Why understanding bearing clearance has become so important

Quick Reference: Bearing Clearance Application Chart

If you are unsure which code to specify, check this table against your operating conditions.

| Class | Description | Operating Conditions | Typical Applications |

|---|---|---|---|

| C2 | Tight (Less than Normal) | Low noise, high precision, low heat. Requires very precise machining of shaft/housing. | Precision Spindles, Gyroscopes, Micro-motors. |

| CN (C0) | Normal (Standard) | Standard temperatures (-20°C to +100°C) and normal fits. The default choice. | Conveyors, Standard Fans, Water Pumps, Agricultural Machinery. |

| C3 | Loose (Greater than Normal) | High speeds, moderate heat, or heavy press fits. Allows for thermal expansion. | Electric Motors, Motorcycle Engines, Automotive Alternators. |

| C4 | Extra Loose | High heat or severe vibration. | Vibrating Screens, Mining Crushers, Paper Mill Dryers. |

| C5 | Extra Extra Loose | Extreme heat environments. | Kiln Cars, Steel Mill Rollers, High-Temp Ovens. |

Engineering Note: Never use C4 or C5 bearings in a standard application “just to be safe.” Excessive clearance will lead to vibration, noise, and reduced load capacity.

Here is the golden rule every buyer must know:

Internal clearance is NOT the same as “precision” or “tolerance”. A loose bearing (C3/C4) can still be high precision (P5/P6).

If you install a standard clearance bearing into a high-temperature motor thinking it is “more precise,” it will seize up and fail. We created this guide to help you avoid these costly purchasing errors and ensure you order the right part the first time:

- Radial vs. Axial: Understanding the direction of movement.

- Decoding the Codes: When to choose C2, CN, C3, or C4.

- Selection Charts: Full ISO 5753 reference tables for quick lookups.

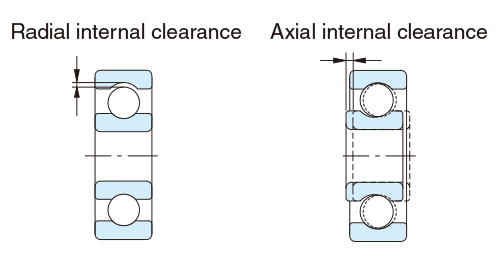

What is Radial vs. Axial Clearance?

Internal clearance is divided into two directions:

-

Radial Internal Clearance: The total movement of the inner ring up and down (vertical) relative to the outer ring. This is the primary specification defined by ISO standards.

-

Axial Internal Clearance: The total movement of the inner ring side-to-side (horizontal) relative to the outer ring.

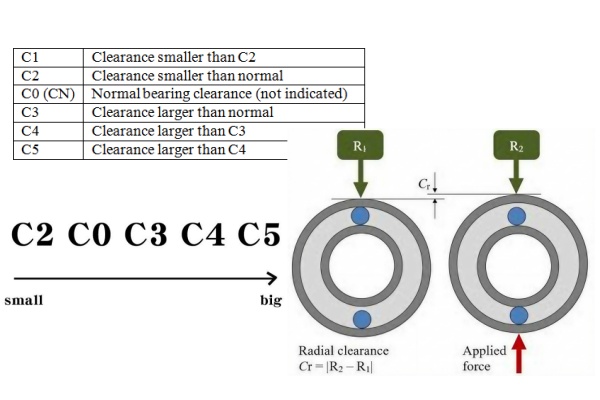

Decoding the Codes: CN, C3, and C4

Manufacturers use standardized suffix codes to identify clearance classes. The scale moves from “Tight” to “Loose”:

-

C2 (Tight): Clearance is smaller than normal. Used in high-precision machine tools where vibration must be minimized. Risk: Easily overheats if not installed perfectly.

-

CN / C0 (Normal): The standard clearance. Usually, this is not marked on the bearing (e.g., a “6205” bearing has CN clearance). Suitable for standard applications with normal temperatures.

-

C3 (Loose): Clearance is larger than normal. This is the most common specification for Electric Motors and pumps.

-

C4 / C5 (Extra Loose): For extremely high-speed or high-temperature environments (like vibrating screens or kilns).

Why Choose C3 (Loose) Clearance?

Customers often ask: “Why would I want a loose bearing? Doesn’t that mean low quality?”

The answer lies in the difference between Initial Clearance (what you buy) and Operating Clearance (what happens when running). Two factors will “eat up” the clearance during operation:

-

Interference Fits: When you press a bearing onto a shaft, the inner ring expands. When you press it into a housing, the outer ring shrinks. This compression reduces the internal space.

-

Thermal Expansion: In operation, the inner ring (shaft) is usually hotter than the outer ring. Steel expands when hot, further closing the gap.

The Rule of Thumb: If you are using a tight interference fit or running at high speeds/temperatures (like in an electric motor), you need C3 to allow for this expansion. If you use a Normal (CN) bearing in these conditions, it will have zero clearance once hot, leading to friction and failure.

When to use C3?

In the B2B market, C3 is the most commonly requested “non-standard” clearance. But why?

The answer is simple: C3 provides room for expansion. When a bearing runs at high speeds, the friction generates heat, causing the inner ring to expand. Additionally, if the bearing is press-fitted onto the shaft (interference fit), the inner ring expands further.

You generally need a C3 clearance if your application involves:

-

Electric Motors: High speeds generate heat; C3 is the industry standard for motor bearings.

-

Heavy Interference Fits: If you are press-fitting the bearing tightly onto the shaft, you lose about 60-80% of the initial clearance immediately. C3 compensates for this.

-

High Vibrations: Equipment like crushers or gearboxes often benefit from the extra flexibility.

-

Temperature Gradients: When the shaft gets much hotter than the housing (e.g., in internal combustion engines).

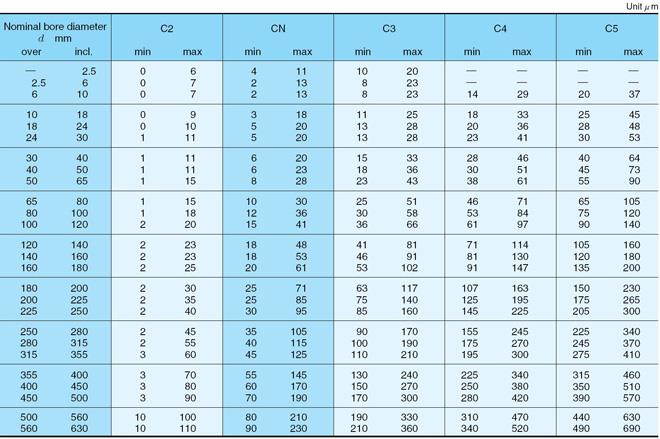

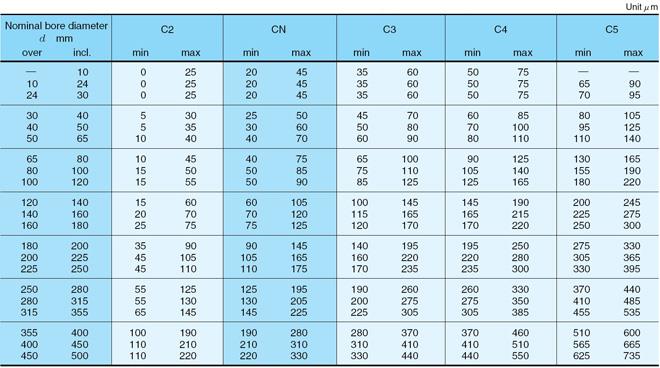

Bearing clearance standard quick reference table

Below are the standard clearance values (in microns, μm) for Deep Groove Ball Bearings and Cylindrical Roller Bearings.

How to read these tables:

-

Identify your bearing’s Bore Diameter (d).

-

Choose your clearance class (e.g., C3).

-

The value shows the minimum and maximum gap in microns.

Conclusion

Choosing between C3 and Normal clearance is a balancing act. Too little clearance leads to heat and seizing; too much clearance leads to noise and vibration.

Not sure which clearance your application needs? Don’t guess. [Contact TFL Bearing’s Engineering Team] today. We can help you calculate the precise fit and clearance for your machinery.