Areas of Application for Electrically Insulated Bearings

Introduction

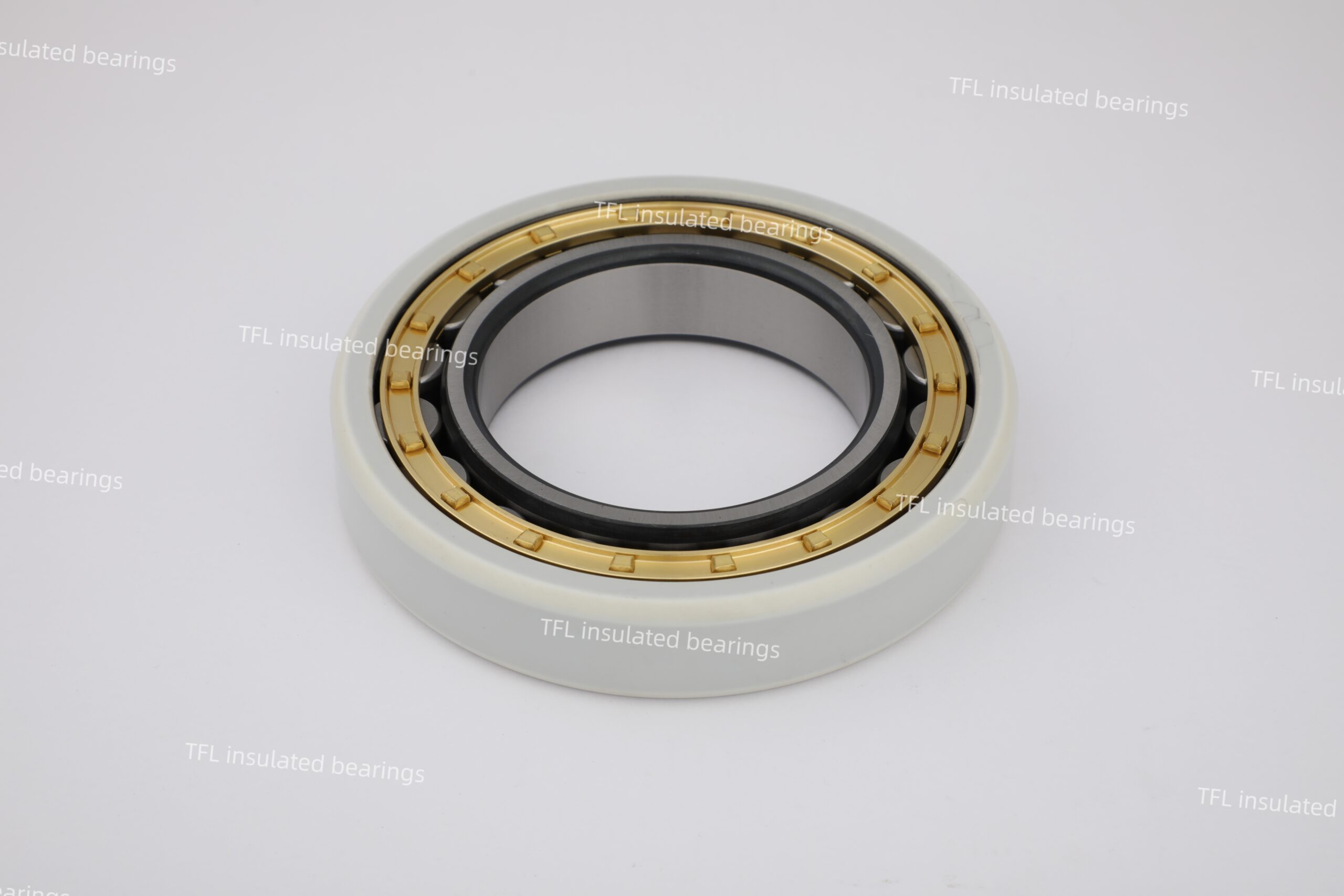

Electrically insulated bearings play a vital role in modern industry. Electrically insulated bearings, also known as insulated bearings, can block the passage of electric current and have excellent insulating properties, which makes electrically insulated bearings widely used in many industrial fields.TFL insulated bearings are produced with advanced spraying technology, in which insulator materials are sprayed on the inner and outer rings of the bearings to produce high-quality insulated bearings. TFL is also the agent of many famous brands, such as SKF, FAG, NTN, etc. The bearings we sell are used in various industries.

Applications in the Power and Energy Sector

TFL insulated bearings are used in the power and energy industry in applications such as wind turbines, solar power plants, and inverter drive motors:

Insulated bearing solutions for wind turbines

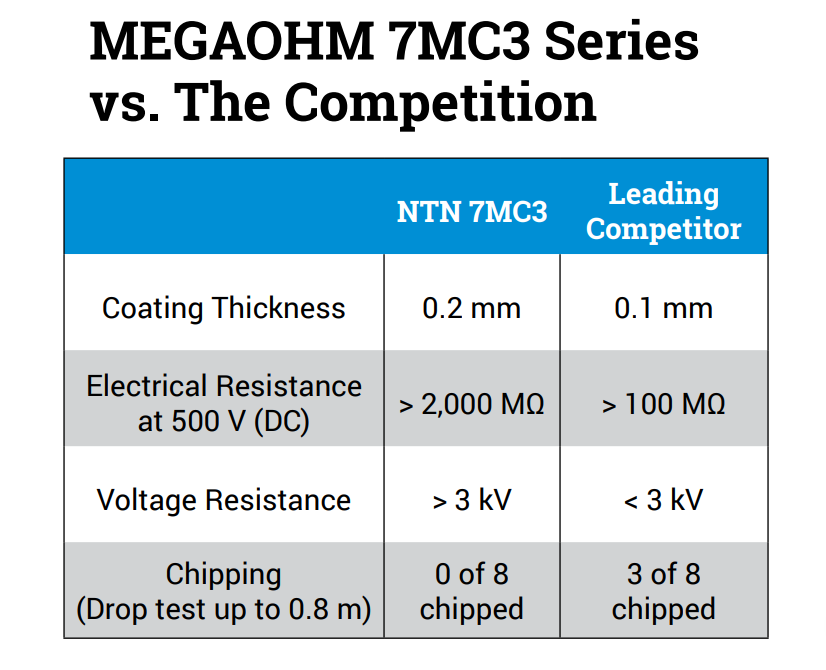

The problem faced by the bearings in wind turbines is firstly the stray current, and secondly, the location may be offshore, outdoors, and in other harsh environments. If current is transmitted through the bearings, it can lead to micro pitting and other types of surface damage. Eventually, the bearings may fail, possibly leading to catastrophic failure of the generator itself. On top of that, it can be costly to repair – especially if it is located offshore. Insulated bearings are non-conductive and resistant to damage caused by galvanic corrosion. This reduces maintenance frequency and improves weather resistance. Bearings can be protected by using different insulation levels to protect wind turbines and increase wind energy production. At the most basic level, ceramic surface coatings help to resist small currents, e.g., NTN’s MEGAOHM 7MC3 series of insulated bearings 7MC3-6214C3/7MC3-6220C3/7MC3-6311C3 For more severe cases, hybrid ceramic bearings with ceramic rollers can be used, e.g., FD-R1025/NKE hybrid ceramic bearings. 6330-C3-HYB. They have no electrical conductivity and have a long service life.

Use in solar power equipment

The application of insulated bearings in solar power generation equipment is mainly to solve the problem of current damage to bearings. When the motors in solar power generation equipment are in operation, due to electromagnetic induction and current flow, galvanic corrosion may occur on the bearings, resulting in damage to the bearings. Insulated bearings prevent the current from passing through the bearings by plating a layer of ceramic coating on the surface of the bearings, which acts as an electrical insulator and prevents the occurrence of a galvanic corrosion phenomenon. This coating is resistant to voltages of up to 1,000 V, ensuring that the bearings can still function properly in high-voltage environments. High load-carrying capacity, stiffness, and positioning accuracy play a crucial role here. These characteristics are absolutely critical to achieving safe, smooth, vibration-free bearing operation in solar collectors. The bearings must also withstand high forces and moments, such as sudden gusts of wind. Bearing support is, therefore, crucial for the reliability and cost-effectiveness of solar power plants.

Bearing protection for VFD-driven motors

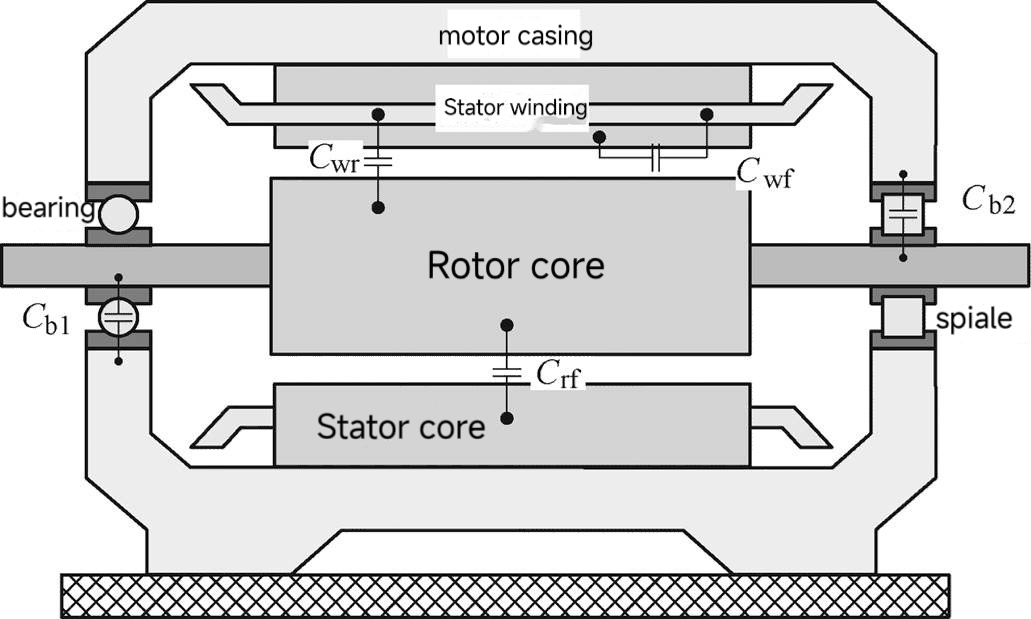

Due to the pulse width modulation (PWM) power supply, the inverter outputs a high-frequency, high-dv/dt common-mode voltage, which is induced between the rotor shaft and the chassis as a result of coupled conduction through the parasitic capacitance inside the motor. When the motor shaft voltage exceeds the insulation threshold of the lubricant film, the energy stored in the lubricant film will be released in the form of an arc discharge, forming an Electrical Discharge Machining (EDM) shaft current. Insulated bearings for Vfd motors are available in a variety of insulated ball and roller bearing designs. High-precision insulated bearings 6230/C3VL2071 are deep groove ball designs with dimensions of 150*270*45mm, with the same dimensions and design as normal bearings 6328M/C3. The biggest difference is the 6230-J20AA-C3 bearing with an aluminum oxide coating; the resistance of the coating can reach 3000VDC.

Innovative Applications in Transportation

TFL-insulated bearings are also used in transportation applications such as high-speed railroads, electric vehicles, aerospace, etc.

Insulated bearing systems in high-speed railways

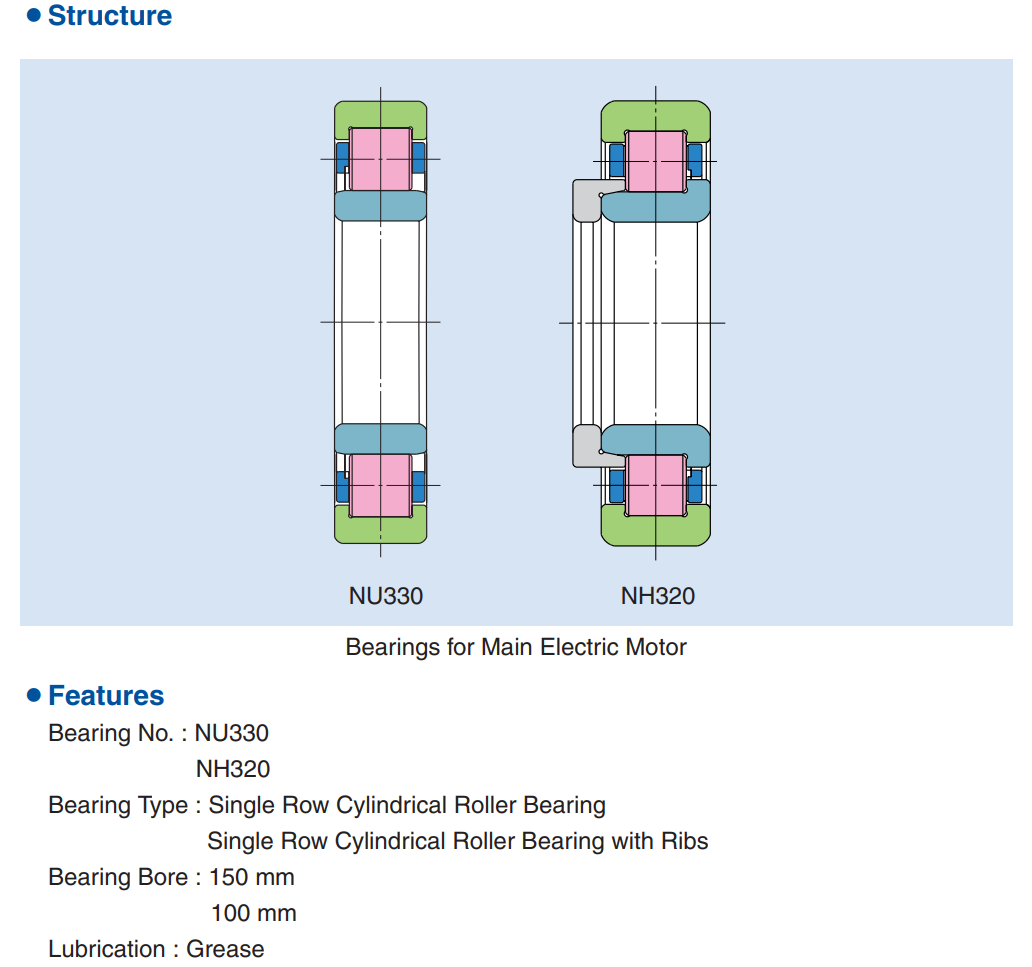

In high-speed trains, the insulated bearings are characterized by 1. high speed: the running speed of high-speed trains is generally more than 300km/hour, so the high-speed train bearings must have the characteristics of high-speed operation.2. high load: the high-speed train bearings are subject to high axial and radial loads during the running process and thus have the characteristics of high loads.3. high accuracy: the high-speed train bearings must have high accuracy and precision to ensure the smooth and safe running of the train.NSK, NTN, SKF, and other brands provide a variety of bearings for axles, drives, and traction motors for railroad vehicles, which help high-speed trains improve safety, reduce noise, and support high-speed operations. Such as SKF 1639454B railroad bearings 1637549AA, NTN insulated bearings NH320, NU330, etc.

Applications in electric vehicle drive systems

The electric vehicle motor is one of the core components of electric vehicles, and it consists of the drive circuit, rotor, stator, end cap, bearing, and other parts. An electric vehicle motor is a device that converts electric energy into mechanical energy, and its working principle is different from that of a traditional fuel engine, which is mainly realized through electrical and magnetic effects. Most electric vehicle motors use insulated bearings to reduce insulation loss and failure rate. Insulated bearings are not subject to wear, looseness, etc., which can lead to damage and malfunction of automotive motors compared to conventional bearings. On the contrary, insulated bearings can greatly reduce the loss and failure rate, ensure the long-lasting performance of automotive motors, and improve reliability and lifespan.

Special requirements in aerospace

Aerospace belongs to the field of emerging industries; with the progress of aviation engine design and transfer of energy and speed increase, power continues to improve, push ratio and power to weight ratio continue to increase, which requires aviation-bearing materials with high-temperature resistance to 350-500 ℃, high surface hardness, high wear resistance, good fracture toughness, impact toughness, and excellent corrosion resistance. Aviation bearings require bearings must be high precision, high strength, low friction, and stable reliability. Rocket turbopump engine with turbopump rotary shaft bearing requirements in the ultra-high-speed low-temperature liquid fuel environment liquid hydrogen (-253 ℃) liquid oxygen (-183 ℃) environment must be stable. High-nitrogen stainless steel bearings can meet the requirements of the application environment in the fields of aviation, aerospace, nuclear power main bearings, rocket fuel pump bearings, as well as nuclear power drive mechanisms.

Insulated bearing solutions in marine transportation

In marine transportation, insulated bearings are mainly used to ensure that equipment can operate normally in wet and corrosive environments and avoid electrical failures. Insulated bearings are usually used in high-voltage motors, fans, and other equipment to prevent electrical short circuits or performance degradation due to humid environments. The insocoat insulated bearing is a bearing suitable for use in high voltage motors and other environments where insulation is required. The bearings provide stable performance and support for motors even in wet and corrosive conditions due to the special manufacturing process and insulating materials. insocoat insulated bearings utilize high-quality ball bearings with insulating coatings or insulating materials to prevent the conduction of electrical current through the bearings, thereby protecting the motor and other related equipment from damage. For example, the 6316/C3VL0241 ball bearing is insulated for high-voltage motors to provide reliable support and rotational function in harsh environmental conditions. These bearings, through their special insulation treatment, not only provide excellent rotational accuracy and load capacity but also ensure the safe operation of motors in humid environments.

Applications in Industrial Automation and Manufacturing

TFL insulated bearings are used in industrial automation and manufacturing industries, such as industrial robotics, CNC machine tools, precision instrument manufacturing, etc.

Applications in industrial robots

During industrial robot operation, shaft voltage is generated due to motor magnetic circuit imbalance, electrostatic induction, and other factors. A shaft current is generated if the shaft voltage forms a circuit through the bearing. The shaft current can lead to localized high temperatures in the bearing, producing galvanic corrosion and damaging the bearing. At the same time, the development of modern industrial robots tends to be lightweight; bearings must be installed in a limited space and be small in size and lightweight. Due to the high load, high rotary accuracy, and other properties of the robot, the electrically insulated bearings must have high load-carrying capacity, high precision, high stiffness, low friction, and long life.

Insulated bearing types commonly used in industrial robots include SKF 6218/C3VL0241, 6312MC3VL0241, and 6324MC3VL0241. These types of bearings are specially designed for high-voltage motors and have excellent insulating properties to meet the needs of industrial robots in complex operating conditions. They are typically used in joints, rotating parts, and other areas of robots, which require high precision and good insulation to ensure stability and safety during operation.

Insulated bearing solutions for CNC machines

When CNC machine tools are connected to variable frequency power supplies or other electrical systems that may generate high-frequency currents, insulated bearings must be considered to prevent damage to bearings from shaft currents. Especially in motor-driven CNC machine tools, if the motor generates shaft current, it may be conducted through the bearings, resulting in damage. As well as for high-voltage motor or large motor-driven CNC machine tools, insulated bearings are recommended to ensure stable operation of the machine tool and extend the bearings’ life.

Applications in conveyor systems

In the conveyor system, we can choose insulated bearings according to the insulating property, load-carrying capacity, working environment, and so on.

- Basis for selection

- Work Environment:

Consider the operating environment of the conveyor, such as temperature, humidity, and corrosiveness. Electrically insulated bearings are resistant to moisture and humidity and are suitable for a wide range of operating environments.

- Insulation Performance Requirements:

Ensure that the insulation of the selected bearings meets the system requirements to prevent galvanic corrosion and damage caused by current passing through the bearings.

- Recommended Bearing Types

| Electrically insulated bearings | Conveyor system load | Inside Diameter Size(mm) | Outer Diameter Size(mm) | Width dimension(mm) | |

|---|---|---|---|---|---|

| Deep groove ball bearings | Light, medium | 40-140 | 80--300 | 18--62 | SKF 6219/C3VL0241 FAG 6320-J20AA-C3 |

| Cylindrical roller bearings | Large radial | 45--140 | 100--300 | 25--62 | SKF NU 320 ECM/C3VL0241 NKE - NU328-E-MA6-C4-SQ77 |

- Insulated bearings with oxide-plated inner or outer rings: According to the specific needs, choose the outer ring or inner ring with coating bearings, coating thickness uniformity, excellent insulation performance, and suitable for high insulation performance occasions.

Importance in precision instrument manufacturing

In precision instrument manufacturing, specific types of insulated bearings are often used to meet the equipment’s high precision and insulation requirements. For example, SKF brand 6324 ball insulated bearings are a common choice, especially for applications such as high-voltage motors and fans. Not only do these bearings have excellent insulating properties, but they also work stably in high-voltage environments to ensure the precise operation of instruments. In addition, the insulated bearing 6312MC3VL0241 is also one of the models that may be considered in the manufacture of precision instruments, and it is also suitable for applications that require high insulation properties.

According to the instrumentation, precision and insulation performance requirements must be considered when selecting the appropriate insulation bearings. The excellent internal structure and materials of the bearings guarantee the equipment’s stable performance and long life in high-speed rotation and high-pressure environments. Therefore, insulated bearings can support and protect precision instruments and equipment and reduce electrical interference or mechanical failure.

Application Prospects in Emerging Technologies

With the development of emerging technology fields, insulation bearings are also gradually applied, such as 5G base stations, smart homes, new renewable energy technology, and so on.

Applications in 5G base station equipment

The application of insulated bearings in 5G base station equipment, although not directly as a core component of 5G base stations, plays a role in guaranteeing the stable operation of base station-related motors and generators. However, the stable operation of these auxiliary equipment is crucial to ensuring the overall performance of 5G base stations. The following is a detailed analysis of the possible applications of insulated bearings in 5G base station equipment:

- Power supply system: 5G base stations require a stable power supply, and these power devices (e.g., UPS power supplies, batteries, etc.) may contain motors or generators, which may use insulated bearings to ensure their reliable operation in high-voltage environments.

- Cooling system: To maintain the stable operation of 5G base station equipment, a cooling system (such as air conditioning) is usually required. The fans or pumps in these cooling systems may be motor-driven, and insulated bearings may be used in these motors to prevent current damage to the bearings and improve the equipment’s service life.

- Maintenance equipment: Some power tools or equipment may be used to monitor and maintain 5G base stations. The motor parts in these tools or equipment may also use insulated bearings to ensure their stable operation in harsh environments.

Bearing requirements in data center cooling systems

Shaft current issues are a common challenge in data center cooling systems, especially motor-driven equipment (e.g., fans in cooling towers, compressors in chillers, etc.). Shaft currents can be generated due to electromagnetic induction, static electricity buildup, or poor grounding, causing galvanic corrosion of bearings, shortening bearing life, and even causing equipment failure. Therefore, it is particularly important to use insulated bearings in these situations. Insulated bearings used in data center cooling systems are typically made of insulating materials such as oxides, resins, or ceramics. They are designed to achieve excellent insulating properties through advanced coating techniques or structural design.

Potential use in smart home devices

The direct application of insulated bearings is not as prevalent in smart home systems as in industrial motors or large electrical equipment. However, electrical drive equipment is also a key component. However, it is possible to indirectly consider the potential for insulated bearings to be used in specific smart home devices. For example, if a smart home system includes electrically driven curtains, doors, windows, automated lifting platforms, etc., and these devices need to be supported by high-reliability and long-life bearings, then the use of insulated bearings in the motors of these devices may be a beneficial option. This can effectively prevent current damage to the bearings and improve the overall performance and longevity of the equipment.

Precision bearing needs in medical equipment

Precision bearings are used in a wide range of medical equipment applications. They are used in surgical instruments, medical imaging, life support, diagnostic, dental, endoscopes, medical robots, rehabilitation, and drug delivery systems. In these applications, the high-speed, low-noise, low-friction, and long-life characteristics of precision insulated bearings ensure smooth, fast movement and high-precision motion, improving the performance and safety of the equipment.

In medical equipment, precision insulated bearings are available in a wide range of models to meet the needs of different applications. Below are some common precision insulated bearing models:

- 6211M/C3VL0241: This is an insulated deep groove ball bearing with an insulating layer on the outer ring and is suitable for equipment such as wind turbine motors.

- 6207, 6208, 6209, 6210, 6211, 6212RSZ: These models of deep groove ball bearings are widely used in medical equipment, especially the 6211 model, which is favored because of its high-temperature resistance and insulation characteristics.

- PEEK6300-6315 Series: These bearings are suitable for medical food equipment, with high-temperature sterilization and acid and alkali corrosion resistance.

These bearings offer high precision and good wear resistance and are also specially designed with an insulating layer to ensure safety and stability when used in medical equipment. Choosing the right type of precision insulated bearings can effectively improve the performance and safety of medical equipment.

Conclusion

Diversified industrial applications of insulation bearings provide a lot of convenience for our production.TFL insulation bearings cooperate with FAG, INA, NSK, NTN, IKO, KOYO, DEBOT, SKFD, and other high-quality brands to provide you with higher-quality insulation bearings.TFL endeavours to thoroughly grasp the actual conditions and environments in which the bearings are used and faithfully reproduce these in evaluation tests. We work tirelessly to establish advanced measurement techniques and improve simulation technology.TFL Insulated Bearings continues to challenge itself to pursue new bearing condition monitoring systems to safeguard the performance of bearings and equipment better.

Frequently Asked Questions

- Which electrical devices are best suited for insulated bearings?

Electrical equipment most suitable for insulated bearings includes generators, wind turbines, hydroelectric generators, thermal generators, internal combustion locomotive traction motors, and high-voltage motors.

- What is the role of insulated bearings in renewable energy?

Insulated bearings in renewable energy can effectively block the passage of electric current, ensure the normal operation of the motor, improve the reliability and efficiency of the entire drive system, and extend its service life.

- How do insulated bearings enhance railway safety?

Insulated bearings ensure the safe and stable operation of railroad facilities by preventing damage to bearings from electrical currents, thereby improving the safety of railroad transportation.

- How do insulated bearings help reduce equipment maintenance costs?

Insulated bearings help reduce equipment maintenance costs by reducing equipment failures, extending service life, increasing equipment reliability, and reducing bearing and equipment maintenance rates.

- What advantages do insulated bearings have over traditional bearings in the automotive industry?

Insulated bearings play a very important role in the automotive industry, can improve the reliability of automotive engines, extend the service life of bearings and equipment, reduce the damage rate so that the maintenance cost is relatively reduced, and effectively prevent galvanic corrosion, is a high-quality mechanical part, especially suitable for use in electric vehicles and other fields.