Spherical Roller Bearing Suffixes Decoder, Guide & Cross-Reference (2026 Updated)

Introduction: More Than Just “Heavy Duty”

A Spherical Roller Bearing (e.g., 22216) may share identical dimensions on the outside, but differ drastically in performance on the inside based on its Suffixes (CC, CA, E, MB).

Choosing the wrong internal design, cage material, or clearance (C3/C4) for a high-vibration mining crusher or a marine propeller shaft can lead to overheating, premature failure, and costly downtime.

This guide breaks down the technical nuances of TFL’s 20000, 22000, and 23000 series, helping you decode the critical suffixes to maximize load rating and match your specific industry needs.

Enter a bearing number (e.g., 22220EK) to understand its features.

Summary Table: Quick Selection Guide

| Suffix / Type | Material / Feature | Key Benefit | Typical Industry |

|---|---|---|---|

| CC / C | Stamped Steel Cage, Window-type | Low Friction, Low Heat, Cost-effective | General Fans, Blowers, HVAC |

| CA | One-piece Machined Brass, Flange Guided | High Strength, Shock Resistance | Steel Mills, Heavy Gearboxes |

| MB / M | Two-piece Machined Brass, Inner Ring Guided | High Precision, Runs Cooler at Speed | Road Rollers, Vibrating Screens |

| E / E1 | Optimized Internal Geometry (Larger Rollers) | Load Rating +25%, Extended Life | Mining Crushers, Heavy Duty Conveyors |

| K | Taper 1:12 | Uses H-Series Sleeve for Easy Mounting | Conveyors, Agricultural |

| K30 | Taper 1:30 | Designed for Wide Series (240xx/241xx) | Paper Mills, Rolling Mills |

| W33 | Lube Groove/Holes | Ensures Direct Lubrication to Raceways | Standard on most TFL Bearings |

| C3 / C4 | Increased Internal Clearance | Compensates for Thermal Expansion & Vibration | Vibrating Screens, Dryers, Kilns |

For most general applications, the CC type (Steel) is sufficient and economical. However, for environments with heavy shock loads (like mining), we strongly recommend upgrading to the E-type for higher load capacity or CA-type (Brass) for maximum durability. Always check if your shaft requires a Tapered Bore (K) and Adapter Sleeve before ordering.

Important Note: Suffix Variations Across Brands. Please be aware that Suffix Codes often vary by Manufacturer, even if the internal structure is identical.

Same Design, Different Name: For example, a window-type stamped steel cage is marked as CC by SKF, but may be labeled as EJ by Timken or CD by NSK.

Scope of This Guide: This article lists the most common international standard suffixes used by major European brands. We have not listed every proprietary code from every manufacturer.

The Golden Rule: Don’t guess based on the code alone. Always provide the full model number of the bearing you are replacing to TFL engineers for accurate cross-referencing.

Internal Design & Suffixes (The Structure)

The internal structure determines the Load Rating, Speed Limit, and Shock Resistance. Choosing the wrong cage design can reduce bearing life by half, even if the dimensions are correct.

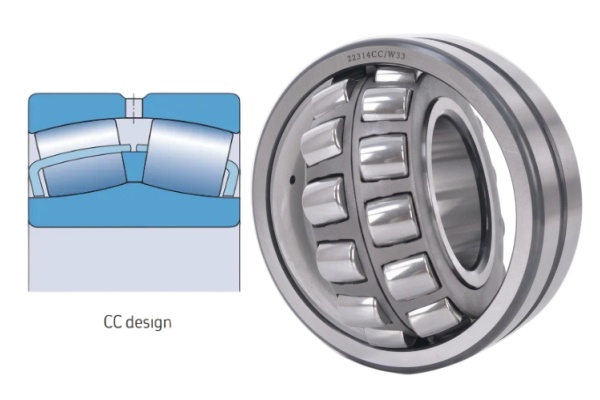

CC Type (Stamped Steel Cage, Floating Guide Ring)

This is the modern standard for general-purpose applications.

-

Design: Features two window-type stamped steel cages and a floating guide ring centered on the inner ring.

-

Key Advantage – Low Friction: The steel cage is lightweight and leaves more space for lubricant, resulting in lower heat generation.

-

Best For: Medium loads and medium-to-high speeds.

-

Applications: Fans, Blowers, General Conveyors.

-

CA Type (One-Piece Machined Brass, Inner Flanges)

When the going gets tough, the industry turns to CA.

-

Design: Uses a robust, one-piece machined brass cage. Unlike the CC type, the CA design features retaining flanges (ribs) on the inner ring to guide the rollers.

-

Key Advantage – Ultimate Durability: The one-piece brass cage offers superior tensile strength. It can withstand heavy shock loads and rapid acceleration/deceleration that would destroy a steel cage.

-

Best For: Heavy impact and high-reliability scenarios.

-

Applications: Steel Mills, Mining Gearboxes, Vertical Motors.

-

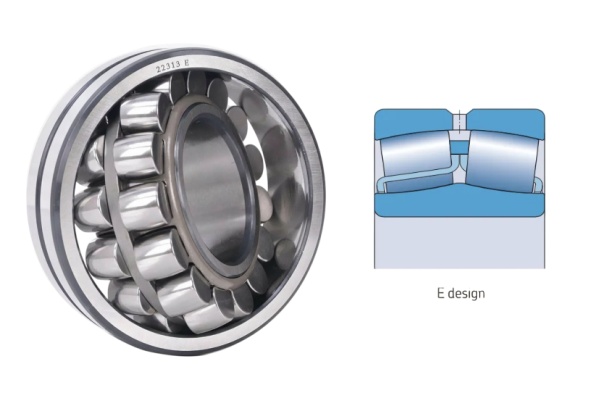

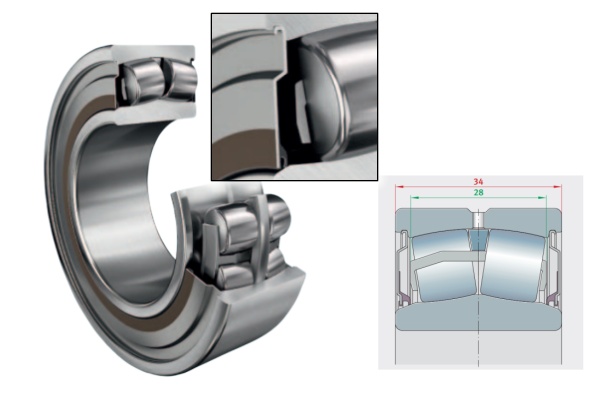

E / E1 Type (High-Load Optimized)

The “E” and “E1” suffixes aren’t just designs; they are performance upgrades.

-

The TFL Advantage: Whether labeled as E (Standard High-Load) or E1 (Enhanced Generation), this design removes the fixed central rib on the inner ring and replaces it with a floating guide ring.

-

Tech Spec: By freeing up this internal space, we can fit longer and larger diameter rollers compared to standard designs.

-

Result: Dynamic Load Rating is increased by 20% – 35%.

-

Application: Ideal for heavy-duty machinery where you need maximum power density in a limited space.

-

E Type: The standard high-load version.

-

E1 Type: Often designates the “Extra Capacity” or next-generation optimization (similar to FAG’s X-life), offering the highest possible load rating in the industry.

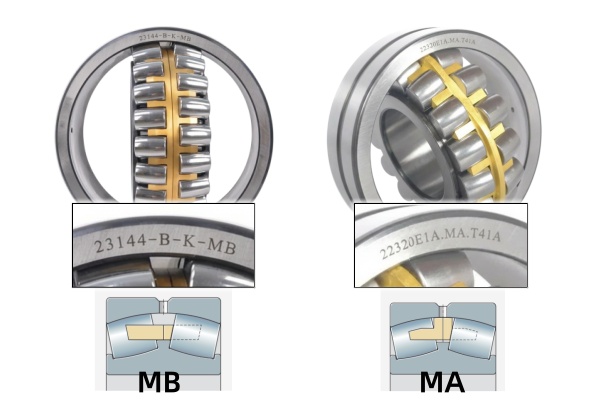

MB & MA Types (Precision Machined Brass)

While CA is for brute force, the M-series (MB/MA) serves a specific niche for precision and speed. These feature a two-piece machined brass cage, differing mainly in how they are guided.

MB Type (Inner Ring Guided – The Standard)

- Design: The cage rides on the inner ring.

- Key Advantage: Because the guide surface is smaller (inner ring), there is less friction at high speeds. This is the preferred choice for running cooler and smoother.

- Best For: High-speed Papermaking Machines, Precision Rolling Mills.

MA Type (Outer Ring Guided – The Specialist)

- Design: The cage rides on the outer ring.

- Key Advantage: The outer-guidance design allows for excellent lubrication access, as centrifugal force naturally pushes grease/oil towards the outer raceway where the cage is guided.

- Best For: Applications with specific lubrication challenges or high centrifugal forces.

Buying Tip: If your application just says “Brass Cage,” clarify if you need CA (One-piece, Heavy Load) or MB (Two-piece, High Speed). MA is less common but available for specific OEM requirements.

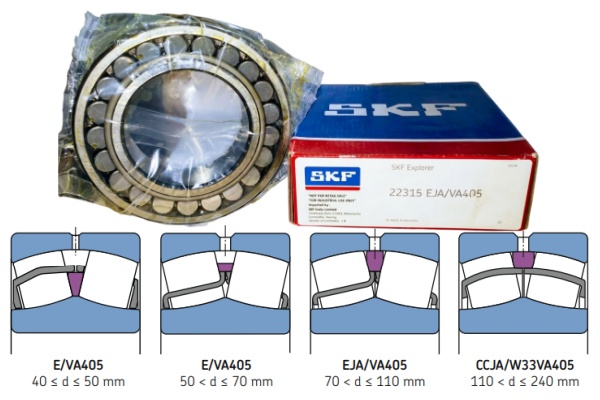

Vibration Screen Specification (VA405 / T41A Design)

Standard bearings, even heavy-duty models, often fail prematurely in vibrating screens (Shaker Screens) due to cage breakage caused by extreme acceleration and chaotic centrifugal forces.

The Industry Standards (SKF & FAG): To tackle these extreme conditions, the industry relies on two specific benchmark designs:

-

SKF VA405 Specification: This is the gold standard for vibration applications. It features a special surface-hardened stamped steel cage (window-type) that is significantly more resistant to fatigue than standard steel. It also includes specific bore and outer diameter tolerances to ensure a precise fit under heavy vibration, typically paired with C4 clearance.

-

FAG T41A Specification: FAG’s dedicated solution (often marked as E1.T41A) is engineered to handle oscillating loads. It utilizes an optimized internal geometry with specific radial clearance (usually C4) and a robust cage design capable of withstanding the high g-forces found in mining shakers and asphalt plants.

The TFL Solution: TFL provides fully interchangeable replacements for both SKF VA405 and FAG T41A series, manufacturing our bearings with the exact same surface-hardened cage technology and C4 clearance to ensure seamless compatibility and performance.

2RS / 2CS (Sealed Spherical Roller Bearings)

The modern trend in the US and European markets is shifting towards Sealed designs to reduce maintenance costs.

-

Design: These bearings come with integrated contact seals (rubber or Viton) on both sides, pre-filled with high-quality lithium grease.

-

Key Advantage – Contamination Proof: In extremely dusty environments (like cement plants or coal mines), external housing seals often fail. The 2RS design acts as the “final line of defense,” preventing dust from destroying the raceways.

-

Benefit: Enables a “Maintenance-Free” operation for the bearing’s service life in many applications.

-

Best For: Conveyor belts in dusty mines, Cement elevators, Agricultural machinery.

Lubrication Suffixes

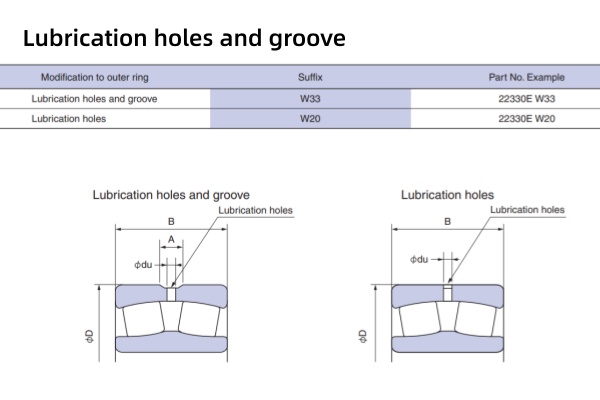

Standard Outer Ring Lubrication (W33 / E4)

This is the most common configuration found in general industrial applications.

-

W33: Indicates an annular oil groove and three lubrication holes in the outer ring. This design allows lubricant to be applied directly into the bearing from the housing while the bearing is rotating.

-

E4: A code often used by Japanese manufacturers (like NSK) to denote the same feature as W33 (Oil groove + holes).

-

Note: In most modern catalogues, W33 is the standard default unless specified otherwise.

Inner Ring Lubrication (Through-Shaft)

Some equipment, such as paper machines, centrifuges, or vibrating screens, utilizes “through-shaft” lubrication where oil is pumped through the center of the shaft rather than the housing.

-

W20: Indicates 3 lubrication holes drilled directly into the inner ring.

-

W26: Indicates 6 lubrication holes drilled into the inner ring to accommodate higher flow rates.

-

W513: The “Universal” Specification. It combines W33 + W26 (groove/holes in the outer ring and holes in the inner ring). This design offers maximum flexibility, allowing the bearing to be lubricated from either the housing or the shaft depending on the machine setup.

Specialized Configurations (Plugged & Solid)

-

W33X (Plugged Holes): The bearing features standard outer ring holes, but they are plugged with screws upon delivery.

-

Purpose: This is often required in heavy-duty gearboxes using oil bath lubrication where direct injection isn’t needed. The plugs prevent oil pressure loss or turbulence. It also allows for a flexible inventory—plugs can be removed if relubrication is needed later.

-

-

W64 (Solid Oil / Solid Lubrication): A growing trend in food processing and high-contamination environments.

-

Technology: Instead of traditional grease, the bearing is filled with a polymer matrix saturated with lubrication oil. This creates a solid, sponge-like structure inside.

-

Benefit: It physically blocks dust/water ingress and eliminates grease leakage, making it ideal for “maintenance-free” locations (e.g., overhead cranes) or hygiene-critical areas.

-

Pre-Greased Specifications (G / L Suffixes)

While standard open bearings are typically shipped with a thin layer of rust-preservative oil, many applications require specific pre-greasing to save installation time.

-

High-Temperature Grease: Bearings pre-filled with fluorinated or synthetic grease designed to withstand temperatures above 150°C.

-

Food-Grade Grease: Bearings pre-filled with NSF H1 standard grease, compliant with safety regulations for incidental food contact.

-

Identification: These are often denoted by codes like G, L, or specific grease codes (e.g., GEM9, VT143) depending on the manufacturer, which specify the grease type and fill percentage.

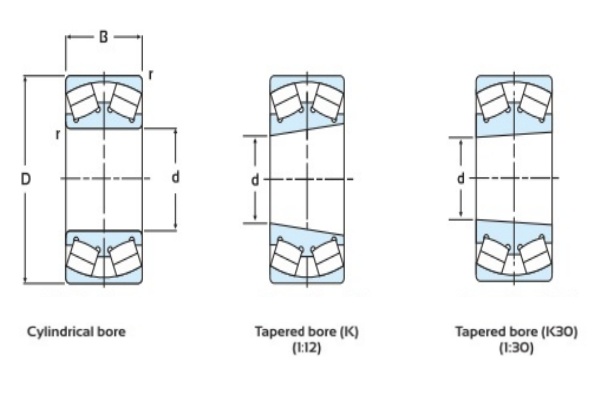

Bore Codes: Cylindrical vs. Tapered

How you mount the bearing dictates which bore code you need. This choice impacts not just installation time, but also future maintenance costs.

Cylindrical Bore (No Suffix)

This is the standard design.

-

Mounting: Fits directly onto the shaft with an interference fit.

-

The Challenge: Installation typically requires heat (using an Induction Heater) to expand the inner ring. Dismounting can be difficult and often requires hydraulic assist.

-

Best For: Applications with high precision requirements or where frequent dismounting is not required.

Tapered Bore (Suffix K & K30)

Designed for flexibility and ease of maintenance. These bearings allow for easier mounting on shafts using sleeves.

-

Suffix K (Taper 1:12): * The Standard: Used on most standard series (e.g., 222xx, 223xx).

-

Essential Partner: Almost always paired with an H-Series Adapter Sleeve.

-

Benefit: Allows the bearing to be mounted anywhere on a plain shaft, eliminating the need for complex shaft machining/shoulders.

-

Application: Long transmission shafts, Conveyor pulleys.

-

-

Suffix K30 (Taper 1:30):

-

The Wide Series Specialist: Found exclusively on wide dimension series (e.g., 240xx, 241xx).

-

Why 1:30? These bearings have thinner inner rings. A standard 1:12 taper would expand the ring too quickly, risking cracks. The shallower 1:30 taper ensures safe, gradual locking.

-

Application: Paper Making Machinery, Rolling Mills.

-

TFL Engineering Warning: Don’t Over-Tighten! When mounting tapered bore bearings, you are essentially driving the bearing up a slope. This expands the inner ring and reduces the internal clearance.

The Risk: If you tighten the lock nut too much, you eliminate the clearance, causing the bearing to overheat instantly upon startup.

The Fix: Always use a Feeler Gauge to measure clearance reduction during installation, or ask for TFL’s Hydraulic Nut solutions for precise mounting.

Interchange Guide: SKF / FAG / NSK to TFL Cross-Reference

| Feature / App | SKF Suffix | FAG Suffix | NSK / Timken | TFL Equivalent (Ready to Ship) |

|---|---|---|---|---|

| Vibration Screens (Shaker Screen) |

VA405 | T41A / E1.T41A | – | VS Series (Surface Hardened) |

| Steel Cage (Window Type) |

CC | E1 | CD (NSK) EJ (Timken) |

CC |

| Oil Groove & Holes (Outer Ring) |

W33 | E1 / Standard | E4 (NSK) | W33 (Standard) |

| Cylindrical Bore (Standard) |

(No Suffix) | (No Suffix) | (No Suffix) | Standard |

| Tapered Bore (1:12 Taper) |

K | K | K | K (+ Adapter Sleeve) |

Note: While TFL bearings are dimensionally interchangeable with SKF, FAG, and NSK, internal designs may vary slightly to optimize performance. Always confirm your operating conditions (Speed, Load, Temp) with our engineers before swapping.

Application Guide: Matching Series to Industry

Different industries require different bearing series. Here is how TFL engineers recommend models based on real-world scenarios.

Mining & Vibration (Crushers, Screens)

The most punishing environment for any bearing.

-

Conditions: Extreme shock loads, heavy dust, constant G-force vibration.

-

Recommended Series: 22300 Series (E-Type or VS Design).

-

Why TFL Recommends This:

-

E-Type: Provides the extra 25-30% Load Rating needed to crush rock without fatigue.

-

VS (Vibration Spec): For Shaker Screens, do not use standard cages. Our VS series uses a surface-hardened cage and C4 Clearance to survive the “shaking” without seizing.

-

Metallurgy & High Heat (Rolling Mills, Continuous Casters)

Where heat and heavy loads meet.

-

Conditions: High ambient temperature (>100°C), low speed, extreme radial loads.

-

Recommended Series: 23000, 24000 & 24100 Wide Series.

-

Why TFL Recommends This:

-

Wide Series (240/241xx): The wider surface area distributes the massive pressure of steel rolling.

-

C4 Clearance: Essential to allow the bearing inner ring to expand with the heat without locking up.

-

CA Cage: The solid brass cage acts as a heat sink and withstands the start-stop shock.

-

Marine & Rail (Propeller Shafts, Axles)

Handling the bend and flex.

-

Conditions: Long shafts that are prone to “deflection” (bending) due to hull movement or track unevenness.

-

Recommended Series: 22200 K Series (Tapered Bore).

-

Example Models: 22222 EK + H322 Sleeve.

-

-

Why TFL Recommends This:

-

Self-Aligning: TFL spherical rollers can accommodate up to 1.5° – 2.5° of misalignment, preventing the shaft from snapping under stress.

-

K-Bore + Sleeve: Allows for easy mounting and dismounting on long propeller shafts where you cannot use a heat press.

-

Power Generation (Hydro Generators, Vertical Motors)

The challenge of gravity.

-

Conditions: Continuous 24/7 operation, often mounted vertically.

-

Recommended Series: 22200 & 29000 (Thrust) Series.

-

Example Models: 22224 E, 29412 E (Thrust Spherical).

-

-

Why TFL Recommends This:

-

Load Capacity: Excellent for supporting the heavy weight of vertical rotors.

-

Pro Tip for Vertical Mounts: Gravity pulls grease down. We recommend upgrading to a Machined Brass Cage (M/MB) or CA for better lubricant retention compared to stamped steel.

-

Conclusion

A Spherical Roller Bearing is not just a standard “off-the-shelf” part; it is a precision system designed to handle the world’s heaviest radial loads.

Two bearings may look identical on the shelf (e.g., 22320), but inside the machine, the difference between a CC cage and a CA cage, or a C0 and C4 clearance, is the difference between a productive year and a catastrophic shutdown.

Your Final Checklist:

-

Crushing Rocks? Don’t risk it. Choose TFL E-Type or the VS (Vibration) Series.

-

High Heat (>100°C)? Ensure you specify C4 Clearance to prevent seizing.

-

Vertical Mounting? Upgrade to a Machined Brass Cage (M/MB) for better lubrication retention.

-

Dusty Environment? Switch to TFL 2RS Sealed bearings to lock out contaminants.

Stop Guessing. Start Engineering. Don’t let a confusing suffix code cause downtime. Contact TFL Bearings today—our engineers are ready to cross-reference your current models and recommend the exact Series + Suffix combination for your specific machinery.

[Get Your Free Technical Consultation] [Download TFL Spherical Roller Bearings Catalog]

FAQ

Q: Which is better, CA or CC cage?

A: Neither is “better”—they are for different jobs.

-

Choose CC (Steel) for general applications (fans, conveyors) where you want low friction and lower cost.

-

Choose CA (Brass) for heavy-duty applications (crushers, steel mills) where shock load resistance is the priority. Using a CC cage in a rock crusher is a recipe for disaster.

Q: My bearing feels “loose” by hand. Is it defective?

A: Likely not. If you ordered a C3 or C4 clearance bearing, it is designed to feel loose at room temperature.

Why: Once the machine starts running, heat generation causes the inner ring to expand. The “looseness” disappears and becomes the perfect operating clearance. If you started with a tight bearing, it would seize up when hot.

Q: Can TFL bearings replace SKF or FAG models directly?

A: Yes. TFL bearings are manufactured to strict ISO standards. For example, a TFL 22220 EK has the exact same boundary dimensions and load ratings as the SKF/FAG equivalent. We can also cross-reference specific competitor suffixes (like SKF’s VA405) to our own solution (TFL VS Series).

Q: What is the difference between W33 and E4?

A: They are essentially the same. W33 is the standard international code for “oil groove + 3 holes.” E4 is a code often used by Japanese brands (like NSK) for the same feature. TFL bearings come with W33 as standard.

Q: When should I use sealed (2RS) spherical roller bearings?

A: Use them in highly contaminated environments (coal mines, cement plants) where fine dust kills open bearings. Although the upfront cost is higher, you save thousands in maintenance hours and grease costs over the bearing’s life