Preloading for Rolling Bearings: Enhancing Performance and Lifespan

Contents

hide

Introduction

Rolling bearings are vital parts of mechanical systems, influencing how efficiently and how long a machine operates.

Preloading for rolling bearings is a key technique used during bearing installation to improve performance. It increases stiffness, enhances rotational accuracy, and reduces vibration and noise. Below, I’ll explain what preloading is, its methods, and how it can benefit your machinery.

What Is Preloading for Rolling Bearings?

Preloading means applying an initial force to the bearing during installation, creating slight pressure between the rolling elements and the inner and outer races. This results in a negative clearance, where the bearing is slightly compressed even before it takes on any external load.

Why Does It Matter?

Preloading offers several advantages:

-

Boosts stiffness: Keeps the bearing firm and stable.

-

Improves accuracy: Ensures precise shaft movement.

-

Lowers noise and vibration: Makes operation smoother and quieter.

-

Extends lifespan: Helps the bearing last longer by reducing wear.

It’s like giving the bearing a little push to prepare it for heavy-duty work!

How Can Bearings Be Preloaded?

There are three main preloading methods: fixed-position preloading, constant-pressure preloading, and radial preloading. Each has unique features and ideal uses.

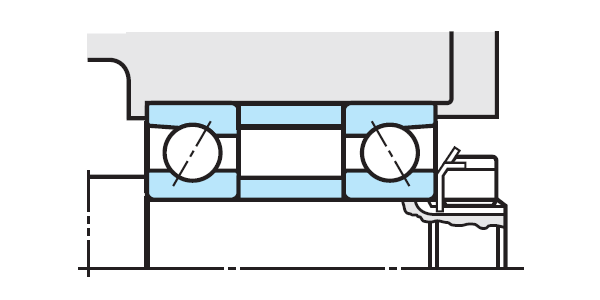

Fixed-Position Preloading

-

How It Works: Adjusts spacers, adds shims, or tightens nuts to fix the bearing’s position.

-

Pros: Stable preload, great stiffness, reliable under steady conditions.

-

Cons: Sensitive to temperature changes, which can affect the preload.

-

Best For: Machines needing high stiffness with stable temperatures.

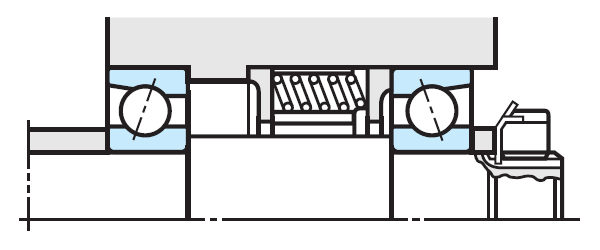

Constant-Pressure Preloading

-

How It Works: Uses springs to apply a consistent force on the bearing.

-

Pros: Adapts to temperature shifts, perfect for high-speed use.

-

Cons: The bearing’s position might shift slightly.

-

Best For: High-speed machines with varying temperatures.

Radial Preloading

-

How It Works: Creates a tight fit between the bearing and shaft to remove radial clearance.

-

Pros: Improves stiffness and precision, reduces slippage at high speeds.

-

Cons: Needs careful assembly to avoid errors.

-

Best For: Precision tools like machine spindles or jet engines.

Why Choose Radial Preloading?

Radial preloading is excellent for precision tasks. It eliminates radial gaps, enhancing stiffness and accuracy while preventing roller slippage at high speeds. This reduces wear and heat, but it requires exact assembly to get the preload just right.

What About Light Axial Preloading?

Sometimes, a gentler approach works best. Light axial preloading uses a small force to:

-

Cut vibration and noise: Keeps things smooth.

-

Protect the bearing: Avoids damage from too much pressure.

It’s ideal when you want smooth operation without needing extreme precision.

How to Remove Preload Safely

When replacing or adjusting bearings, you may need to unload the preload:

-

Fixed-position: Adjust or remove spacers.

-

Constant-pressure: Ease or remove the springs.

-

Tip: Be gentle to avoid damaging the bearing.

Think of it as letting the bearing relax carefully after hard work!

Final Thoughts

Preloading is a smart way to improve bearing performance and durability. Whether you use fixed-position, constant-pressure, or radial preloading, the method depends on your machine’s needs. With the right technique, you can achieve better stiffness, precision, and quieter operation. Hopefully, this clears up what preloading is all about!