NSK Insulated Bearings

Introduction

NSK Bearing Company was established in 1916. Over the years, it has specialized in research and development and accumulated production experience in the bearing field. Eventually, it gained a high reputation for its high-quality, high-precision, and highly reliable insulated bearings. At the same time, NSK-insulated bearings are highly recognized for their excellent durability and ability to provide superior performance in the automotive, machinery, electric power, electronic equipment, and other industry sectors.

What are NSK Insulated Bearings?

NSK has a wealth of production experience and technical strength and, as a globally recognized bearing manufacturer, continues to develop a wide range of insulated bearing products. On the basis of maintaining the excellent mechanical properties of traditional bearings, these bearings effectively improve the electrical insulation properties of the bearings through the use of special insulating materials and process treatments, thus significantly reducing the risk of galvanic corrosion and extending the service life of the bearings.

How NSK Insulated Bearings Work

- Insulation coating: NSK insulated bearings in the bearing inner ring, outer ring, or rolling body surface are coated with a layer of insulating coating, usually ceramic materials (such as aluminum oxide) coating; the thickness is generally between 50 to 200 microns. This layer of coating is responsible for the electrical insulation function and can effectively block the current through the path of the bearing.

- Insulating Properties: The insulating coating has excellent insulating properties and is resistant to electrical jump fires at up to 1000V or even higher voltages. Thicker coatings can provide higher voltage tolerance, further enhancing the insulating effect of the bearings.

Importance of electrical insulation properties

The importance of the electrical insulation properties of NSK insulated bearings is reflected in a number of ways:

- Prevention of current leakage and electrical accidents

Electrical insulation is the process of separating the conductors of an electrical component or equipment from the rest of it, and it is important to prevent electric current from passing through components or structures that should not be energized, thus preventing electric shocks and other electrical accidents.

- Improving the reliability and durability of motors and electrical equipment

NSK insulated bearings can effectively avoid the galvanic corrosion effect of shaft current on bearings and prevent damage caused by current to grease and rolling elements and raceways, thus enhancing the reliability and durability of motors and electrical equipment.

III. Reduction of electrical noise and electromagnetic interference

NSK insulated bearings use special insulating materials and coating technology, which not only have good electrical insulation properties but also can effectively reduce electrical noise and electromagnetic interference. This is of great significance for improving the efficiency of motors and electrical equipment and reducing energy loss.

- Adaptation to harsh working environments

NSK insulated bearings use special insulating materials and coating technology to maintain stable insulating properties in harsh environments such as high temperatures, extreme cold, and corrosion.

- Enhance the overall performance of the equipment

NSK insulated bearings are used in electric motors and electrical equipment because of the advantages of excellent electrical insulation properties, reliability and durability, which help to improve the overall performance of the equipment and bring greater economic benefits to the enterprise.

HDY2 Ceramic Coated Insulated Bearings

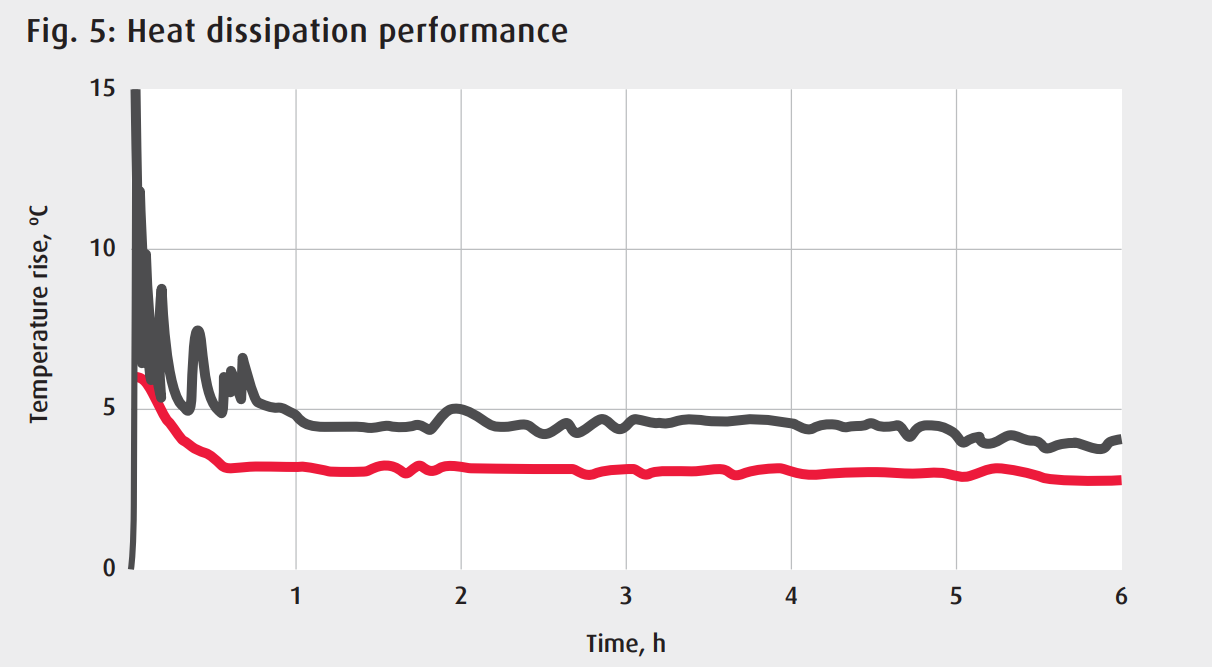

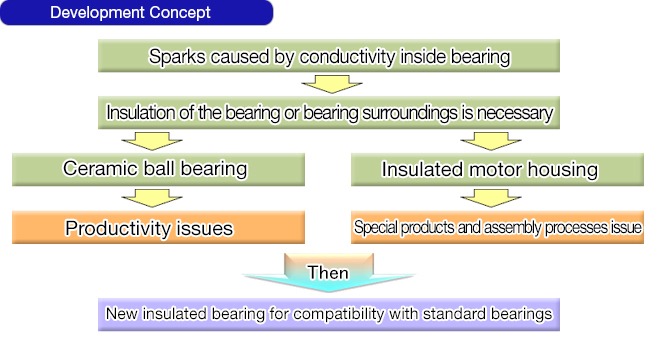

NSK’s HDY2 ceramic-coated insulated bearings feature optimized insulation and thermal conductivity to support energy efficiency and the increasing use of inverters to control motors while effectively addressing the risks associated with current damage to bearings.

Proven Advantage:

- Effective protection against galvanic corrosion damage, excellent insulation properties, and more than 10 times higher performance.

- Excellent durability, optimized coating

- 3 times the impact resistance of conventional ceramic-coated bearings

- Excellent heat dissipation and dimensions interchangeable with standard bearings

Design features and performance characteristics

NSK’s “HDY2” series ceramic-coated bearings provide excellent insulation resistance to extend bearing life for applications prone to galvanic corrosion or arcing, thereby improving the reliability and efficiency of industrial motors.

Design Features.

- Made of ultra-clean steel

- High-grade balls for quiet, stable operation at high speeds

- Open bearings with pressed steel cages

- The standard radial internal clearance is C3

- The outer ring of the bearing is coated with an alumina-based ceramic material and an optimal blend of additives.

- Bearings are plasma coated to ensure proper bonding to bearing steel

- Ceramic coating sealed with special acrylic resin for moisture resistance

- Dimensionally interchangeable with standard bearings (by ISO standards).

NSK insulated bearing specifications

HDY2 ceramic-coated insulated deep groove ball bearings are available for bore diameters from 75 to 130 mm, series 62; for bore diameters from 60 to 110 mm, series 63–6218HDY2C3

| 62 | 18 | HDY2 | C3 |

|---|---|---|---|

| Dimension Series | Bore Reference Number | Ceramic Coated Insulated | Radial Internal Clearance |

| BEARING NO. | BOUNDARY DIMENSIONS (MM) | ||

|---|---|---|---|

| O.D. | Bore | Width | |

| 6312HDY2C3 | 130 | 60 | 31 |

| 6314HDY2C3 | 150 | 70 | 35 |

| 6216HDY2C3 | 140 | 80 | 26 |

| 6219HDY2C3 | 170 | 95 | 32 |

| 6224HDY2C3 | 215 | 120 | 40 |

| 6322HDY2C3 | 240 | 110 | 50 |

Rolling bearings for industrial motors

NSK has the core product development technology and expertise to develop bearings that are reliable and highly efficient.NSK’s extensive range of rolling bearings for industrial motors optimize raceway contact to reduce noise, energy consumption, and power loss, combined with advanced lubrication technology and seal design for durability. Special materials and coatings to isolate current transmission. From high-efficiency motors and inverter motors to servo motors and EV motors, NSK rolling bearings power the industry with quiet, smooth, and trouble-free operation.

NSK bearings for vacuum conditions

Vacuum bearings are the standard series of NSK’s SPACE series for special environments. Other specialized SPACEA bearings are available for corrosive, clean room, and high-temperature applications.

FG9 Grease-filled bearings

FG9 grease-filled stainless steel bearings are suitable for use in cleanroom environments under atmospheric pressure or vacuum. Specific features include low grease dispersion particle emissions and corrosion resistance. They are often used in semiconductor manufacturing equipment and organic electroluminescence (OEL) manufacturing equipment.

Mixed Ceramic Bearings

Hybrid ceramic bearings combine ceramic balls with fluoropolymer self-lubricating cages for excellent corrosion resistance under both atmospheric pressure and vacuum. Specific features include: 1. No grease 2. The lubrication provided by solid lubricants eliminates the need for grease 3. Self-lubricating cages 4. Fluorocarbon resin cages provide continuous lubrication through solid lubricants. Often used in vacuum transportation/conveying equipment and inspection equipment.

Cleaning Lubricant DFO Bearings

DFO bearings are coated with special lubricating coatings on the rings, balls, and cages to provide superior cleanliness and long service life. The E-DFO specification uses a low vapor pressure hydrocarbon lubricant coating, while the V-DFO uses a fluorine oil lubricant coating. Specific features include: 1. Low particulate emissions 2. Specialized cleanroom grease keeps generated particles at a low level 3. Low outgassing. Common applications: semiconductor manufacturing equipment and organic electroluminescence (OEL) manufacturing equipment.

YS High-temperature bearings with spacer joints

YS bearings with spacers use an alloy-based self-lubricating material (sintered alloy) between the balls to withstand high-temperature vacuum environments. Specific features include: 1. They are suitable for high-temperature vacuum, 2. YS bearings can withstand vacuum environments up to 350°C, 3. They have a long service life, and 4. Solid lubricant spacers lubricate bearings and extend service life.

SJ High-temperature bearings with solid lubricant

SJ bearings have a “pea-shaped” construction with a solid lubricant spacer joint mounted between two balls in a single cage pocket, making them suitable for high-temperature environments at atmospheric pressure or in a vacuum. Specific features include: 1. Suitable for high temperatures 2. SJ bearings can withstand temperatures up to 400°C in both atmospheric pressure and vacuum environments 3. Long service life 4. Solid lubricants provided by gaskets and a unique cage structure prolong the life of the bearing. Common applications: transportation/conveying equipment in furnaces and high-temperature film manufacturing equipment, etc.

All-ceramic bearings (oxide-based ceramic bearings)

All ceramic bearings with ceramic outer/inner rings and ball rollers have self-lubricating fluoropolymer cages for excellent corrosion resistance in non-magnetic environments such as atmospheric pressure and vacuum.

Specific features include 1. Non-magnetic structure 2. Full ceramic structure gives these bearings the highest corrosion resistance 3. Long service life 4. Anti-friction properties help to extend service life. Common applications: semiconductor manufacturing equipment and organic electroluminescence (OEL) manufacturing equipment.

Applications for NSK Insulated Bearings

NSK-insulated bearings are used in applications such as automobiles, mechanical motors, wind power generation, electronic equipment, etc. They are capable of effectively supporting rotary and reciprocating motions, providing excellent performance and long-lasting durability in a variety of applications.

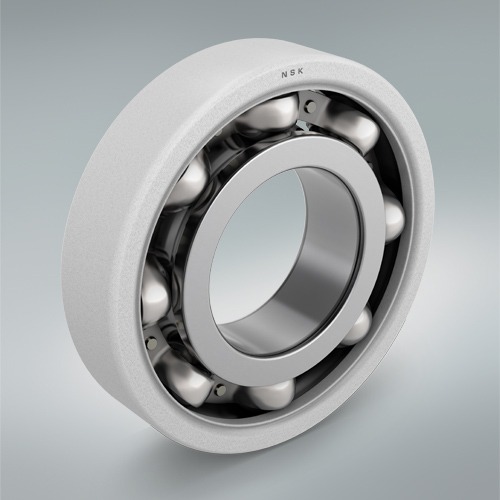

Insulated bearings for variable frequency motors

Ceramic-coated insulated bearings for inverter motors are coated with an insulating ceramic material on the outer ring of the bearing so that electric current cannot pass through the bearing and does not cause galvanic corrosion. NSK insulated bearings have been successfully applied to inverter motors mounted on general industrial machinery such as pumps, compressors, and fans and have demonstrated excellent performance. These products are particularly suitable for industrial applications that require high reliability and long life. NSK has also developed “low-loss bearings for energy-saving motors” that reduce friction losses within the bearing, thereby improving the motor’s energy-saving effect.

Insulated bearings for rail transportation

Traction motor bearings in rail transportation must be powerful, environmentally friendly and cost-effective. The weight of the rail vehicles and long maintenance-free operating times must be taken into account to ensure a high degree of reliability and safety. In addition to reducing the weight of the drive train, traction motors in rail transportation are subjected to high radial and axial loads, as well as strong currents and the possibility of high-speed passage. To meet these demanding requirements, NSK has developed insulated bearings with ceramic coatings and high-strength cages. Traction motor bearings often fail due to damage caused by the passage of electric current (electrical pitting). To prevent electrical pitting, NSK has developed insulated bearings with ceramic coatings and PPS resin coatings. Both solutions provide high insulation resistance in excess of 100Mohms and a breakdown voltage of 4KV at access.

Wind turbine insulated bearings

A leading European wind turbine manufacturer is to use NSK high load capacity tapered roller bearings in the gearboxes of its 15 MW class offshore wind turbines. By utilizing high-load-capacity tapered roller bearings, manufacturers in this industry can overcome engineering challenges unique to wind turbines. For example, the optimized shape of the bearing roller crown helps to withstand the harsh operating conditions to which wind turbine gearboxes are subjected, and NSK uses its numerical simulation expertise to derive the shape and balance the pressure on the contact surfaces between the rollers and the inner and outer rings. Even under high loads, this feature prevents excessive roller end surface pressure, resulting in a 25% increase in load capacity and more than twice the service life of conventional products.

Technical Features of NSK Insulated Bearings

NSK has a long history of developing and manufacturing bearings since its founding in 1916, and its insulated bearings enjoy a high degree of credibility in the industry for their high quality, precision, and reliability.NSK insulated bearings are designed to prevent galvanic corrosion problems and protect equipment.

Ceramic Coating Technology

NSK has developed ceramic-coated insulated and PPS-Resin-coated insulated bearings to prevent electrical pitting. The relationship between temperature and insulation resistance of ceramic insulated bearings was evaluated. As a result, no deterioration in insulation resistance was observed below 110°C.

The new NSK hybrid ceramic bearings have five times the service life of stainless steel in flooded environments. The extended service life helps reduce maintenance, downtime, and excessive replacement costs.

Precision Manufacturing Process

NSK bearings are manufactured using state-of-the-art manufacturing processes, enabling the bearings to not only meet stringent standards in terms of size and performance but also improve the precision and consistency of the products. To meet the needs of different industrial applications, NSK bearings also focus on durability and stability.

Reduced maintenance costs

NSK insulated bearings not only reduce galvanic damage but also reduce equipment failure rates and maintenance requirements. This means that service intervals can be extended, and downtime and maintenance costs can be reduced, thus providing users with cost-effective operational solutions.

Specifications and Models

NSK insulated bearings are available in a wide range of sizes and models to suit various applications. From standard sizes to customized options, NSK is committed to providing customers with diverse choices to ensure the right solution for any application. Each model is carefully designed to optimize performance and increase service life.

TFL Bearings: Your Trusted Supplier of NSK Insulated Bearings

TFL Bearings, as your trusted NSK insulation bearings supplier, provides high-quality bearing products and guarantees customers a full range of services. The following are our core advantages:

Extensive product line and inventory

TFL Bearings has partnered with several well-known bearing brands to ensure an extensive product line and adequate inventory. No matter what specification of insulated bearings you need, we can respond quickly and offer the best selection of products to fit your needs.

Professional technical support team

Our technical support team consists of experienced engineers who can provide you with comprehensive support from selection to application. No matter what kind of technical problems you encounter, our team will be by your side to provide professional solutions.

Rapid delivery capability

We understand how important time is to business, so TFL Bearings is committed to providing a fast and efficient delivery service. With our advanced logistics network and management system, we are able to ensure that our products reach their destinations in the shortest possible time.

Perfect after-sales service

TFL Insulated Bearings will provide comprehensive pre-sale and after-sale services for every customer, focusing on the needs of each customer. Whether it is product maintenance, technical support, or problem-solving, we will respond positively.TFL bearings ensure that the product operates efficiently in the process of use to your satisfaction.

Conclusion

With the continuous progress of industrial technology and the expansion of application areas, the market demand for NSK insulation bearings will continue to grow. In the future, NSK will continue to increase its investment in R&D and optimize the performance indexes and production processes of insulated bearings to meet the market’s urgent demand for high-performance and high-reliability bearings. At the same time, NSK will actively promote the application scope of insulated bearings to promote technological progress and industrial upgrading in the entire bearing industry. Come to contact us at TFL Insulated Bearings to get the best offer for NSK Insulated Bearings!

Frequently Asked Questions

- How do NSK insulated bearings prevent current damage?

NSK insulated bearings prevent current damage by spraying an insulating coating on the bearing surface. Insulated bearings are designed by coating the bearing surface with a 50-200 μm thick ceramic coating that resists electrical jump fires generated by voltages up to 1000 V. Thicker coatings can resist even higher voltages. This design not only improves the life of the bearings but also reduces the risk of bearing failure due to current damage and ensures the normal operation of the equipment.

- What are the main differences between insulated and normal bearings?

- Different materials

The main difference between insulated bearings and normal bearings is the difference in material. The inner and outer rings and rolling bodies of insulated bearings are made of insulating materials, while the inner and outer rings and rolling bodies of ordinary bearings are usually made of metal materials.

- Different insulation properties

Insulated bearings have good insulating properties and can effectively isolate the current, thus avoiding damage caused by current flow into the bearing. Ordinary bearings do not have such insulating properties.

- Differences in corrosion resistance

Since insulated bearings are made of insulating materials, they are less susceptible to the effects of corrosion. Ordinary bearings, on the other hand, are susceptible to corrosion.

- price difference

Insulated bearings are relatively expensive, while plain bearings are relatively inexpensive.

- What industries and applications are NSK insulated bearings suitable for?

NSK insulated bearings are suitable for inverter motors, the mining and metallurgy industry, the wind power industry, machine tools, moving vehicles, and the automobile industry.

- How to install and maintain NSK insulated bearings correctly?

Correct installation of NSK insulated bearings requires special tools, thorough bearing inspection before installation, checking of the fit dimensions with the rotor shaft, and control of the amount of oil in the bearings and housings.

- How much longer do NSK insulated bearings last than ordinary bearings?

The service life of NSK insulated bearings is indeed longer compared to ordinary bearings, but exactly how much longer is not a fixed value because it is affected by various factors.