Ceramic Deep Groove Ball Bearings: Ultimate Guide to High-Performance

Ceramic deep groove ball bearings are a kind of rolling bearing that combines the excellent performance of ceramic material with the structural characteristics of deep groove ball bearing, which has the characteristics of high precision, corrosion resistance, abrasion resistance, high-temperature resistance, low noise, etc. It is widely used in aerospace and machinery manufacturing equipment.

Reading the most detailed ceramic bearings guide in this article, you can grasp the latest technical information so that you can find the right ceramic deep groove ball bearings more quickly.

Understanding Ceramic Deep Groove Ball Bearings

Composition and Types

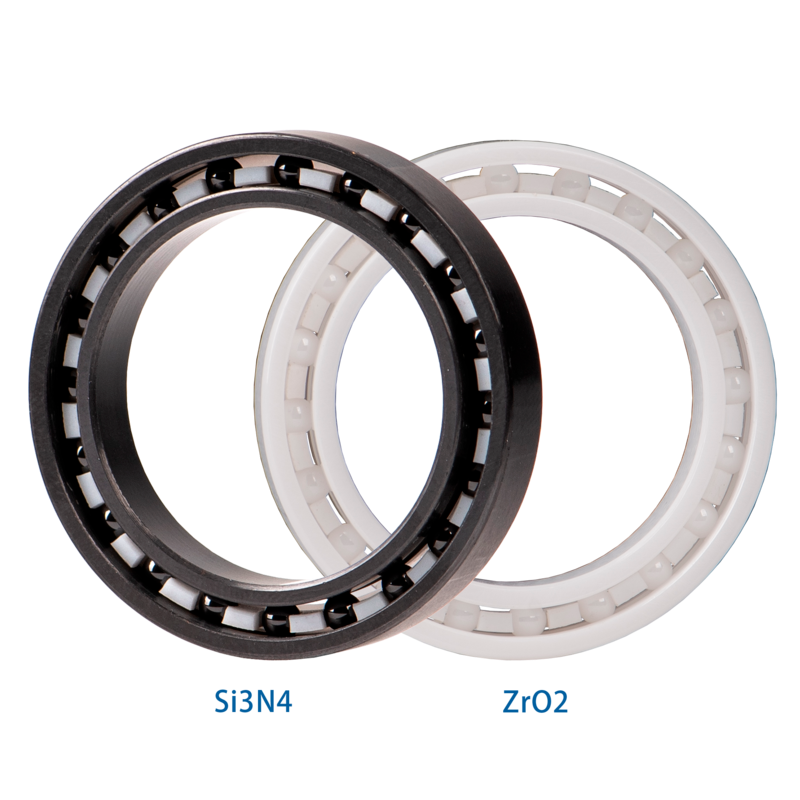

- Full ceramic vs. hybrid ceramic bearings: Full ceramic bearings are bearings in which all parts of the bearing are made of ceramic materials, which have very high-temperature resistance, corrosion resistance and low coefficient of friction and are able to maintain stable operation under extreme working conditions. Hybrid ceramic bearings are bearings in which the rolling bodies are made of ceramic materials, while the inner and outer rings and cages are made of metal materials. This kind of bearing combines the advantages of ceramic material and metal material; not only has the characteristics of ceramic material, such as high hardness and high wear resistance, but it also has the good processing performance and mechanical properties of metal material.

- Materials used (e.g., silicon nitride, zirconia): The materials used in ceramic deep groove ball bearings are mainly focused on the rings (inner and outer rings) and rolling elements (balls), which are usually made of ceramic materials, commonly used ceramic materials are silicon nitride (Si3N4) and zirconium oxide (ZrO2).

Design Features

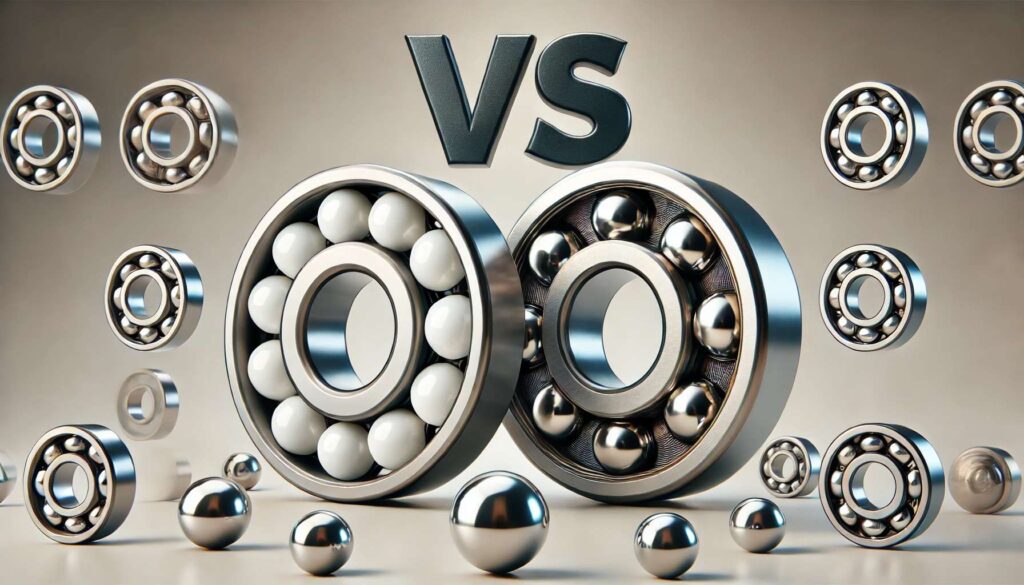

- Comparison with traditional steel bearings: The unique characteristics of ceramic deep groove ball bearings include high wear resistance, high-temperature stability, corrosion resistance, low coefficient of friction, high precision, self-lubrication, insulation and non-conductivity, and lightweight.

- Unique characteristics of ceramic bearings: Ceramic bearings outperform conventional steel bearings in terms of wear resistance, corrosion resistance, speed and acceleration, lubrication requirements, rigidity and accuracy, and other characteristics.

Advantages of Ceramic Deep Groove Ball Bearings

- Higher speed capabilities: Ceramic deep groove ball bearings have higher speed capability due to their unique material properties and design advantages. They are widely used in a variety of high-speed mechanical equipment, such as aircraft engines and high-speed motors.

- Lower friction and heat generation: Ceramic deep groove ball bearings have lower friction and heat generation due to their material properties and unique design, which makes ceramic deep groove ball bearings have superior performance and longer service life under severe working conditions such as high speed, high temperature and high precision.

- Resistance to corrosion and wear: Ceramic material has excellent chemical stability and can resist a variety of acids, alkalis and corrosive media erosion. Making ceramic deep groove ball bearings in a humid, corrosive environment can maintain good performance. At the same time, the ceramic material has a very high hardness so that the ceramic deep groove ball bearings in the operation process can resist the rolling body and the wear between the grooves so as to maintain a long service life.

- Performance in extreme temperatures: Ceramic deep groove ball bearings can maintain stable performance and reliable operation in both high and low-temperature environments due to the ceramic material’s high melting point, low expansion coefficient, excellent heat resistance and stable mechanical properties.

- Electrical insulation capabilities: The electrical insulating ability of ceramic deep groove ball bearings is mainly due to the ceramic coating on their surface. This coating not only has good insulating properties but also resists the erosion of the bearing by electric current, thus prolonging the bearing life.

Applications of Ceramic Deep Groove Ball Bearings

Ceramic deep groove ball bearings require no maintenance, reduce friction and are lighter in weight than standard bearings. Very often, they can be customized for most applications and can, therefore, be used in a wide range of applications.

Machine tool spindles: Precision CNC machines and milling centres

The high precision and stability of ceramic deep groove ball bearings can improve the machining accuracy of machine tools, and due to the high wear resistance of ceramic materials, it can extend the service life. At the same time, it has the advantages of adapting to harsh working conditions and reducing maintenance costs.

Turbomachinery: Gas turbines and turbochargers

Ceramic deep groove ball bearings can be used in gas turbine main shaft support, compressor rotor support and other critical parts. Their characteristics of high temperature and wear resistance help to ensure the stable operation of gas turbines under high temperature, heavy load and high-speed working conditions. At the same time, it helps to improve the overall performance of the gas turbine and reduce maintenance costs and downtime. The bearings in the turbocharger need to withstand the severe working conditions of high temperature, high speed and high pressure, so the durability and reliability of the turbocharger can be significantly improved.

Industrial pumps: High-speed centrifugal and vacuum pumps

Ceramic deep groove ball bearings are able to enhance the overall performance of industrial pumps by improving the wear resistance, high-temperature resistance, corrosion resistance, friction loss and noise level of the equipment, with significant effects in high-speed centrifugal pumps and vacuum pumps.

Textile machinery: High-speed spindles in spinning and weaving equipment

Ceramic deep groove ball bearings are characterized by high hardness, wear resistance, low friction, corrosion resistance and high rotational stability, making ceramic bearings ideal for improving the performance of textile machinery, reducing operating costs and extending service life. In textile machinery, in the spinning and weaving equipment, high-speed spindle has a significant advantage.

Electric motors: High-efficiency motors for industrial and automotive applications

Ceramic deep groove ball bearings have a wide range of applications in electric motors, especially in high-efficiency motors in the industrial and automotive fields, which have brought significant economic and social benefits to the industrial and automotive fields by improving the operating efficiency of motors and reducing energy consumption and failure rate.

Semiconductor manufacturing equipment: Wafer handling robots and precision stages

Ceramic deep groove ball bearings are important in semiconductor manufacturing equipment, especially in wafer handling robots and precision platforms, due to their high precision, low friction, high load carrying capacity, corrosion resistance, high-temperature resistance, low vibration and noise, high stability and long service life, and high precision rotation.

Wind turbine generators: Main shaft and gearbox bearings

With its excellent performance, ceramic deep groove ball bearings can ensure the long-term stable operation of wind turbines and improve the overall power generation efficiency, which improves the operational efficiency and reliability of wind turbines and also reduces the maintenance cost and energy consumption.

Hard disk drives: High-speed spindle motors for data storage devices

In hard disk drives, the spindle motor is the key component that drives the hard disk platters to rotate. Ceramic deep groove ball bearings improve the data access speed of hard disk drives by virtue of their wear-resistant and high temperature-resistant characteristics, reduce the failure rate of hard disk drives due to bearing wear, and guarantee data security and stability.

Aircraft engines: Auxiliary power units and engine accessories

The application of ceramic deep groove ball bearings in aircraft engines, especially in auxiliary power units (APUs) and engine accessories, fully demonstrates their excellent performance under the requirements of high temperature, high speed, high load and high precision.

Satellite systems: Reaction wheels and momentum wheels for attitude control

Ceramic deep groove ball bearings play an important role in the attitude control of satellite systems. They are ideal for key components such as reaction and momentum wheels due to their excellent performance.

Helicopter transmissions: Main and tail rotor gearboxes

The application of ceramic deep groove ball bearings in helicopter transmission systems, especially in the main rotor and tail rotor gearbox, can improve transmission efficiency, prolong service life, reduce maintenance cost, enhance flight stability and reduce noise and vibration.

Unmanned aerial vehicles (UAVs): Propulsion systems and control surfaces

The application of ceramic deep groove ball bearings in UAV propulsion systems and control surfaces can improve transmission efficiency, extend life, adapt to high-speed rotation, reduce weight, etc., which can help to enhance the overall performance of UAVs.

Medical imaging devices: CT scanners and MRI machines

In CT scanners, ceramic deep groove ball bearings are mainly used to support and drive rotating parts to ensure a smooth and accurate scanning process. In MRI machines, ceramic deep groove ball bearings have the characteristics of adapting to strong magnetic field environments, high-precision transmission, low friction and high efficiency.

Dental equipment: High-speed dental drills and air turbines

Ceramic deep groove ball bearings used in high-speed dental drills are characterized by high precision, high speed and low wear, which can significantly improve the rotational stability and accuracy of the drills. Ceramic bearings used in pneumatic turbine handpieces can reduce the temperature and noise when the handpieces are in operation.

Centrifuges: Ultra-high-speed laboratory centrifuges

Ceramic deep groove ball bearings in ultra-high-speed laboratory centrifuges have the advantages of adapting to high-speed environments, reducing friction and noise, improving equipment life, meeting the needs of special working environments, and enhancing experimental efficiency.

Precision analytical instruments: Spectrometers and chromatography equipment

Ceramic deep groove ball bearings, due to their unique performance characteristics in precision analytical instruments (such as spectrometers and chromatography equipment), can meet the strict requirements of precision analytical instruments for high precision, high stability and long life.

Solar tracking systems: Precision bearings for solar panel positioning

Ceramic deep groove ball bearings have important applications in solar tracking systems. Their high precision, corrosion and high-temperature resistance, as well as low noise and vibration, provide reliable support for the precise positioning of solar panels and efficient power generation.

Tidal and wave energy converters: Underwater turbine bearings

Ceramic deep groove ball bearings have important applications in tidal and wave energy converters. Their excellent corrosion and temperature resistance, high precision, and low friction characteristics make them ideal for use in underwater turbines.

Geothermal power plants: High-temperature pump bearings

The application of ceramic deep groove ball bearings in high-temperature pumps of geothermal power plants gives full play to its characteristics of high wear resistance, high hardness, high-temperature resistance and corrosion resistance, which improves the operational efficiency and reliability of the equipment and reduces maintenance costs.

Hydrogen fuel cells: Air compressor bearings for fuel cell systems

Ceramic deep groove ball bearings have significant advantages and importance when used as bearings in air compressors for hydrogen fuel cell systems, and their excellent performance characteristics help to improve system efficiency, extend equipment life and enhance system reliability.

Robotic arms: Joint and end-effector bearings

The application of ceramic deep groove ball bearings in the joints and end-effector of robot arms gives full play to their performance advantages such as high-temperature resistance, corrosion resistance, high precision and low noise. These advantages not only improve the stability and accuracy of the robot arm but also extend the service life and reduce maintenance costs.

3D printers: High-precision motion control bearings

The application of ceramic deep groove ball bearings in the high-precision motion control of 3D printers shows its unique advantages. Its high precision, low friction, wear resistance and good stability make ceramic deep groove ball bearings an ideal choice for 3D printer drive systems. XMAKE’s 3D printing integrates advanced ceramic bearings for ultra-smooth operation, ensuring print accuracy and reliability.

Automated guided vehicles (AGVs): Wheel and steering mechanism bearings

The application of ceramic deep groove ball bearings can significantly improve load-carrying capacity, operational efficiency, navigation and positioning accuracy, and overall reliability of AGVs, as well as reduce costs, among other things.

Packaging machines: High-speed conveyor and sealing mechanism bearings

The excellent performance of ceramic deep groove ball bearings, such as high speed, low friction, wear resistance, high-temperature resistance and good sealing and other advantages, applied to the high-speed conveyor belt and sealing mechanism of the packaging machine, has the advantages of improving the performance of the packaging machine, reducing maintenance costs, adaptability and so on.

How to Choose the Right Ceramic Deep Groove Ball Bearings

When choosing the right ceramic deep groove ball bearings, two factors need to be considered: speed and load. For speed, factors such as material properties, bearing type and structure, and lubrication conditions need to be considered. The load needs to consider material strength and toughness, bearing size and structure, basic dynamic load rating (Cr) and other factors.

The life cycle cost consideration of ceramic deep groove ball bearings includes many aspects such as procurement cost, mounting cost, running cost, maintenance cost and scrapping cost. In order to reduce the life cycle cost of ceramic deep groove ball bearings, measures can be taken to select good quality bearings, optimize the mounting process, reduce running costs, strengthen maintenance management, and reasonably plan for scrapping.

Maintenance and Care for Ceramic Deep Groove Ball Bearings

Specialized lubricants for ceramic bearings

Ceramic deep groove ball bearings are high-performance, high-precision bearings; their special lubricant should be based on the specific conditions of use to choose the right type and brand and follow the correct use of methods and precautions to ensure the normal operation and service life of the bearing. Common kinds of lubricants include synthetic oil, polymer grease, and solid lubricants.

Lubrication intervals and methods

The factors for determining the lubrication interval of ceramic deep groove ball bearings include bearing type, size, rotational speed, operating temperature, type of grease, space around the bearing, and the working environment of the bearing. Common lubrication methods include manual lubrication, oil mist lubrication, and oil bath lubrication.

Conclusion

The main advantages of ceramic deep groove ball bearings include high-speed performance, high temperature and corrosion resistance, low friction and high transmission efficiency, long life and low maintenance, non-magnetic and electrical insulation and vacuum environment adaptability; its main application areas include machinery manufacturing, electronic equipment, aviation and aerospace, medical equipment, automotive industry.

Ready to improve your mechanical performance and longevity? Contact TFL today for expert advice on choosing the perfect ceramic deep groove ball bearing. Request a quote or speak with our technical team to find your ideal solution!

Frequently Asked Questions

What are the main advantages of ceramic deep groove ball bearings?

Ceramic deep groove ball bearings have significant advantages in high-speed performance, high temperature and corrosion resistance, long life and low maintenance, as well as insulation, non-magnetic and so on.

Are ceramic bearings more expensive than traditional steel bearings?

Ceramic bearings are usually more expensive than traditional steel bearings due to their material cost, processing difficulty, production technology requirements, and performance advantages.

How long do ceramic deep groove ball bearings typically last?

The typical life of ceramic deep groove ball bearings may range from tens of thousands of hours to hundreds of thousands of hours, and the exact value needs to be analyzed specifically according to the actual situation.

Do ceramic bearings require special lubrication?

In most cases, ceramic bearings are able to operate with their lubrication; however, at high speeds, in high-temperature environments, or under severe operating conditions, additional lubrication may be required to ensure proper operation and extended service life.

Expanded Reading

Types of Deep Groove Ball Bearings: A Comprehensive Guide

Deep groove ball bearings, also known as single-row radial ball bearings, are a widely used and most common type. The basic structure includes inner and outer rings, steel balls and…

Deep Groove Ball Bearing Applications: Comprehensive Guide

Deep Groove Ball Bearing Applications Guide: Key to Industrial Efficiency Introduction Deep groove ball bearings are characterized by high load-carrying capacity, low friction, high-speed performance, good wear resistance and life…

Deep Groove Ball Bearing Materials: Choosing the Best for Your Application

Choosing the right material for deep groove ball bearings is important for their performance, lifespan, and overall efficiency. Different materials give bearings unique features like good wear resistance, great corrosion…

Comprehensive guide to deep groove ball bearings

Introduction: Deep groove ball bearings are components of modern industrial workshops and play a key role in many mechanical systems. From daily household appliances to advanced industrial equipment, deep groove…

Single-Row Deep Groove Ball Bearings: The Versatile Powerhouse of the Bearing World

Introduction: Single-Row Deep Groove Ball Bearings: The Versatile Powerhouse of the Bearing World Single-row deep groove ball bearings (GB/T 276-2003), formerly known as single-row radial ball bearings, are the most…

2025 Comprehensive Guide to Deep Groove Ball Bearing Installation

Deep groove ball bearings are widely used rolling bearings with high load-carrying capacity, high rotational speed, low frictional resistance, good durability and long service life, which have become indispensable components…