Cylindrical Roller Bearings vs. Ball Bearings

Introduction

Choosing the right bearing is critical for machine performance and longevity. While both Cylindrical Roller Bearings and Ball Bearings reduce friction and support loads, they serve very different purposes in industrial applications.

The main difference lies in their contact area: Ball bearings use “point contact” for high speeds and lighter loads, while Cylindrical roller bearings utilize “line contact” to handle heavy radial loads.

Making the wrong choice can lead to premature equipment failure or inefficiency. In this guide, we will break down the technical differences between Cylindrical Roller Bearings vs. Ball Bearings regarding load capacity, speed, and durability to help you make the best decision for your machinery.

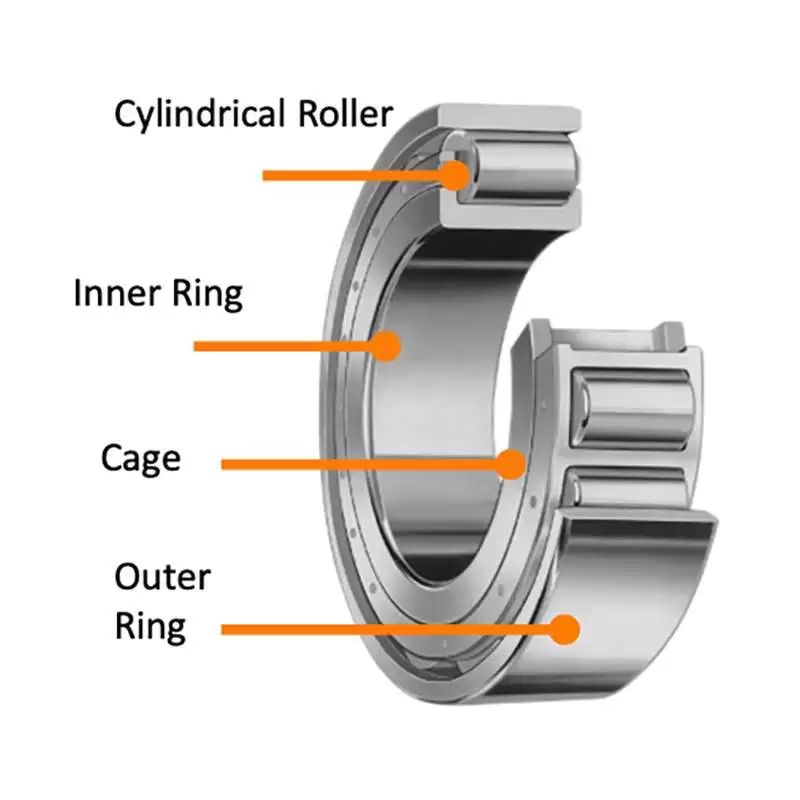

What is a Cylindrical Roller Bearing? (Structure & Function)

Sometimes mistakenly referred to by users as a “cylindrical ball bearing,” a Cylindrical Roller Bearing is actually distinct because it uses cylinders instead of balls as rolling elements.

The defining characteristic of this structure is Line Contact. unlike the “point contact” of ball bearings, the cylindrical rollers create a line of contact with the raceway. This larger surface area allows the bearing to distribute pressure more evenly, giving it a significantly higher Radial Load Capacity.

As shown in the diagram above, the core components include:

-

Outer & Inner Rings: Provide the raceway for rollers.

-

Cylindrical Rollers: The rolling elements that carry the load.

-

Cage (Separator): Keeps rollers evenly spaced to reduce friction and heat.

Key Features & Advantages:

-

High Radial Load Capacity: They are the go-to choice for heavy-duty machinery. Note: Standard designs handle radial loads only and are not suitable for significant axial (thrust) loads.

-

High-Speed Capability: Thanks to precision cages, they offer the highest speed capability among all roller bearings.

-

Separable Design: In many N or NU types, the inner and outer rings can be separated, making installation and maintenance much easier than ball bearings.

Typical Uses

You will typically find cylindrical roller bearings in equipment where reliability under heavy weight is non-negotiable:

-

Industrial Gearboxes

-

Large Electric Motors

-

Rolling Mills

-

Pumps and Compressors

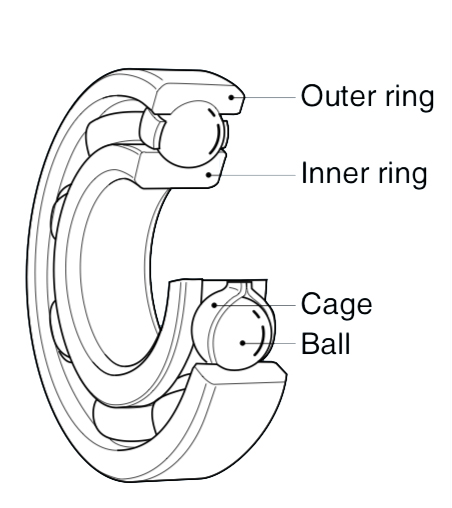

What is a Ball Bearing? (Key Characteristics)

While cylindrical bearings are built for heavy loads, Ball Bearings are designed for versatility and speed. They are the most common type of bearing used globally, with the Deep Groove Ball Bearing being the standard configuration.

The fundamental difference lies in Point Contact. The spherical balls make contact with the raceway at only a tiny point.

-

The Advantage: This minimal contact area drastically reduces friction, allowing the bearing to spin much faster and cooler than roller bearings.

-

The Trade-off: Because the load is concentrated on a single point, they have a lower load capacity compared to cylindrical rollers and can deform under extreme weight.

Key Characteristics

-

Multidirectional Load Handling: Unlike standard cylindrical roller bearings, ball bearings can handle both radial loads and axial loads (thrust) in both directions. This is their biggest advantage.

-

Low Friction & High Speed: The point contact design generates very little rolling resistance, making them ideal for high-speed applications.

-

Quiet Operation: They tend to run more quietly and smoothly, which is crucial for precision instruments and consumer appliances.

Typical Uses

Ball bearings are the “all-rounders” of the industry. You should choose them when speed is high, and loads are moderate:

-

Electric Motors: Small to medium-sized motors (where low noise and high speed are needed).

-

Automotive: Transmission shafts, alternators, and wheel hubs.

-

Precision Tools: Robotics, hard drives, and medical equipment.

-

Household: From washing machines to skateboard wheels.

Major Differences: Cylindrical Roller Bearings vs. Ball Bearings

| Feature | Cylindrical Roller Bearings | Ball Bearings | Winner For... |

|---|---|---|---|

| Contact Type | Line Contact (Higher friction) | Point Contact (Lower friction) | - |

| Radial Load | Excellent (Heavy Duty) | Moderate | Roller Bearings |

| Axial Load | Poor (Often zero) | Good (Bi-directional) | Ball Bearings |

| Speed (RPM) | Moderate | Very High | Ball Bearings |

| Noise & Vibration | Moderate | Low (Quiet) | Ball Bearings |

| Impact Resistance | High (Resists shock) | Low (Balls can dent raceway) | Roller Bearings |

The Core Difference: Line Contact vs. Point Contact

The fundamental difference lies in the physics of contact.

-

Ball Bearings (Point Contact): Imagine a marble on a floor. It touches only a tiny point. This results in minimal friction, allowing for high speeds but limiting load capacity.

-

Cylindrical Roller Bearings (Line Contact): Imagine a rolling pin. It touches the surface along a full line. This distributes weight over a larger area, providing superior support for heavy loads but generating slightly more friction (Reference: Acar et al., 2022, on energy efficiency in bearing designs).

Load Capacity: Radial vs. Axial Forces

This is the most critical factor in your selection process.

-

Choose Cylindrical Rollers for Radial Loads: If your application involves heavy weight pressing down on the shaft (like in a conveyor belt or gearbox), rollers are essential. They distribute the stress evenly, preventing metal fatigue.

-

Choose Ball Bearings for Axial/Thrust Loads: Cylindrical rollers struggle with axial forces (thrust parallel to the shaft). If your equipment faces cornering forces or multidirectional stress—such as in automotive wheels—ball bearings are the superior choice because they can handle combined loads.

Speed and Friction

Durability and Wear Resistance

In harsh environments like mining or rock crushing, equipment suffers from “shock loads” (sudden impacts).

-

Cylindrical Bearings: Their robust structure handles shock loads exceptionally well without sustaining damage.

-

Ball Bearings: Under heavy impact, the balls can indent the raceway (a failure mode known as “Brinelling”), leading to noise and eventual failure.

Design and Maintenance (Separability)

Many cylindrical types (like N and NU series) allow the inner and outer rings to be mounted independently. This makes mounting and dismounting in tight machinery much faster than ball bearings, which are typically non-separable units.

Quick Selection Guide: When to Choose Which?

Still deciding? Use this quick checklist to match your application to the right bearing.

Choose a [Cylindrical Roller Bearing] if:

-

Your primary need is heavy radial load capacity (e.g., gearboxes, crushers).

-

The equipment operates at moderate to high speeds but requires high rigidity.

-

You need a bearing that is separable for easier mounting and dismounting.

-

Do NOT use if: There are significant axial (thrust) loads present.

Choose a [Deep Groove Ball Bearing] if:

-

You need to handle both radial and axial loads simultaneously.

-

Your application runs at very high speeds with minimal friction (e.g., fans, small motors).

-

You need a quiet, low-vibration solution for precision equipment.

-

Do NOT use if: The application involves heavy shock loads or extreme weight.

Conclusion

Selecting between cylindrical roller bearings and ball bearings isn’t about finding the “better” bearing—it’s about finding the right fit for your specific operating conditions.

-

Ball bearings are your best bet for speed, versatility, and multidirectional loads.

-

Cylindrical roller bearings are the champions of heavy radial loads and industrial durability.

Making the wrong choice can result in costly downtime. At TFL Bearings, we don’t just sell components; we provide solutions. Whether you need high-speed precision or heavy-duty reliability, our engineering team is ready to help you optimize your machinery’s performance.

Ready to upgrade your equipment?

Explore our catalog of [Cylindrical Roller Bearings] or [Contact TFL Bearings] today for a free consultation on your specific application.

Frequently Asked Questions

Q: Which carries more load, a ball bearing or a roller bearing?

A: Generally, cylindrical roller bearings carry significantly more load than ball bearings of the same size. Their “line contact” design distributes weight across a larger surface area.

Q: Can I replace a ball bearing with a roller bearing?

A: Usually, no. While they may share similar dimensions, they handle loads differently. Replacing a ball bearing with a roller bearing in an application with axial (thrust) force could lead to immediate failure. Always consult an engineer before swapping types.

Q: Why are ball bearings faster?

A: Ball bearings use “point contact,” which generates less friction than the line contact of roller bearings. Less friction means less heat, allowing for higher rotational speeds (RPM).