What is the Ball Bearing?

Introduction: The Small but Powerful Component

Ball bearings may be small, but they play a huge role in modern machinery. They help reduce friction between moving parts, ensuring smooth rotation and efficiency. Without ball bearings, machines would wear out quickly, consume more energy, and operate inefficiently. From bicycles and cars to industrial robots and wind turbines, ball bearings are everywhere.

How Does a Ball Bearing Work?

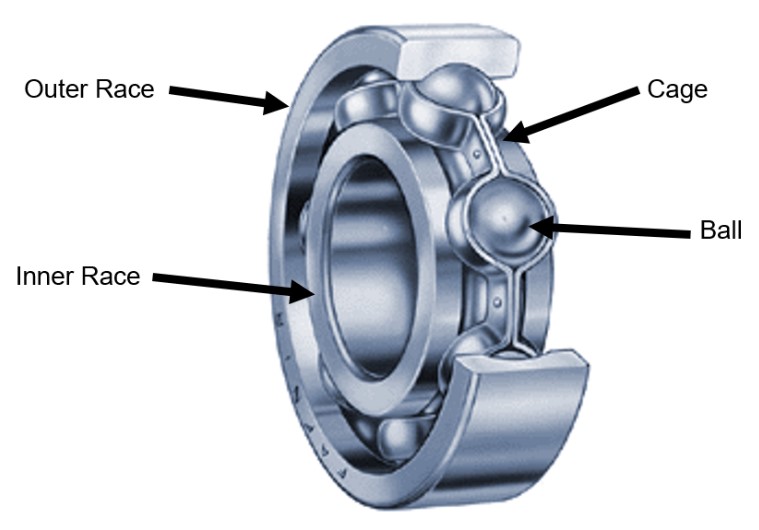

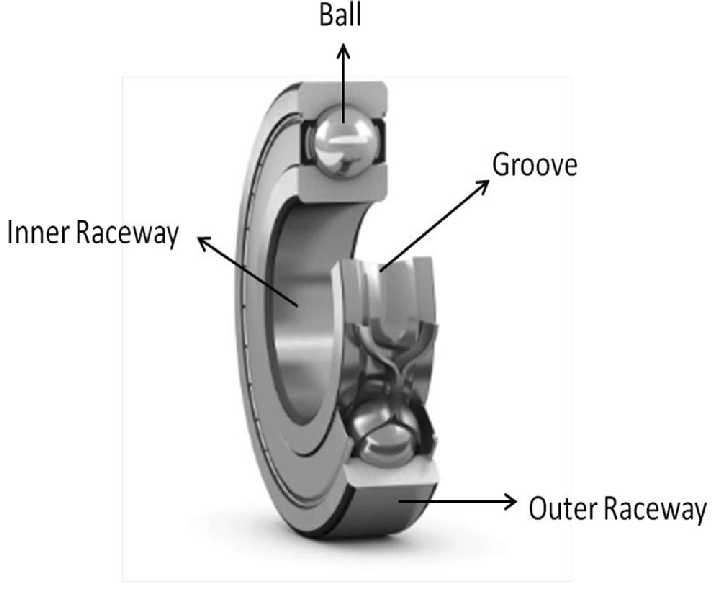

A ball bearing consists of four main parts:

- Outer Ring – The stationary part that holds everything together.

- Inner Ring – The part that rotates with the shaft.

- Balls – Small steel or ceramic spheres that roll between the rings.

- Cage – A structure that keeps the balls evenly spaced and prevents them from colliding.

The secret behind ball bearings is that they convert sliding friction into rolling friction, which requires much less force. Imagine pushing a heavy box across the floor—it’s hard. But if you put wheels under the box, it moves easily. Ball bearings work in a similar way.

Types of Ball Bearings: Choosing the Right One

Different applications require different types of ball bearings. Here are the most common ones:

1. Deep Groove Ball Bearings

- The most widely used type.

- Handles both radial (side-to-side) and axial (up-and-down) loads.

- Found in electric motors, home appliances, and conveyor belts.

2. Angular Contact Ball Bearings

- Designed for higher-speed applications.

- Supports both radial and axial loads at the same time.

- Commonly used in car engines, pumps, and turbines.

3. Thrust Ball Bearings

- Handles only axial loads (force applied in one direction).

- Found in automobile gearboxes and industrial cranes.

4. Self-Aligning Ball Bearings

- Can correct small misalignments.

- Ideal for shafts that bend slightly due to heavy loads.

- Used in printing machines and textile equipment.

Where Are Ball Bearings Used?

Ball bearings are used in almost every industry. Some of their key applications include:

- Automobiles – Bearings in wheels, gearboxes, and engines improve performance and efficiency.

- Bicycles & Motorcycles – They ensure smooth wheel rotation and reduce wear.

- Wind Turbines – Bearings in the turbine allow blades to rotate efficiently, converting wind into energy.

- Industrial Machinery – Bearings are essential in motors, conveyor belts, and robotic arms.

- Medical Devices – Used in MRI scanners and surgical tools for precision movement.

Materials Used in Ball Bearings: More Than Just Steel

Most ball bearings are made of chrome steel, but other materials offer unique benefits:

- Stainless Steel – Corrosion-resistant, perfect for humid or chemical-exposed environments.

- Ceramic – Lightweight, low friction, and can run without lubrication.

- Plastic – Found in medical and food-grade applications where metal bearings are not suitable.

Advantages of Ball Bearings: Why Are They So Important?

Ball bearings offer several key benefits:

✅ Reduce Friction – Less energy is wasted as heat.

✅ Support High Speeds – Many machines rely on ball bearings for smooth, fast operation.

✅ Increase Durability – High-quality ball bearings last for years with proper maintenance.

✅ Compact & Lightweight – Despite their small size, they can handle heavy loads.

The Future of Ball Bearings: Innovation & Smart Technology

With advances in technology, ball bearings are getting smarter:

- Self-lubricating Bearings – Reduce maintenance needs.

- Sensors in Bearings – Monitor wear and performance in real time.

- Eco-friendly Materials – Reducing environmental impact while improving efficiency.