Cylindrical Roller Bearing Accuracy Guide

Introduction

Imagine building with LEGOs. If the LEGO bricks are not the right size, your cool creation won’t work, right?

It’s the same with big machines! They need parts that fit perfectly to move and work well. One of these super important parts is called a cylindrical roller bearing. And when it comes to these bearings, getting the size just right is a really big deal. This is why we should care about the bearing’s accuracy. Let’s break it down so you can understand what bearing accuracy is all about and why it’s important.

What Exactly is Bearing Accuracy?

Bearing accuracy is all about how perfectly a bearing’s parts are made. The closer they are to their ideal size and shape, the better they’ll work.

Imagine wearing shoes that are too big—you’d trip a lot. Similarly, sloppy bearings cause friction, wear out faster, and make machines noisy or shaky. High-accuracy bearings? They’re like custom-fit shoes. They reduce friction, last longer, and keep your machines running smoothly.

The bearing accuracy includes dimensional accuracy, geometric accuracy, and rotational accuracy.

Dimensional Accuracy: Like Clothes Fitting Just Right

Imagine installing a bearing into a machine – it’s like wearing clothes, the size must fit right! Dimensional accuracy refers to how well a bearing fits when installed on a shaft or into a housing. This includes measurements like the inner diameter, outer diameter, width, and other critical dimensions. If these measurements aren’t exact, the bearing might not fit right, which could cause problems like noises or uneven wear.

Geometrical Accuracy: Shape Needs to be “True”

Having the right size isn’t enough; the shape of the bearing also needs to be “true”!

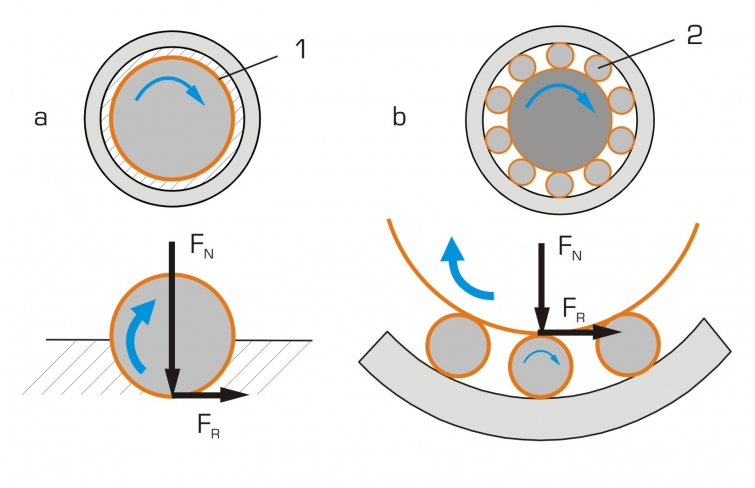

Geometric accuracy focuses on the shape and alignment of the bearing components. Even if the dimensions are correct, small imperfections in the geometry can cause issues like uneven load distribution or excessive friction.

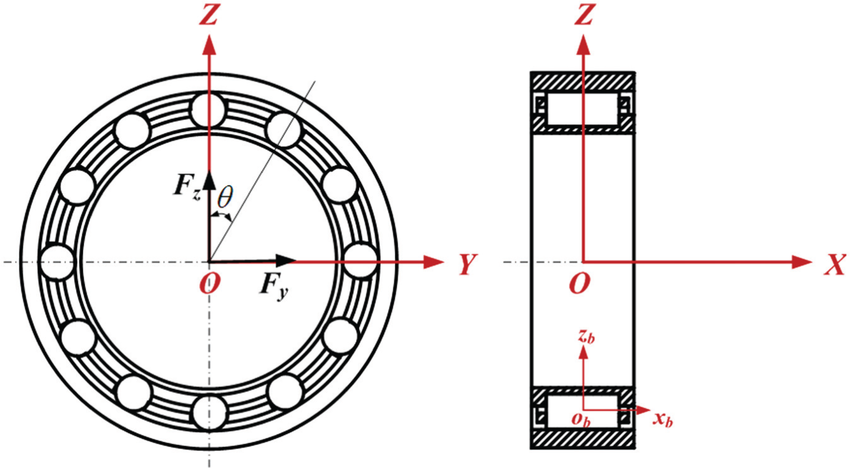

Rotation Accuracy: Runs Smoothly When Spinning

Bearings are made to rotate, so they must rotate smoothly! Rotational accuracy is all about how smoothly a bearing rotates. If a bearing isn’t accurate in this area, it can cause vibrations, noise, or even machine failure. This is especially important for cylindrical roller bearings, which are often used in high-speed or precision applications.

Factors Affecting the Accuracy of Cylindrical Roller Bearings

Material Quality in Cylindrical Roller Bearings

Cylindrical roller bearings are very exact because of the material that is used to make them. Chrome steel or clay are examples of high-quality materials that can last longer and handle more stress.

Manufacturing Process for Cylindrical Roller Bearings

How a cylindrical roller bearing is made also affects its accuracy. Precision machining ensures that every part of the bearing is made to exact specifications.

Environmental Factors Impacting Cylindrical Roller Bearings

Cylindrical roller bearings can’t always work right because of things like weather, humidity, and dirt. As an example, a bearing might not work as well if it gets too hot or is dusty. To protect your cylindrical roller bearings, try to keep them clean and in a stable environment.

Installation and Maintenance of Cylindrical Roller Bearings

Even the best cylindrical roller bearings won’t work well if they’re not installed correctly. Make sure to follow the manufacturer’s instructions when putting them in. Regular maintenance, like cleaning and lubrication, also helps keep cylindrical roller bearings accurate and extends their life.

Common Bearing Accuracy Standards for Cylindrical Roller Bearings

Just like clothes come in different sizes (S, M, L), cylindrical roller bearings come in different “accuracy grades.” These grades tell you how precise the bearing’s size and shape are. Different groups have made standards for these grades—kind of like different countries having their own shoe size systems. Let’s look at some common ones:

GB/T Standard (China)

The GB/T307-94 standard is China’s national guideline for classifying bearing precision. It divides bearings into five grades based on their accuracy: G, E, D, C, and B. Each grade represents a different level of precision, with G being the lowest and B being the highest.

ISO Standard (International)

The ISO standard is used worldwide and is another way to measure bearing precision. It has six levels: CLASS0 (no longer used), CLASS2, CLASS4, CLASS5, CLASS6, and NORMAL.

-

CLASS 2: The highest precision, used in advanced machinery.

-

CLASS4 and CLASS5: High precision, great for demanding tasks.

-

CLASS 6: Standard precision, good for general purposes.

-

NORMAL: A non-standard grade, often used for specific applications.

Remember, CLASS0 is outdated, so avoid it when choosing bearings.

DIN Standard (Germany)

The DIN standard is similar to ISO and GB/T307-94. It also has five grades: P0, P2, P4, P5, and P6.

-

P0: Basic precision, suitable for everyday use.

-

P2, P4, P5, P6: Higher precision levels, ideal for machines that need extra accuracy.

ANSI Standard (USA)

In the U.S., the ANSI standard uses something called ABEC grades. These include ABEC1, ABEC3, ABEC5, ABEC7, and ABEC9.

-

ABEC1: Basic precision, good for general use.

-

ABEC3: A step up, used when slightly better accuracy is needed.

-

ABEC5: High precision, great for demanding applications.

-

ABEC7 and ABEC9: Super-precise, used in high-performance machines.

JIS Standard (Japan)

The JIS standard is very similar to GB/T307-94 and DIN. It also has five grades: P0, P2, P4, P5, and P6.

-

P0: Basic precision, good for everyday tasks.

-

P2, P4, P5, P6: Higher precision levels, perfect for machines that need exact measurements.

How Do These Standards Compare?

While each standard has its own names and numbers, they’re pretty similar in terms of what they mean. For example:

-

P2 in GB/T307-94 is about the same as CLASS2 in ISO, P2 in DIN, ABEC9 in ANSI, and P2 in JIS.

-

The main difference is how each standard was created, so there might be slight variations depending on where you are.

| Standard | Precision Grade | ||||

|---|---|---|---|---|---|

| GB/T307-94 | G (P0) | E (P6) | D (P5) | C (P4) | B (P2) |

| ISO | Normal Class | Class 6 | Class 5 | Class 4 | Class 2 |

| DIN | P0 | P6 | P5 | P4 | P2 |

| ANSI | ABEC 1 | ABEC 3 | ABEC5 | ABEC 7 | ABEC 9 |

| JIS | JIS 0 | JIS 6 | JIS 5 | JIS 4 | JIS 2 |

When choosing a bearing, think about the machine you’re using and the level of precision it needs. If you’re not sure, don’t hesitate to ask us at TFL Bearings—we’ll help you find the right product!

Conclusion

Bearing accuracy is just how close to perfect a bearing is made. And believe it or not, this tiny bit of “perfectness” makes a HUGE difference in how well your machines work and how long they last.

Whether you’re looking for standard cylindrical roller bearings or something with super precision, TFL Bearings has you covered. We’re here to provide high-quality, reliable products that meet your needs.

At TFL Bearings, we know accuracy matters. Ready to get the right cylindrical roller bearings for your project? Contact TFL Bearings today! Our team is here to help you find the perfect solution for your needs.

5 Popular Questions

What does bearing accuracy mean for cylindrical roller bearings?

Bearing accuracy refers to how precisely a cylindrical roller bearing is made. High accuracy means the bearing will work better and last longer, especially in machines that need exact movements.

What are cylindrical roller bearings used for?

Cylindrical roller bearings are used in machines that carry heavy loads, like conveyor systems, wind turbines, and industrial equipment. They are known for their ability to handle pressure while staying accurate.

What are the main bearing accuracy standards for cylindrical roller bearings?

The main standards include China’s GB/T, ISO standards for global use, Germany’s DIN standards, and the USA’s ABEC ratings. Each standard ensures specific levels of precision and quality for cylindrical roller bearings.

Why is bearing accuracy important for machinery using cylindrical roller bearings?

Accurate cylindrical roller bearings reduce wear and tear, improve efficiency, and prevent breakdowns. Machines with poor-quality cylindrical roller bearings may not work properly or could fail sooner.

Where can I buy reliable cylindrical roller bearings?

You can buy reliable cylindrical roller bearings from trusted manufacturers like TFL Bearings. We offer a wide range of high-quality products for global customers.