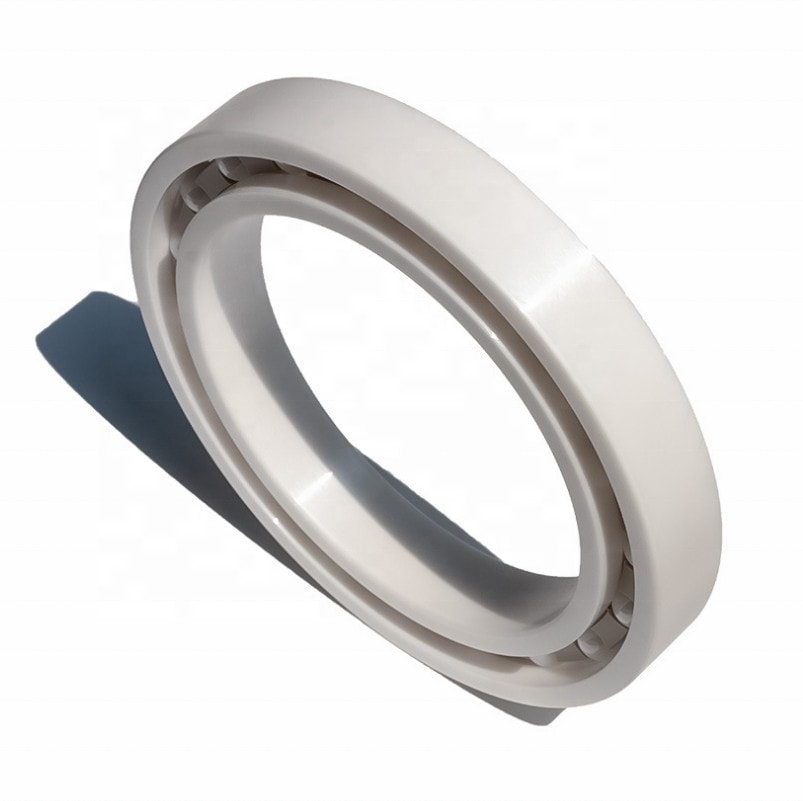

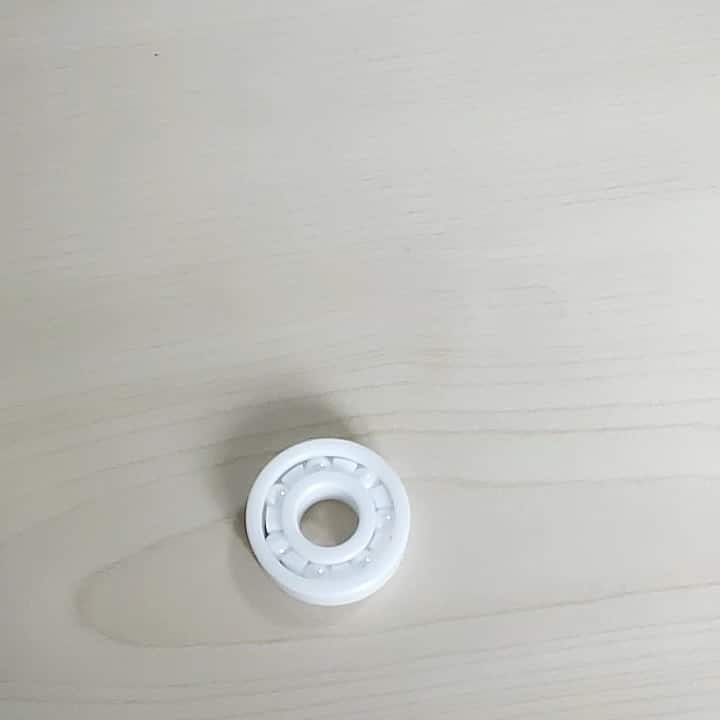

Full ZrO2 Ceramic 6901CE Thin Section Bearing for plating equipment

- Samples:

-

$8.70/Piece | 1 Piece (Min. Order) |

- Customization:

-

Customized logo(Min. Order: 100 Pieces)Customized packaging(Min. Order: 100 Pieces)

ABEC9 High-Temperature Full ZrO2 Ceramic 6901CE Thin Section Bearing for plating equipment

Material: Chrome steel, stainless steel, ceramic ZrO2 & Si3N4, Plastic

Type: Open, ZZ, 2rs

Full ceramic bearing ZrO2 material has perfect propriety, such as being suitable for low and high temperatures, high load capacity, corrosion resistance, nonmagnetic insulated and self-lubrication. Thus it suits the specific applications not available for bearing steel and hybrid construction ceramic ball bearing materials.

1. Ceramic Bearings have two types of ceramic bearing, hybrid ceramic bearing and full ceramic bearing. The hybrid ceramic bearing has steel inner and outer rings with ceramic balls.

2. Ceramic Bearings, Si3N4 stands for the silicon nitride ceramic material and is black coloured,

3. Ceramic Bearings, SiC stands for the silicon carbide material and is also black coloured.

4. Ceramic Bearings, ZrO2 stands for the zirconium dioxide, also known as zirconia or zirconium oxide; they are white-coloured, a ZrO2 ball looks exactly like a pearl.

5. The ceramic material is not stronger than steel, but ceramic bearings are lighter and have lower friction than steel, making ceramic bearings go faster with lower heat generated.

1. Ceramic bearing has high-temperature resistance, cold resistance, abrasion resistance, corrosion resistance and insulation, and can be used in extremely bad environments and special conditions.

2. Ceramic bearings can be widely used in skateboard, aviation, spaceflight, navigation, petroleum, chemical industry, automobile, electronics, metallurgical, power, textile, pumps, medical equipment and scientific research.

| Bearing Type | Dimensions | Weight(kg) | |||

| d | D | B | ZrO2 | Si3N4 | |

| 695CE | 5 | 13 | 4 | 0.0019 | 0.0010 |

| 686CE | 6 | 13 | 3.5 | 0.0015 |

0.0008 |

| 696CE | 15 | 5 | 0.0030 | 0.0016 | |

| 606CE | 17 | 6 | 0.0046 | 0.0025 | |

| 687CE | 7 | 14 | 3.5 | 0.0017 | 0.0009 |

| 697CE | 17 | 5 | 0.0040 | 0.0022 | |

| 607CE | 19 | 6 | 0.0059 | 0.0032 | |

| 627CE | 22 | 7 | 0.0098 | 0.0053 | |

| 688CE | 8 | 16 | 4 | 0.0025 | 0.0014 |

| 698CE | 19 | 6 | 0.0056 | 0.0030 | |

| 608CE | 22 | 7 | 0.0093 | 0.0050 | |

| 628CE | 24 | 8 | 0.013 | 0.0072 | |

| 689CE | 9 | 17 | 4 | 0.0027 | 0.0015 |

| 699CE | 20 | 6 | 0.0065 | 0.0035 | |

| 609CE | 24 | 7 | 0.011 | 0.0060 | |

| 629CE | 26 | 8 | 0.015 | 0.0081 | |

| 6000CE | 10 | 26 | 8 | 0.014 | 0.0075 |

| 6200CE | 30 | 9 | 0.025 | 0.013 | |

| 6300CE | 35 | 11 | 0.040 | 0.022 | |

| 6801CE | 12 | 21 | 5 | 0.005 | 0.0025 |

| 6901CE | 24 | 6 | 0.008 | 0.0042 | |

| 6001CE | 28 | 8 | 0.017 | 0.0092 | |

| 6201CE | 32 | 10 | 0.028 | 0.015 | |

| 6301CE | 37 | 12 | 0.046 | 0.025 | |

| 6802CE | 15 | 24 | 5 | 0.005 | 0.0029 |

| 6902CE | 28 | 7 | 0.012 | 0.0063 | |

| 6002CE | 32 | 9 | 0.024 | 0.013 | |

| 6202CE | 35 | 11 | 0.035 | 0.019 | |

| 6302CE | 42 | 13 | 0.064 | 0.035 | |

| 6803CE | 17 | 26 | 5 | 0.005 | 0.0029 |

| 6903CE | 30 | 7 | 0.013 | 0.0071 | |

| 6003CE | 35 | 10 | 0.032 | 0.017 | |

| 6203CE | 40 | 12 | 0.052 | 0.028 | |

| 6303CE | 62 | 17 | 0.21 | 0.11 | |

| 6804CE | 20 | 32 | 7 | 0.013 | 0.007 |

| 6904CE | 37 | 9 | 0.028 | 0.015 | |

| 6004CE | 42 | 12 | 0.052 | 0.028 | |

| 6204CE | 47 | 14 | 0.082 | 0.045 | |

| 6304CE | 52 | 15 | 0.11 | 0.060 | |

| 6805CE | 25 | 37 | 7 | 0.016 | 0.009 |

| 6905CE | 42 | 9 | 0.032 | 0.018 | |

| 6005CE | 47 | 12 | 0.061 | 0.033 | |

| 6205CE | 52 | 15 | 0.099 | 0.054 | |

| 6305CE | 62 | 17 | 0.18 | 0.098 | |

| 6006CE | 30 | 55 | 13 | 0.089 | 0.048 |

| 6206CE | 62 | 16 | 0.15 | 0.083 | |

| 6306CE | 72 | 19 | 0.27 | 0.14 | |