Bearing Selection Guide (2026): Types, Sizing & Applications

Selecting the correct bearing type is the most critical step in mechanical design. A wrong choice often leads to premature failure, costly downtime, and decreased machine performance. With thousands of options available—from deep groove ball bearings to tapered roller bearings—how do you choose the right bearing?

In this updated 2026 Bearing Selection Guide, we will walk you through the different types of bearings, explain key selection factors (such as load, speed, and environment), and help you calculate the correct bearing size for your application.

To simplify the process, follow this proven bearing selection sequence:

- Analyze Operating Conditions: Define the load (radial/axial), rotational speed (RPM), and operating temperature.

- Define Requirements: Determine the necessary precision, rigidity, and expected lifespan.

- Select Bearing Type: Choose the appropriate category (e.g., Ball Bearings for high speed, Roller Bearings for heavy loads).

- Determine Arrangement: Decide how the bearings are positioned (Fixed vs. Floating) within the housing.

- Calculate Bearing Size: Verify load ratings and size constraints to ensure longevity.

Step 1: Analyzing Operating Conditions & Environment

Before selecting a specific bearing model, you must gather precise data about the application. The operating conditions will directly dictate whether you need a ball bearing (for speed) or a roller bearing (for load).

Key factors to analyze include:

- Load (Magnitude & Direction): This is the most critical factor. Determine if the load is Radial (perpendicular to the shaft), Axial (thrust), or Combined.

- Tip: generally, Roller Bearings are preferred for heavy loads, while Ball Bearings are suitable for light-to-moderate loads.

- Speed (RPM): High operational speeds generate heat. Deep groove ball bearings typically handle higher speeds better than roller types due to lower friction.

- Space Limits (Bearing Size): Check the available space for the shaft and housing. This determines the bore diameter and width constraints, helping you choose the correct bearing size.

- Temperature: Consider the operating range. High temperatures (over 150°C) may require special heat-stabilized materials or greater internal clearance (C3, C4).

- Vibration & Shock: Heavy machinery (like crushers) imposes shock loads. In these cases, specific types like Spherical Roller Bearings are often used to accommodate misalignment.

- Ambient Atmosphere: Is the environment dusty, wet, or corrosive? This dictates the need for sealed/shielded bearings or stainless steel materials.

Step 2: Define Requirements (Precision & Rigidity)

Once you know the operating environment, you must define the performance requirements of the machine itself. This step filters out bearings that technically “fit” but won’t perform well.

- Precision (Running Accuracy):

Does your application require high precision (like a machine tool spindle) or is standard precision enough (like a conveyor roller)?- Tip: Standard bearings use ISO Class 0 (ABEC 1). High-precision applications may need Class 5 or 6.

- Rigidity (Stiffness):

How much elastic deformation can you tolerate under load?- Tip: If the shaft position must not change (e.g., in cutting gears), you need high rigidity. Preloaded angular contact ball bearings or tapered roller bearings are best here.

- Noise & Torque:

For household appliances or test equipment, low noise and low friction torque are priorities. Deep groove ball bearings are generally quieter than roller bearings.

Step 3: Types of Bearings Explained (Rolling vs. Sliding)

Once you understand the conditions, the next step is to choose the broad category. Bearings are broadly classified into two main categories based on their friction mechanism: Sliding and Rolling.

3.1 Sliding Contact Bearings (Plain Bearings)

While rolling bearings are popular, simple sliding bearings are still crucial for specific applications.

1. Bush Bearings (Plain Bearings)

This is the simplest type of bearing. It consists of a cast-iron block and a soft metal bush (usually brass or gunmetal). The shaft slides directly against the bush surface, separated by a film of oil.

- Structure: A base plate with a hole for the shaft. An oil hole is provided at the top for lubrication.

- When to Select: Choose this for low-speed shafts carrying light loads where precision is not critical (e.g., simple agricultural machinery).

- Pros: Extremely cheap, silent operation, and easy to replace.

2. Plummer Block (Pedestal Bearing)

Technically, a Plummer Block is a bearing housing used to support a long shaft at an intermediate point. It typically houses a self-aligning ball or roller bearing.

- Structure: It consists of a cast-iron pedestal and a split cap bolted together. This “split” design allows you to lift the shaft out without dismantling the whole machine.

- When to Select: Ideal for long transmission shafts in factories or conveyors where installation and maintenance ease are the top priority.

3. Footstep Bearing (Pivot Bearing)

This is a specific type of thrust bearing used to support the lower end of a vertical shaft. The shaft end rests on a steel disc (pad) to handle the downward axial load.

- Application: Commonly found in older textile machinery or turntables.

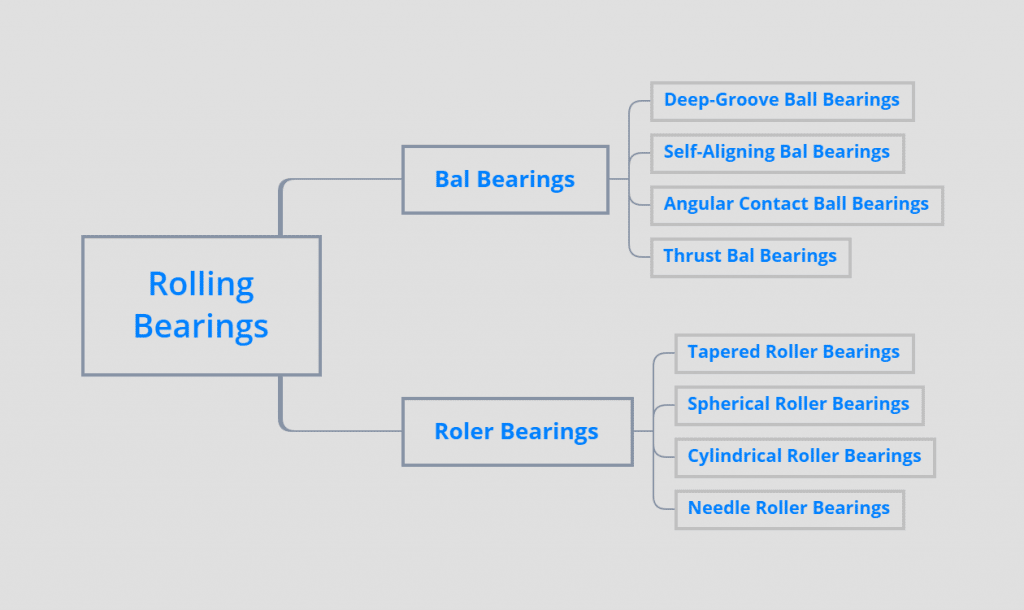

3.2 Rolling Contact Bearings (Anti-friction)

As mentioned in the “Rolling vs. Sliding” section, these are known as Anti-friction Bearings because they replace sliding friction with rolling motion.

Why use Rolling Bearings?

- Low Friction: The rolling elements (balls or rollers) minimize energy loss.

- High Load Capacity: Hardened steel races allow them to carry significant loads.

- Standardization: They come in standard bearing sizes, making global sourcing easy.

We classify them based on the shape of the rolling element:

1. Ball Bearings (Point Contact)

- Mechanism: Theoretical point contact between the ball and the raceway.

- Best For: High-speed applications with light to medium loads.

- Example: Electric motors, fans.

2. Roller Bearings (Line Contact)

- Mechanism: The roller makes line contact with the raceway, providing a larger surface area to distribute pressure.

- Best For: Heavy load applications operating at lower speeds.

- Example: Conveyor belts, crushers, heavy vehicle axles.

Comparison Summary:

- Choose Ball Bearings if your priority is Speed.

- Choose Roller Bearings if your priority is Load Capacity.

FAQ: Why are Rolling Contact Bearings preferred over Sliding Contact Bearings?

n modern machinery, Rolling Contact Bearings are often preferred over Sliding Contact Bearings for the following reasons:

- Low Starting Friction: Rolling bearings have much lower static friction, meaning machines need less power to start moving. This is why they are called “Anti-friction bearings.”

- Compact Length: They occupy less axial space compared to sliding bearings.

- Standardization: They are internationally standardized, making replacement and sourcing (like finding a specific bearing size) much easier.

- Lubrication: They consume less lubricant and are easier to seal against dust compared to hydrodynamic sliding bearings.

- Versatility: They can handle both radial and thrust loads simultaneously (e.g., Tapered Roller Bearings).

However, keep in mind that Rolling Bearings are sensitive to shock loads and require high-precision housing fits. preferred for extremely high loads or silent operation where shock absorption is needed (e.g., engine crankshafts).

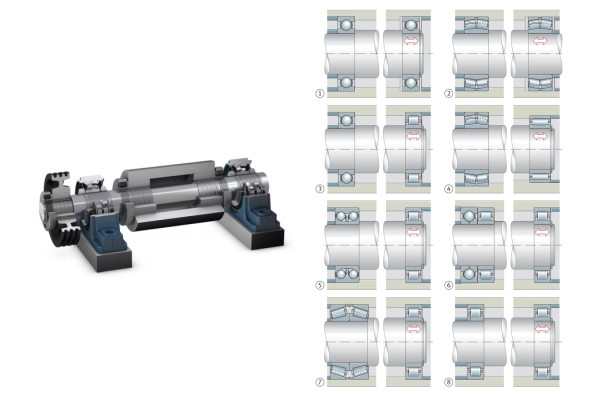

Step 4: Determining the Bearing Arrangement

After selecting the bearing type, you must decide how to mount them. You cannot simply lock both bearings in place; thermal expansion will cause the shaft to seize.

To prevent this, the standard arrangement consists of a Locating (Fixed) side and a Non-locating (Floating) side.

1. The Locating Bearing (Fixed Side)

This bearing positions the shaft axially. It must support both radial and axial loads to keep the shaft in place.

- Function: Anchors the shaft and restricts axial displacement.

- Best Bearing Choices:

- Deep Groove Ball Bearings: Ideally suited for small to medium motors.

- Spherical Roller Bearings: Best for heavy loads where shaft misalignment might occur.

- Angular Contact Ball Bearings: Used in pairs for high-precision applications.

2. The Non-locating Bearing (Floating Side)

This bearing handles radial loads only. Crucially, it must allow for axial movement (displacement) to compensate for the thermal expansion of the shaft or mounting errors.

- Function: Absorbs shaft expansion to prevent stress.

- Best Bearing Choices:

- Cylindrical Roller Bearings (NU, N types): These are the perfect “floating” bearings because the inner and outer rings can slide relative to each other.

- Deep Groove Ball Bearings (Loose Fit): Can be used if the outer ring is mounted with a loose fit in the housing.

Step 5: Calculate Bearing Size & Lifespan

This is the final verification step. You have the type and the arrangement; now you need to determine the specific bearing size and ensure it will last long enough.

1. Bore Diameter (Shaft Size)

Usually, the machine design dictates the shaft diameter first. Your bearing bore diameter must match the shaft.

- Note: If the shaft design is flexible, you can choose a smaller shaft to save cost, or a larger one for rigidity.

2. Load Ratings (C vs. C0)

Check the catalog for two key values:

- Dynamic Load Rating (C): Crucial for rotating bearings. It is used to calculate the fatigue life.

- Static Load Rating (C0): Crucial for bearings that rotate very slowly or are stationary under load. Ensure the static safety factor is sufficient to prevent permanent deformation.

3. Life Calculation (L10 Life)

How long will the bearing last? The standard industry formula for basic rating life is:

L10 = (C / P)^p

- L10: Basic rating life (in millions of revolutions).

- C: Dynamic load rating.

- P: Equivalent dynamic load (actual load).

- p: Exponent (Use 3 for ball bearings; use 10/3 for roller bearings).

Decision Rule: If the calculated L10 life is shorter than your required service life (e.g., 20,000 hours), you must switch to a larger bearing size or a type with a higher load capacity (like switching from Ball to Roller).

Conclusion: Making the Right Choice

Selecting the right bearing is a balancing act between Load Capacity, Rotational Speed, and Cost. There is no single “best bearing”—only the best bearing for your specific application.

To summarize this guide, use this quick checklist for your final decision:

- Need High Speed & Precision? → Stick with Ball Bearings (Deep Groove or Angular Contact).

- Facing Heavy Radial Loads? → Choose Cylindrical or Spherical Roller Bearings.

- Facing Heavy Axial (Thrust) Loads? → Choose Thrust Bearings or Tapered Roller Bearings.

- Need a Low-Cost, Low-Speed Solution? → A simple Bush Bearing might be sufficient.

- Complex Mounting? → Consider using a Plummer Block unit for easier maintenance.

Still not sure which bearing size fits your project?

Don’t risk machine failure with a guess. Check out our TFL Bearings Catalog or Contact our engineering team today for a custom selection guide tailored to your machinery.