Single vs. Double vs. Full Complement: Which Cylindrical Roller Bearing Do You Need? (Updated 2026)

Introduction

Quick Comparison Table

Type of Bearing Design Applications Benefits Limitations

Single-Row Cylindrical Roller Bearings One row of cylindrical rollers; compact and efficient. Gearboxes, electric motors, automotive. High-speed capability, simple design, easy maintenance. Limited axial load capacity.

Double-Row Cylindrical Roller Bearings Two rows of rollers for greater radial load capacity. Compressors, turbines, railways, construction machinery. Enhanced load capacity, improved stability. Bulkier design, lower speed compared to single-row bearings.

Four-Row Cylindrical Roller Bearings Four rows of rollers; designed for heavy-duty applications. Rolling mills, steel mills, heavy industrial machinery. Exceptional load distribution, durability under extreme loads. High cost, complex installation, and maintenance requirements.

Full Complement (Cageless)

(Series: NCF, SL)No cage. Packed with the maximum number of rollers possible. Heavy-duty Gearboxes, Crane Sheaves, Excavators, Bucket wheels. Maximum Radial Load Capacity. Handles heavy loads in compact spaces better than any other type. Low Speed Limits. Increased friction (roller-to-roller contact) generates more heat.

Single Row Cylindrical Roller Bearings: The High-Speed Standard

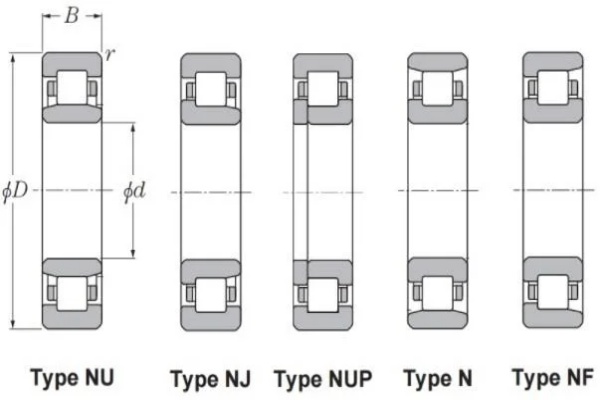

(Series: NU, NJ, NUP, N)

Best For: Electric motors, pumps, compressors, and general industrial gearboxes.

Why Choose Single Row? Single-row bearings are the most common type. They consist of one cage and one row of rollers. Their primary advantage is low friction, making them the ideal choice for high-speed applications.

-

High Speed Capability: The simplified design minimizes internal friction, allowing for higher RPMs compared to multi-row designs.

-

Separable Components: The inner and outer rings can usually be separated. This makes mounting and dismounting easy, especially when tight interference fits are required.

-

Axial Load Limitations:

-

NU & N Types: Can only handle radial loads (perfect for the “free end” of a shaft).

-

NJ & NUP Types: Can handle limited axial loads in one or both directions.

-

TFL Engineering Note: For details on flange configurations (NU, NJ, NUP) regarding axial loads, please refer to our specific article: [Difference Between NU, NJ, NUP, and N Designs]

Double Row Cylindrical Roller Bearings: The High-Rigidity Specialist

(Series: NN, NNU)

Best For: High-precision machine tool spindles, rolling mill stands.

Why Choose Double Row? When precision is non-negotiable, Double Row bearings are the answer. As the name suggests, they feature two rows of rollers. They are engineered for stiffness (rigidity) rather than just pure load capacity.

-

Superior Rigidity: Because there are more contact points with the raceway, the deformation under load is minimal. This is critical for machine tools where shaft deflection would ruin the workpiece accuracy.

-

Compact Design: Despite having two rows, their cross-section is usually kept low (thin), allowing for larger shaft diameters without increasing the overall housing size.

-

Vibration Control: The double-row structure offers better stability, significantly reducing vibration during operation.

Comparison: unlike Single Row bearings, Double Row types (NN/NNU) generally cannot accommodate any tilting or misalignment. Alignment must be precise.

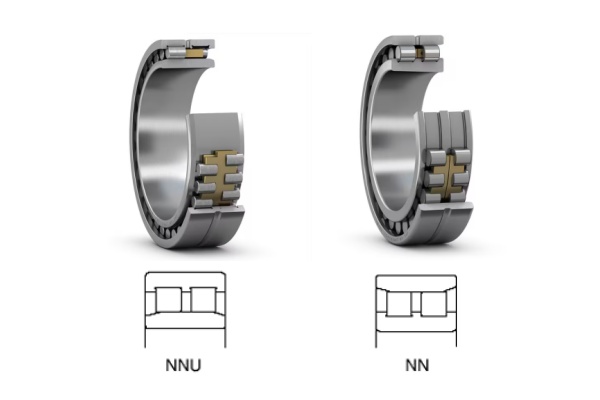

Designations: NN vs. NNU Series

While both series offer high rigidity, the difference lies in the flanges (ribs), which affects how they are mounted and lubricated:

-

NN Series (Inner Ring Flanges):

-

Structure: The inner ring has three integral flanges, while the outer ring has no flanges.

-

Benefit: This design is often preferred for machine tool spindles because the grease is better retained within the bearing during rotation.

-

-

NNU Series (Outer Ring Flanges):

-

Structure: The outer ring has three integral flanges, while the inner ring has no flanges.

-

Benefit: This allows the inner ring to be separable, making it easier to mount and dismount when the inner ring is fitted with an interference fit on the shaft.

-

Note: Since neither handles axial loads, they are typically paired with a Double Direction Angular Contact Thrust Ball Bearing (e.g., 2344 series) to fix the shaft position.

Four-Row Cylindrical Roller Bearings: The Heavyweight Champion

(Series: FC, FCD, FCDP)

Best For: Steel industry (Rolling mill backup rolls), cement crushers.

Why Choose Four-Row? These are the giants of the bearing world. Used exclusively in extremely heavy industries, Four-Row bearings are designed to carry massive radial loads that would crush other bearings instantly.

-

Extreme Load Capacity: With four rows of rollers working simultaneously, the radial load capacity is maximized within the available bearing space.

-

Lower Friction than Tapered: Compared to four-row tapered roller bearings, cylindrical types have lower friction, making them suitable for the high-speed rolling often found in modern steel mills.

-

Mounting: These bearings are almost always mounted with a tight fit on the roll neck.

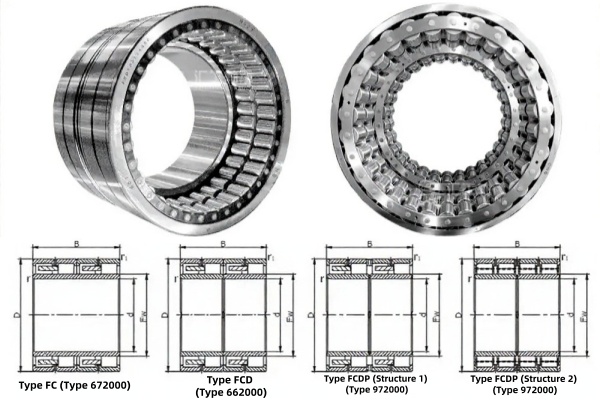

FC vs. FCD vs. FCDP

Not all four-row bearings are built the same. The difference lies in the ring structure and cage design, which dictates the bearing’s size suitability and load capacity.

1. FC Series (1 Inner Ring + 2 Outer Rings)

-

Structure: Features a single integral inner ring and two separate outer rings.

-

Best For: Smaller to medium-sized roll necks.

-

Advantage: Since the inner ring is one solid piece, it offers higher precision for smaller diameters but is harder to manufacture in giant sizes.

2. FCD Series (2 Inner Rings + 2 Outer Rings)

-

Structure: Features two separate inner rings and two separate outer rings.

-

Best For: Medium to large-sized applications.

-

Advantage: Essentially behaves like two double-row bearings combined. The split inner ring design allows for easier manufacturing and mounting on larger shafts compared to the FC type.

3. FCDP Series (Pin-Type Cage / Component Assembly)

-

-

Structure: Complex assembly with two inner rings, two outer rings, but uses a Pin-Type Cage (pierced rollers).

-

Best For: Extra-large roll necks (e.g., flat product rolling mills).

-

Advantage: The pin-type cage allows for the maximum number of rollers (since no space is wasted on cage bars between rollers). This creates the highest possible radial load capacity of any bearing type.

-

| Series | Structure (Inner/Outer) | Cage Type | Typical Size | Key Characteristic |

|---|---|---|---|---|

| FC | 1 Inner / 2 Outer | Machined / Steel | Small – Medium | High precision, solid inner ring. |

| FCD | 2 Inner / 2 Outer | Machined / Steel | Medium – Large | Split inner rings for easier mounting. |

| FCDP | 2 Inner / 2 Outer | Pin-Type | Extra Large | Max Load Capacity (More rollers). |

Full Complement Cylindrical Roller Bearings (Cageless)

Best For: Heavy-duty gearboxes, construction machinery, cranes, and lifting equipment.

What is a Full Complement Bearing? Standard bearings use a cage (retainer) to separate the rollers. Full Complement bearings remove the cage entirely. By eliminating the cage, we can fit the maximum possible number of rollers between the inner and outer rings.

The Trade-Off: Load vs. Speed This design creates a clear trade-off that every engineer must understand:

-

Pro: Maximum Load Capacity: Since the bearing is packed with rollers, it can support significantly higher radial loads than a caged bearing of the same size.

-

Con: Lower Speed Limit: Without a cage, the rollers come into direct contact with each other (roller-to-roller friction). This generates more heat and limits the maximum rotation speed.

Common Types:

-

NCF Series: Single row, full complement. Used where heavy loads meet slow speeds.

-

SL / NNUF Series: Double row, full complement. Commonly used in pulley sheaves for cranes.

Comparison: Caged vs. Full Complement

| Feature | Caged Bearing (With Retainer) | Full Complement (No Retainer) |

|---|---|---|

| Roller Quantity | Fewer (Space taken by cage) | Maximum (Packed solid) |

| Load Capacity | Standard / High | Very High (approx. +20-40%) |

| Speed Limit | High Speed | Low Speed |

| Friction | Low (Separated rollers) | Higher (Roller-to-roller contact) |

| Typical Use | Motors, Pumps, Spindles | Cranes, Sheaves, Heavy Gearboxes |

TFL Advantage: “Need maximum power in a compact space? TFL offers high-performance Full Complement bearings (SL04, NCF series) with surface-treated rollers to minimize friction and extend life even under extreme loads.”

How to Select the Right CRB: An Engineering Checklist

Cage Material (The “Silent” Factor)

The cage doesn’t carry load, but it dictates the speed and durability.

-

Pressed Steel (Suffix J/W): Standard for general motors. Cost-effective but noisy.

-

Polyamide/Nylon (Suffix TVP/TN9): Best for quiet running and high speeds. Warning: Limit to 120°C.

-

Machined Brass (Suffix M): Required for heavy vibration and extreme shock loads (e.g., Mining, Vibrating Screens).

Internal Clearance (C3, C4)

Cylindrical bearings are rigid. If your shaft gets hot, it expands.

- CN (Normal): Standard applications.

- C3 (Greater than Normal): Essential for electric motors or high-temperature environments to prevent the bearing from seizing up when hot.

Shaft Misalignment

CRBs are notorious for hating misalignment. Standard cylindrical bearings allow for almost zero tilt (max 2-4 minutes of arc).

Pro Tip: If your shaft has deflection, consider switching to a Spherical Roller Bearing or using a CRB with a modified “crowned” roller profile (TFL Premium Series) to handle slight misalignment.

Flange Configuration (Axial Load)

Double-check your axial load requirements. Remember:

-

NU/N: Radial load ONLY.

-

NJ/NUP: Can handle limited axial loads.

-

(Using the wrong one is the #1 cause of installation failure.)

Table: Quick Selection Cheat Sheet

| If your application involves… | Then you likely need… | Critical Spec to Check |

|---|---|---|

| High Speed (Electric Motors) | Single-Row (Caged) | Check Internal Clearance (C3) for heat expansion. |

| Extreme Loads / Low Speed (Cranes) | Full Complement | Ensure No Cage design for max density. |

| High Precision (Spindles) | Double-Row (NN/NNU) | Verify Runout Accuracy (P4/P5 class). |

| Heavy Vibration (Mining/Shakers) | Single-Row with Brass Cage | Must use Machined Brass Cage (M) to resist fracture. |

| Axial (Thrust) Loads | NUP or NJ Type | Standard NU/N types will fail here. |

The 3 Golden Rules of CRB Selection:

-

Respect the Speed Limit: Never put a Full Complement bearing on a high-speed motor shaft. It will overheat in minutes.

-

Cage Matters: For standard use, Steel (J) is fine. For silence, go Nylon (TVP). For vibration, pay extra for Brass (M).

-

Don’t Ignore Expansion: If your machine runs hot (>100°C), you likely need C3 clearance, not Standard (CN).

Why TFL Should Be Your Primary Bearing Partner in 2026?

In an industrial landscape where downtime costs are rising, simply buying a bearing off the shelf is no longer enough. Here is why leading OEMs are switching to TFL Bearings this year:

-

98% On-Time Delivery: While major brands struggle with 20-week lead times, TFL’s optimized inventory ensures your production line never stops. We deliver speed, not just parts.

-

Engineering-First Approach: We don’t just quote part numbers. Our engineers review your Speed (RPM) and Load (Cr) parameters to prevent the “almost right” selection errors that lead to premature failure.

-

Cost-Performance Ratio: Get P5/P4 precision quality comparable to top-tier global brands, but at a price point that explicitly protects your profit margins in a volatile 2026 market.

-

Customization Ready: Need a special clearance (C4)? Or a machined brass cage (M) for mining? We manufacture what standard catalogs don’t stock.

Conclusion: Don’t Let the Wrong Bearing Stop Your Production

As we have explored, sourcing Cylindrical Roller Bearings is not just about matching dimensions (Bore x OD x Width); it is about matching internal structure to your specific operating conditions.

-

Misapplying a Full Complement bearing in a high-speed motor will lead to overheating.

-

Using a standard Single-Row bearing in a heavy-impact crusher will result in fatigue failure.

-

Ignoring Axial Load requirements (NU vs. NUP) will cause catastrophic installation issues.

At TFL Bearings, we go beyond the catalog. From precision P4 grade Double-Row spindle bearings to rugged Brass-Caged mining series, we ensure that the bearing you buy is the bearing your machine actually needs.

Ready to optimize your machinery’s performance?

Stop guessing. Let our engineering team verify your Load Ratings and Fitment today.

[CONTACT TFL ENGINEERING] | [VIEW FULL CRB CATALOG]