BLOG

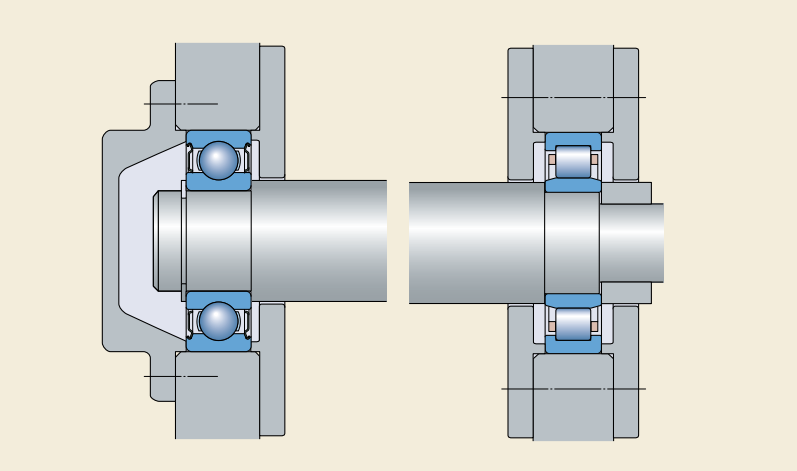

Mastering the One Cylindrical One Ball Bearing Configuration in Motors

Introduction Ever wondered why some motors use a specific bearing setup with one cylindrical roller bearing and one deep groove ball bearing? Known as the “one cylindrical one ball bearing” structure, this configuration is a popular…

Electrically Insulated Bearings: Which Method Is Best for You?

Introduction Electrically insulated bearings are essential in preventing electrical damage in various industrial applications, such as motors, generators, and other equipment exposed to electrical currents. These bearings protect against premature wear, reduce maintenance costs, and extend…

Crusher Bearings Guide: Types & Applications for Jaw, Cone, and Impact Crushers

Introduction Crusher bearings act as the critical pivot points in mining heavy equipment, directly impacting the efficiency and lifespan of the machinery. Whether operating a primary jaw crusher or a high-capacity cone crusher, these components must endure extreme shock loads, vibration,…

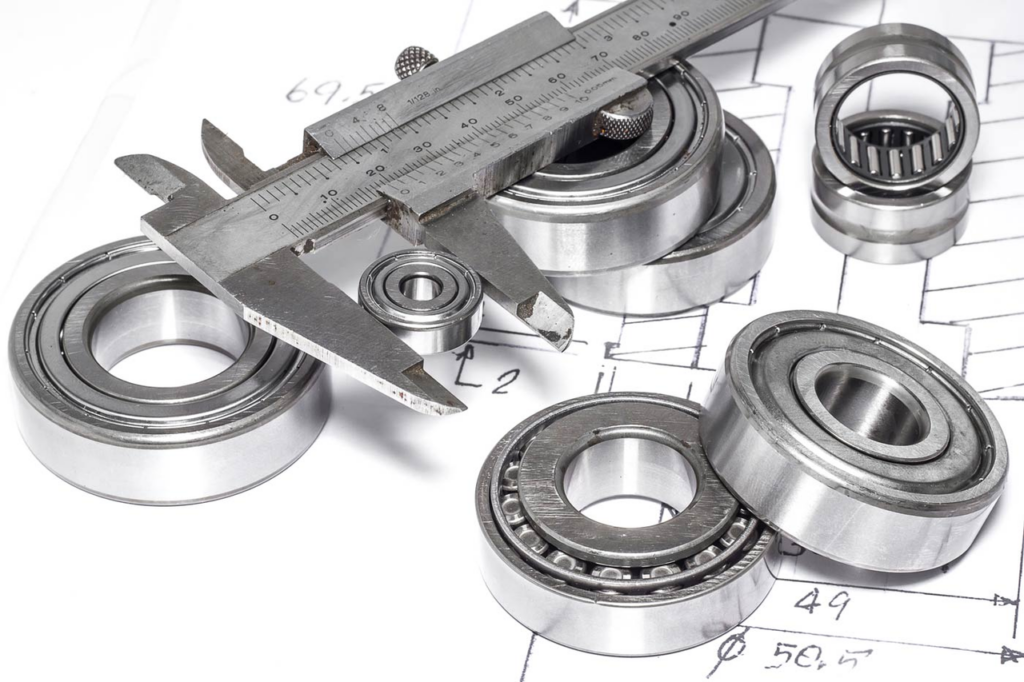

Bearing Material Guide: Ceramic vs. Stainless Steel vs. Bearing Steel

Introduction Bearings might be hidden components, but the bearing material you choose dictates the performance, speed, and lifespan of your entire machine. Whether you are upgrading a road bike or sourcing for industrial machinery, the debate often comes…

Shielded vs. Sealed Bearings: Differences, Types, and How to Choose

Introduction Bearings are the critical joints in machinery, ensuring smooth motion and efficiency. However, to maintain peak performance and extend lifespan, they require robust protection against contaminants and lubricant loss. This is where the choice between bearing…

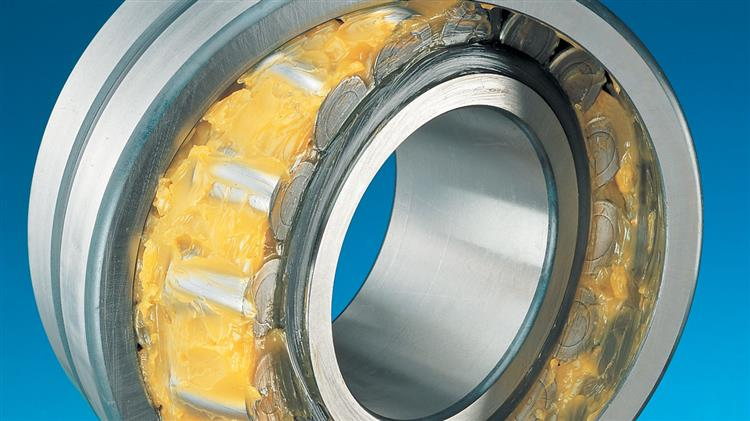

Bearings and Lubrication: The Heart and Blood of Machinery

Introduction If bearings are the heart of machinery, then lubrication is its blood. Both are essential for reducing friction and ensuring the smooth operation of mechanical systems. Bearings—whether rolling or sliding—are designed to minimize friction through…

Bearing Precision Grades: Why P4 Costs More Than P0?

Introduction: Bearings are like the joints of machines—they keep everything moving smoothly. But not all bearings are created equal. You’ve probably seen labels like P0 or P4, and noticed that P4 bearings cost significantly more. A common question…

No posts

Application of deep groove ball bearings in the food industry

Application of deep groove ball bearings in the food industry Hygiene and humidityMost food processing areas, as part of the process or necessary cleaning methods, need to be in a humid, humid, or chemically aggressive environment….

Application of Deep Groove Ball Bearing in Coal Industry

Application of Deep Groove Ball Bearing in Coal Industry Mechanical mine coal mining equipment in a transmitted dedicated transport large mechanical equipment, including mining, conveyors, mine boring equipment, auxiliary transport underground, vehicle equipment, mine winches, ventilation…