SKF Insulated Bearings

Introduction: The Revolutionary Impact of SKF Insulated Bearings

SKF insulated bearings revolutionize the traditional bearing technology of the pinnacle of the work with the continuous development of industrial technology. Bearings, as important mechanical transmission components in a variety of industrial fields, play a vital role. The introduction of SKF insulated bearings is not only a breakthrough in traditional bearing technology but also a revolution in industrial safety. As a cutting-edge product that improves the electrical conductivity of conventional bearings, insulated bearings not only provide a high level of safety but also reduce maintenance costs and improve the efficiency of equipment. Therefore, SKF insulated bearings are gradually being widely used in various industries.

How SKF Insulated Bearings Work

Most of the bearings in SKF’s current fixed-point or mass production use the carbonitriding heat treatment process. Bearings that undergo this heat treatment process have a longer life span in response to specific operating conditions, which can help realize the high reliability of the overall electric drive system through better durability.

Hybrid Ceramic Insulated Bearings

The inner and outer rings of hybrid ceramic ball bearings are still made of bearing steel, and the rolling elements are made of silicon nitride. The highlight of this product is that silicon nitride, as a natural electrical insulator, can effectively avoid bearing failures caused by galvanic corrosion. Other performance advantages of SKF hybrid ceramic ball bearings are also evident, such as the ability to reduce frictional torque by 15-30%, increase speed performance by at least 10%, and extend grease life by 100%.

Conductive rings + hybrid ceramic ball bearings – helping to solve the “galvanic corrosion” problem

Galvanic corrosion often brings bearing surface damage, premature ageing of the lubricant, rattling, and other effects. It can also shorten the life of the bearing and lubricant, ultimately leading to bearing failure. In this regard, SKF believes that the configuration of hybrid ceramic ball bearings with conductive rings solves most of the problems associated with the risk of galvanic corrosion, whether caused by system ring currents or EDM axial currents. First of all, in the conductive ring, SKF has been developed for many years; the product is suitable for both dry environment grease lubrication of the motor and for the oil-cooled environment of the motor and can always be maintained in a relatively low contact resistance, with excellent conductive properties.

INSOCOAT insulated bearings

The insulating coating on the outer ring of INSOCOAT bearings is made from aluminum oxide and applied using plasma spray technology.SKF has carried out extensive research and development in this area and is looking to improve the process further.SKF offers INSOCOAT insulated bearings that are resistant to galvanic corrosion under a wide range of conditions, including high humidity. Sealed protective coatings on the outer or inner ring integrate insulation into the bearing, effectively eliminating galvanic corrosion problems, increasing reliability, and extending machine uptime. These bearings are typically coated with aluminum oxide, which has a resistance of 200 mΩ and can withstand DC voltages of up to 3,000 volts.

INSOCOAT bearings of SKF

INSOCOAT insulated bearings are a very economical solution compared to other insulation methods that protect bearings from the passage of electric current. By integrating the electrical insulation function into the bearing, SKF virtually eliminates the damaging effects of stray currents, thereby increasing reliability and machine uptime.

INSOCOAT Technology Introduction

For galvanic damage, INSOCOAT bearings with electrically insulating coatings are an extremely cost-effective solution designed to provide a high level of reliability and uptime in electrical applications. A sealing protective coating on the outer or inner ring adds insulating properties to the bearing, thus protecting it from harsh or even wet environments. Aluminum oxide insulation is applied using a precision plasma spraying process. Two coatings are available: standard and premium. The standard coating provides a minimum resistance of 200 [MΩ], while the premium coating reaches 400 [MΩ]. To prevent condensation from penetrating the coating, INSOCOAT bearings utilize a unique sealant that ensures consistent electrical performance.

INSOCOAT Insulated Bearing Design

The standard series of INSOCOAT insulated bearings has the most common sizes and variants: single-row deep groove ball bearings and single-row cylindrical roller bearings. INSOCOAT insulated bearings have the same performance data as standard non-insulated bearings as well as the same dimensions and running accuracy.

- INSOCOAT insulated bearings with coated outer ring

Bearings with an electrically insulating coating on the outer surface of the outer ring are the most common type of INSOCOAT insulated bearings. INSOCOAT insulated bearings with coated outer rings are recommended for medium-sized motors using 6215, 6313 or larger bearing sizes. For applications with smaller bearings, SKF recommends mixed ceramic deep-groove ball bearings.

- INSOCOAT insulated bearings with coated inner ring

Bearings with an electrically insulating coating on the outer surface of the inner ring provide enhanced protection against current damage. The protection is enhanced by the increased impedance due to the smaller surface area of the coating. Bearings with coated inner rings are identified by the suffix VL2071 and are recommended for larger motor sizes (typically starting with bearing sizes 6226, 6324 and larger) or other applications where the bearings may be subjected to high shaft voltages.

INSOCOAT technology features and benefits

- The coating is applied using plasmaspray technology. Sophisticated pre- and post-coating processes produce excellent coating quality.

- INSOCOAT insulated bearings are treated with a unique sealant to prevent moisture and water from penetrating the coating and reducing its effectiveness.

- Due to the quality of the application and finishing process, INSOCOAT bearings provide reliable and consistent insulation that is virtually insensitive to heat, moisture and chemicals.

- SKF can provide values for the relevant electrical parameters of the bearing (capacitance, impedance) to optimize the insulation solution for any application.

- INSOCOAT insulated bearing is environmentally friendly.

- INSOCOAT insulated bearings with coated outer rings are suitable for all types of housings. No additional mounting precautions are required.

- INSOCOAT insulated bearings can be mounted using standard methods and tools and are very robust in use, as well as during transportation and handling.

INSOCOAT Bearing Electrical Characteristics and Related digital

INSOCOAT insulated bearings provide effective protection against AC and DC currents. The specifications for the different models are:

| VL0241 | VL0246 | VL2071 | VL2074 | |

|---|---|---|---|---|

| Resistive | Minimum 50 MW | > 150 MW | Minimum 50 MW | > 150 MW |

| Breakdown voltage | Maximum1000 V DC | Maximum3000 V DC | Maximum1000 V DC | Maximum2000 V DC |

- Dimensions: INSOCOAT deep groove ball bearings and cylindrical roller bearings have external dimensions in accordance with ISO 15:1998.

- Tolerances and fits: INSOCOAT insulated bearings are manufactured to common tolerances. Some deep groove ball bearings are also produced to higher tolerances, with a tolerance class of P5. Aluminum oxide layers coated on the outer surface of the outer ring or on the outer and inner ring surfaces do not affect the running accuracy. NSOCOAT insulated bearings can be mounted in motors or generators as standard bearings without damaging the coating. It is possible to mount the inner ring-coated variant p6 and the outer ring-coated variant P6 (max.).

- Internal clearance: Standard INSOCOAT deep groove ball bearings and cylindrical roller bearings have a radial internal clearance of the class shown in the bearing designation. Before ordering, check the availability of bearings with non-standard clearances.

- Cages: Depending on the type and size of the bearing, INSOCOAT insulated bearings are equipped with one of the following cages: 1. Stamped steel riveted cage without name suffix 2. Two-piece machined brass cage with rolling element guide, type suffix M.

Common types of INSOCOAT bearings

SKF process insulated bearings are categorized into inner or outer ring insulated bearings with oxide plating and mixed ceramic bearings with ceramic rolling elements. Specific models include deep groove ball bearings (e.g. VL0241, VL2071), cylindrical roller bearings (e.g. NJ, NU, NUP series) and so on. These bearings are available in insulation classes up to 2000V, 3000V and 5000V for different voltage requirements.

Common suffixes used for INSOCOAT bearings are:

VL024 and VA309 breakdown voltage to 500V and VL0241 and VA3091 breakdown voltage up to 1,000V. VA309 and VA3091 are applied to bearings for traction motor applications.

6324M/C3VL2071: This type of bearing has a high-resistance aluminium oxide coating and can withstand up to 3000 volts of DC.

6222/C3: This type of bearing is a motor-insulated bearing imported from Sweden with a coating that can withstand up to 1000 volts.

6320M/C3VL0241 and 6316/C3VL0241: These two types of bearings also have an insulating coating and are suitable for mechanical equipment requiring insulating properties.

Applications of SKF Insulated Bearings 、

SKF insulated bearings are mainly used in motors, industrial equipment, and electric railroad vehicles.

A new generation of tapered roller bearings – the pursuit of extremely low friction

The gearbox will often choose to withstand large axial load tapered roller bearings, but tapered roller bearings friction torque is usually high in the gearbox and will often consume most of the energy, and the automotive bearings are in the category of “energy consumption”. Reducing the frictional torque of tapered roller bearings contributes significantly to the energy efficiency of 3-in-1 electric drive systems. By optimizing the design and improving the grinding process, SKF’s new generation of tapered roller bearings reduces frictional torque energy losses by up to 60 percent compared to standard bearings at regular vehicle speeds. This low energy consumption also helps to increase the service life of the bearings.

High-speed ball bearings – helping to speed up motors

As early as 2018, SKF discovered an unusual change in the market: its own new energy-saving insulated bearings, an industrial product, suddenly became a big seller in the new energy market because of its high-speed capability ahead of traditional ball bearings, and many manufacturers chose to fit them into new energy vehicle motors. At that time, the motor speed of new energy vehicles on the market was generally about 10,000rpm. Then the speed requirement became higher and higher, gradually moving towards 15,000rpm, 20,000rpm or even higher.

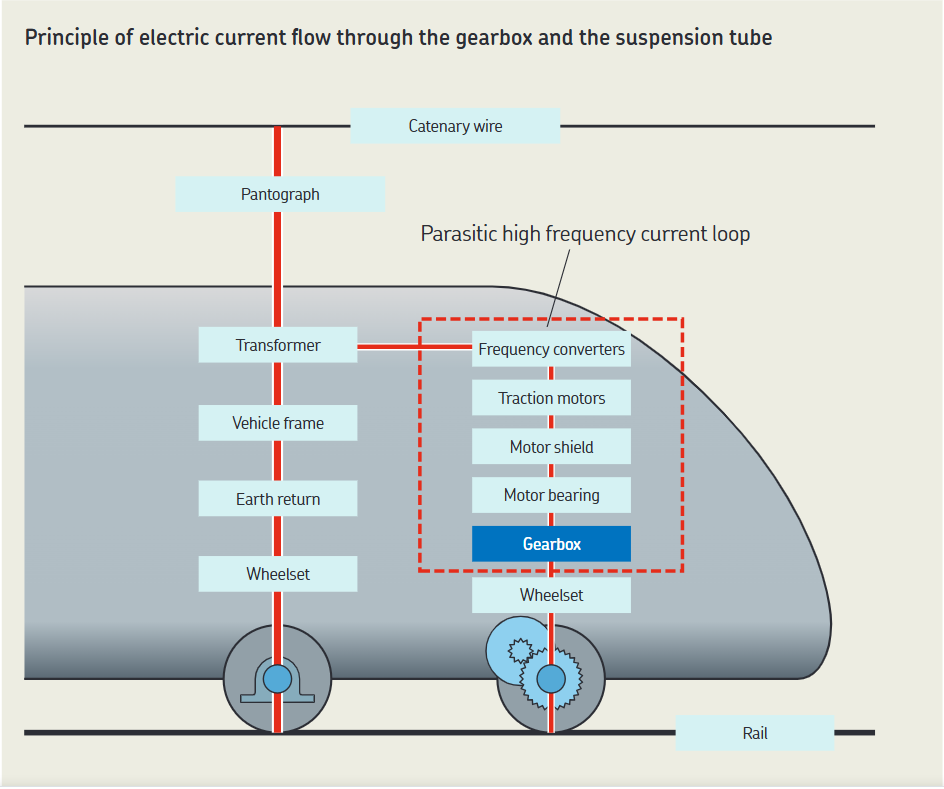

Transportation: Applications in Railways and Electric Vehicles

Harmful high-frequency stray currents are unavoidable in most applications in the railroad industry. When the current passes through rolling bearings, it poses a threat to the reliability of the machine. Galvanic corrosion can damage and degrade the performance of bearings in traction motors, electric motors and generators, resulting in costly downtime and unscheduled maintenance.

The INSOCOAT VL0241 and VL0246 are ideal for small and heavy-duty traction motors:

- Their design is based on cylindrical roller bearings and deep groove ball bearings.

- Electrical insulation by means of aluminum oxide coating on the outer surface of the outer ring

- VL0241 Standard Layer 200 [MΩ]; VL0246 Advanced Layer 400 [MΩ]

INSOCOAT VL2071 and VL2076 are perfectly suited for larger traction motors:

- Aluminium oxide coating on the outer surface of the inner ring: holes, chamfers and end faces

- Reduced capacitance due to smaller coating surface area

- Increased electrical impedance

- Improved electrical insulation properties compared to coated outer ring design VL0241

- VL2071 Standard Layer 200 [MΩ]; VL2076 Advanced Layer 400 [MΩ]

Applications in recirculation fans

Major international producers of heavy-duty cartonboard are incurring high maintenance and repair costs due to their large flue gas recirculation fans. These costs are due to the premature failure of bearings caused by stray currents intruding into the bearings through the frequency converter. Bearings in boiler hot air blower motors only last an average of six months. A solution was needed to eliminate damaging currents, increase reliability and reduce maintenance and repair costs. SKF hybrid ceramic bearings with ceramic rolling elements are an alternative to INSOCOAT bearings, which have additional features to enhance the performance of the fan. Since the manufacturer switched to insulated bearings five years ago, there have been no more bearing failures in the heaters. In addition, variable frequency drives can be used at full load. The savings in maintenance and repair costs for this plant are enormous. The reduction in downtime and the increase in capacity have significantly impacted the final benefit.

Selecting and Installing SKF Insulated Bearings

To prolong the service life of the bearings, we should choose suitable insulated bearings, pay attention to the installation method, and check and verify the performance of the insulated bearings in time.

How to choose the right model according to the application requirements

Selecting the right SKF bearing type requires detailed consideration based on application requirements, mainly including the following aspects:

- Radial and axial loads:

Radial load: bearings that mainly bear radial loads are radial bearings, such as cylindrical roller bearings and ball bearings. n-type and nu-type cylindrical roller bearings can only bear radial loads, while other types of centripetal bearings can bear both radial and axial loads.

Axial load: mainly axial load bearing for thrust bearings, such as thrust cylindrical roller bearings and thrust spherical roller bearings. These bearings can withstand one or two directions of axial force at the same time, depending on the structure.

- Size limitations and speed of rotation:

Size Limitations: Mounting space for bearings is usually limited, so bearing type and size selection needs to be based on mechanical design constraints. Deep groove ball bearings, self-aligning ball bearings and cylindrical roller bearings are suitable for high speeds.

Speed: The permissible speed of a bearing depends on factors such as its type, size, accuracy, type of cage, load, lubrication method and cooling method. Generally, deep groove ball bearings, self-aligning ball bearings and cylindrical roller bearings are suitable for high speeds.

- Precision and rigidity:

Precision: For machinery requiring high precision and high-speed operation, it is recommended to use bearings with grade 5 or higher precision, such as deep groove ball bearings, centripetal thrust ball bearings, or cylindrical roller bearings.

Rigidity: Roller bearings produce less elastic deformation than ball bearings and are suitable for machinery requiring high rigidity.

SKF insulated bearings mounting precautions

- Avoid directly striking the bearing surface: the insulating coating on the outside of the insulated bearings is hard and fragile, so do not use a hammer to directly strike the bearing surface when installing the bearings to avoid damaging the coating.

- Use special tools: Use professional bearing dismantling tools and avoid the use of the copper rod tapping method in order to prevent the bearing axial force from being uneven, resulting in cage deformation, rolling body damage, and other problems.

- Check the bearing insulation layer: carefully check whether the bearing package is complete before installation to ensure that the insulation layer is not broken so as not to reduce the insulation capacity, resulting in current corrosion.

- Control the oil quantity: When installing, pay attention to controlling the oil quantity of the bearing and the bearing housing to avoid too much oil causing the rolling body to slip and affect the lubrication conditions.

- Ensure insulation function: For bearings with insulation design on the outer ring, ensure that the insulation is intact during installation to avoid spark corrosion caused by rupture of the oil film.

- Selection of suitable shoulders: When installing, select suitable shoulders to avoid current flowing through the side of the bearing and affecting the insulation effect.

- Bearing chamber treatment: The bearing chamber should be poured at least a 0.5MM deep slope, with an angle of 10-15 degrees, to prevent the current from flowing through the side.

- DC Motor Testing: For DC motors, the shaft needs to be grounded during the resistance test to ensure test accuracy.

Common installation errors and how to avoid them

Common mounting errors for SKF insulated bearings include the following:

- Walking the inner ring: the shaft and bearing bore fit too loosely, resulting in sliding friction between the shaft and the bore surface, causing heat and ultimately leading to bearing damage. Sliding friction will also cause thermal cracks on the end face of the inner ring and even cause the inner ring of the bearing to fracture when used.

- Hammer directly striking the bearing: When installing bearings with inner ring interference fit, directly striking the bearing end face with a hammer is likely to damage the bearing retaining edge. The correct practice is to use a sleeve to place on the end face and install it by tapping the sleeve.

- Transmission of mounting forces through the rolling elements: This method transmits forces to the bearing raceways and rolling element surfaces, resulting in noise and premature damage to the bearing during operation.

- Heating temperature is too high: the use of an acetylene spray gun on the bearing bore heating, the temperature exceeding 727 ℃ will lead to changes in the internal metallurgical organization of bearing steel, and the cooling bearing size can not be restored to the original size.

Measures to avoid these mistakes include:

- Choose the right fit: the fit between the shaft and the bearing bore should be appropriate, avoiding too loose or too tight, in order to minimize sliding friction and heat generation.

- Use special tools: When installing, you should try to use special tools and avoid using unsuitable tools such as cloth or short fibers.

- Correct tapping method: For bearings that require an interference fit, a sleeve should be placed on the end face and installed by tapping on the sleeve, avoiding direct tapping on the bearing end face.

- Control of heating temperature: when using heating methods to install bearings, the heating temperature should not exceed 727 ℃ to prevent changes in the internal metallurgical organization of bearing steel.

- Keep clean: Keep the working environment clean when installing the bearings to avoid dust and metal debris from entering the inside of the bearings.

Post-installation performance checks and verifications

The performance check and verification of SKF insulated bearings after installation mainly includes the following aspects:

- Measurement of insulation resistance: Use a 250V specification insulation resistance meter, connect the E end of the meter to the rotating shaft, and the insulated part of the bearing (e.g., the outer ring) is covered with aluminum foil and then fixed with a bare copper wire tie, and then connected to the L end of the meter. Or install the insulated bearing into the bearing chamber of the bearing housing or motor end cover, and measure the insulation resistance between the rotating shaft and the bearing housing or motor end cover under the condition that there is no electrical access between the bearing housing or motor end cover and the rotating shaft with the insulated bearing installed.

- Determination of Bearing Current: For motors using rolling bearings, the shaft current can be determined by a specific method to know the value of the current flowing through the motor bearings.

- Lubricant inspection: Check that the lubricant is clean and free of contaminants. If the lubricant is contaminated, it needs to be replaced with a new lubricant, and the oil must be filtered before use.

- Inspection of radial clearance: radial clearance should be inspected after installation to ensure that the bearings are smooth and flexible, with no vibration and no left or right swing. For bearings that cannot be measured with a plug gauge, the reduction of radial clearance can be replaced by measuring the movement of the bearing in the axial direction.

- Checking the tightness of the bearing against the shoulder: Use the light method or the thickness gauge inspection method to ensure that the bearing is tight against the shoulder. The light method is to judge by the light leakage, and the thickness gauge inspection method is to judge the gap by inserting the thickness gauge.

- Inspection of seals and axial fasteners: Ensure that the seals and axial fasteners are installed correctly and that the lubricant flows freely into the bearings.

Maintenance and lubrication requirements

Maintenance and lubrication requirements for SKF insulated bearings include the following:

- Lubricant selection: SKF insulated bearings are mainly lubricated with two types of oil and grease. Oil bath lubrication is suitable for low and medium-speed bearings, where a part of the bearing is immersed in an oil bath, and the lubricant is brought up by the rotating bearing parts and then flows back into the oil bath. Circulating oil lubrication is suitable for high-speed bearings, where filtered oil is transferred to the inside of the bearing by means of an oil pump, and the lubricant is then filtered and cooled for use.

- Lubrication method: For high-pressure jet lubrication, a high-pressure oil pump is used to shoot the lubricant into the bearing through the nozzle, which is especially suitable for high-speed rotating bearings. The nozzle should be placed between the inner ring and the cage. Circulating oil lubrication uses an oil pump to transfer filtered oil to the inside of the bearing, and the lubricant is filtered and cooled again for use after operation through the bearing.

- Cleaning and maintenance: When disassembling the bearings, first make a record of the appearance by taking pictures and using other methods, confirm the amount of remaining lubricant, and sample the lubricant. Cleaning is divided into rough cleaning and fine cleaning, rough cleaning in the oil with a brush or other to remove grease or adhesion, fine cleaning in the oil slowly rotating bearings, and the use of neutral water-free diesel oil or kerosene. Immediately after cleaning, apply antirust oil or antirust grease on the bearings.

- Storage and Handling: SKF bearings must be handled and stored with care to avoid rust or corrosion. Newly received bearings should not be removed directly from their packaging until they are ready for mounting. Store them away from moisture or sudden temperature changes, preferably on pallets or shelves.

Future Trends in SKF Insulated Bearings

The future development direction of SKF Insulated Bearings will focus on technological innovation, market demand adaptation, intelligent management and environmentally sustainable development to cope with changing market demand and industry trends.

New material development and performance enhancement

Innovations in material technology and manufacturing processes: Future trends will focus on innovations in material technology and improvements in manufacturing processes to enhance wear resistance, reduce friction and improve thermal conductivity. Through continuous research and development of new materials and new processes, SKF insulated bearings will be more efficient and environmentally friendly.

Intelligent monitoring and predictive maintenance integration

Intelligent and digital management: with the arrival of industry 4.0, intelligent manufacturing and digital management will become an important trend.SKF insulated bearings will introduce automated production lines, Internet of Things technology and big data analysis to realize intelligent management of the production process and improve production efficiency and product quality.

Prospects for applications in emerging industries

Increased demand for e-mobility and renewable energy: with the rise of e-mobility and renewable energy, the demand for electrically insulated bearings will further increase. sKF insulated bearings will adapt to this trend and promote its development in the direction of being more efficient and more environmentally friendly.

Environmental and sustainable development considerations

Environmental certifications and solutions: The SKF Group, as the first bearing company to achieve ISO 14001 environmental certification, continues to be committed to environmental protection and sustainable development. By providing innovative solutions, we help our customers to improve their overall production capacity.

Global market demand and growth forecast

Changes in market demand: the development of downstream industries such as automotive, machinery manufacturing and new energy will drive the demand for high-performance, high-reliability bearings. SKF insulated bearings will be adapted to these market demands and provide better quality products and services.

Conclusion: Choose SKF Insulated Bearings to Enhance Your Equipment Performance

SKF, as a leading company in the bearing industry, has strong R&D strength and manufacturing capability. Its insulated bearing products are not only technologically advanced but also of excellent quality, providing users with a reliable choice. SKF has continuously optimized the INSOCOAT insulated bearings with a new generation of versions that are more resistant to moisture and maintain a high and stable insulation resistance even under extreme climatic conditions. This spirit of continuous optimization and innovation has kept SKF insulated bearings at the forefront of technology. Choosing SKF insulated bearings not only prevents current from passing through the bearings and extends bearing life but also significantly improves the reliability and operational efficiency of the equipment, reduces maintenance costs, and is suitable for a wide range of equipment, making it an ideal choice for improving equipment performance.

TFL Insulated Bearings, as a professional agent and marketer of SKF, selects the most suitable products according to your needs, welcome to consult us!

Frequently Asked Questions

- What is the difference between SKF insulated bearings and normal bearings?

The main differences between SKF insulated bearings and normal bearings are insulation properties, application scenarios and maintenance costs.

- insulation properties

SKF insulated bearings are made insulating by applying a uniform ceramic (alumina) coating to the inner or outer ring of the bearing using plasma spray technology, or by machining the rolling elements using ceramic materials.

- application scenario

SKF-insulated bearings are particularly suitable for electric motors, generators and other equipment, especially when the frequency conversion motor is more widely used. Due to their insulating properties, they can effectively guarantee the operational reliability of the equipment and reduce the damage caused by the current.

- maintenance cost

Since SKF-insulated bearings are protected from current-induced damage, the frequency of repairs and maintenance is reduced, thus lowering maintenance costs. In addition, the longer service life of insulated bearings reduces the frequency of replacement, further reducing the total cost of ownership.

- How can I tell if my equipment requires insulated bearings?

The main basis for determining whether equipment needs insulated bearings is whether the equipment will be affected by galvanic corrosion.

- What is the service life of SKF insulated bearings?

The service life of SKF insulated bearings is usually between 10 and 20 years, depending on a variety of factors, including the use of the environment, maintenance and operating habits.

- Do I need special tools to install SKF insulated bearings?

Mounting SKF-insulated bearings requires the use of some special tools.

- Specialized tools: Professional bearing dismantling tools can avoid damage to the bearings due to improper operation. For example, the use of the copper rod knock-in method is likely to lead to the uneven axial force of the bearing, resulting in deformation of the cage and rolling element damage.

- Insulation protection: During installation, special attention should be paid to protecting the insulation of the bearings. Do not strike the bearing surface directly with a hammer, as the insulating coating on the outside of the insulated bearing is hard and fragile.

- Cleaning Requirements: The bearing chamber and bearings should be cleaned prior to installation to ensure that there are no conductive bodies attached to avoid damage caused by current passing through the bearings.

- Suitable Shoulder: Choose a suitable shoulder to avoid current flowing through the side of the bearing and causing damage to the bearing.

- Angle treatment: The bearing chamber needs to be poured at least 0.5MM deep slope 10-15℃ angle to prevent the current from passing through the bearing.

- DC Motor Handling: For DC motors, the shaft needs to be grounded during the resistance test to prevent current from passing through the bearings.

- Can SKF-insulated bearings be used in high-temperature environments?

SKF high-temperature bearings are designed to operate over an extremely wide operating temperature range of -150 to +350°C. These bearings are suitable for use in equipment in high-temperature environments such as ovens, furnaces, or paint applicators, and meet the need to reduce equipment operating costs, extend operating life, and improve equipment operational reliability.