Bearing Failure: Causes and Analysis Made Simple

Introduction

Bearings are crucial components in machinery, but they often fail, causing headaches for engineers and operators alike. When a bearing fails, it’s essential to analyze why it happened to prevent future issues.

While technical books and articles often dive into complex jargon, this guide aims to simplify the process. In this article, we’ll break down bearing failure into easy-to-understand categories and explore the root causes behind them.

Whether you’re a seasoned engineer or just curious, this article will help you grasp the basics of bearing failure analysis.

Note: This article simplifies concepts for clarity. For a more detailed, technical explanation, please refer to specialized resources.

Types of Bearing Failure: A Simple Classification

Instead of overwhelming you with technical terms, let’s categorize bearing failures into two main types:

-

Failures that start from the outside (surface-related issues)

-

Failures that start from the inside (material-related issues)

Failures That Start from the Outside

When a bearing fails from the outside, it means something has gone wrong with its surface.

Normally, a well-functioning bearing has a smooth, polished appearance after the initial break-in period. But when things go wrong, you might notice the following signs:

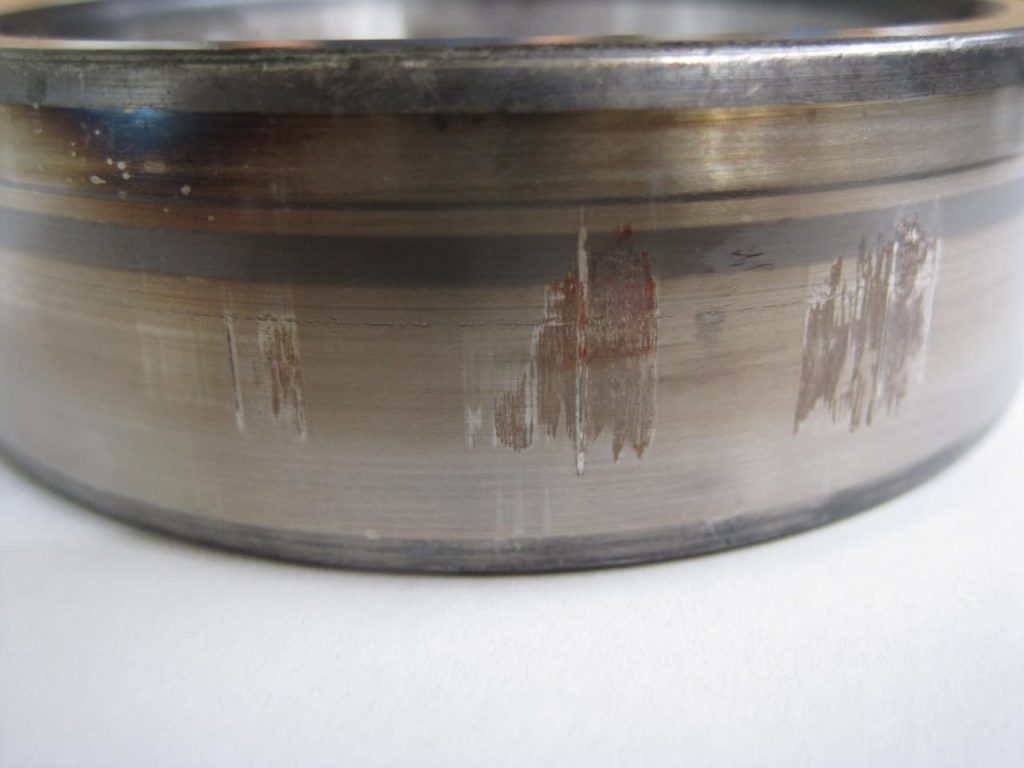

Worn or Abraded Surfaces

-

What it looks like: The bearing surface appears rough or “rubbed” instead of smooth.

-

Why it happens: Bearings are designed for rolling friction, not sliding. If there’s sliding, it means something is causing the bearing to slip instead of roll.

-

Possible causes:

-

Insufficient load: The bearing isn’t under enough pressure to maintain proper rolling.

-

Contamination: Dirt or debris is interfering with the rolling motion.

-

Internal jamming: Something inside the bearing is preventing smooth rotation.

-

-

Think about it: If your bearing looks like it’s been “rubbed” the wrong way, it’s time to check for sliding issues.

Scratched Surfaces

-

What it looks like: Visible scratch marks on the bearing surface.

-

Why it happens: Scratches usually occur when foreign objects, like dirt particles, get trapped in the bearing.

-

Possible causes:

-

Contamination: Particles have entered the bearing.

-

Interference: Other machine parts are rubbing against the bearing.

-

Overloading or poor lubrication: This can cause the rolling elements to slide instead of roll, leading to scratches.

-

-

Ever wonder how a tiny speck of dirt can cause so much damage? It’s like a grain of sand in your shoe—small but painful!

Dented or Pitted Surfaces

-

What it looks like: Indentations or small pits on the bearing surface.

-

Why it happens: Dents and pits can form due to various reasons, including impact, vibration, or electrical issues.

-

Possible causes:

-

Large area material loss: Such as the cage or the raceway has been worn thinner. This could indicate poor lubrication or contamination.

-

Single dents: If the dents are spaced similarly to the rolling elements, the bearing might have been overloaded while stationary or subjected to rough handling during installation.

-

Tiny, dense pits: These are often caused by electrical erosion, which can be seen under a magnifying glass.

-

Plastic deformation: The entire bearing surface is deformed, usually due to excessive impact loads.

-

-

Pro tip: If your bearing looks like it’s been through a war zone, check for impact or electrical issues.

Broken or Fractured Bearings

-

What it looks like: The bearing ring, cage, or rolling element is cracked or split.

-

Why it happens: Breakage is a clear sign of excessive stress or improper handling.

-

Possible causes:

-

Ring fracture:

-

Axial cracks: Check for improper fitting or overheating.

-

Circumferential cracks: Look for signs of fatigue (shell-like patterns) or impact (plastic deformation).

-

-

Cage fracture:

-

Cages aren’t designed to handle heavy loads. If broken, check for excessive wear or operational issues like frequent starts or vibration.

-

-

-

Quick question: If your bearing cage is broken, is it always a quality issue? Not necessarily—it’s often due to how the bearing is used.

Failures That Start from the Inside

Internal failures are less common but can be more challenging to diagnose. These failures originate within the bearing material itself, typically due to fatigue.

-

What it looks like: The bearing surface may have uneven, somewhat flat pits.

-

Why it happens: This is often due to subsurface fatigue, where the bearing material weakens over time under repeated stress.

-

Possible causes:

-

Check the bearing’s load and fatigue life. If these are within normal limits, the issue might be with the bearing’s material quality, such as impurities in steel.

-

- Did you know? Internal failures are less frequent because modern bearings are made from high-quality steel(Such as spherical roller bearing 24048 CC W33). If you see this type of failure, it might be time to review your bearing supplier.

Summary: It’s Often About Application, Not Just Quality

While bearing quality matters, most failures stem from how the bearing is used. Here’s a quick recap:

-

External failures are usually linked to operational issues like contamination, improper loading, or poor lubrication.

-

Internal failures are more likely related to material fatigue or quality issues.

When analyzing a failed bearing, start by identifying whether the failure began from the outside or inside. Then, dig deeper into the specific signs to find the root cause.

Bearing failure isn’t always the manufacturer’s fault. Often, it’s about how we install, maintain, and operate our machinery.

By following this simple approach, you can quickly identify the cause of bearing failure and take steps to prevent it in the future.

If you need more detailed guidance, or more durable bearings, feel free to contact us.