Electrically Insulated Bearings for Electric Motors

Introduction

Electrically insulated bearings are mainly used in various types of motor industries, and as an important equipment support component, the electrical insulation in bearings plays a crucial role. High-performance electrically insulated bearings can protect motor and generator equipment well, reduce energy consumption, and extend life. TFL, as a specialized insulated bearing supplier, provides better quality electrically insulated bearings to protect the stability and safety of the motor during high-speed operation.

What are Electrically Insulated Bearings?

Electrically insulated bearings, also known as insulated bearings, are a special type of rolling bearings whose main feature is the insulating property that prevents current from passing through the bearing itself. The use of ceramic coating or other insulating materials to prevent the passage of current to avoid current damage to the bearing and its equipment is widely used in need for electrical insulation protection occasions, such as motors, generators, and other equipment to ensure the safe operation of equipment and systems.

Benefits of Electrically Insulated Bearings

- Improve the reliability of the equipment:

Electrically insulated bearings avoid the negative effects of electrical currents on bearings and, to a greater extent, enable safer operation and longer stable operation of equipment.

- Extend the service life of the equipment:

Electrically insulated bearings, because of the use of special materials and manufacturing processes, have better resistance to high temperature, corrosion resistance, and other properties but are also more adaptable to harsh environments.

- Reduce maintenance costs:

Reduce the number of equipment failures and repairs, and reduce downtime and maintenance costs.

- Prevent galvanic corrosion:

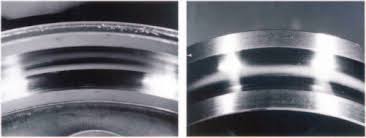

The coating process of electrically insulated bearings guarantees good insulation properties and protects the bearings from galvanic corrosion effects.

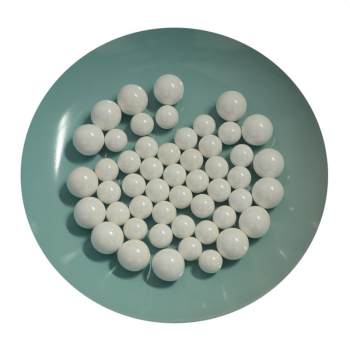

- Wear-resistant:

Because the insulated bearings use ceramic rolling elements made of Si3N4 material, which greatly improves wear resistance, the requirements for lubrication action are reduced.

- Wide range of applications:

The same dimensions and technical characteristics with non-insulated bearings can be seamlessly replaced to meet a variety of work requirements.

To summarize, electrically insulated bearings, through their unique design and excellent performance, provide higher reliability and longer service life for a variety of equipment and machinery while reducing maintenance costs and are an indispensable and important component in modern industry.

Applications of Electrically Insulated Bearings

- Electric power industry:

Insulated cylindrical roller bearings for generators, wind turbines, hydroelectric generators, and thermal generators, applicable to motors, and generators, especially for frequency conversion motors.

- Railway industry:

Insulated cylindrical roller bearings for traction motors of internal combustion locomotives: applied to locomotives and so on.

- Mechanical and metallurgical industries:

Insulated bearings for high-power frequency conversion motors: applied to cranes, textile machinery, printing machinery, ironmaking equipment, steelmaking equipment, steel rolling equipment, cutting equipment, cooking equipment, smelting equipment, and so on.

- Mining Machinery Industry:

Insulated bearings for high-power high-voltage motors, applicable to mining machinery, coal separator, coal washers, crushers, ball mills, grinders, and sand mills.

- Petrochemical Industry:

Insulated bearings for high-power explosion-proof motors: applied to Compressor, etc.

How to Choose the Right Insulated Bearing

- Size selection:

According to the motor bearing size selection, consider the use of machinery and design life, intentionally increasing the fatigue life coefficient. The selection of bearings is not only to consider the size of the bearing but also to consider its ability to adapt to specific operating environments and conditions.

- Design life:

Users can select suitable bearings by using empirical fatigue life coefficients based on usage conditions and design life.

- Accuracy selection:

Customers can refer to international standards and select the size and rotational accuracy that suits their needs.

- Match selection:

Two fits need to be referenced: the bearing ID to the shaft and the OD to the housing. Depending on the condition and type of load, choose either an interference fit or a clearance fit to ensure the proper operation and service life of the bearing.

- Insulation performance check:

Test insulation steps include wrapping metal with conductive media on the outside of the bearing for measurement or pressing the insulated bearing into the housing for measurement. Ensure that the selected bearings have good insulation properties to avoid current damage to the bearings.

- Considering special application scenarios:

For example, in special application scenarios such as inverter motors, insulated bearings can block the current, avoid galvanic corrosion damage, and improve the reliability and service life of the equipment.

In summary, the selection of suitable electrical insulation bearings requires comprehensive consideration of size, design life, accuracy, fit and insulation performance and other factors to ensure that the selected bearings can meet the specific application requirements and environmental conditions so as to improve the reliability and service life of the equipment.

Advantages of TFL Electrically Insulated Bearings

TFL Bearing Company is dedicated to producing high-quality bearings for customers, using advanced insulating materials and coating technology to prevent galvanic corrosion more effectively, maximize the protection of motors and improve reliability. In particular, the inner and outer rings in the electrically insulated bearing are coated with silicon nitride and zirconium oxide materials, which provide excellent insulating properties and wear resistance. These ceramic rolling elements maintain good insulation properties at high temperatures and are suitable for high-speed, low-friction, low-temperature operating environments, even under dry friction conditions.

Meanwhile, our electrically insulated bearings are not only used in traditional motors and generators but also in wind power, the electric vehicle industry, industrial automation, etc. They are widely used to meet the needs of different industries, and insulated bearings also have significant advantages in terms of cost-effectiveness.

Maintenance Tips for Electrically Insulated Bearings

In order to maintain the original performance of the bearings in good condition for as long as possible, it is necessary to maintain and overhaul the bearings in order to prevent accidents before they occur, to ensure the reliability of operation, and to improve productivity and economy. Maintenance should be carried out regularly in accordance with the operating conditions of the machine.

- Avoid extreme operating conditions such as overloading and overspeed, and avoid overloading the insulated bearings.

- Inspect and replace the insulated bearings regularly to avoid deterioration of insulation performance due to the aging of the insulating material.

- Avoid using too much grease, which will affect the insulation performance of the insulated bearings.

- Avoid using corrosive liquids such as acidic, alkaline, etc., which may damage the insulating materials.

- Avoid using metal tools so as not to scratch the surface of the insulating bearing.

Conclusion

Insulated bearings in the non-driven end of the motor are important to ensure stable operation and long service life of the motor. Choosing high quality insulated bearings and regular inspection and maintenance make your motor safer and more reliable.TFL Bearings offers high quality options to meet a variety of industrial applications. Contact us today for more information or to place an order.

Frequently Asked Questions

What are electrically insulated bearings used for?

Electrically insulated bearings are generally used in a variety of motor and generator equipment in the electric power industry, railroad industry, machinery and metallurgy, mining machinery and petrochemical industry.

How do electrically insulated bearings work?

Electrically insulated bearings use the spraying process, spray coating on the outer surface of the bearing to increase the insulating material. The coating and the substrate bonding force are strong, so the bearings have good insulating properties and can avoid the current on the bearings to produce galvanic corrosion to prevent the current caused by the damage to the equipment.

Why are insulated bearings important?

Insulated bearings play an important role in the operation of the motor, on the one hand, because the role of the insulated bearings is to isolate the current inside the motor from the outside world by isolating the current to protect personal safety; on the other hand, it is to protect the motor from the damage of the current to extend the life of the motor.

Where can I buy electrically insulated bearings?

If you want to buy insulated bearings, there are many excellent manufacturers of electrically insulated bearings in Chin, among which TFL Bearing Company tries its best to provide customers with better goods and services and guarantee your trust with professional product quality. Come to TFL to meet high-performance bearings.

What are the benefits of using insulated bearings?

Insulated bearings are a high-quality mechanical component that can avoid equipment failures caused by electrical problems, improve equipment reliability, extend equipment life and reduce maintenance costs.