The Ultimate Guide to Bearing Installation and Startup in Cold Weather

When temperatures drop to 0°C or plummet below -20°C, industrial machinery faces a severe tribological test. Cold weather causes metal contraction, drastically increases grease viscosity, and embrittles sealing materials. These factors not only complicate bearing installation but are the primary causes of winter startup failures, including cage fracture and raceway skidding.

To ensure operational stability, maintenance teams must abandon “rule of thumb” methods and adopt a standardized engineering protocol. This guide covers the correct procedures from storage to startup, ensuring your rotating equipment survives the winter.

Part 1: Bearing Installation in Low Temperatures

The core challenges of installing bearings in freezing environments are managing dimensional changes and material brittleness.

1. Three Pre-Installation Essentials

A. Thermal Equilibrium & Condensation Control:

Never take a bearing from cold outdoor storage and install it immediately in a warm workshop. The rapid temperature change causes condensation to form on the raceways, leading to immediate corrosion.

-

-

Protocol: Allow the bearing and housing to acclimatize to the installation environment temperature (typically 24 hours) inside their original packaging.

-

Pro Tip for High Humidity: If storing bearings in a damp, cold warehouse, place Desiccant Packs (Silica Gel) inside the storage cabinet or bin. This actively removes moisture from the air, preventing the “dew point” from triggering rust on the precision surfaces.

-

B. Scientific Pre-heating:

Low temperatures cause the bearing inner ring to shrink, abnormally increasing the interference fit required for installation. Forcing a cold installation can crack the inner ring.

-

-

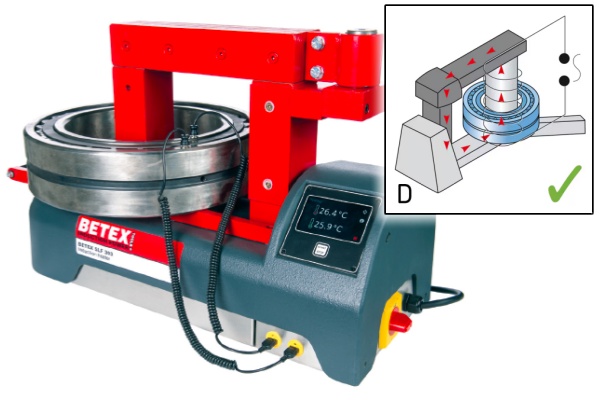

Best Practice: Use an induction heater to uniformly heat the bearing to 80-100°C (max 110°C). This expands the inner ring for a smooth slide-fit.

- Safety First (PPE): Always wear heat-resistant thermal gloves when handling bearings heated to 80-100°C. Contact with steel at these temperatures causes instant, severe burns.

-

Warning: Never use an open flame. Localized overheating alters the steel’s metallurgy (annealing), permanently softening the raceway.

-

C. Grease Selection (The Viscosity Factor):

Standard mineral oil greases can solidify like wax in extreme cold, leading to high starting torque.

-

-

Standard Applications (Manual Packing): Use NLGI Grade 1 or 2. Avoid Grade 3 in winter as it is too stiff.

-

Centralized Lubrication Systems: Use NLGI Grade 0 or 00 (Semi-fluid) to ensure pumpability through cold lines.

-

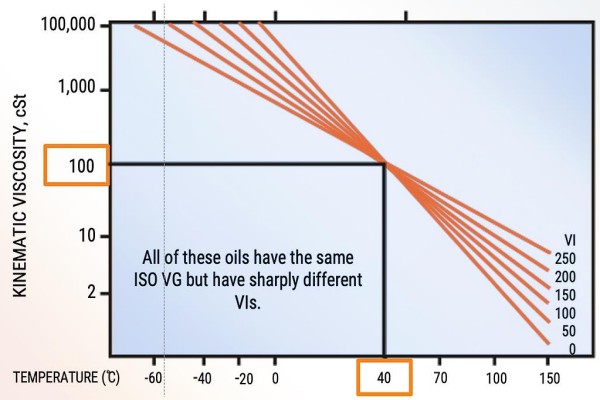

Below -20°C: You must upgrade to Synthetic Grease (PAO or Ester-based). These have a high Viscosity Index (VI), ensuring the oil film remains fluid at low temps.

-

⚠️ CRITICAL WARNING: Grease Compatibility

Do not mix different grease types! When upgrading to Synthetic Grease for winter, you must verify compatibility with the existing grease in your system.

- The Risk: Mixing incompatible thickeners (e.g., Lithium vs. Polyurea) or base oils (e.g., Mineral vs. Ester) can cause the mixture to harden or liquefy immediately, leading to catastrophic bearing failure within hours.

- The Protocol: If changing grease types, the bearing and housing must be thoroughly cleaned and purged of all old lubricant before applying the new winter grease.

2. The Installation Window: Monitoring Temperature

In cold environments, a pre-heated bearing cools rapidly. Once the bearing shrinks back to the shaft diameter, it locks in place.

-

Action: Install immediately after heating. Use a dedicated fitting tool that applies force only to the ring being fitted (usually the inner ring).

-

Prohibition: Never strike the outer ring, seals, or cage. Cold metal and plastic cages (polyamide) are brittle and prone to shattering under impact.

-

Sealing: Apply a thin layer of low-temp compatible grease to seal lips to prevent tearing against the shaft during assembly.

3. Post-Installation Verification

-

Clearance Check: Thermal contraction of the housing (if cold) can squeeze the bearing outer ring, reducing internal clearance. Always verify that the shaft rotates freely by hand before coupling the load.

-

Correct Grease Fill: Do not overfill.

-

Standard: Fill 30% to 50% of the free space inside the bearing/housing.

-

Risk: Overfilling causes “churning,” which generates excessive heat and pressure, potentially blowing out seals even in winter.

-

Part 2: Equipment Startup Protocols in Winter

The first startup after a freezing night is the most critical moment for wear. Cold lubricant may channel, causing metal-to-metal contact (skidding) before the oil film forms.

1. Thawing the Lubrication System

-

Lubricant Upgrade: For extreme cold (below -30°C to -40°C), ensure the grease uses a Synthetic PAO (Polyalphaolefin) or Ester base oil. (Note: PFPE is typically reserved for high-temp/chemical environments and is unnecessary/too costly for standard cold applications unless specified by OEM).

-

Active Heating:

-

Oil Baths: Use immersion heaters to bring oil to at least 15°C before pumping.

-

Grease Lines: Turn on heat tracing for centralized systems 30 minutes prior to startup to prevent pipe blockages.

-

2. The “Creep Speed” Warm-Up

-

No Full Load: Never start directly under full load/speed. Cold grease creates immense drag.

-

Procedure:

1. Jog/Inch: Jog the motor to break the static friction (stiction).

2. Idle Run: Run the machine at 10-20% speed (Creep Speed) for 15-20 minutes. This generates internal friction heat, softening the grease gradually.

What if you don’t have a VFD? (Fixed-Speed Motors)

If your equipment uses Direct-on-Line (DOL) starters and cannot run at “Creep Speed” (10-20%), use the “Jog-Wait-Jog” Method:

- Jog (Pulse): Start the motor for 2-3 seconds, then immediately Stop.

- Wait: Let it sit for 2 minutes. The starting current generates heat in the windings, which conducts to the bearings.

- Repeat: Perform this cycle 3-4 times.

- Check: Hand-check the housing temperature. Once it feels noticeably warmer than the ambient air, start the continuous run.

3. Monitor (Advanced Checks)

-

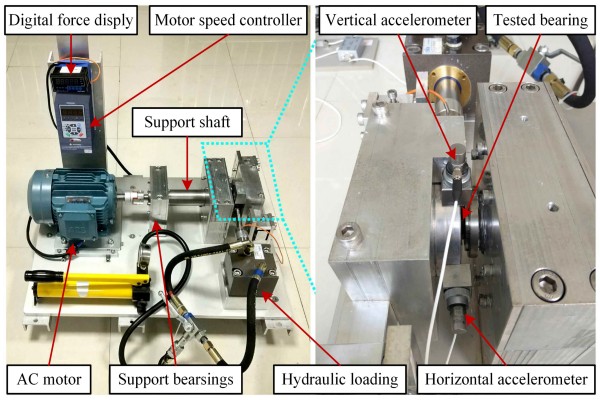

Sound: Listen for irregular grinding sounds which indicate skidding (rollers sliding instead of rolling).

-

Advanced Monitoring (Beyond Sound): In noisy plants, human ears are often unreliable.

-

Vibration Pen: Use a handheld vibration meter. High-frequency spikes during startup often indicate insufficient lubrication film.

-

Temperature Gun: Monitor the housing temp. A rapid spike (e.g., rising >10°C in 5 minutes) indicates excessive friction or over-greasing. Stop immediately.

-

Part 3: Specialized Scenarios & Checklists

Scenario A: Heavy Mining Equipment (Excavators/Conveyors)

-

Grease: Confirm use of Synthetic NLGI 0/00 for auto-lube systems in sub-zero conditions.

-

Radial Clearance: Refer strictly to the manufacturer’s C3 or C4 clearance tables. Large machinery often requires C4 (larger clearance) in winter to accommodate the temperature differential between the hot inner ring (operation) and cold outer housing.

-

Warm-Up: Low-speed idle for at least 30 mins until the hydraulic fluid and bearing temperatures rise above 10°C.

Scenario B: Precision Machine Tools (CNC Spindles)

-

Spindle: Pre-heat the spindle oil circulation system 20 mins early; target oil temp ≥15°C.

-

Air Seal: Maintain 0.2-0.3MPa positive air pressure to block cold damp air from entering the spindle nose.

-

Accuracy Check: Run a warm-up program (varying RPMs) to stabilize thermal expansion before performing precision cutting.

Part 4: Troubleshooting Common Winter Failures (FAQ)

| Symptom | Probable Cold Weather Cause | Corrective Action |

|---|---|---|

| High Starting Torque | Grease is too stiff (channeling). | Switch to Synthetic PAO grease or lower NLGI grade. |

| Squealing Noise on Startup | Skidding: Rollers are sliding on raceway due to high viscosity drag. | Reduce acceleration rate; extend warm-up time. |

| Seal Leakage | Seals hardened/shrunk; Vent blocked by ice. | Upgrade Seal Material: Standard NBR becomes brittle at -30°C. Use Low-Temp NBR (limits at -40°C) or Silicone/VMQ (limits at -60°C). Clear breather vents. |

Make It Actionable: Download the Field Checklist Don’t let your maintenance team rely on memory alone in freezing conditions. We’ve condensed this entire guide into a single-page, field-ready protocol. Print it out, clip it to your clipboard, and ensure every step is followed for a safe winter startup.

📥 Download the Winter Installation Checklist

Equip your maintenance team with this one-page, field-ready guide.

Includes safety checks, heating parameters, and startup protocols.

*Free resource for maintenance engineers. No email required.

Conclusion

Operating machinery in cold weather requires a shift in maintenance strategy. By controlling the installation environment, selecting synthetic lubricants with the correct pour point, and adhering to a gradual warm-up protocol, you can prevent catastrophic winter failures.

Stop Winter Breakdowns Before They Happen

Incorrect installation and lubrication are the #1 causes of bearing failure in winter. Ensure your machinery is equipped with the right components. TFL Bearing provides durable, high-precision solutions tested for the toughest industrial environments.

Get your low-temperature bearing solutions now:

- Email Us: info@tflbearing.com

- Call Direct: +86 158 0663 1151