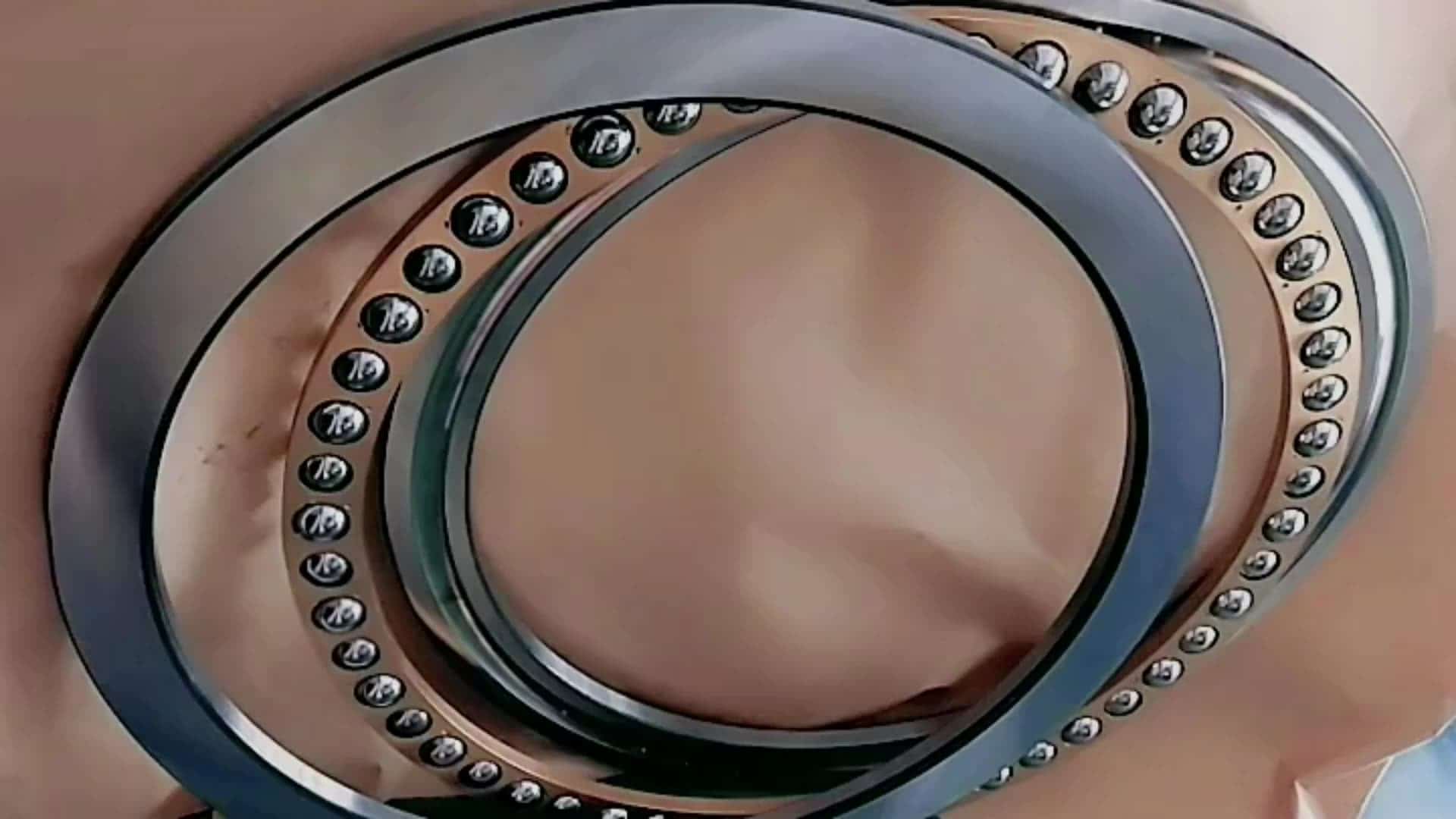

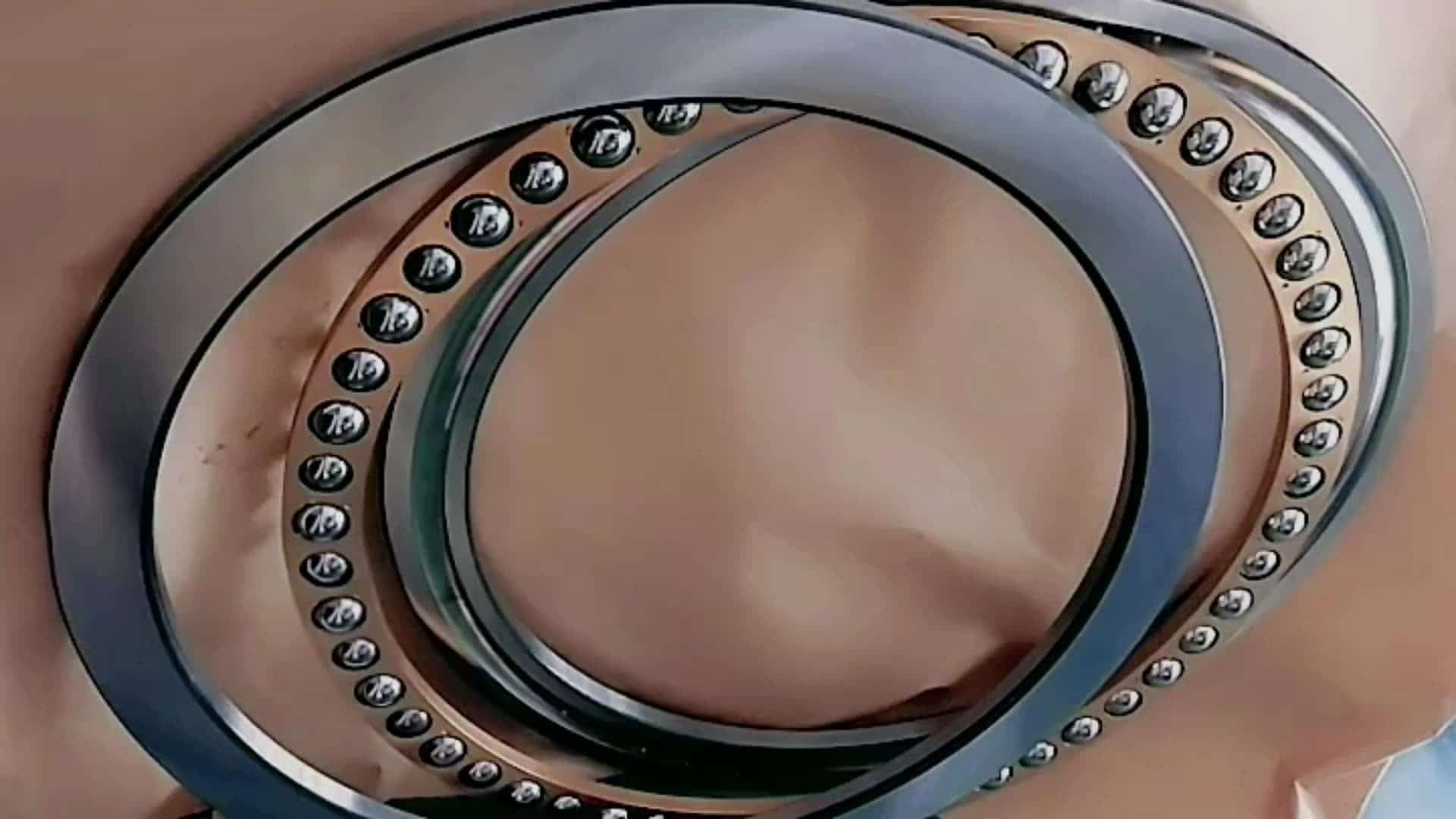

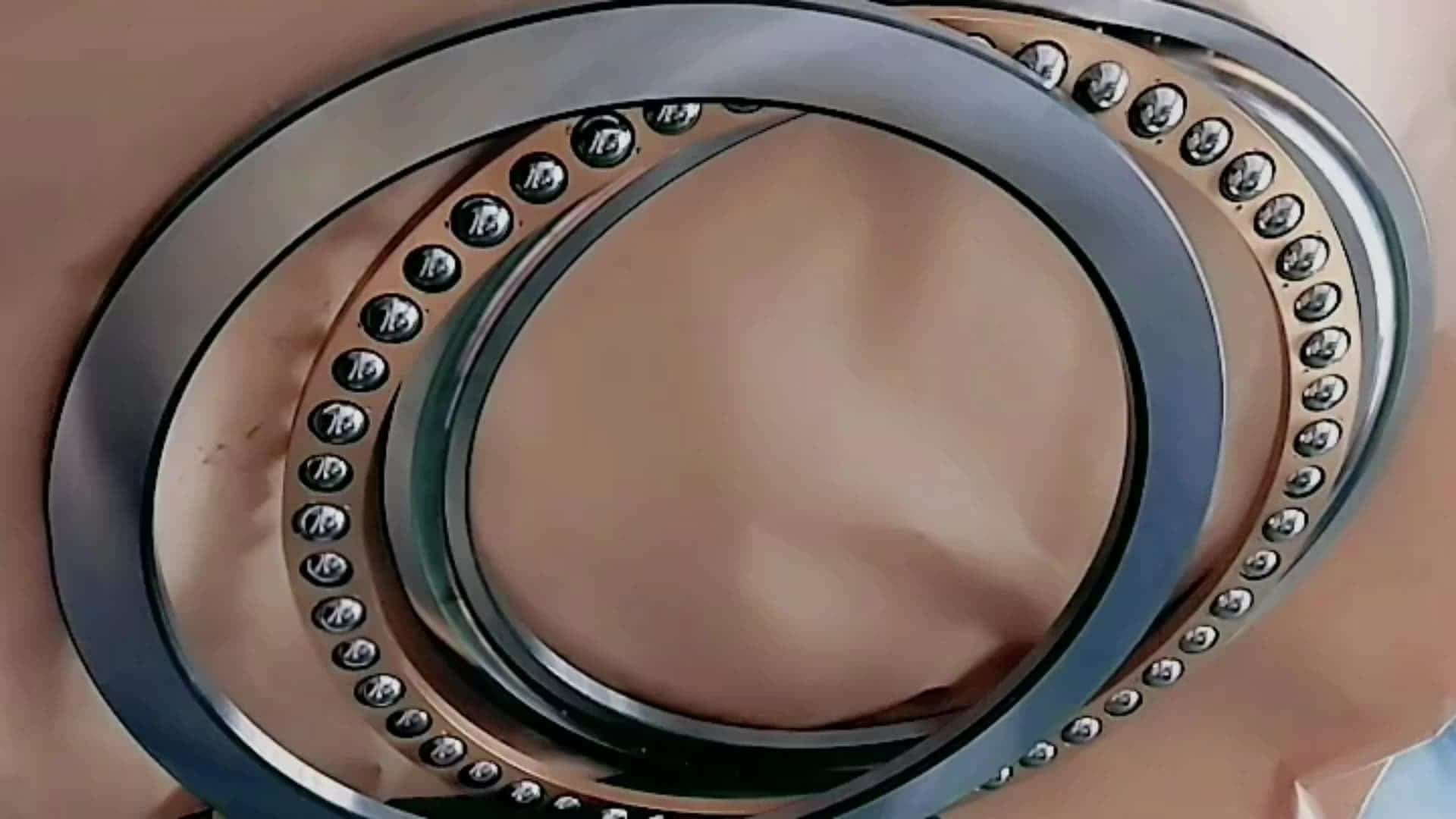

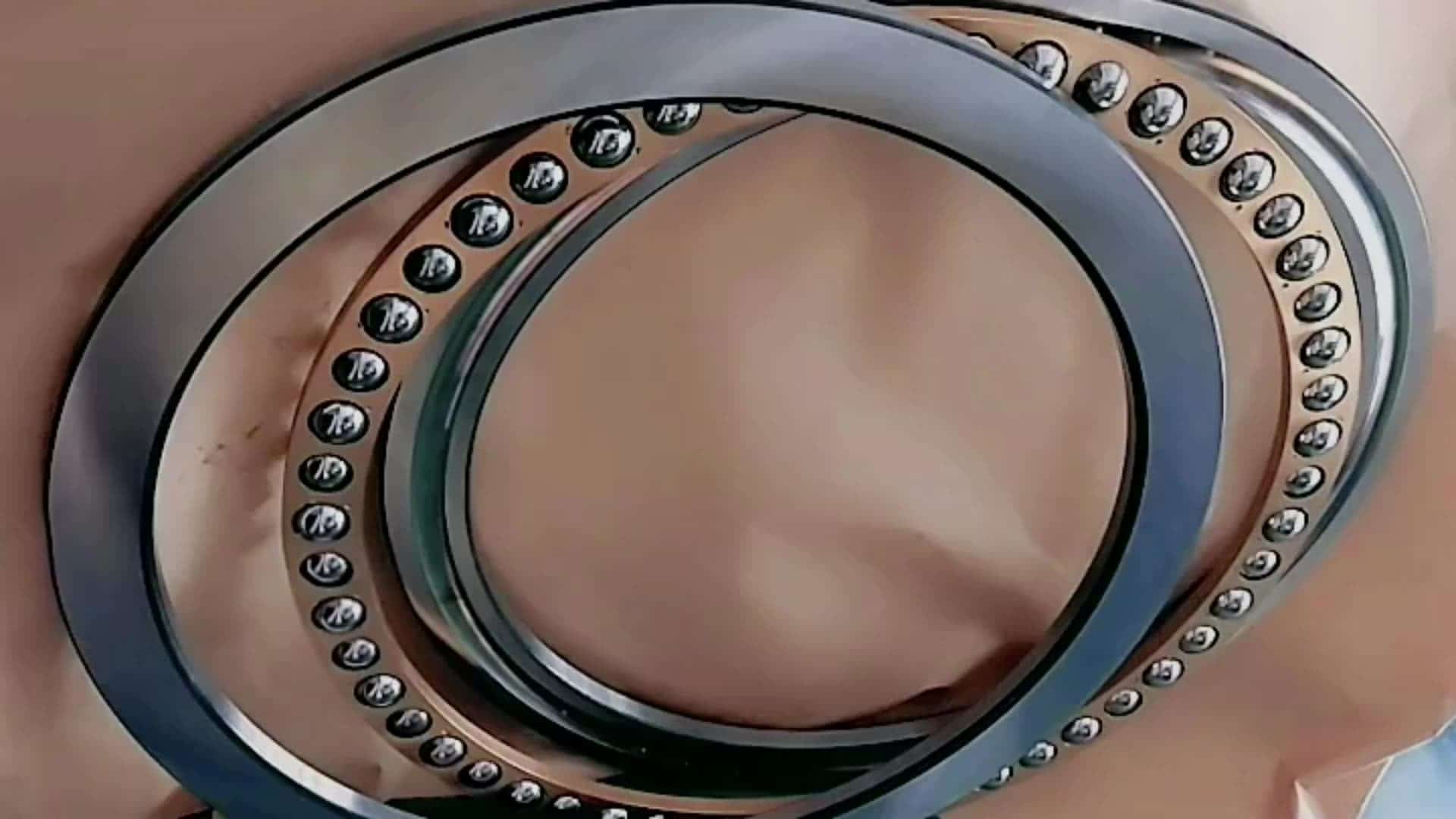

Thrust Ball Bearings

TFL as a leading bearing manufacturer and supplier in China, can provide standard thrust ball bearings, stainless steel thrust ball bearings, ceramic thrust ball bearings, one-way thrust ball bearings, angular contact thrust ball bearings, s thrust ball bearings for shaft ends, miniature thrust ball bearings, large diameter thrust balls Bearings, imperial thrust ball bearings, bearing sizes support metric and inch.

Various sizes can also be customized according to customers’ needs for bearings. If necessary, please email me.

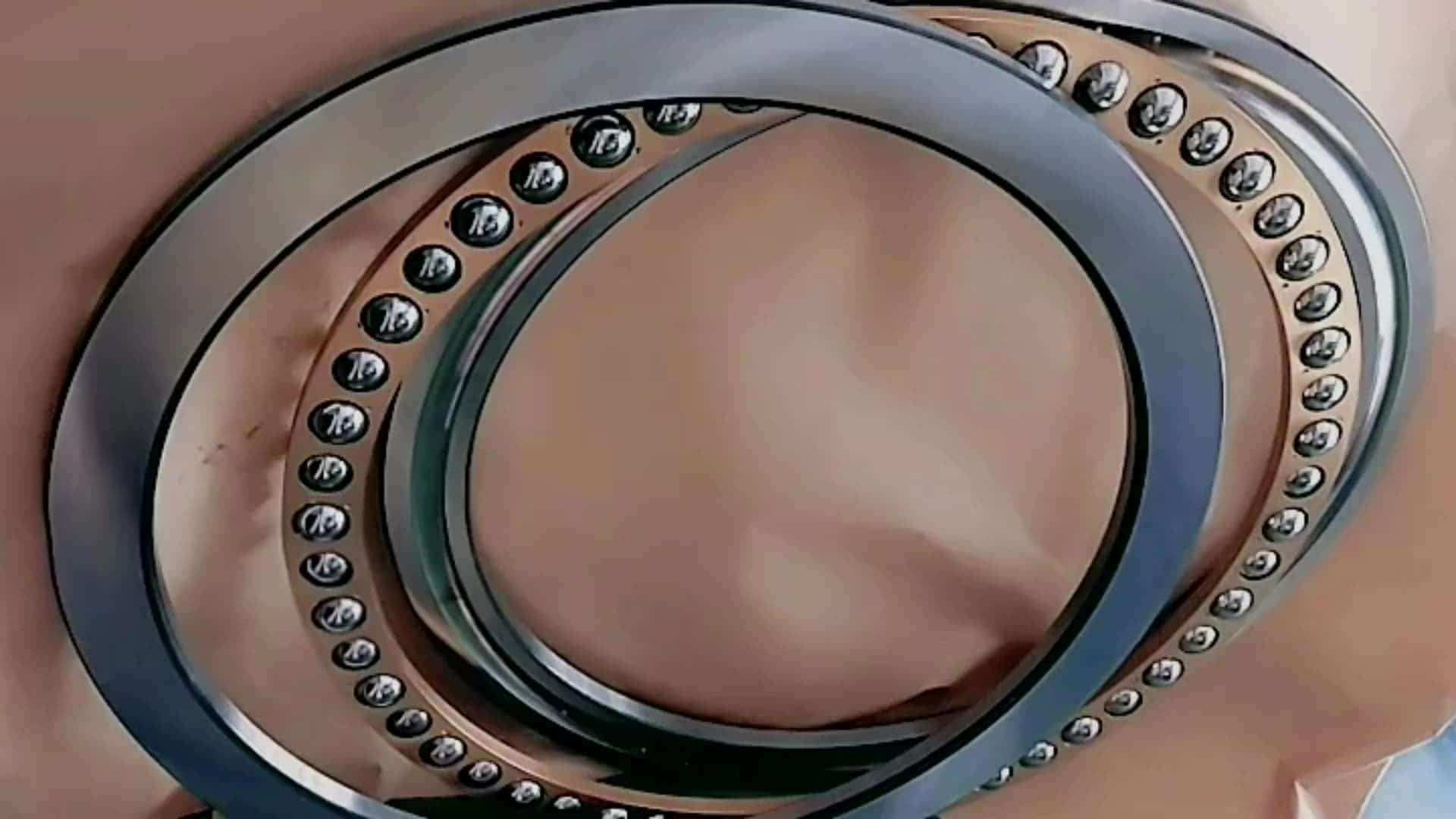

What is a Thrust Ball Bearing?

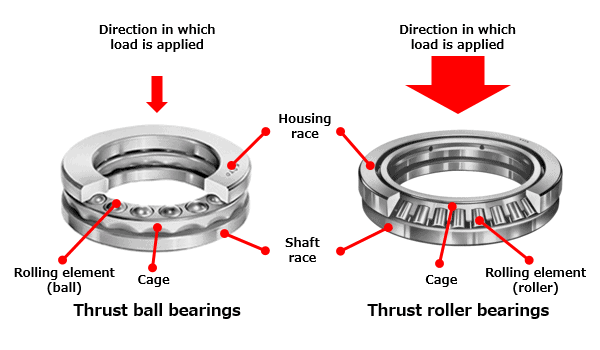

Thrust ball bearings are divided into flat seats or self-aligning seats according to the shape of the outer ring seat (bearing seat washer). They can bear axial load but cannot bear radial load. For one-way thrust ball bearings, pressed steel cages and machined brass cages are usually used. The thrust ball bearing cage is the same as the one-way thrust ball bearing of the same diameter series.

What Are Thrust Ball Bearings Used For?

Thrust ball bearings-Thrust ball bearings cannot transmit any radial load. This type is prone to misalignment, and manufacturers often install spherical grooves on the housing gasket to reduce this possibility. Although very suitable for high-speed applications, their performance will be affected under heavy loads.

Application of Ball Bearing

- Pump

- Fluid control valve

- Machine tool

- Turntable

- Agricultural machinery

- Industrial machinery for cleaning and bottling

How Do You Choose Thrust Bearings?

Single direction and double direction thrust bearings are available. Double direction thrust ball bearings contain two rows of balls and additional washers. The caged ball set sits within the outer raceways. Most thrust bearings are made from metal, primarily steel, which requires lubrication to reduce friction, enable optimal performance, and prevent corrosion.

When deciding which bearing to choose, it is essential to consider the following points: the direction of the load, the magnitude of the load, the speed of rotation, and the specific environment in which the bearing is used. It is also worthwhile to ensure that high-quality standards manufacture the bearings to achieve the highest level of rollability even under heavy thrust loads.

Of course, the correct assembly is as important as the choice of bearings. In any application, contamination during assembly will directly lead to bearing failure. Dust and dirt can significantly reduce bearing lubrication or cause surface wear. Similarly, improper alignment of the two thrust washers will shorten the life of the bearing.

When thrust bearings are used at higher speeds but low loads, another problem may arise. Centrifugal force causes the balls to run on the outer edge of the raceway, resulting in slippage and rapid wear. This is called smearing. In this case, the load should be increased artificially to keep the balls more concentrated in the raceway.

Overloading, incorrect installation, and contamination can cause bearing damage and failure. It is essential to consider all factors when choosing a thrust bearing, as these bearings can be very demanding.

FAQ

Latest content

Category

30-Day Money-Back Guarantee

We back every sale with a 30-day money-back guarantee. If you’re somehow not happy with your purchase, just let us know.