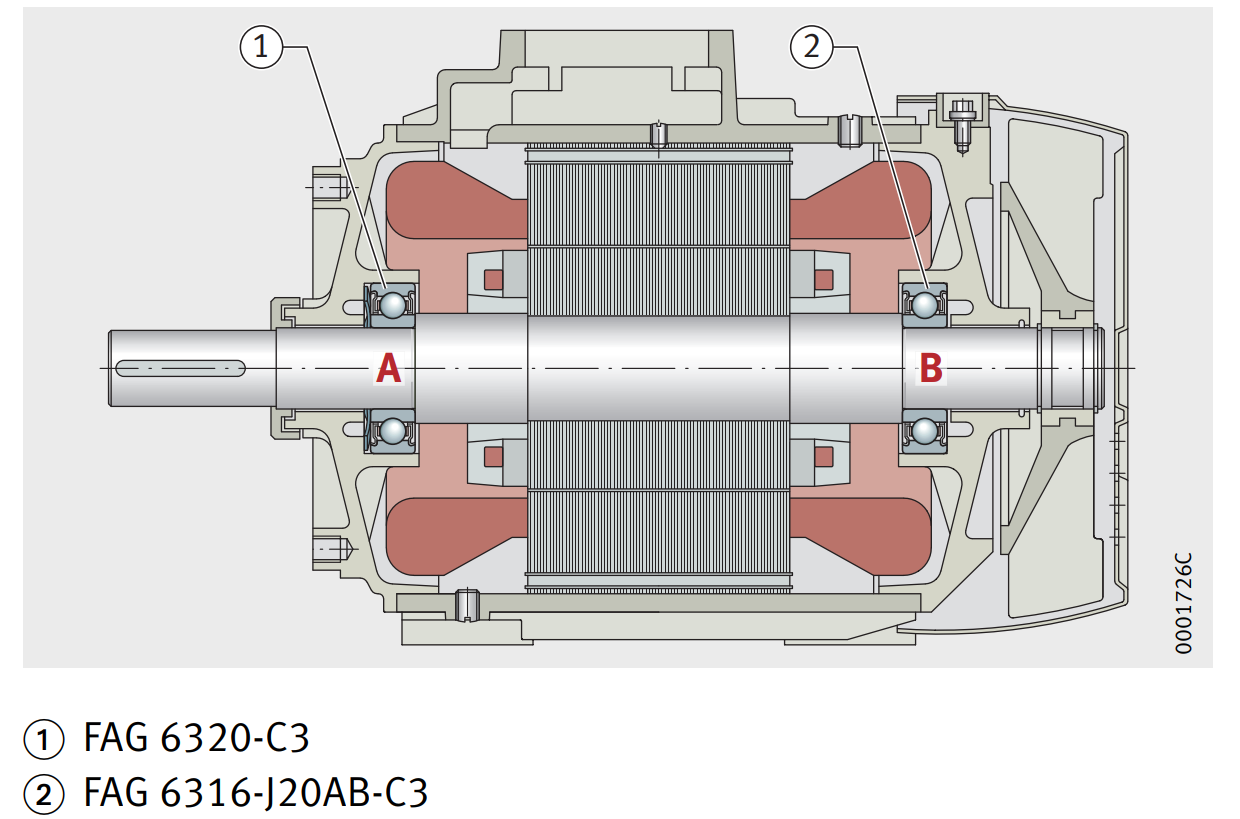

Applications in motors and generators

Deep groove ball bearings with J20AB coating are used in three-phase motors with current direction feed to prevent damage caused by current passage. Three-phase motors with current direction feed are mounted on the fan side of three-phase motors with current-insulated deep groove ball bearings FAG 6316-J20AB-C3 and deep groove ball bearings FAG 6320-C3 on the drive side. Current-insulated deep groove ball bearings interrupt the current flow generated by induced voltages along the shaft. Both bearings are lubricated with grease. Supplementary lubrication facilities are provided.

Use in wind power generation

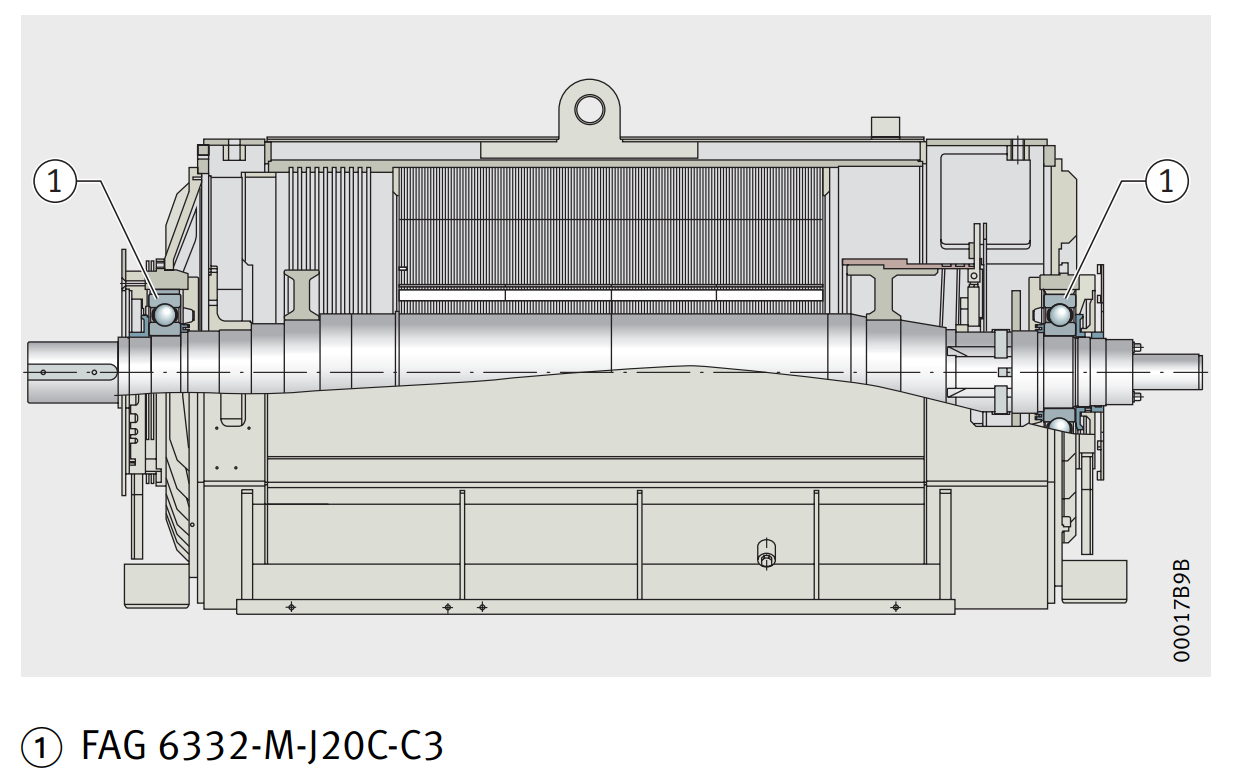

In wind turbines, deep groove ball bearings with J20C coating are used to prevent damage due to current passage. In order to avoid damage to the bearings due to induced voltages caused by the passage of electric current, the wind turbine is fitted with two deep groove ball bearings FAG 6332-M-J20C-C3. Due to the voltage transitions, high-frequency electric currents will flow through both bearings. The best way to prevent current flow for these deep groove ball bearings is to apply a 200 m coating to the inner ring.

Applications in railway transportation

Railroad bearings are exposed to various harsh conditions, including vibration, heavy loads, and contaminants such as dust and moisture. FAG insulated bearings can withstand these challenges while maintaining their insulating properties, ensuring reliable performance even in harsh environments. Not only that, it also plays a role in reducing environmental pollution in society. A comparison of CO2 emissions from standard cylindrical roller bearings and hybrid cylindrical roller bearings used in high-speed train drives over a period of one year and a distance of approximately 600,000 kilometers by FAG insulated bearings shows a reduction in CO2 emissions of 20 kilograms.

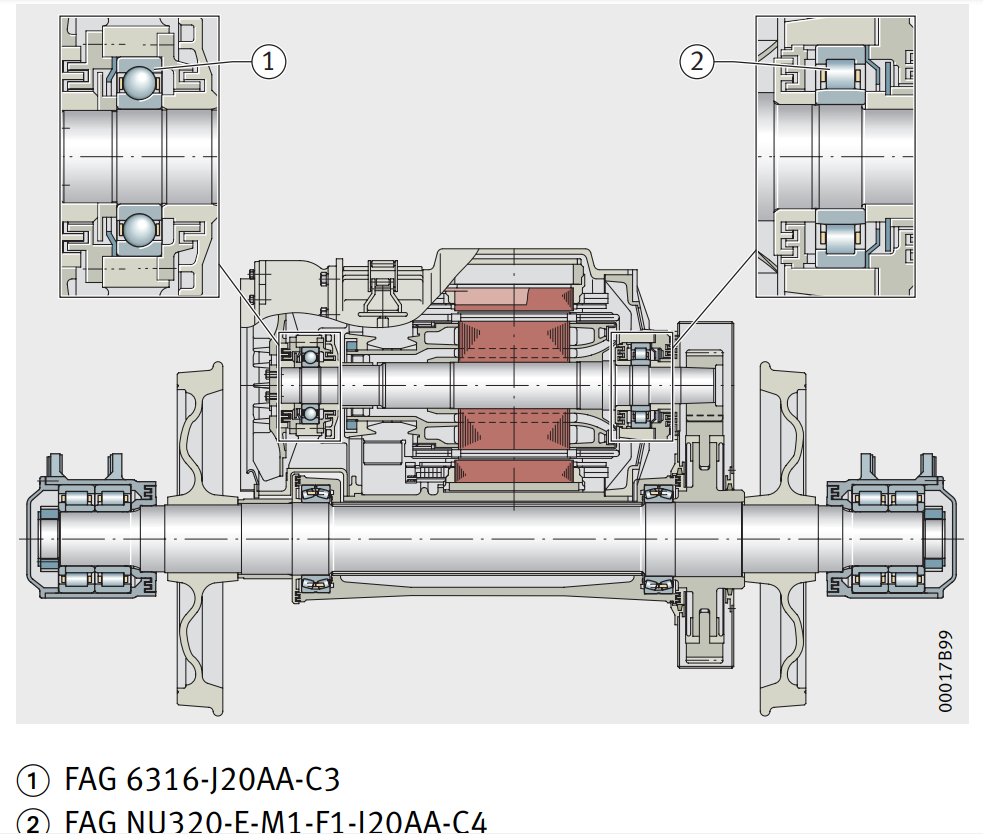

Application of traction motor bearings in streetcars

Deep groove ball bearings and cylindrical roller bearings with J20AA coating are used in three-phase motors with a rated power of 500 kW to prevent damage due to current passage. The rotor shafts of three-phase motors are fitted with deep groove ball bearings FAG 6316-J20AA-C3 (fan side) and cylindrical roller bearings FAG NU320-E-M1-F1-J20AA-C4 (drive side). The cylindrical roller bearings and the deep groove ball bearings are coated with a high-quality coating J20AA. Both bearings are lubricated with grease and protected against contamination and environmental influences by labyrinth seals. Supplementary lubrication facilities are available.

Benefits and Advantages of FAG Insulated Bearings

The advantages and benefits of FAG insulated bearings include the following:

Extending equipment lifespan

High rigidity and long life: FAG insulated bearings form a coating of uniform thickness and very strong adhesion on the surface of the outer or inner ring by means of a special spraying process. They are able to withstand high voltages and are unaffected by moisture and humidity, which further enhances the rigidity and service life of the bearings. At the same time, playing a better role in protecting the equipment also extends its life.

Improving energy efficiency

Electrical insulation properties: FAG insulated bearings with ceramic coatings, or ceramic rolling elements can effectively prevent the passage of electric current, avoid the galvanic corrosion effect of induced electric current on bearings, and prevent the damage caused by electric current to grease and rolling elements and raceways, thus increasing the service life of bearings. As a result, the productivity and energy efficiency of the equipment is greatly increased.

Enhancing system reliability

FAG insulated bearings have the advantages of high transmission efficiency and high running accuracy.FAG rolling bearings have high transmission efficiency, less heat generation, reduced lubricant consumption, and lubrication maintenance is more economical. FAG rolling bearings have small internal clearance, high machining accuracy, high running accuracy, can increase the rigidity of the bearing by preloading method, and are suitable for precision machinery. Therefore FAG insulated bearings are very helpful for improving system reliability.

Reducing maintenance costs

The use of FAG insulated bearings brings significant economic benefits to companies. By reducing equipment failures and downtimes due to bearing damage, the company reduces maintenance and production costs. At the same time, the long life and reliability of the insulated bearings improve the overall performance and utilization efficiency of the equipment, creating more value for the company. At the social level, FAG insulated bearings contribute to sustainable development by reducing equipment failures and downtime, lowering energy consumption and emissions, and so increasing energy utilization and reducing environmental pollution.

Conclusion

To summarize, FAG insulated bearings provide important technical support and guarantee for the power industry and other industrial fields by virtue of their own advanced insulation technology and refined bearing product types, which enable the bearings to have excellent insulation performance, long service life, and the ability to adapt to complex environments. As the Chinese agent of FAG bearings, TFL insulated bearings specializes in the sale of FAG original imported bearings, complete models, sufficient stock, high-quality bearings with high precision, and smoother operation; welcome to consult!

Frequently Asked Questions:

- How to choose the right FAG insulated bearing?

Selecting the right FAG insulated bearing requires consideration of the following aspects:

- Breakdown strength of the insulating coating: FAG insulated bearings have a breakdown strength of the insulating coating of at least 1,000 V (J20AB coating), 3,000 V (J20AA/J20C coating) or 500 V (J20B coating).

- DC resistance value: At room temperature, the DC resistance value of FAG insulated bearings can reach 1GΩ to 10GΩ. When the humidity rises, the resistance value decreases, but there are still a few MΩ resistance values at 60℃.

- AC impedance: The insulation layer is similar to a capacitor, and bearings with ceramic oxide coatings typically have capacitance values of 2 nF to 20 nF. The capacitive impedance of bearings under an AC voltage ranges from 0.15 MQ to 1.5 MQ.

- Application Scenario: FAG insulated bearings are widely used in electric power, railroad, machinery and metallurgy, mining machinery, petrochemical, and other industries. Select the appropriate bearing type and coating type according to the specific application scenario.

- Dimensions and tolerance grades: The dimensions and tolerance grades of FAG insulated bearings maintain strict interchangeability with standard bearings.

- Installation guide for FAG insulated bearings.

FAG Bearing Mounting Tips:

- When mounting, under no circumstances can tapping mounting the force exerted on the FAG bearing, never through the rolling body from one bearing ring to another bearing ring transfer; otherwise, it may cause damage to the raceway. Depending on the type and size, we can choose mechanical, heating, or hydraulic methods for this.

- When installing the eccentric bushing, the eccentric bushing should be put on the eccentric step of the inner bushing of the bearing and tightened by hand in the direction of rotation of the shaft. Then, the small iron rod should be inserted into or pressed against the countersunk hole on the eccentric bushing. The small iron rod should be struck with a hand hammer in the direction of rotation of the shaft to make the eccentric bushing firmly installed, and finally, the hexagonal screws on the eccentric bushing should be locked.

- Do not tighten the bolts holding the bearing housing first, but allow the bearing jacket to rotate inside the housing before tightening the bearing housing bolts.

- Apply lubrication to the mating surfaces of the housing and the bearing, and install the bearing into the housing.

- For clearance-fit bearing rings, it is recommended that a thin layer of creep corrosion inhibitor be applied to the mating surfaces.

- Routine maintenance and inspection.

Routine maintenance and inspection of FAG insulated bearings mainly includes the following aspects:

- Cleaning: Keeping the bearings and their surroundings clean is the first task of maintenance. Periodically clean the area around the bearing to ensure there is no residue or debris.

- Lubrication: Lubrication maintenance is critical to the normal operation of the bearings. It is important to select the proper lubricant for the type of bearing and the operating environment and to replace the lubricant periodically, usually based on time of use and mileage.

- Temperature monitoring: Bearings generate a certain amount of heat during operation, so temperature control is very important. It is important to check the bearing temperature regularly to ensure that it is within the normal range.

- Regular Inspection and Maintenance: Regular inspection of the bearings is the key to preventing failures. It is important to check the appearance, lubrication, and fixation of the bearings, etc., so that potential problems can be detected and dealt with in a timely manner.

- Avoid overloading: Overloading is one of the common causes of bearing damage. Ensure the equipment operates within the rated load range and avoids overloading.

- Reduce shock and vibration: Shock and vibration can cause serious damage to bearings. It is important to avoid exposing bearings to shock or vibration to minimize the risk of damage.

- Common problems and solutions for FAG insulated bearings.

Problem 1: FAG bearing surface peeling, peeling and jamming phenomenon.

The reason for this problem is mainly due to the FAG bearings bearing load being too large, and installation is not standardized, there being foreign objects in the bearing inside, the use of lubricants is not appropriate, and so on. In the use of FAG bearings before to check whether the installation is fully standardized, the use of the process to avoid the occurrence of FAG bearing load phenomenon, in the use of fag bearings, the need for lubrication, to check whether the lubricant is qualified, whether there is no foreign matter into the lubrication, and in the lubrication is to clean the bearing surface and then coated with lubricant.

Problem 2: FAG bearings have cracks, fissures and fractures.

The reason for this problem is mainly due to the installation; the bearing received a blow, and in the use of the process of bearing load is too large, or FAG bearings bear too much shock load and so on. Therefore, we had better change the traditional installation method when installing FAG bearings, using the hot mounting method for installation, and the use of FAG bearings in the process of load conditions should be frequently checked.

Problem 3: fag bearing indentation, pitting wear phenomenon.

The emergence of this type of problem is mainly because FAG bearings have been invaded by foreign objects inside, resulting in the use of the process of bearing damage by foreign objects. Therefore, regularly check the sealing of fag bearing sealing device on time, find abnormal, timely improvement, in addition, is to do a good job of bearing lubrication.