Understanding Full Complement Cylindrical Roller Bearings and Standard Cylindrical Roller Bearings

Introduction

Imagine two kinds of workhorses. One is super strong and can pull a heavy wagon. The other is fast and graceful, like a racehorse.

Cylindrical roller bearings are similar. Full complement cylindrical roller bearings are your heavy haulers, best for big loads at lower speeds. Standard cylindrical roller bearings are your speed racers, ideal for faster rotations where friction is a concern.

Choosing between them depends on what your machine needs to do. We’ll compare full-complement cylindrical roller bearings and standard bearings to help you choose the right one.

What Are Full Complement Cylindrical Roller Bearings?

Design Features

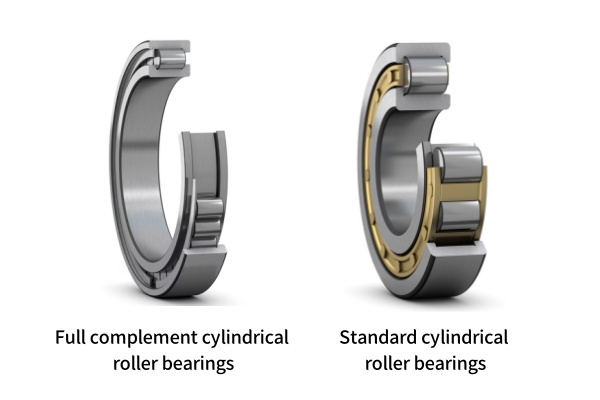

Full complement cylindrical roller bearings use the maximum number of rollers to accommodate heavier loads. They do not have a cage, which increases the roller capacity. The increased number of rollers increases the load capacity of the bearing.

However, due to the greater friction between the rollers, the speed of this bearing is lower than that of a standard (caged) cylindrical roller bearing.

(Reference: Optimal Design Of Self-Retaining Full Complement Cylindrical Roller Bearings by Ursache et al. 2019)

Therefore, full complement cylindrical roller bearings are suitable for applications where high radial loads are required, and space is a concern.

Key Advantages

-

Handles heavy loads well

-

Works best at low to medium speeds

-

Great for tight spaces where size is limited

Common Uses

Full complement cylindrical roller bearings are workhorses in many industries, especially where heavy loads and reliable performance are needed. Here’s a broader look at where you’ll find them:

-

Manufacturing and Industrial Equipment: These bearings are widely used in machine tools (like lathes and mills), presses, gearboxes, and other heavy machinery used to make things. They handle the forces involved in shaping, cutting, and assembling products.

-

Transportation: From trains and heavy trucks to construction vehicles and agricultural equipment, these bearings are essential for handling the weight and movement of large vehicles. They’re found in wheel axles, transmissions, and other key components.

-

Energy Production and Resources: Power plants (including wind turbines), oil and gas drilling equipment, and mining machinery all rely on these bearings. They can withstand the demanding conditions and heavy loads common in these industries.

-

Processing and Material Handling: Industries that process materials like chemicals, food, and textiles use these bearings in mixers, conveyors, and other equipment. They often need to meet specific hygiene or corrosion resistance requirements.

What Are Standard Cylindrical Roller Bearings?

Design Features

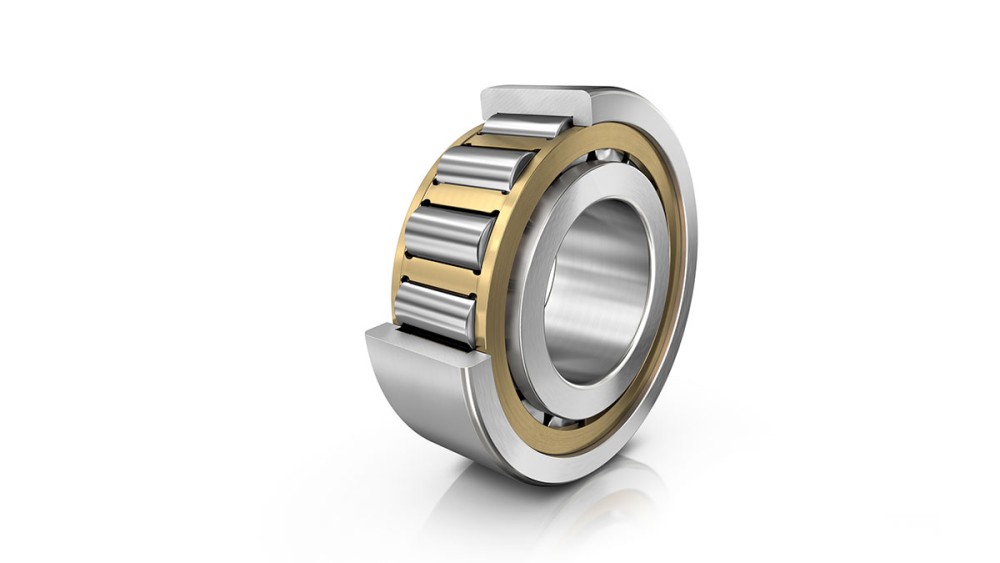

Standard cylindrical roller bearings generally include a cage. The rollers use this cage (some are retaining blocks) to prevent tilting or friction. This can reduce wear and support higher speeds.

Key Advantages

-

Better for high-speed applications

-

Ability to support high load capacities

-

Longer service life due to less wear

Common Uses

Standard cylindrical roller bearings are versatile components found in various industries where moderate to high radial loads and moderate speeds are common. Here’s a broader look at where you’ll find them:

-

Manufacturing and Industrial Equipment: These bearings are frequently used in electric motors, gearboxes (especially smaller to medium-sized ones), pumps, and compressors. They provide reliable support for rotating shafts and handle the radial forces generated during operation. They are also found in some machine tools where higher speeds are a factor.

-

Transportation: While heavy-duty transportation often uses full complement bearings, standard cylindrical roller bearings can be found in lighter-duty trucks, cars (in some applications), and certain types of railcars. They are used in transmissions, differentials, and other rotating components.

-

Material Handling and Automation: Bearings like these are often used in robotic arms, conveyor systems, and packaging machines because they can handle moderate loads at decent speeds.

-

Agricultural and Construction Equipment: In smaller agricultural machinery and certain types of construction equipment, standard cylindrical roller bearings can be found in implements, gearboxes, and other rotating parts. They offer a good balance of load capacity and speed capability for these applications.

Full-Complement vs. Standard Bearings: Key Differences

| Feature | Full-Complement Cylindrical Roller Bearings | Standard Cylindrical Roller Bearings |

|---|---|---|

| Load Capacity | Higher | Moderate |

| Speed Capability | Lower (Limited to slower speeds) | Higher |

| Maintenance & Durability | Higher Maintenance, Lower Durability | Lower Maintenance, Higher Durability (Longer Lifespan) |

Choosing the Right Bearing for Your Needs

Application Considerations

Think about what your machine needs.

If you’re working with heavy loads in tight spaces, like in construction or industrial settings, full complement bearings are a solid choice.

If your equipment needs to run fast and efficiently, like in electric motors or automotive systems, standard bearings are likely a better fit.

Budget Factors

Cost is another thing to think about. When it comes to heavy-duty work, full-complement bearings are usually cheaper.

But standard bearings might save you money in the long run if you want something that will last and not need as much upkeep.

Conclusion

Your needs will determine whether you should use full-complement or normal cylindrical roller bearings. It is best to use full complement bearings for big loads. Choose normal bearings for faster speeds and less upkeep.

At TFL, we make high-quality bearings for a wide range of businesses. We can meet your needs whether they are long-lasting, fast, or able to carry a lot of weight.

Check out TFL Bearings for options that are reliable and work well. Today, go to our website to find the right bearing for your needs.