KOYO&JTEKT participated in the 2020 China International Bearing and Special Equipment Exhibition

The 17th China International Bearing and Special Equipment Exhibition ended successfully on December 12, 2020, at the National Convention and Exhibition Center (Shanghai). The exhibition brought together nearly a thousand bearing-related companies worldwide to participate in the exhibition, with as many as 100,000 visitors. The chairman of JTEK, Tristone, attended the opening ceremony and was invited to cut the ribbon for the exhibition’s opening.

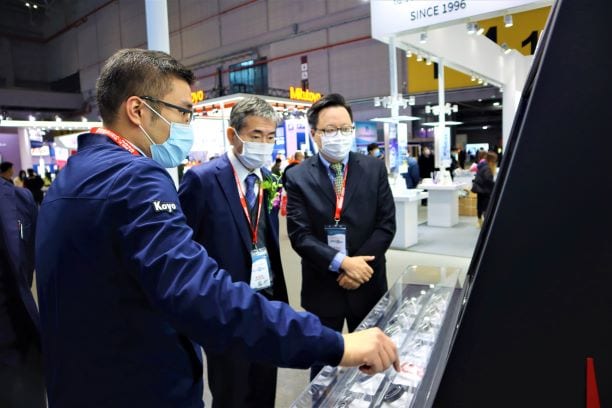

Professionals and R&D teams under JTEKT (China) Investment Co., Ltd. conducted in-depth exchanges with customers at home and abroad at the exhibition site. Among them, the Lexus LC500 cutting car model of JTEKT and the special environment teaching machine used to show the bearing application scene attracted the attention of the visitors and exhibitors.

Main exhibits

- Bearings for robots

As a key development area of ”Made in China 2025″, the robotics industry has attracted attention from all walks of life. In recent years, the development of domestic robots has grown by leaps and bounds, with an increase of more than 30%, and the market prospects continue to improve. Reducer, servo motor, controller, as the key parts of the robot, its stability, reliability, safety, and low cost have become the top priority for the further improvement of the industrialization level. To this end, JTEKT will display ultra-small tapered roller bearings for reducers, ultra-thin wall ball bearings for reducer spindles, long-life and high-load needle roller bearings and special shaft rotation for servo motors. In addition, JTEKT will cooperate with Yaskawa Robots to exhibit the oil seal products for rapid acceleration and deceleration to show visitors the location of Koyo bearings more vividly.

- Bearings for special environments

JTEKT EXSEV bearing series can be used in special environments such as purification, vacuum, high temperature, and corrosion. To achieve special properties such as non-magnetic, insulation, and high speed, the bearing adopts special materials and lubricants, including a new generation of New ultra-clean (clean pro) bearings, ceramics with various characteristics as high strength, corrosion resistance, and high-temperature resistance. Bearings, grease-packed bearings for ultra-high temperature, etc. This series improves the service life of the product, effectively reduces the equipment’s operating cost, and contributes to product yield and quality improvement.

- High-precision bearings

The high-precision and high-rigidity ball screw support bearings provided by JTEKT are widely used in various industrial equipment and precision instruments. The customer combines the bearing with the precision-machined housing to convert the rotary motion into linear motion or convert torque into axial repetitive force. At the same time, it has the characteristics of high precision, reversibility, and high efficiency. JTEKT has made unremitting efforts to improve the convenience of product assembly, reduce costs and shorten the delivery period of Chinese users.

In the spirit of “in China, for China,” 26 JTEKT Group companies in China work together to strive for excellence in production, sales, and technology and strive to be a high-quality supplier for Chinese customers. Through our efforts, To provide our customers with better service.