Common Problems with Cylindrical Roller Bearings and How to Fix Them

Introduction

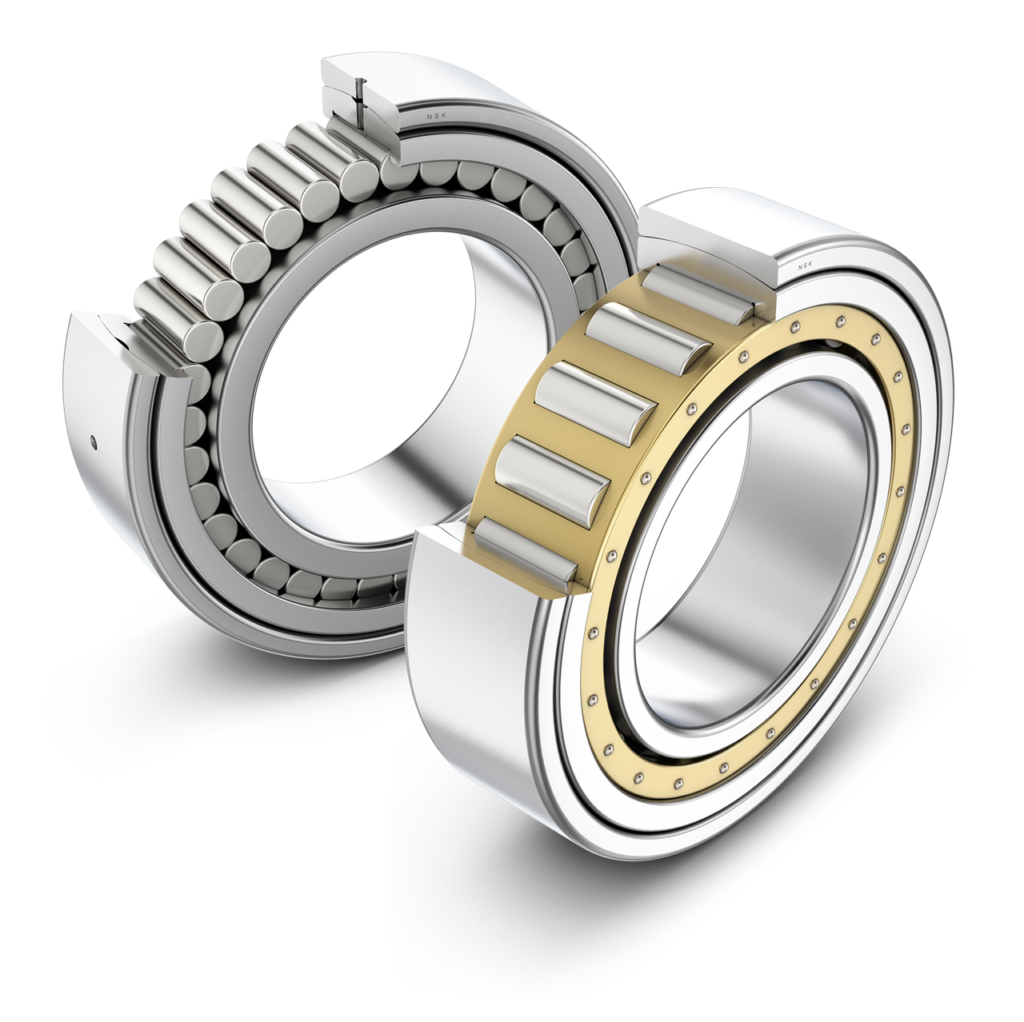

Bearings are like the helpers inside machines that let things spin and move smoothly. Cylindrical roller bearings are a type of bearing used in lots of machines because they are strong. Think of them as the muscles that keep things going!

But just like anything that works hard, problems can happen with cylindrical roller bearings. If you know what to look for, you can catch problems early and fix them before they become big headaches.

In this article, we’ll walk you through the most common issues people face with cylindrical roller bearings, why they happen, and how you can fix them. By the end, you’ll have a better idea of how to keep your equipment running without headaches.

Contents

hide

Problem 1: Overheating in Cylindrical Roller Bearings

What Causes Overheating?

Overheating happens when the bearing gets too hot. This can be caused by things like not enough lubrication or too much load on the bearing. When the cylindrical roller bearing’s temperature is severely high, it will affect the machine’s operation.

How to Fix Overheating Issues

-

Use the right amount of lubricant. Too much or too little can cause trouble.

-

Make sure the machine isn’t overloaded. Check the load limits for your bearing.

-

Keep the area around the bearing clean and well-ventilated.

Problem 2: Excessive Wear in Cylindrical Roller Bearings

What Causes Excessive Wear?

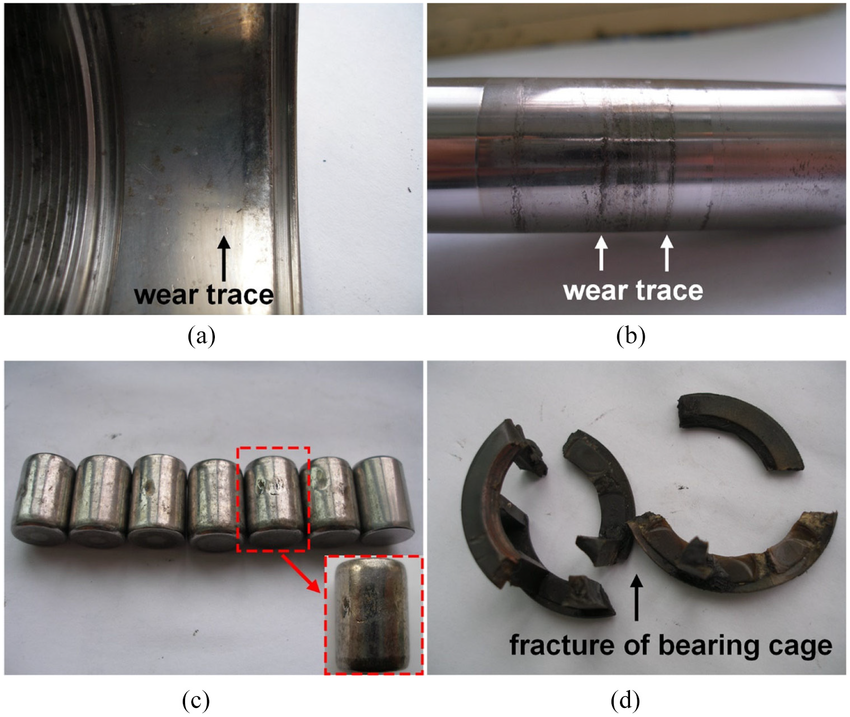

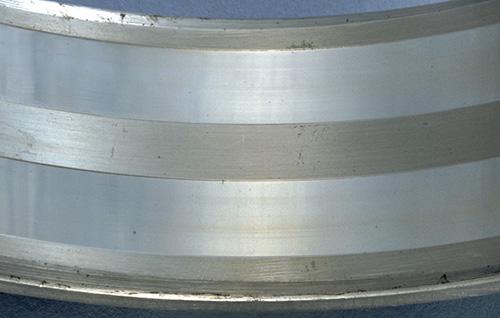

If the rollers or raceways (the surfaces the rollers roll on) start wearing out, it’s usually because the cylindrical roller bearing wasn’t installed correctly or hasn’t been maintained properly. The wear will cause the bearing’s unstable running, increased noise, and even the bearing failure.

How to Fix Excessive Wear

-

Double-check that the bearing is aligned properly during installation.

-

Replace worn-out parts as soon as you notice they’re damaged.

-

Don’t push the bearing beyond its limits. Stick to the recommended load and speed.

Problem 3: Corrosion in Cylindrical Roller Bearings

What Causes Corrosion?

Corrosion happens when the bearing is exposed to moisture or chemicals. Over time, this can damage the surface and make the bearing less effective.

How to Prevent Corrosion

-

Use bearings made from corrosion-resistant materials, like stainless steel.

-

Store your bearings in a dry, clean place when they’re not in use.

-

Avoid exposing the bearing to harsh chemicals unless absolutely necessary.

Problem 4: Noise and Vibration in Cylindrical Roller Bearings

What Causes Noise and Vibration?

If your bearing starts making noise or vibrating, it’s a sign something is wrong. This could be due to misalignment, dirt in the bearing, or damage to the rollers.

How to Fix Noise and Vibration Issues

-

Clean the bearing to get rid of dirt or debris.

-

Check that the bearing is aligned properly during installation.

-

Inspect the rollers and raceways for damage. If you see any, replace the damaged parts.

Problem 5: Improper Lubrication in Cylindrical Roller Bearings

What Happens When Lubrication Is Wrong?

Using the wrong type of lubricant, or using too much or too little, can cause big problems. It might lead to overheating, increased friction, or even damage to the bearing.

How to Fix Lubrication Problems

-

Follow the manufacturer’s instructions for lubrication. They know best!

-

Use the right type of lubricant for your specific application.

-

Reapply lubricant regularly to keep the bearing running smoothly.

How to Prevent Problems with Cylindrical Roller Bearings

Regular Maintenance

The easiest way to avoid problems is to check your bearings regularly. Look for signs of wear, overheating, or dirt buildup.

Proper Installation

Take your time when installing the bearing. Make sure it’s aligned properly and fits snugly in place.

Monitoring Bearing Status

Regularly check the temperature and vibration of bearings and other indicators, timely find problems and take appropriate measures.

Conclusion

Cylindrical roller bearings are tough little parts, but they still need care to work their best. By understanding the common problems and how to fix them, you can save yourself a lot of time and money.

At TFL Bearings, we make high-quality cylindrical roller bearings that are built to last. Whether you’re running a small workshop or managing a big factory, we’ve got the right bearings for you. If you’re ready to upgrade your equipment with reliable parts, reach out to us today. We’re here to help!

5 Most Popular Related Questions About Cylindrical Roller Bearings

What are cylindrical roller bearings used for?

These bearings are used in machines that need to handle heavy loads and high speeds, like cars, conveyor belts, and industrial equipment.

How long do cylindrical roller bearings last?

It depends on how much load and speed they handle, as well as how well you maintain them. With proper care, they can last for years.

Why do cylindrical roller bearings overheat?

Overheating happens when there’s too much friction, which can be caused by lack of lubrication, overloading, or poor ventilation.

How do I know if my cylindrical roller bearing is damaged?

Look for signs like noise, vibration, overheating, or visible wear on the rollers or raceways.

Can I repair a damaged cylindrical roller bearing?

Sometimes you can clean or relubricate the bearing to fix minor issues. But if the damage is severe, it’s better to replace it.