Cylindrical Roller Insulated Bearings

Introduction

Cylindrical roller insulated bearings are electrically insulated with added insulation properties to standard cylindrical roller bearings. They are primarily used in various modern industrial fields and become an essential category of industrial insulated bearings.TFL insulated bearings have a good reputation in the industry, advanced insulation technology, and high-quality cylindrical roller bearings production.

How Cylindrical Roller–Insulated Bearings Work

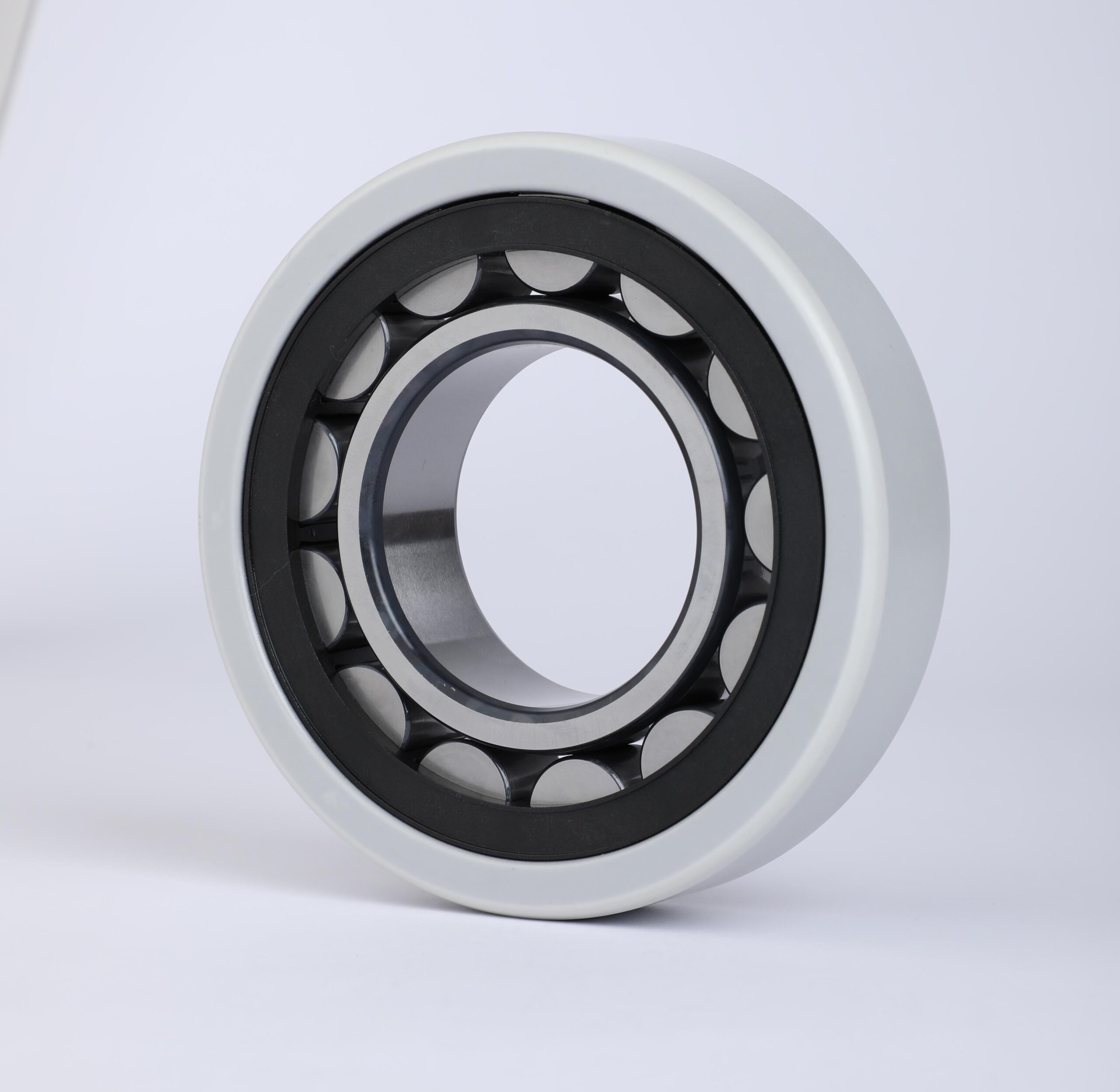

Cylindrical roller insulated bearings work by rolling the rollers on the inner and outer cylindrical surfaces, thus reducing frictional resistance and enabling the bearing to withstand enormous loads and maintain smooth motion. The bearings are insulated by adding an insulating layer to prevent electric current from passing through the bearing.

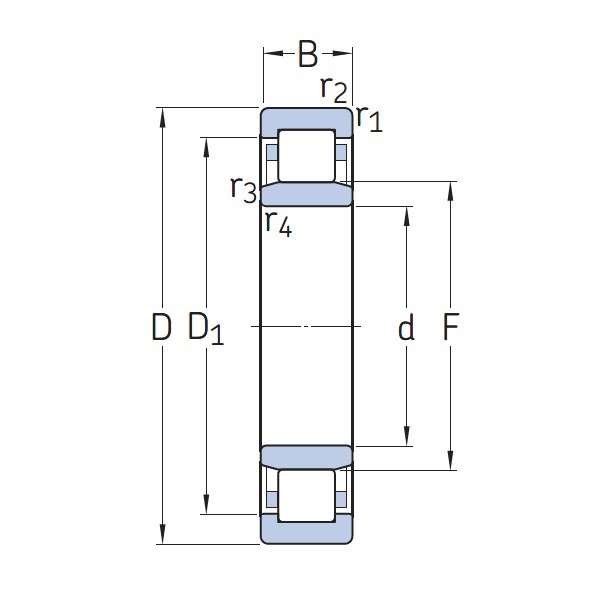

Basic Structure of Cylindrical Roller Bearings

Cylindrical roller insulated bearings are based on the basic structure of cylindrical roller bearings, which mainly include inner and outer rings, cylindrical rollers, cages, and insulating coatings. Insulated bearings improve on standard cylindrical roller bearings by utilizing a unique sealing process to encapsulate the bearings, especially in preventing current from passing through them.

Types and Characteristics of Insulation Coatings

Insulating coatings are essential for protecting various surfaces against current flow, moisture, and corrosion. Insulating coatings applied in bearings are generally aluminium oxide, silicon nitride, zirconium oxide, etc.

| Type | Chemical formula | Specificities | Application Areas | Representative Models |

|---|---|---|---|---|

| Aluminium oxide | Al₂O₃ | High boiling point, high hardness | Refractory materials, dental and medical applications, lasers | NU315 ECP/C3VL0241 NU226ECM/C3VL0241 SKF |

| Silicon nitride | Si3N4 | High-temperature resistance, high hardness, wear and corrosion resistance | High-temperature bearings, automotive and gas turbine engines | |

| Zirconium oxide | ZrO2 | High wear resistance, high rigidity, and corrosion resistance | Oxygen sensors, electronic ceramics, soldering processes, and wire-forming tools |

Mechanism of Electrical Insulation Performance

The mechanisms for realizing electrical insulation performance include the following:

- Performance of insulation materials: Insulating materials are the basis for electrical insulation performance. They need good electrical properties, thermal properties, mechanical properties, chemical properties, moisture absorption properties, and anti-biological properties.

- Rheological properties of the insulating material: The rheological properties of the insulating material are crucial for electrical products such as cables.

- Degassing properties: Good degassing properties can reduce air bubbles and impurities in production and improve the uniformity and stability of the insulation layer.

- Performance parameters of electrical insulation: Key parameters that characterize thermal insulation performance include conductivity, breakdown field strength, etc.

Design Principles for High Load Capacity

The design principles for high-bearing load capacity include the following:

- Material selection: Bearing materials need to have high strength, hardness, wear resistance, and other characteristics to ensure that they can withstand a variety of forces in the working process and reduce wear and damage.

- Structural design: Reasonable structural design is the key to ensuring bearings’ high load capacity. The design needs to take into account the uniform distribution of force and avoid the concentration of force.

- Lubrication: Good lubrication can effectively reduce friction and improve bearings’ service life. Select the appropriate lubrication method and lubricant, such as oil lubrication, grease lubrication, or solid lubrication, such as Oil-lubricated insulated bearing.

- Precision and stability: High-precision bearings can ensure smooth and accurate rotation of mechanical equipment and reduce vibration and noise.

- Reliability and safety: To ensure that the bearings work correctly in all kinds of harsh environments, rigorous strength and fatigue analyses are required to ensure that they can withstand a variety of forces without damage, such as heavy-duty insulated roller bearings.

Advantages of TFL Cylindrical Roller Insulated Bearings

TFL cylindrical roller insulated bearings offer multiple advantages through their unique insulation design and high-performance materials, including excellent electrical insulation, high load capacity, high-speed resistance, excellent thermal Performance, low friction, and long life. These characteristics make them indispensable high-quality mechanical components in modern industry.

Superior Electrical Insulation Performance

In general, the electrical insulation capability of insulated bearings is required to withstand at least kilovolt levels of industrial frequency voltage. Electrical insulation bearings block the passage of electric current through insulating materials to prevent galvanic damage.TFL insulated bearings have excellent electrical insulation performance and guaranteed quality.

High Load Capacity

Insulated cylindrical roller bearings can withstand high radial and axial loads due to the small roller clearance and linear contact of the raceway surfaces. They have a high load-carrying capacity and are more suitable for heavy loads and high speeds in mechanical equipment.

High-Speed Operation Resistance

High-speed insulated cylindrical bearings have a large support area, adequate contact between the bearings and the track, and a small friction coefficient. Therefore, when the rotational speed is high, and the load is large, the smoothness of operation is good, and the vibration and noise are relatively small. This gives insulated cylindrical roller bearings better high-speed rotating performance.

Excellent Thermal Performance

The excellent thermal Performance of insulated cylindrical roller bearings is mainly reflected in their high-temperature resistance and heat dissipation efficiency. Thermal-resistant insulated bearings are made of unique materials and manufacturing processes for excellent high-temperature resistance. These bearings can maintain stable operation under high-temperature environments and are not susceptible to performance degradation or damage due to rising temperatures. Their high-temperature resistance is essential for many industrial applications because it ensures the reliability and stability of equipment under high-temperature conditions.

Low Friction and Long Lifespan

Due to the cylindrical roller’s larger rolling contact area and lower coefficient of friction, it has better lubrication performance and lower friction resistance, which can effectively reduce mechanical energy consumption and wear. In addition, the bearing surface is made of special insulating material, thus extending the service life of cylindrical roller insulated bearings, e.g., low-friction insulated roller bearings.

Applications of Cylindrical Roller Insulated Bearings

Insulated cylindrical roller bearings are widely used in many critical applications, especially in those where high demands are placed on the insulating properties of the bearings. The following are the main areas of application for insulated cylindrical roller bearings:

Electric Motor Systems

The design of the insulated cylindrical roller bearings considers the unique characteristics of the motor system. A unique coating process and sealing treatment ensure that the bearings can maintain good insulation and mechanical properties in high humidity and moisture environments. The application of electric motor-insulated bearings significantly improves the safety and reliability of motor systems, reduces equipment damage and production interruptions caused by galvanic corrosion, and is an indispensable component in modern motor systems.

Generators

The application of insulated cylindrical roller bearings in generators mainly solves the galvanic corrosion effect of current on bearings and improves their service life and operational reliability. Generator-insulated bearings prevent the current from damaging the grease, rolling body, and raceway and meet the insulation requirements for bearings in various power equipment, providing an essential guarantee for generator operation.

Industrial Gearboxes

Industrial gearbox bearings are treated with a unique insulating material and coating process to create an insulating layer of protection for the equipment and bearings. Cylindrical roller insulated bearings play an irreplaceable role in demanding equipment such as industrial gearboxes due to their excellent anti-electrical corrosion performance and stability.

Steel Mill Rollers

The role of insulated cylindrical roller bearings in steel mills is mainly reflected in their ability to withstand heavy loads and shock loads to ensure the stable operation of the mill and long working hours. Steel mill bearings, as special cylindrical roller bearings, not only inherited the advantages of ordinary cylindrical roller bearings, suitable for the need to withstand heavy loads of machinery and equipment but also in the design of the particular focus on preventing induced current on the bearings of the galvanic corrosion effect. This characteristic makes insulated cylindrical roller bearings particularly important when applying steel mills.

Railway Traction Motors

Insulated cylindrical roller bearings were initially designed to prevent current from passing through the bearings, which is particularly important in railroad traction motors. Since railroad locomotives are subject to electromagnetic field interference during operation, conventional cylindrical roller bearings cannot effectively isolate the current, which can easily lead to galvanic corrosion, thus affecting the service life and Performance of the bearings. Traction motor bearings effectively solve this problem by spraying a layer of zirconia or silicon nitride coating with insulating properties on the inner ring’s outer surface or the outer ring’s outer surface.

Choosing the Right Cylindrical Roller Insulated Bearing

There are several factors to consider when selecting the right cylindrical roller insulated bearing:

Assessing the Application Environment

Environmental factors include temperature, humidity, and chemical corrosion. High-temperature environments require the selection of insulating bearing materials and lubricants that can withstand high temperatures. For humid environments, choose insulated bearings with good rust and corrosion resistance. The selection of insulating bearing materials that can resist chemical corrosion, such as stainless steel or special coatings, can effectively extend the bearing’s service life.

Determining Load and Speed Requirements

Bearings are selected according to the size and nature of the load on the equipment. Roller bearings are suitable for heavy loads and radial loads. For high-speed rotation, bearings with a low coefficient of friction need to be selected. Insulated cylindrical roller bearings are ideal for high-speed rotation.

Considering Insulation Performance Needs

Insulation performance requirements are a critical factor in selecting cylindrical roller-insulated bearings. Insulated bearings can block the passage of electric current, usually by coating the outer or inner ring of the bearing with a layer of insulating material or using ceramic rolling elements. This insulating property prevents galvanic corrosion and extends the life of the bearing, which is especially important in applications such as motors and generators.

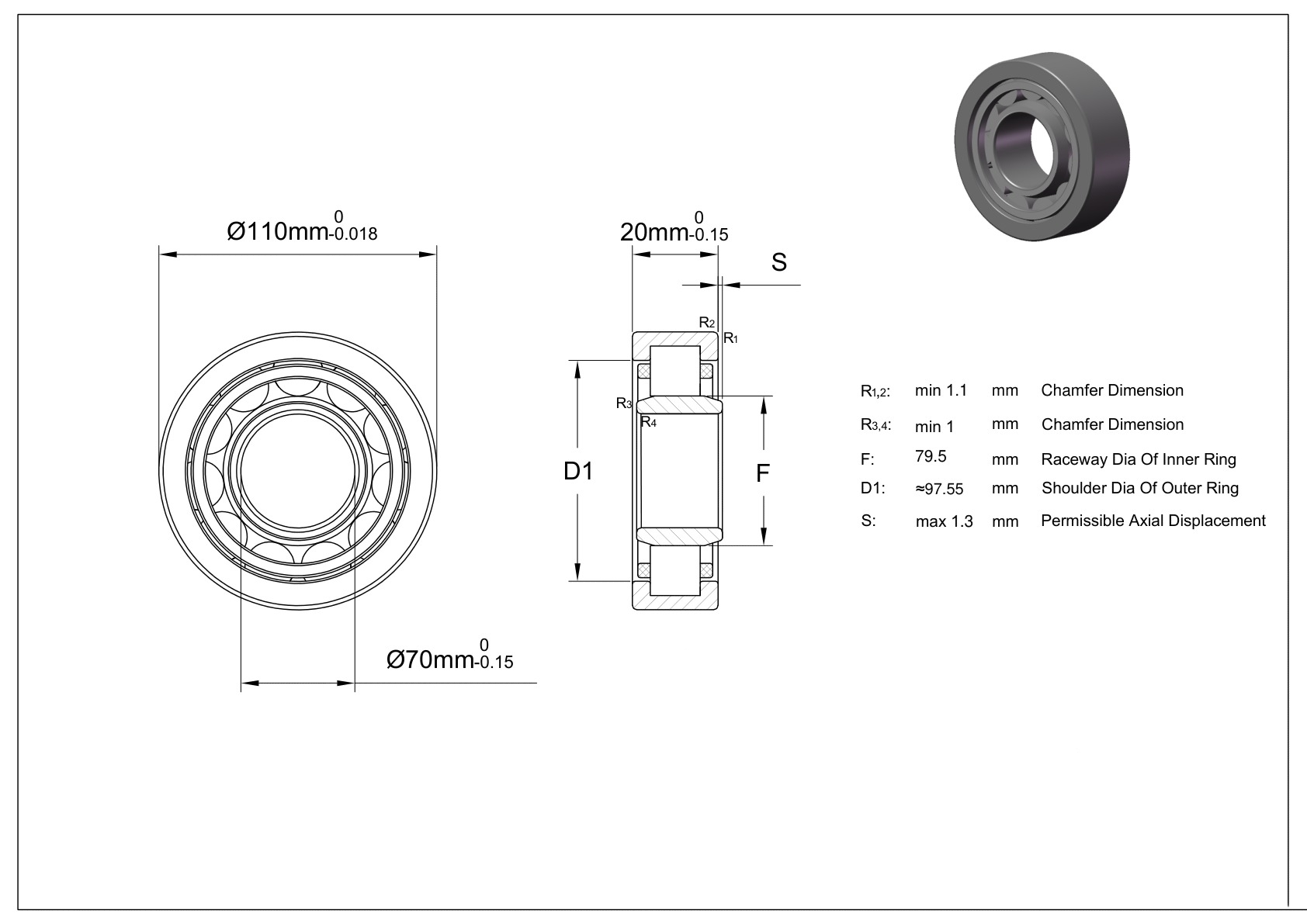

Size and Installation Constraints

The selection of bearings is based on size and mounting limitations. Each bearing has its specific external dimensions, and usually, the shaft diameter is based on mechanical design limitations. Therefore, the bearing’s inside diameter determines the bearing’s type and size. Standard bearings are available in a wide range of dimensional forms. Using standard bearings helps ensure that bearings are easy to procure, thereby reducing design costs and procurement time, as well as facilitating maintenance and replacement at a later stage.

Maintenance and Lifespan Expectations

To extend the life of the insulated bearings and to facilitate maintenance, it is recommended that a bearing design with high load-carrying capacity, high rigidity, and low friction be selected. In addition, the sealed design prevents contamination and retains lubricant, extending life and reducing maintenance requirements.

TFL’s Technical Support and Customization Services

TFL Insulated Bearings as a leading bearing manufacturer, TFL Bearings always focuses on the research and development of today’s most advanced bearing technology to continuously improve the quality and Performance of bearings.

Professional Technical Consultation

We have been engaged in the bearing industry for ten years and in international bearing trade import and export for more than eight years. We have professional technical support and an expert team to help you answer all kinds of questions and provide more professional technical and custom Solutions.

TFL produces a wide range of bearings. Customers can also request the production of non-standard bearings. The technical and production capacity is among the leading bearing manufacturers and suppliers. Come to us, and we will customize the solution to your satisfaction.

Comprehensive After-Sales Support

TFL insulated bearings have guaranteed quality and after-sales service that makes you worry-free. Comprehensive after-sales support demonstrates our thoughtful service and professional attitude.

Rigorous Quality Control

China Bearing Suppliers and Manufacturers are also numerous worldwide. We produce insulation bearings with high insulation, low noise, high rotational accuracy, and good sealing performance.TFL Insulation Bearing always adheres to strict quality control and wins trust with reputation.

Conclusion

TFL insulated bearings have high-quality insulating Performance and great value for money, using advanced insulation technology to protect your bearings and equipment safety. We have the most advanced bearing production equipment and testing equipment, a first-class production line, and a strict testing process. We are committed to selling branded bearings, such as SKF, NSK, KOYO, NTN, FAG, and other international brands, with favourable prices and complete services, as well as original brand bearings.

You can contact us at any time that is convenient for you. We are available 24/7 via fax or e-mail. We are happy to interact with you!

Frequently Asked Questions

How do cylindrical roller-insulated bearings work?

Cylindrical roller-insulated bearings’ working principles and characteristics are mainly reflected in their structure and design. The rollers of this type of bearing are in line contact with the raceway, which has a large radial load capacity and is suitable for bearing heavy loads and shock loads, as well as for high-speed rotation. In addition, cylindrical roller insulated bearings use steel plate stamping cages, copper alloy cut cages, pin type cages, synthetic resin moulding cages and so on, to adapt to different application requirements.

What are the benefits of insulated roller bearings in motors?

Insulated roller bearings effectively prevent the galvanic corrosion effect of electric current on the bearings by covering the surface of their inner and outer rings with an insulating coating, thus avoiding damage to the bearings caused by electric current. This design not only improves the insulating properties of the bearings but also significantly reduces the “scrubboard” groove striations caused by current corrosion, which reduces noise and vibration and ensures the smooth operation of the motor.

Can insulated bearings reduce maintenance costs?

Insulated bearings reduce maintenance costs. Insulation protects bearings and equipment from damage caused by electrical currents, dramatically reducing the number of repairs and maintenance costs and increasing productivity.

Where can you buy high-quality cylindrical roller–insulated bearings?

Buy high-quality cylindrical roller insulated bearings; come to TFL Insulated Bearings; we sell bearing brands including Germany: FAG, INA, Japan: NSK, NTN, IKO, NMB, FYH, NACHI, THK. Sweden: SKF, America: TIMKEN, DEBOT, and many other high-quality resources.

What industries use cylindrical roller-insulated bearings most?

Cylindrical roller-insulated bearings are most commonly used in the electric power, railroad, machinery and metallurgy, mining machinery, and petrochemical industries.