Bearing Buying Mistakes: A Guide to Sourcing Reliable Bearings from China

After 20 years in the bearing industry, I’ve learned a hard truth: Most bearing failures don’t start in the factory. They start in the purchase order.

If you have worked with the TFL Bearing team, you might have noticed we ask a lot of specific questions:

-

“What equipment will this be used in?”

-

“Is this for your own inventory or a specific client project?”

-

“What is the operating speed and temperature?”

We aren’t prying into your business secrets. We ask because we are trying to understand the operating conditions. A “good quality” bearing with the wrong specs will fail just as fast as a bad one. Our goal is to help you match the perfect bearing to the reality of your application.

In this article, we break down the five most common specification errors we see on purchase orders—and how to fix them before they cost you money:

-

The “Golden Sample” Trap: Assuming bulk consistency matches the sample.

-

The Material Switch: Falling for the “Carbon Steel” price trap.

-

Ignoring Clearance: Forgetting thermal expansion (C3 vs CN).

-

Overlooking Noise Levels – Z1V1 vs Z3V3: Missing the Z/V grade requirement.

-

The “Direct Replacement” Trap: Ignoring hidden specs when swapping brands.

The “Golden Sample” Trap: Why Mass Production Fails to Match Prototypes

The Mistake: Falling for “Quality Fade”

Many buyers assume the bulk order will match the pre-production sample 100%. This is the classic “Golden Sample” trap. Unethical factories often hand-pick or specially craft high-precision bearings just to win your trust. However, once the contract is signed, they switch to cheaper materials or looser tolerances during mass production. This leads to severe quality inconsistency within a single container.

The Reality

A European distributor once approved a flawless sample set from a new supplier and ordered 50,000 units. The result? When the container arrived, the batch consistency was terrible. Over 10% of the bearings failed vibration tests (noisy operation), and another 5% had visible surface defects.

-

The Impact: They faced a surge in customer returns and their hard-earned brand reputation took a massive hit—all because the mass production quality didn’t match the sample.

The TFL Way: Consistency is Our Core Product

At TFL, we don’t just sell bearings; we sell reliability. We understand that for B2B clients, consistency > perfection.

-

Fully Automated Manufacturing: We strictly use Automated Match-Grinding technology. This means machines—not humans—measure and pair the inner and outer rings within 3 microns (μm) of precision. Whether it’s ABEC-7 precision bearings or standard industrial units, the sample you approve is identical to what you’ll receive in your 10th container.

-

Strict Process Control: We ensure that the tolerance range and vibration levels of the 50,000th bearing are identical to the 1st one. The bearing you test in the sample phase is exactly the same bearing you will receive in your 10th container. No surprises, just stable performance.

-

No Cherry-Picking: We perform 100% on-line vibration testing on every unit. The sample you receive is simply the first unit off the line, and your order is the rest.

The “Carbon Steel” Switch: Paying for Steel, Getting Iron

The Mistake: Prioritizing Price Over Material Grade

The most dangerous trap in bearing sourcing is the “Material Swap.” Unethical suppliers often quote a low price by substituting Chrome Steel (GCr15 / SAE 52100) with cheap Carbon Steel.

-

The Deception: To the naked eye, both look identical when new.

-

The Risk: Carbon steel lacks the necessary heat treatment capabilities. While Chrome Steel reaches a hardness of HRC 60-64, Carbon steel is significantly softer. It cannot withstand high speeds or heavy loads, leading to dramatically reduced fatigue life.

The Reality

A caster wheel manufacturer sourced “budget-friendly” bearings that appeared shiny and perfect.

- The Aftermath: After just 3 months of use, the internal balls caused plastic deformation on the raceways (severe pitting).

- The Failure: The wheels began to wobble and seize under normal loads.

- The Cost: The manufacturer faced a wave of complaints and was forced to issue a product recall, damaging their relationship with key retailers.

The TFL Way: 100% GCr15 Material Guarantee

We deal in transparency, not just low prices. TFL guarantees 100% GCr15 (SAE 52100) Bearing Steel for all precision orders.

-

Verified Quality: We never downgrade material to hit a target price.

-

Spectral Analysis: Every incoming batch is tested with an optical emission spectrometer to prove it contains 1.40-1.65% Chromium. If the graph is off, the batch is returned.

-

Proof Provided: Every shipment comes with a Mill Test Certificate (MTC) and a Hardness Report. We ensure the steel structure is durable enough to handle the calculated load rating for years, not just months.

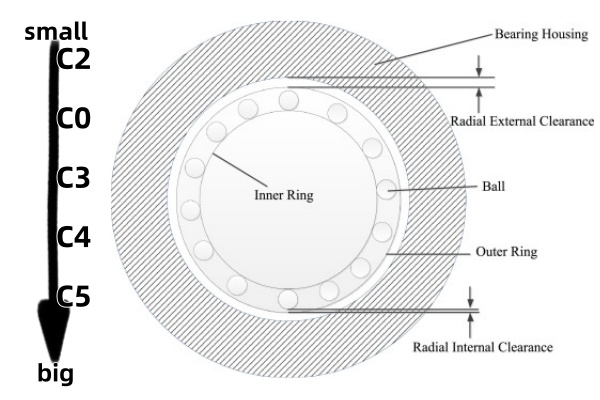

Overlooking Internal Clearance (C3 vs CN)

The Mistake: Ignoring Thermal Expansion

A common oversight is ordering “Standard Clearance” (CN) for electric motors or high-temperature applications. Internal Radial Clearance (RIC) is the internal “play” that allows the bearing to rotate freely.

-

The Science: When an electric motor runs, the inner ring gets hotter than the outer ring. This heat causes Thermal Expansion.

-

The Trap: If you use CN clearance, the expansion combined with the tight interference fit on the shaft will use up all the remaining room. The result? The bearing runs out of space, friction spikes, and it seizes (locks up).

The Reality: “It’s Not the Grease, It’s the Gap”

An electric motor repair shop kept burning out motors and initially blamed the grease quality.

- The Investigation: TFL engineers analyzed the failed bearings. We found severe overheating marks (blue discoloration) on the inner raceways, but the grease was fine.

- The Root Cause: They were using Standard (CN) clearance for a 3,000+ RPM application. As the motor heated up, the clearance vanished, causing the bearing to seize mid-operation. It was a geometry failure, not a lubrication failure.

Many suppliers confuse P6 (Precision) with C3 (Clearance). Make sure you know the difference. Check our [C3 vs Normal Clearance Guide] to specify correctly.

The TFL Way: Application-Based Sizing

We don’t just take orders; we act as your application engineers.

-

Fit Verification: We ask about your shaft tolerances (e.g., tight interference fits like m6 or n6). If the fit is tight, we automatically recommend C3 or C4 to compensate for ring expansion during mounting.

-

The Standard for Motors: For electric motor applications, TFL almost exclusively recommends C3 Clearance (providing extra radial play per ISO 5753 standards).

-

Transit Protection: To safeguard these precise internal components from false brinelling (indentations from static vibration during transport) or impact damage, we use robust individual packaging and secure palletization. This ensures the engineered clearance arrives intact and ready for optimal performance.

Ignoring Noise & Vibration Levels: Precision Isn’t Enough (Z/V Grades)

The Mistake: Forgetting the “V” and “Z” Grades

A critical error is assuming that a high-precision bearing (e.g., ABEC-5) is automatically a quiet bearing. It is not. Buyers often specify dimensions but forget to define the Noise & Vibration Grade (Z and V ratings).

-

The Mismatch: If you put a standard industrial bearing (Z1V1) into a ceiling fan, HVAC system, or EV motor, it will sound like a tractor.

-

The Standard: For precision applications, you need EMQ (Electric Motor Quality) bearings, not just standard industrial ones.

The Reality

A home appliance manufacturer sourced bearings that were “dimensionally correct” and cheap.

-

The Problem: When installed in their premium air purifiers, the bearings generated a subtle but persistent high-pitched whine.

-

The Consequence: While the bearings didn’t “fail” technically, customers perceived the product as “low quality” and “cheap.” The manufacturer suffered a 15% return rate and negative Amazon reviews, all because the bearings weren’t rated for EMQ (Electric Motor Quality) standards.

The TFL Way: Z3V3 Grade & Super-Finishing

We understand that silence equals quality. TFL provides Z3V3 Grade Bearings (the highest standard for motors) by default for these applications.

-

Defining the Standard: TFL clarifies your application noise requirements upfront. For motors, fans, and pumps, we provide EMQ Grade Bearings (Z3V3) (noise <28 dB, vibration <5 μm, per GB/T 307 standards).

-

100% Testing: You cannot judge a Z3 bearing by spinning it by hand. Every single bearing passes through automated BVT (Bearing Vibration Testers, S0910 standard) to measure vibration velocity (mm/s).

The “Direct Replacement” Trap (Ignoring Hidden Specs)

The Mistake: Trusting the Base Number, Ignoring the Suffix

The most expensive mistake in maintenance is blindly swapping a premium bearing for a cheaper alternative based solely on the basic part number (e.g., “6309“).

-

The Misconception: “It fits, so it works.”

-

The Trap: The part number only tells you the dimensions (ID, OD, Width). It does not reveal the internal DNA of the bearing. Premium OEM bearings often have “hidden specs” not visible in the standard catalog: reinforced Nylon/Brass cages, specific grease fills for extreme temps, or stabilized heat treatment (S1/S2) for shock loads.

The Reality

A client in the mining industry wanted to replace a costly European brand bearing on a Vibrating Screen to cut costs. They matched the dimensions and ordered a standard “Generic 6309.”

-

The Failure: The original bearing was a customized version with a machined brass cage (M) and C4 clearance to handle vibration. The standard steel-cage replacement couldn’t handle the g-force and shattered under shock load within 48 hours.

-

The Cost: The $50 saving on the bearing cost them $20,000 in unplanned downtime and labor.

The TFL Way: We Don’t Just Quote, We Decode

At TFL, we act as Reverse Engineering Specialists. We know that a “Direct Replacement” requires more than just a ruler.

-

The Detective Work: We ask for photos of the old bearing’s complete suffix code or request a sample.

-

Suffix Decoding: If you send us an SKF number like 6205-2RSH/C3GJN, we know exactly what that means (Polyurea grease, specific noise level, Rubber Seal). We don’t guess; we map it precisely to the TFL equivalent.

-

The Match: We analyze the cage material, clearance (C3/C4), Internal Geometry, and Heat Treatment profile. We ensure the TFL alternative matches the performance specifications, not just the mounting dimensions. We replace the function, not just the part.

Summary: Ask Before You Order

Sourcing bearings from China shouldn’t feel like a gamble. Don’t let these preventable mistakes eat your profits. Before you finalize your next PO, run through this quick checklist:

-

Consistency: Is the factory automated?

-

Material: Is it guaranteed GCr15 Chrome Steel?

-

Clearance: Do I need C3 clearance for heat/speed?

-

Noise: Do I need Z3V3 for a quiet application?

-

Substitutability: Did I tell the supplier about any special cages or structures in the original bearing?

You shouldn’t have to be a metallurgist or a lubrication expert to buy a bearing. That is our job.

Send your application details to the TFL Bearing team, and let us handle the technical specs for you.

Let’s get your specifications right—before we cut the steel.