Double-Row Deep Groove Ball Bearings: Unmatched Support for Heavy-Duty Applications

Introduction: Unveiling the Power of Double-Row Deep Groove Ball Bearings

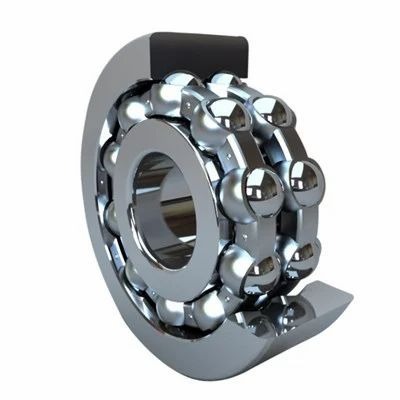

Double-row deep groove ball bearings are a common bearing type for applications where the load capacity of a single-row deep groove ball bearing is insufficient for the bearing configuration. The width of double-row deep groove ball bearings with the same outside and inside diameters as deep groove ball bearings is larger, and the load capacity is considerably higher than that of single-row deep groove ball bearings of the 62 and 63 series. Double-row deep groove ball bearings have the characteristics of a simple structure, are easy to use, and are widely used in various mechanical equipment.

Understanding Double-Row Deep Groove Ball Bearings

The structure of double-deep and single-row deep groove ball bearings is similar; both have deep groove spherical raceways and steel balls. However, double-deep groove ball bearings have two raceways and can withstand greater radial and axial loads. The radial load-carrying capacity of double-deep groove ball bearings is 1.62 times higher than that of single-row deep groove ball bearings, and they can also withstand axial loads. This gives them an advantage in certain applications, especially where greater radial and axial loads must be carried.

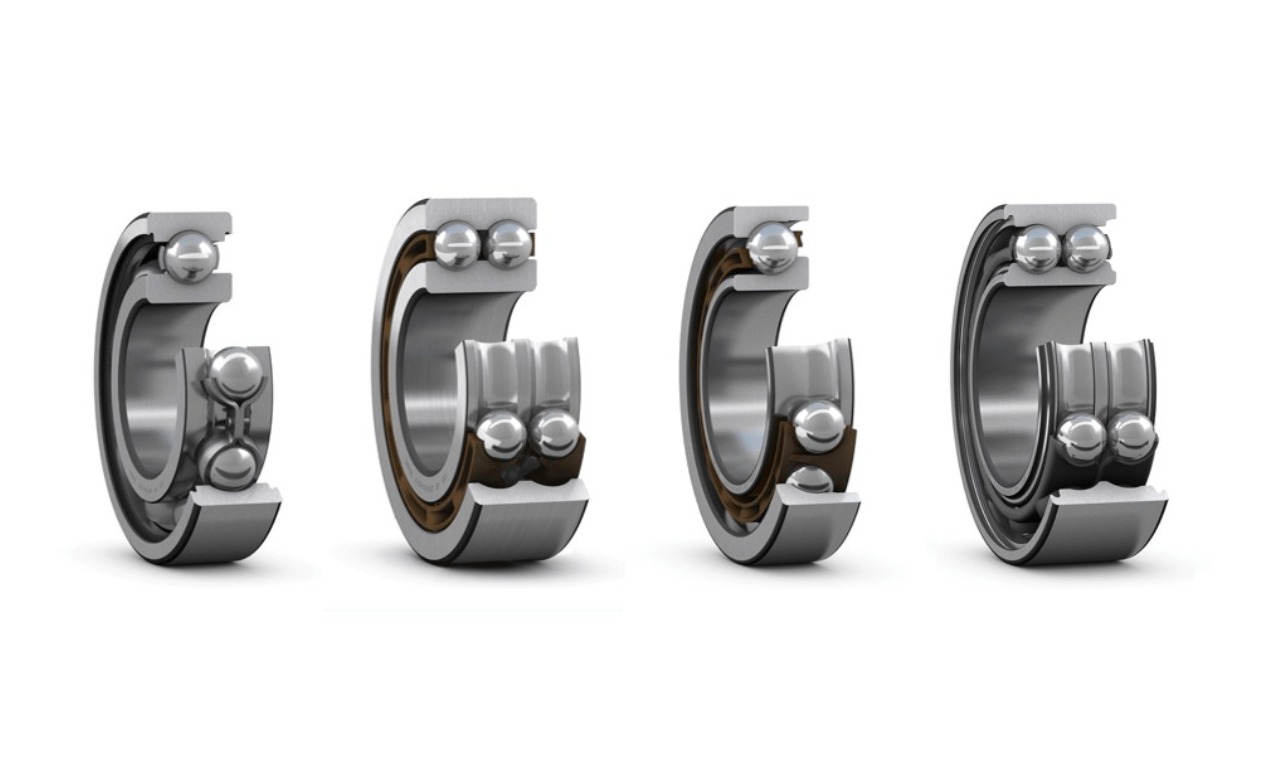

Structural Design

Double-row deep groove ball bearings consist of inner and outer rings, cages and steel balls and are non-separable bearings. The inner and outer ring raceways are deep grooves in the form of circular arcs, and the radius of the grooves is slightly larger than the radius of the balls. The cage is usually made of steel plate stamping, and large-size or high-speed bearings are used in the solid cage.

Operating Principles

Double-row deep groove ball bearings mainly bear radial load but can also bear a certain axial load. When the radial clearance is increased, they have the function of angular contact ball bearings and can withstand a larger axial load. They are suitable for high-speed rotation, and in the shell hole and shaft, relative tilt at a certain angle can still work normally. They have a small friction coefficient, low vibration and noise, high limiting speed and high precision.

Materials and Manufacturing

The materials of double-row deep groove ball bearings mainly include high carbon chrome steel, stainless steel, ceramics and so on.

High-carbon chrome steel, such as GCr15 (AISI 52100), is heat-treated to provide excellent strength and wear resistance for high-load and high-speed conditions.

Stainless Steel: Excellent corrosion resistance, commonly used in wet or chemically corrosive environments.

Ceramics: such as alumina ceramics and silicon nitride oxide ceramics with high strength, high hardness and low coefficient of friction, suitable for high-speed, high-temperature and high-precision application scenarios.

Advantages of Double-Row Deep Groove Ball Bearings

The main advantages of double-row deep groove ball bearings include high load-carrying capacity, suitability for high-speed environments, simplicity of construction and ease of maintenance. Compared with single-row deep groove ball bearings, double-row deep groove ball bearings have higher load-carrying capacity and can provide greater load-carrying capacity under the same inner and outer diameter demand conditions. In addition, double-row deep groove ball bearings are suitable for high-speed operating environments and can maintain good performance at high-speed rotation.

Simple structure and high load capacity

Double row deep groove ball bearings consist of the outer ring, inner ring, steel balls and cage, simple structure, easy to manufacture and assemble, lightweight and compact size. Double-row deep groove ball bearings can be adapted to radial and axial loads in both directions, are easy to install and have low maintenance requirements. Double-row deep groove ball bearings can withstand large radial and axial loads, and can also limit the axial displacement of the shaft or shell in both directions, with a certain degree of self-aligning ability, improving the stability of the bearing.

Flexible rotation and low coefficient of friction

Due to their structure and material characteristics, double-row deep groove ball bearings are flexible when rotating, able to withstand high speed and environments, and have a small friction coefficient, reducing the friction loss of machinery and equipment and improving efficiency. Double-row deep groove ball bearings are suitable for high-speed operation working environments and can provide greater load-bearing capacity under the demand conditions of the same inner and outer diameters.

Long service life and easy installation

Due to their excellent material and structural design, double-row deep groove ball bearings are not easily worn or deformed during long-term use, which can ensure the bearings’ service life and reduce maintenance costs. The outer ring and inner ring of double-row deep groove ball bearings can be mounted separately, which is very convenient in bearing mounting and maintenance and can greatly shorten maintenance time.

Wide range of applications

Double-row deep groove ball bearings are widely used in electric motors, household appliances, office automation equipment, automobiles and other fields. Standard double-row deep groove ball bearings include 4200A and 4300A types, in which the A-type bearings have no ball loading notch. Two reinforced nylon cages are inserted from each side of the bearing. On the market, double deep groove ball bearings can be found in various specifications and sizes to meet the needs of different applications. For example, some products are designed as miniature deep groove ball bearings for models, while others are used in larger industrial applications.

Applications of Double-Row Deep Groove Ball Bearings

Double-row deep groove balls are widely used in various industries: heavy industrial machinery, power generation and energy industry, automotive and transportation, aerospace, agriculture and food processing.

Heavy Industrial Machinery

Construction Machinery: In construction machinery, double-row deep groove ball bearings are commonly used in transmission devices, steering systems, and other components. They can withstand large loads and ensure the stable operation of equipment.

Excavators: The working environment of excavators is complex, and they need to withstand large radial and axial loads. Double-row deep groove ball bearings can meet these requirements and ensure the normal work of excavators.

Metallurgical equipment: In high-temperature and strong-corrosive environments, double-row deep-groove ball bearings have good resistance performance and are widely used in metallurgical equipment, such as steel rolling mills, blowing furnaces, etc.

Mining machinery: In mining, mineral processing, powder equipment, etc., double-row deep groove ball bearings are used to withstand large radial and axial loads to ensure that the corresponding reducer and transmission device work stably.

Power Generation and Energy

Double-row deep groove ball bearings also play an important role in hydroelectric power plants. As hydroelectric equipment is subjected to long-term operation and complex load variations, the durability and reliability of double-row deep groove ball bearings make them an ideal choice. These bearings provide stable support in the rotating parts of the turbine, ensuring the normal operation of the hydroelectric power plant.

In solar tracking systems, double-row deep groove ball bearings support and transmit torque. Their special rolling mechanism and sealing design ensure high-speed performance and long service life, which can maintain stability in harsh environments and prolonged operation. In addition, SKF offers solar bearings designed for customized solar requirements that can accurately track the sun throughout the system’s entire life cycle, thereby increasing the efficiency of the solar tracking system.

Automotive and Transportation

Engine: Double-row deep groove ball bearings mainly support the crankshaft and other key components to ensure the engine’s stable operation. Due to its strong ability to withstand radial load and high-speed rotation stability, it can meet the engine’s needs in various working conditions.

Transmission: In a transmission, double-row deep groove ball bearings are used to support the rotation of the shaft and the transmission of the gears, ensuring that the transmission can work properly under different driving conditions. Particularly in manual transmissions, the bearings allow the gears and shafts to rotate at different speeds, adapting to different driving conditions.

Steering gear: The bearings in the steering gear need to withstand large radial loads and impacts. Double-row deep groove ball bearings, due to their excellent load-carrying capacity and wear resistance, can ensure the stable operation of the steering gear.

Differential gears: Differential gears are the key components of the car that realize smooth turning, where double-row deep groove ball bearings provide the necessary support to ensure the correct gears meshing and effective power transmission.

Aerospace and Aviation

Aircraft engines: Double-row deep groove ball bearings are widely used in various parts of aircraft engines, such as turbines, turbine shafts, clutches and so on. These bearings can work in high temperature, high pressure, and high-speed environments, support high-speed rotating parts, and bear huge speed and load. The material’s temperature and corrosion resistance are very high.

Flight control system: Double-row deep groove ball bearings can be used in the rudder, wing flap controller, and other components to ensure the smooth operation of the main and tail rotors. These components require high-precision motion control, and the stability and reliability of the bearings are critical.

Agricultural and Food Processing

Agricultural machinery: In agricultural machinery such as tractors, combine harvesters, seeders and other equipment, double-row deep groove ball bearings are used to support the rotating spindle and other components to ensure the normal operation of the equipment.

Deep groove ball bearings are also widely used in food processing and packaging equipment. Their economy, simplicity and ease of maintenance make them the bearing type of choice in the food processing industry. High-quality materials and finished surfaces ensure that the bearings maintain operational reliability and minimize noise in the event of tilting. In addition, new sealing concepts and lubrication options further extend the life of the bearings. For example, TIMKEN has developed a range of corrosion-resistant and hygienic deep groove ball bearings that are particularly suitable for the food processing and packaging industry. These bearings minimize bacterial build-up and the risk of contamination and are suitable for use with a wide range of greases, such as food-grade, non-toxic USDA H1 grease.

Oil and Gas Industry

Drilling equipment: e.g., mud pumps, winches, top drives, overhead cranes, etc. This equipment needs to withstand large loads and shock vibration during operation. Double-row deep groove ball bearings can support the turntable and top drive, providing sufficient load-carrying capacity and shock resistance.

Offshore Platforms: Whether fixed or floating, they must withstand complex marine environments, including wind, waves, tides, currents and other natural forces. The equipment on these platforms, such as drilling, oil recovery, navigation, etc., all require high-precision bearings to support their stable operation. Double-row deep groove ball bearings are indispensable to offshore platform equipment due to their unique structure and excellent performance.

Selecting the Right Double-Row Deep Groove Ball Bearing

Choosing the right double-row deep groove ball bearing requires consideration of the following factors: load size specification requirements, accuracy and performance requirements, and mounting and maintenance.

Load size specification requirements

Double-row deep groove ball bearings need to withstand large radial and axial loads. Based on the specific load requirements of the application scenario, select the appropriate bearing type and size. Determine speed limits and dimensional requirements, including inside diameter, outside diameter and width. Ensure that the bearing dimensions match the equipment’s design requirements to accommodate the equipment’s structural and space constraints.

Accuracy and performance requirements

Gearboxes require high-precision bearings. Select the appropriate precision grade (e.g. P0, P6, P5) to ensure smooth operation and minimize vibration. At the same time, low noise and low vibration bearings are selected to enhance the smoothness and comfort of equipment operation. Choose high-strength materials such as high-carbon chrome or alloy steel, and consider corrosion- and wear-resistant surface treatments, such as zinc plating, nitriding or phosphating, to improve bearing durability and reliability.

Installation and maintenance

Ensure that the mounting of bearings meets the specifications and requirements of the equipment design. Correct alignment and mounting can avoid additional load and wear. Regularly check the condition of the bearings, including noise, vibration and temperature, to detect potential problems in time. Select the appropriate lubrication method (lubricant or grease) according to the working environment and maintenance requirements, and choose the appropriate type of sealing (e.g., sealing caps, rubber seals) to prevent the ingress of dust, moisture and contaminants.

Maintenance and Care for Double-Row Deep Groove Ball Bearings

The maintenance and repair of double-row deep groove ball bearings mainly include the following aspects: cleaning and inspection, lubrication practice, installation and use, etc.

Cleaning and inspection

After removing the bearings, clean them with neutral water-free diesel or kerosene. When cleaning, first use a brush to remove the adhesive material, and then slowly rotate the bearing, rotate in all directions, and carefully clean the inside of the deep groove ball bearing. Check the dimensional accuracy, rotational accuracy, internal clearance, mating surfaces, raceway surfaces, cages and seals of the bearings to judge whether they can be reused.

Lubrication Practices

According to the bearing’s working conditions, choose the appropriate lubrication method, such as oil cup drip lubrication, oil bath lubrication, splash lubrication, circulating oil lubrication and oil mist lubrication. When selecting lubricants, pay attention to their compatibility with bearing materials, sealing materials and lubricants; viscosity should be moderate, have good oxidation resistance and anti-wear, and be kept clean. Regularly check the lubrication condition and supplement or replace the lubricant in time to ensure the good operation of the bearings.

Installation and use

Pay attention to the alignment error of the bearings when mounting; the permissible angular error is only 2 arc minutes; any larger angular error will lead to increased noise and thus shorten the working life of the bearings. Bearings must withstand a certain minimum load, especially at high speeds, high acceleration, or rapid changes in the direction of the load. Otherwise, the inertial force of the ball and cage and the friction within the lubricant will have an adverse effect on the rolling of the bearing.

Conclusion: Harnessing the Power of Double-Row Deep Groove Ball Bearings

Double-deep groove ball bearings are a type of bearing that offers high performance and a wide range of applications. They play an important role in many machines and equipment, helping to achieve smooth and efficient operation. The structure and characteristics of double-deep groove ball bearings allow them to withstand greater radial and axial loads, thus providing an advantage in certain applications. When selecting double deep groove ball bearings, you must choose the right specification and size for your specific application. Upgrade your heavy machinery with our quality double-row deep groove ball bearings. Contact us today at TFL Bearings for personalized advice.

Frequently Asked Questions

- What are the main advantages of double-row deep groove ball bearings?

The main advantages of double-row deep groove balls include high load-carrying capacity, good rigidity, strong sealing, long service life, easy installation and disassembly, and a wide range of applications.

- Can double-row deep groove ball bearings handle both radial and axial loads?

Double-row deep groove ball bearings can withstand both radial and axial loads. The design of double-row deep groove ball bearings enables them to withstand axial loads in both directions. In addition to withstanding radial loads, they can also withstand axial loads acting in both directions.

- What is the load capacity of double-row deep groove ball bearings compared to single-row?

Compared with single-row deep groove ball bearings, double-row deep groove ball bearings have a greater load capacity. They have two rolling columns, which allows them to withstand greater loads and makes them suitable for occasions with larger loads, such as heavy machinery and large equipment.

- What are the signs that a double-row deep groove ball bearing needs replacement?

Signs that a double-row deep groove ball bearing needs to be replaced include the following:

- Sounds and Vibrations: If the bearings exhibit unusual sounds, such as sharp rubbing, buzzing, or knocking, or if vibrations increase beyond the normal range, this may be a sign of bearing wear or damage.

- Temperature and Temperature Changes: Abnormally high bearing temperatures and sudden temperature fluctuations may also indicate a bearing problem and require further inspection.

- Lubrication condition: grease is black, dry, or has impurities, or the amount of lubricant is insufficient, there is leakage, etc. You may also need to replace the bearing.

- Appearance Inspection: Bearings that are visibly worn, cracked, spalled or deformed are clear signs that the bearing needs to be replaced. If rust and corrosion are present, bearing replacement should also be considered.

- Running performance: equipment in the operation of the efficiency decline or unstable operation, such as the production of axial or radial displacement, vibration increase, etc., indicating that the bearing may have problems.

- Can double-row deep groove ball bearings be used in high-temperature environments?

The operating temperature range of double-row deep groove ball bearings is generally 60℃~80℃. If the bearing temperature exceeds 80℃, it should be stopped immediately for inspection, and measures should be taken to prevent affecting the service life and performance of the bearings. Therefore, the use of double-row deep groove ball bearings in a high-temperature environment requires special attention to temperature control.